4.4 (Fig. 4.4)

Using a metal saw, saw off the fork

shaft to the specied length through

the horizontal slot in the tool.

4.5 (Fig. 4.5)

Now use the saw to saw diagonally

from above along the right and left

edges of the vertical saw guide slot

into the existing drill hole. This cre-

ates an approx. 4 mm wide, vertical

slot in the fork shaft, which ends in

the 6 mm drill hole.

4.6 (Fig. 4.6)

Carefully remove sharp edges from

the saw cuts and the bore inside and

outside with a half-round metal le.

Remove the cloth and the resulting

sawdust carefully. Clean and grease

the inside of the fork shaft. Now you

can install the Speedlifter.

Reverse option: To use the slotted

fork again with a normal A-head stem,

the by.schulz Speedlifter Ready Kit

reinforcement sleeve with the correct

spacer must be used.

5. MAINTENANCE / CARE

Clean the Pro Cut Tool after each use

and free it from saw and drill particles.

Store the Pro Cut Tool in a dry and

clean place.

4. TOOL USAGE

Info: If no stem and no A-Head claw are mounted yet, you can ignore the fol-

lowing section!

Unscrew the existing A-Head end cap. Remove the A-Head claw basically upwards

with the stem installed. Loosen the stem and remove all unneeded spacer rings.

4.1 (Fig. 4.1)

Align the front wheel standing to the

ground exactly parallel to the frame.

Place the 2 mm spacer (only sup-

plied with production no. 641117) on

the headset bearing or the spacer

rings above it and slide the ProCut

tool (imprint "Top" facing upwards)

over the fork shaft onto the 2 mm

spacer. Align the tool so that the 6

mm drill guide (imprinted "REAR")

points backwards towards the sad-

dle and the imaginary center line of

the lengthwise slot is exactly aligned

with the driving direction.

4.2 (Fig. 4.2)

Press the tool rmly against the

headset with the 2 mm spacer

(only for production no. 641117) and

secure it with the integrated Allen

screw (5-6 Nm). Important: Tool and

headset must be free of play!

Tip: Place a piece of cloth around

the area of the headset and the

front area of the wheel to protect the

sensitive bearing area from drilling

and sawdust.

4.3 (Fig. 4.3)

Drill the 6 mm hole into the fork shaft

with the included metal drill bit using

the drill guide.

Fig. 4.1

Fig. 4.3

Fig. 4.2

Fig. 4.4

Fig. 4.5

Fig. 4.6

Instruction manual by,schulz Pro Cut Tool - version from start of 2019

by,schulz © 2023 No reprints, translations or copies of any kind allowed without the prior written approval of by,schulz GmbH. Subject to technical alterations, errors and misprints excepted. Used photos can

vary from the original product. by,schulz GmbH, Saarbrücken/Germany. M-PCT-after-20230329-EN / AN-10564

by.schulz GmbH

Bühler Str. 121

D-66130 Saarbrücken

GERMANY

Tel : +49(0)681-95 97 25 0

Fax : +49(0)681-95 97 25 20

info@byschulz.com

www.byschulz.com

www.byschulz.com

www.youtube.com

Safety instructions and warranty/guarantee:

see detailed operating instructions on

www.byschulz.com

Operating instructions

available for download:

Installation videos

available under :

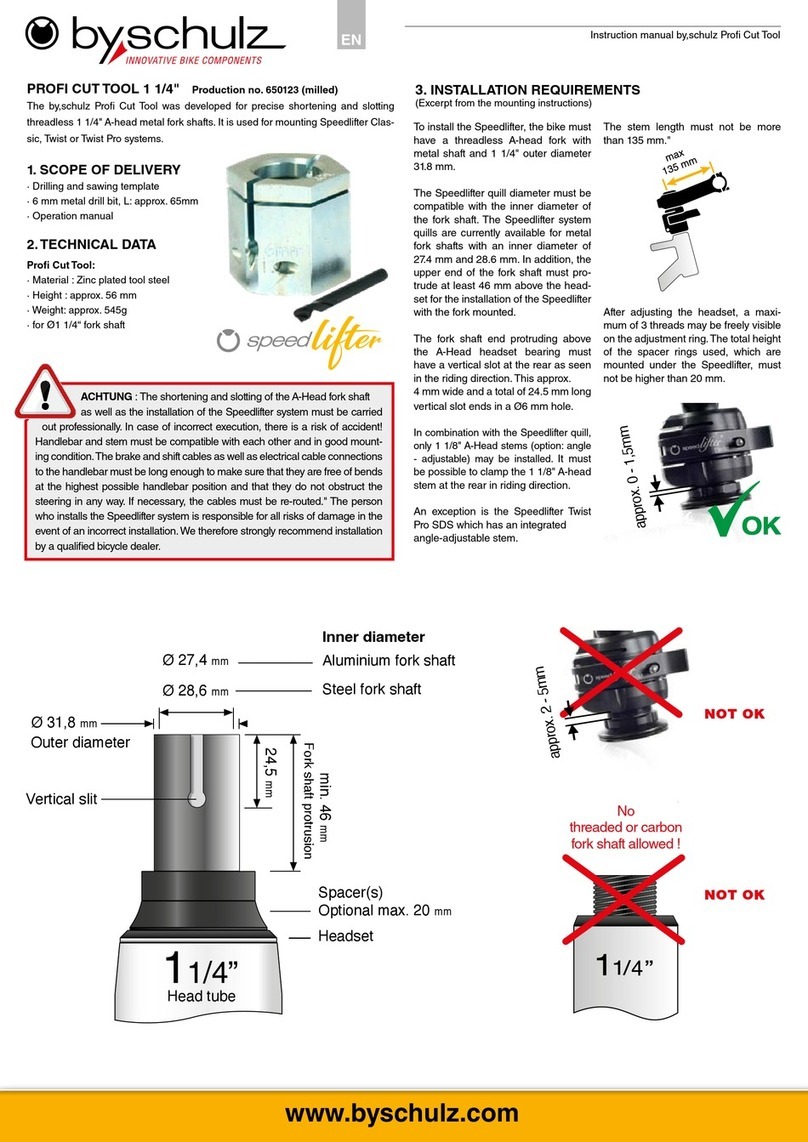

ATTENTION: The vertical slot in the fork shaft must be centered at

the rear in the driving direction. If a spacer ring (maximum 20 mm)

is used, the height to be shortened changes accordingly.

The fork shaft must be undamaged inside and outside after shortening

and slotting with the Pro-Cut tool.

for steel fork shafts

inner Ø 25,4mm

for aluminium fork shaft

inner Ø 24,4 / 24,5 / 24,6mm

More about

the product