INTRODUCTION

Thank you for purchasing a by.schulz product. Please

read the manual carefully before installation and usage. If

you have any further question please contact your specia-

list dealer. Have a great ride!

TABLE OF CONTENTS Page

1. Usage Permission 02

2. Delivery Contents 02

3. Safety Instructions 02

4. Technical Data 03

5. Function 03

6. Components 04-05

7. Spring Elements 05

8. Installation Requirements 06

9.1 Seatpost Installation 06

9.2 Saddle Installation and Adjustments 07

10. Changing the Spring Element 08-09

11. Maintenance and Care 10

1. USAGE PERMISSION

by.schulz products (e.g. the speedlifter system) are availa-

ble on the bike market for more than 20 years. By.schulz is

an international supplier for bike manufacturer, wholesale

dealers and dealers. Multiple components are standard

equipment on bicycles, cross country MTB, pedelecs and

e-bikes.

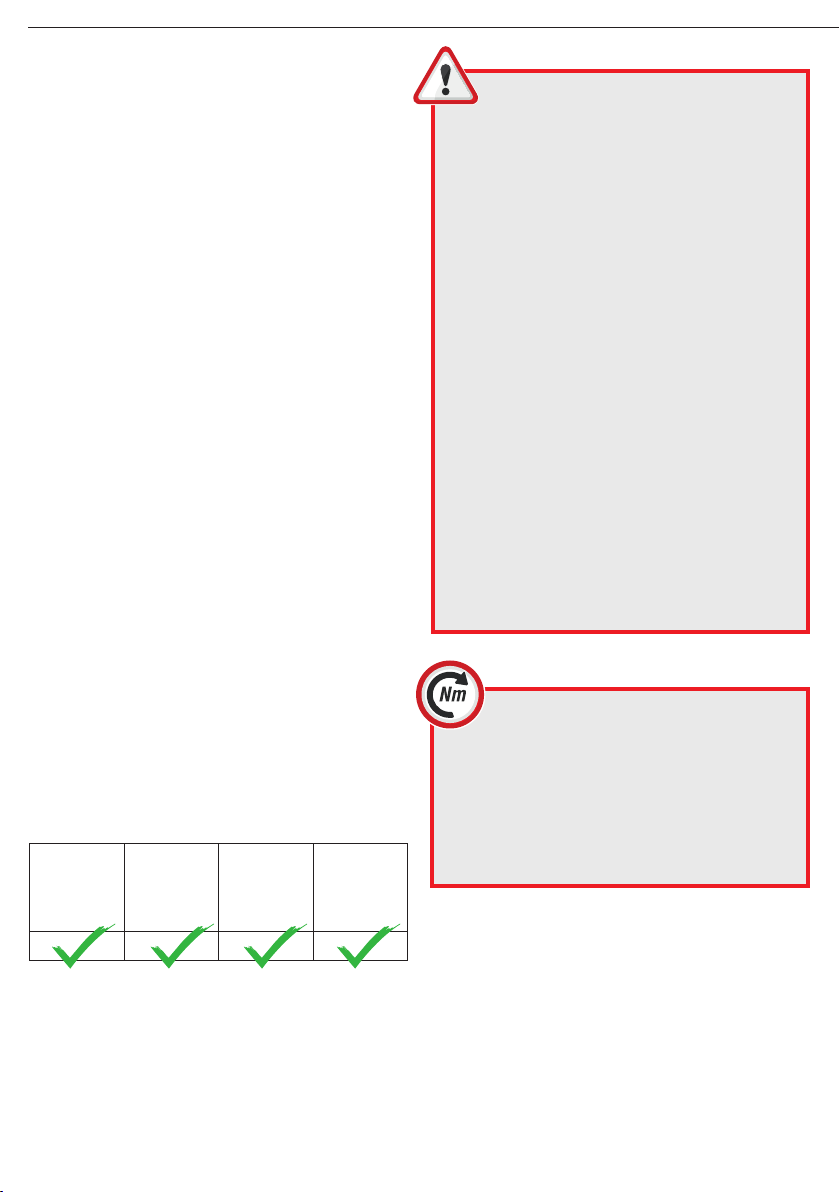

The G.2 ST/ G.2 LT seat post is suited for use in bicycles,

pedelecs and e-bikes up to 45 km/h. It is not usable for ext-

reme stress such as downhill riding, dual slalom, free-riding

or riding with jumps.

The G.2 ST/ G.2 LT seat post is forged from aluminium

and is tested according to the DIN norm and approved:

City

Trekking

DIN EN

ISO 4210

Ebike

bis 25km/h

Pedelec

DIN EN

ISO 15194

Speed-Ebike

bis 45km/h

S-Pedelec

DIN EN

ISO 15194

MTB

Cross Country

DIN EN

ISO 4210

2. DELIVERY CONTENTS

· Seatpost

· Mudcover (nicht bei Erstausstattung)

· Operating instructions

3. SAFETY INSTRUCTIONS

Before the rst ride:

We strongly recommend checking the overall tness of the

bicycle and the operational safety of the seat post before

each ride. Start with checking if the saddle is rmly atta-

ched in the saddle clamp. Then make sure that the seat

post tube is rmly attached to the bicycle frame without

slack. It must be clamped in the desired position so that

it cannot be turned or shifted inside the seat post tube.

