10/16 Installation + Operating Instructions D.1 Ri Seatpost

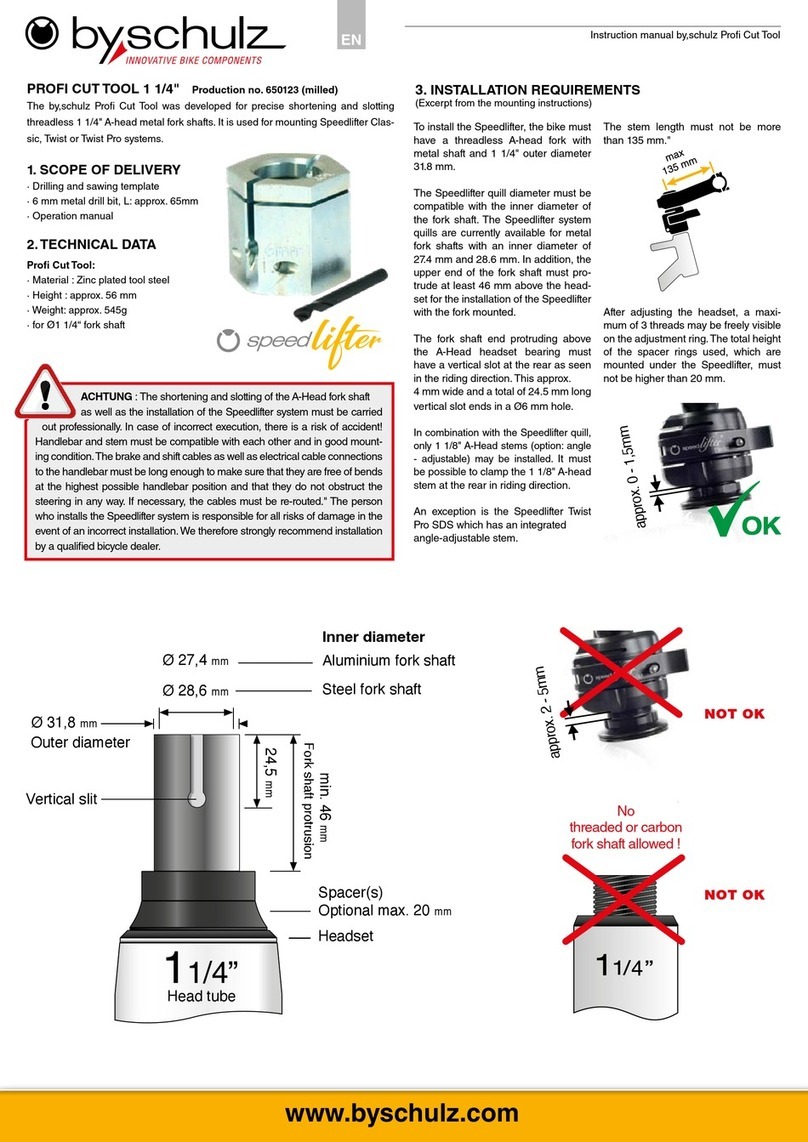

Fig. 8.3.2

8. INSTALLATION

8.1 Tools

You will need the following tools and aids to install the

seatpost:

1. Torque wrench (2 - 20 Nm) with interchangeable bits:

Torx T20 / T25, hexagon socket 2 / 2.5 mm.

2. Bowden cable cutter, side cutter (optional)

3.Assembly grease (metal frame), or assembly paste (car-

bon frame) and cleaning agent

Optionally, a round le for removing sharp edges in the

seat tube of the frame, as well as pliers for tensioning the

inner cable, can be helpful.

8.2 Preparation

To be noted before assembly:

Measure and note the previously set saddle height. This

will make it easier for you to adjust the mounted D.1 Ri

seatpost later. Remove the existing seatpost and saddle.

Clean the seat tube of the frame and check it for burrs.

If necessary, deburr the seat tube with e.g. a round le.

Only shorten the cable housing and the inner cable after

you have installed the parts for testing and checked the

cable length.

For frames made of metal, we strongly recommend that

you grease the inside of the upper part of the seat tube.

Any reduction sleeve used should also be greased. This

ensures smooth height adjustment of the seatpost later

on. Do NOT use grease on frames made of carbon bre

reinforced plastic (carbon). Use an assembly paste for

components and frames made of carbon instead.

With small bicycle frames or frames with bottle cage eye-

lets in particular, it is possible that the seatpost cannot be

inserted far enough into the seat tube of the bike. In this

case, the D.1 cannot be installed!

The remote lever of the by,schulz D.1 Ri seatpost is pref-

erably designed for mounting on the left side of the han-

dlebar, but can be mounted on both sides. Locate a good

position on your handlebars. It may be necessary to slight-

ly move existing controls such as brake levers and other

attachments. The clamp usually ts under gearshift indi-

cators or controls. Afterwards, make sure that all controls

still work and are in a position that is easy for you to reach.

8.3 Mounting the remote lever:

1. Slide the open clamp band onto the handlebar tube at

a good position. The handle does not have to be removed

for this. The O-ring on the open screw serves as an an-

ti-loss protection. Bend the clamp band by hand and screw

the M5 clamp screw lightly into the clamp base with a Torx

T20 tool so that the remote lever can still be positioned

later.

Fig. 8.3.1

The position and alignment of the clamp base, the lever

base and the remote lever can be adjusted in many ways

to suit your wishes and needs.

2. The clamp base can be positioned by moving it along

the handlebar or by rotating it around the handlebar tube.

(Fig. 8.3.2)

NOTE: All parts of the D.1 Ri are technically

matched to each other. Only use an original by,schulz

remote lever. If products from other manufacturers

are used, the proper function of the D.1 Ri dropper

post cannot be guaranteed!