SAFETY

AGR-BGR-BRGR 08/22 Safety Section 1-5

SAFETY

© 2022 Alamo Group Inc.

Use extreme caution when getting onto the Implement to perform repairs, maintenance and

when removing accumulated material. Only stand on solid flat surfaces to ensure good

footing. Use a ladder or raised stand to access high spots which cannot be reached from

ground level. Slipping and falling can cause serious injury or death. (SG-33) str

Use extreme care when loading, carrying or handling any agricultural

fertilizers, chemicals or biological residue. Follow the manufacturer’s

handling instructions and wear appropriate Personal Protective Equipment

including gloves, safety glasses and respirator when required. If you are

using a tractor equipped with a cab, make sure the cab is rated for

appropriate environmental exposure. Be safe and always wear proper

protection. Short or long term exposure to certain chemicals and materials

can result in serious injury or death. (SL-19) str

Repeated or substantial breathing of hazardous dusts, including crystalline

silica, could cause fatal or serious respiratory disease including silicosis.

Concrete, masonry, many types of rock, and various other materials contain

silica sand. California lists respirable crystalline silica as a substance

known to cause cancer. Operation of this equipment under certain

conditions may generate airborne dust particles that could contain

crystalline silica. In those conditions, personal protective equipment

including an appropriate respirator must be used. If excessive dust is