Please note that the minimum insertion depth of the seat

post is 90 mm.

4. TECHNICAL DATA

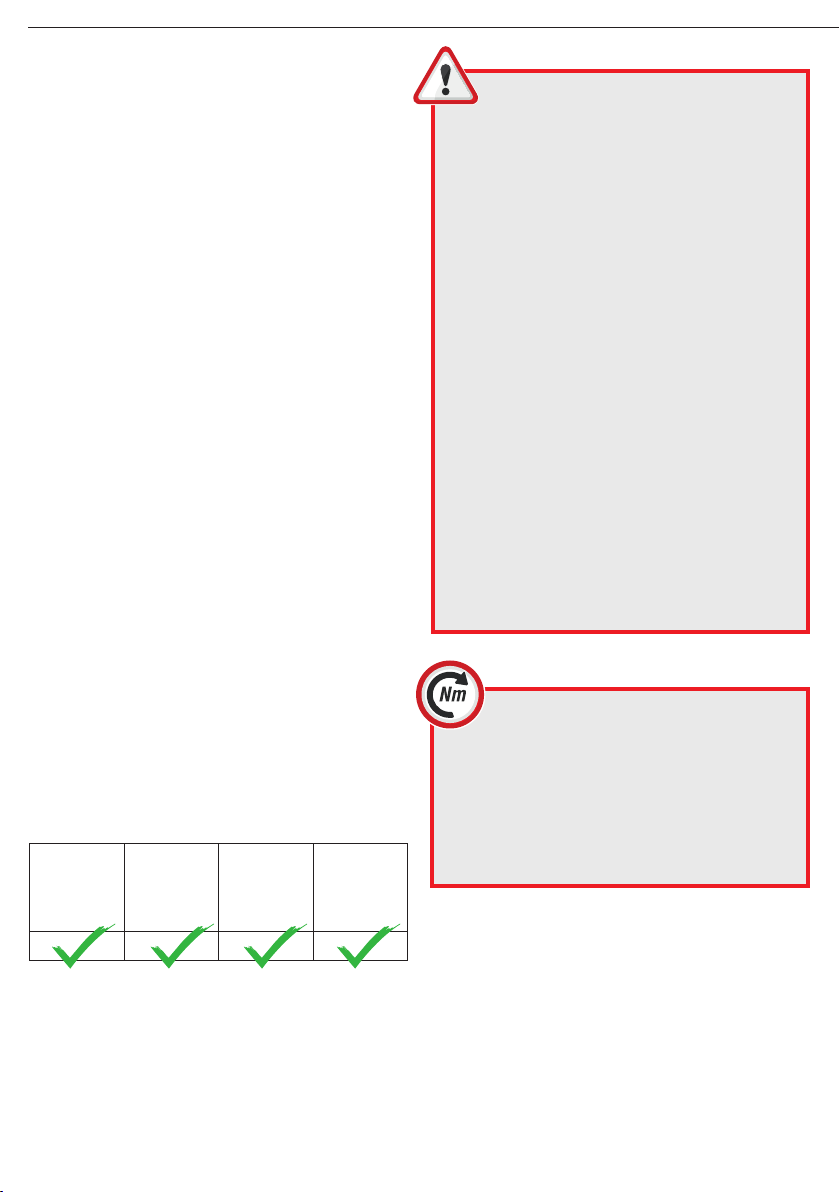

1. This instruction contains important informa-

tion about the proper installation, usage, and

maintenance of the G.2 ST/ G.2 LT seat post. Please

take the listed warnings and safety instructions seri-

ously. Otherwise personal injury and material dama-

ge may occur, for which the dealer or manufacturer

is not liable.

2. In order to avoid further risks of accidents the seat

post must be replaced after damaged due to a fall or

accident.

3. Child seats, trailer couplings or luggage racks

may not be attached to the G.2 ST/ G.2 LT seat post

because this can lead to breakage or damage.

4. Always use the neoprene mud cover to cover the

spring mechanism when a child seat is installed be-

hind the seat post. The cover prevents the child’s

nger from getting caught in the spring mechanism.

There is considerable risk of injury for the hands of

the children when no cover is used!

5. The installation is easy with bicycles and e-bikes,

but please be aware of the installation requirements.

If you do not have the appropriate expertise, we

strongly recommend the installation by a specialist

dealer.

02/12

This symbol indicates an important screw

connections, and the screw must be tightened

with an specic tightening torque. The correct tigh-

tening torque is either listed on the part itself or in the-

se operating instructions. A torque wrench is required

for proper installation Screws that are not tightened

correctly, may loosen or break without warning. This

may cause a fall and lead to personal injuries and

material damage.

Installation + Operating Instructions G.2 ST / LT Seatpost