11. MAINTENANCE / CARE / CLEANING

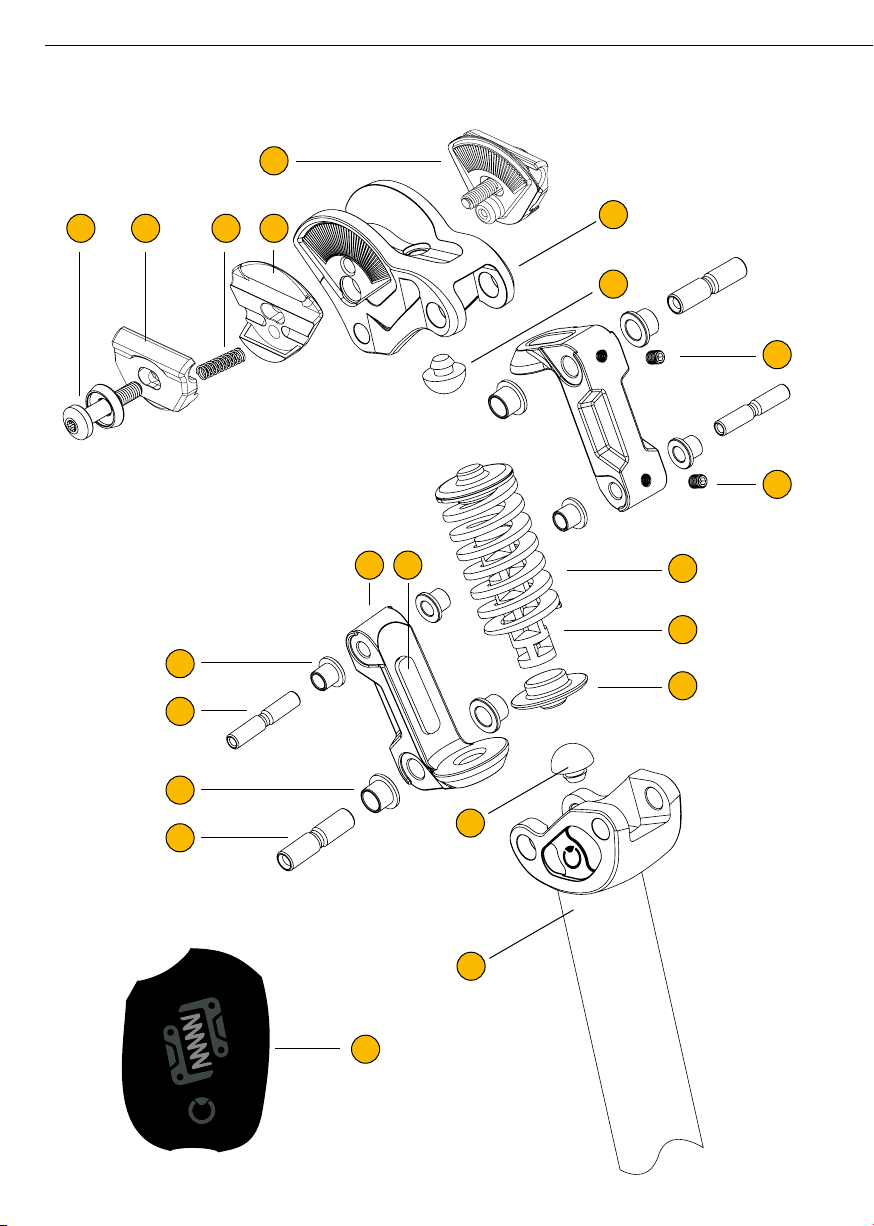

The G.2 ST / LT suspension seatpost is based on a well

thought out concept and consists of high-quality compo-

nents. This guarantees you a long riding pleasure with reg-

ular maintenance.

After the rst 3 months or approx. 250 km of riding, check all

screws for correct tightening torques. Have this check car-

ried out and documented by a specialist dealer every year

thereafter, or after approx. 2000 km. To ensure trouble-free

use of the G.2 support, all bearing pivot points should also

be cleaned and lubricated during this check.

The supplied protective and safety cover made of neoprene

effectively prevents dirt build-up (mud, sand, etc.) and thus

ensures low cleaning and maintenance effort. We recom-

mend the permanent use of the neoprene sleeve.

Keep the parallelogram mechanism of your G.2 ST / LT

seatpost and the bearings free of dirt and mud and clean

them regularly.

Tough dirt can usually be removed with warm water and

standard dishwashing detergents. For the care of the bear-

ing pivots, we recommend the manufacturer Ballistol (uni-

versal spray). Do not use a steam cleaner or harsh cleaning

agents such as acetone, trichloroethylene or methylene for

cleaning, as these cleaning agents attack the components,

elastomers and bearings.

If you disassemble the seat post completely for cleaning or

maintenance purposes, it is recommended to lubricate the

bearings and axles with acid- and resin-free bearing grease

when reassembling.

When cleaning the G.2 seat post, look for damage, defor-

mation or other changes to the components. If you have

any questions regarding operational safety, your dealer will

be happy to help you.

12. WARRANTY / GUARANTEE

The following conditions, which describe the requirements

and scope of our warranty service, do not affect the warran-

ty obligations of the seller under the purchase contract with

the end user. For the processing of a warranty claim, the

proof of purchase with the date of purchase and delivery

must be submitted in each case.

A warranty obligation is not triggered by minor deviations

from the target condition, which are insignicant for the val-

ue and usability of the product.

Please keep the proof of purchase. Your specialist dealer

or source of supply is the contact person in the event of a

complaint.

For the by,schulz seat post type G.2 ST / LT we provide

warranty according to the following conditions / points:

1. We will remedy free of charge defects which are demon-

strably based on a material and/or manufacturing defect,

if these are reported to the rst end user immediately after

detection and within 24 months after delivery. If the defect

becomes apparent within 6 months of delivery, it shall be

presumed to be a material or manufacturing defect.

2. No guarantee can be given if the defects in the product

are due to transport damage for which we are not respon-

sible, improper assembly, misuse, non-standard use, lack

of maintenance or care or failure to observe operating or

assembly instructions. Excluded are damages and their

consequences caused by improper assembly, modication

of the original parts, accidents, overloads (downhill, jumps,

competitions etc.).

3. The person who mounts the by,schulz G.2 ST / LT seat-

post bears full responsibility for the assembly, compatibility

and condition of the mounting parts. The warranty claim ex-

pires if repairs or interventions are carried out by persons

who do not have sufficient professional knowledge, or if

our product is provided with spare parts, supplements or

accessories that are not original parts and thus cause a

defect.

4. In the event of a warranty claim, if we refuse or fail to

remedy the defect, a replacement of equal value will be de-

livered free of charge within the above-mentioned period.

5. Warranty services do not cause an extension of the war-

ranty period, nor do they set a new warranty period in mo-

tion. The warranty period for installed spare parts ends with

the warranty period for the product.

6. Further or other claims, damages caused by misuse are

excluded - as far as a liability is not mandatorily ordered

by law.

7. These warranty conditions apply to products purchased

in Germany. For by,schulz products purchased abroad, the

warranty conditions issued by our respective country repre-

sentative shall apply.You can request these from the dealer

from whom you purchased the product.

Our customer service and service partners will be happy to

assist you even after the warranty has expired.

010/12 www.byschulz.com