6. INSTALLATION

Before mounting, make sure that all clamping surfac-

es of the stem, fork shaft and handlebars are clean and

free of grease!

6.1 Mounting the stem

1. Loosen the two M5 Torx T25 clamping screws of the

Stem Alpha 35° SDS.

2. Push the Stem Alpha SDS onto the fork shaft end so that

it rests directly on the headset or the spacer ring (Design

Spacer, Riser). When using the Design Spacer, it should be

mounted directly under the Stem Alpha. (Fig. 6.1.1)

Abb. 6.1.1 Abb. 6.1.2

3. The use of the Design Spacer is not obligatory and has a

purely optical function.

4. Insert the A-head screw into the A-head claw in the fork

shaft and tighten it slightly.

(Fig. 6.1.2)

5. Align the stem exactly in the riding direction.

6. Adjust the headset by tightening the A-head screw clock-

wise so that there is no play. It must still be possible to turn

the fork easily in the head tube. If the bearing play cannot be

adjusted with the A-head screw, check the fork shaft protru-

sion. (Fig. 6.1.3)

Abb. 6.1.3

7. Tighten the two M5 Torx

T25 clamping screws of the

stem clockwise with a

torque wrench to 7-8 Nm.

8. The stem is now rm-

ly xed on the fork shaft,

check bearing clearance

and alignment of the stem,

correct if necessary. Now

the handlebar assembly

takes place

6.2 Installing the handlebar

1. Loosen the four Torx T25 clamping screws of the SDS

front cap counterclockwise. After removing the screws, re-

move the front cap.

2. Place the clamping area of the handlebar on the clamp-

ing area of the stem eye.

3. Reattach the SDS front cap using all 4 screws.

4. Tighten the top two bolts slightly clockwise so that the

handlebar can be aligned and rotated to the desired grip

position. (Abb.6.2.1)

Abb. 6.2.1

6. If necessary, the grips, brake and shift levers must be

realigned.

7. The Stem Alpha 35° SDS is now ready for use.

7. MAINTENANCE

After the rst assembly of the stem and a short running-in

period of approx. 20 km, check the fork and handlebar

play. Readjust them if necessary. Clean the stem regular-

ly. At every annual bicycle inspection (at least every 1000

km), the play of the headset and Stem Alpha 35° SDS

should be checked professionally.

4. TOOLS

which are needed for the installation:

· Allen key 5 mm

· Torx T25 wrench

· Torque wrench with T25 Torx bit

· Torque wrench with 5 mm Allen key bit

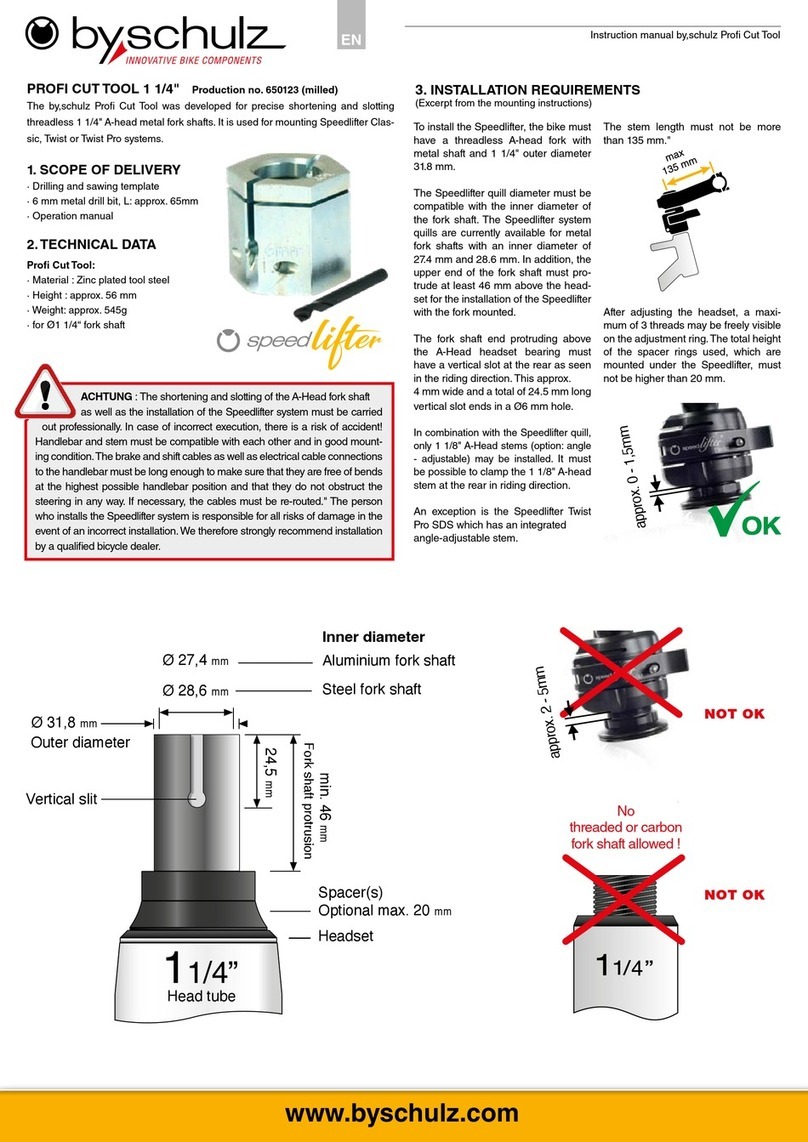

5. INSTALLATION REQUIREMENTS

· A-Head fork shaft 1 1/8“ threadless, outer diameter 28,6 mm.

· The necessary fork shaft protrusion is 38-39 mm.

In combination with the design spacer, approx. 48-49 mm

protrusion is required.

· Spacers/risers can be installed to achieve the correct

projection.

· The threadless fork shaft can be shortened to the cor-

rect length. When cutting, make sure that the fork shaft end

still has an outer diameter of 28.6 mm and has no sharp

edges.

· An A-head claw (starnut) with an M6 thread or a similar

device must be placed in the fork shaft approx. 10 mm be-

low the end of the tube. This is used to adjust the headset

clearance.

· The brake and shift cables, as well as electrical cable

connections to the handlebars, must be of sufficient length

to keep them free of bends and to ensure that they do not

interfere with the steering in any way.

· Handlebar and stem must be compatible with each other

and must have the same clamping diameter of 31.8 mm.

We recommend the use of by,schulz handlebars, as they

are adapted for mounting on the Stem Alpha 35 ° SDS.

5. Then rst tighten the two upper clamping

screws without a gap and then the two lower ones

evenly with a torque spanner to 5-6 Nm (Fig. 6.2.2).

Abb. 6.2.2

Ø 28,6 mm

Design Spacer

Protruding 1 1/8ʻʻ

A-Head fork shaft

Spacer ring

Conical spacer / riser

Headset

Head tube/ Frame

38-39 mm

48-49 mm

with Design Spacer

Head tube

Technical Installation Requirements

Stem Alpha 35°