generated, a dust collection or suppression system should also be used

during operation. (SG-41) str

EQUIPMENT OPERATION SAFETY INSTRUCTIONS AND PRACTICES

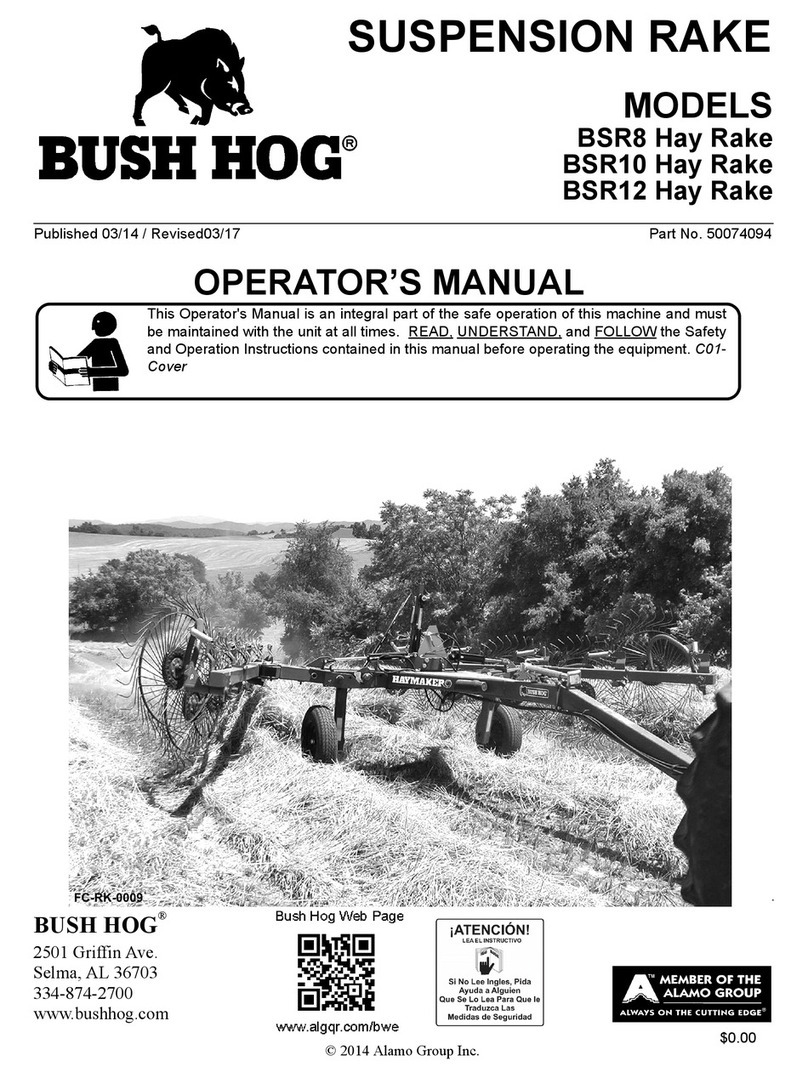

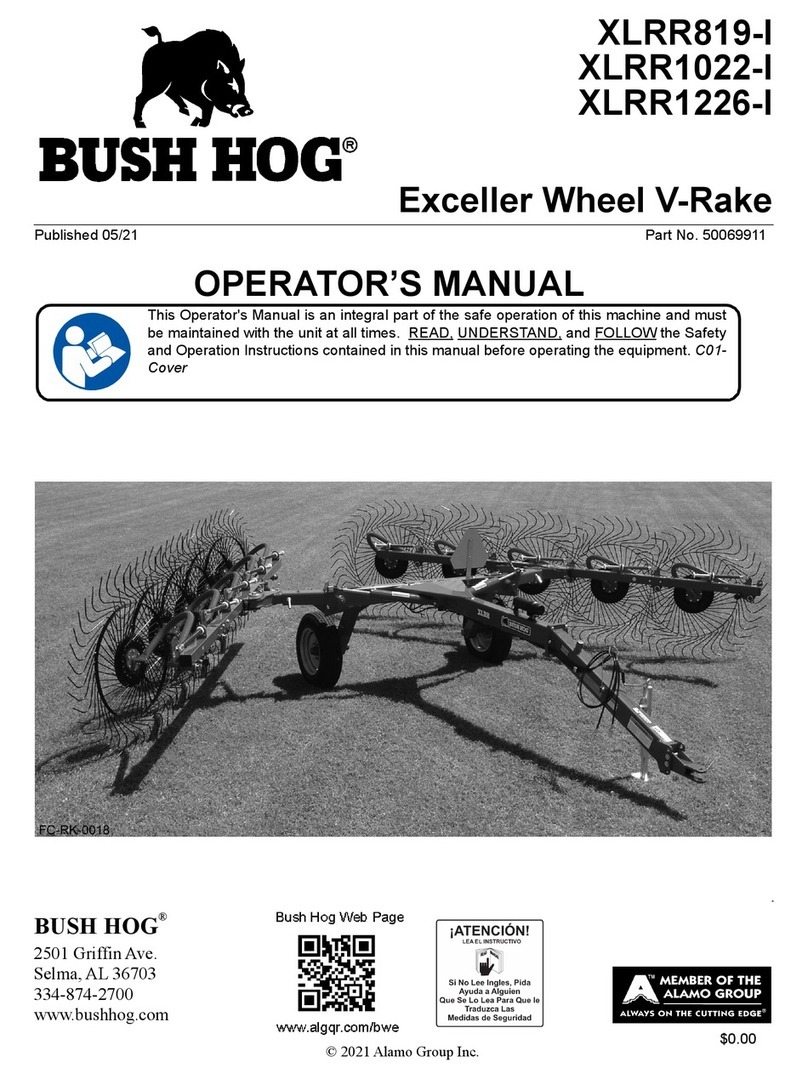

This Implement may be wider than the Tractor. Be careful when operating or transporting this

equipment to prevent the Implement from running into or striking sign posts, guard rails,

concrete abutments or other solid objects. Such an impact could cause the Implement and

Tractor to pivot violently resulting in loss of steering control, death, or serious injury. Never

allow the Implement to contact obstacles. (S3PT-12)str

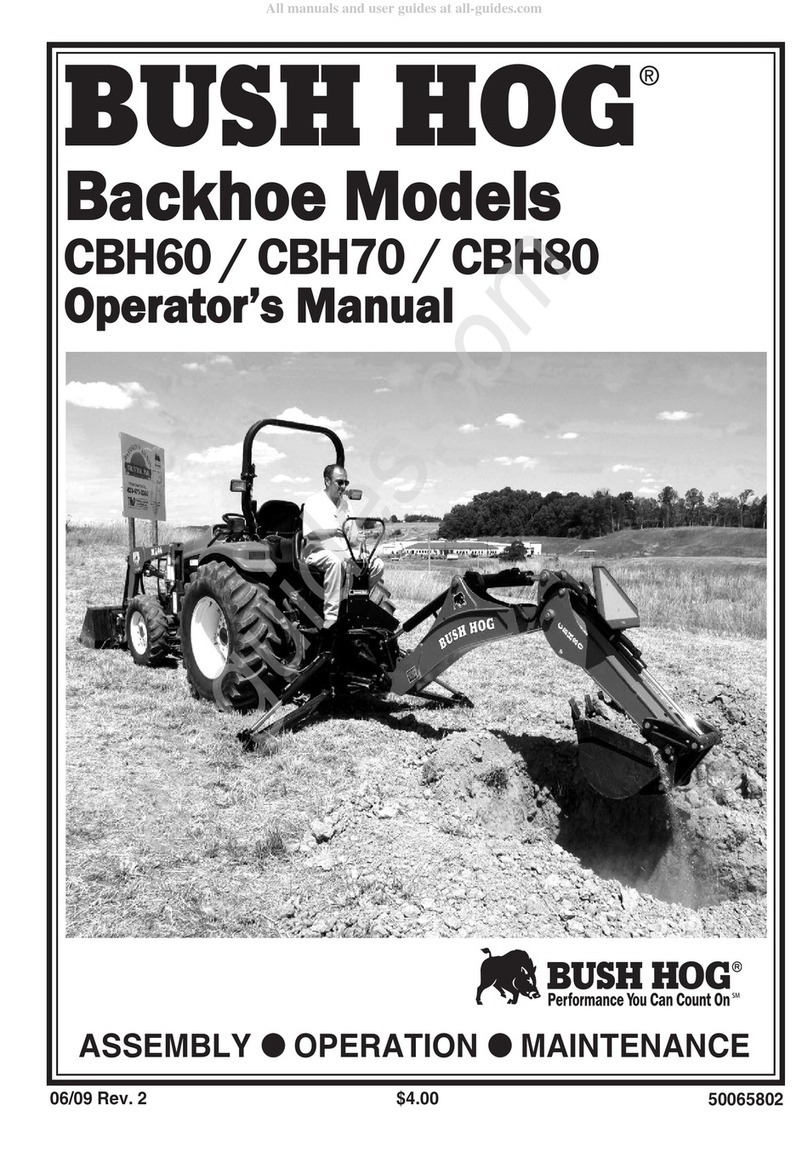

Never grasp control levers when mounting the machine. (SBH-4) str

The Boom is designed only to position and operate the Bucket which is attached to it. Never

attempt to lift, pull, or push other solid objects with the boom or bucket. Serious injury could

result from a structural failure when the Boom is used for purposes other than those for which

it was designed. (SBH-9) str

Operate this Implement only in conditions where you have clear visibility in daylight or with

adequate artificial lighting. Never operate in darkness or foggy conditions where you cannot

clearly see at least 100 yards in front and to the sides of the tractor and implement. Make sure

that you can clearly see and identify passersby, steep slopes, ditches, drop-offs, overhead

obstructions, power lines, debris and foreign objects. If you are unable to clearly see these

types of items discontinue operating this equipment. (S3PT-21) str