2/20 Installation + Operating Instructions D.2 ST-Ri Seatpost

INTRODUCTION

Thank you for choosing a by,schulz product. Please read

these instructions carefully before assembly and use, and

keep them in a safe place. If you have any further ques-

tions about this product, please contact your dealer.

We wish you a safe ride!

TABLE OF CONTENTS Page

1. Usage approval 02

2. Safety instructions 02

3. Scope of delivery 03

4. Function 03

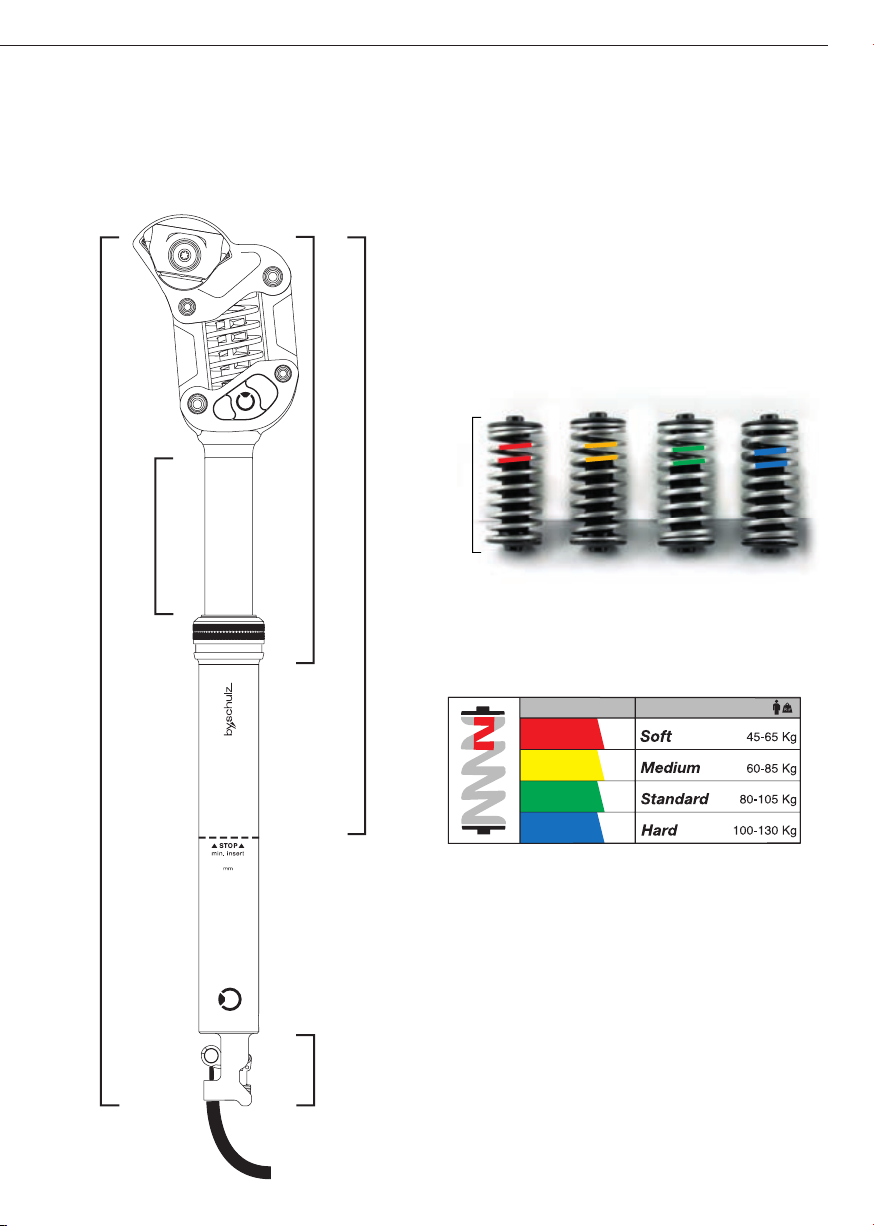

5. Technical Data 04-05

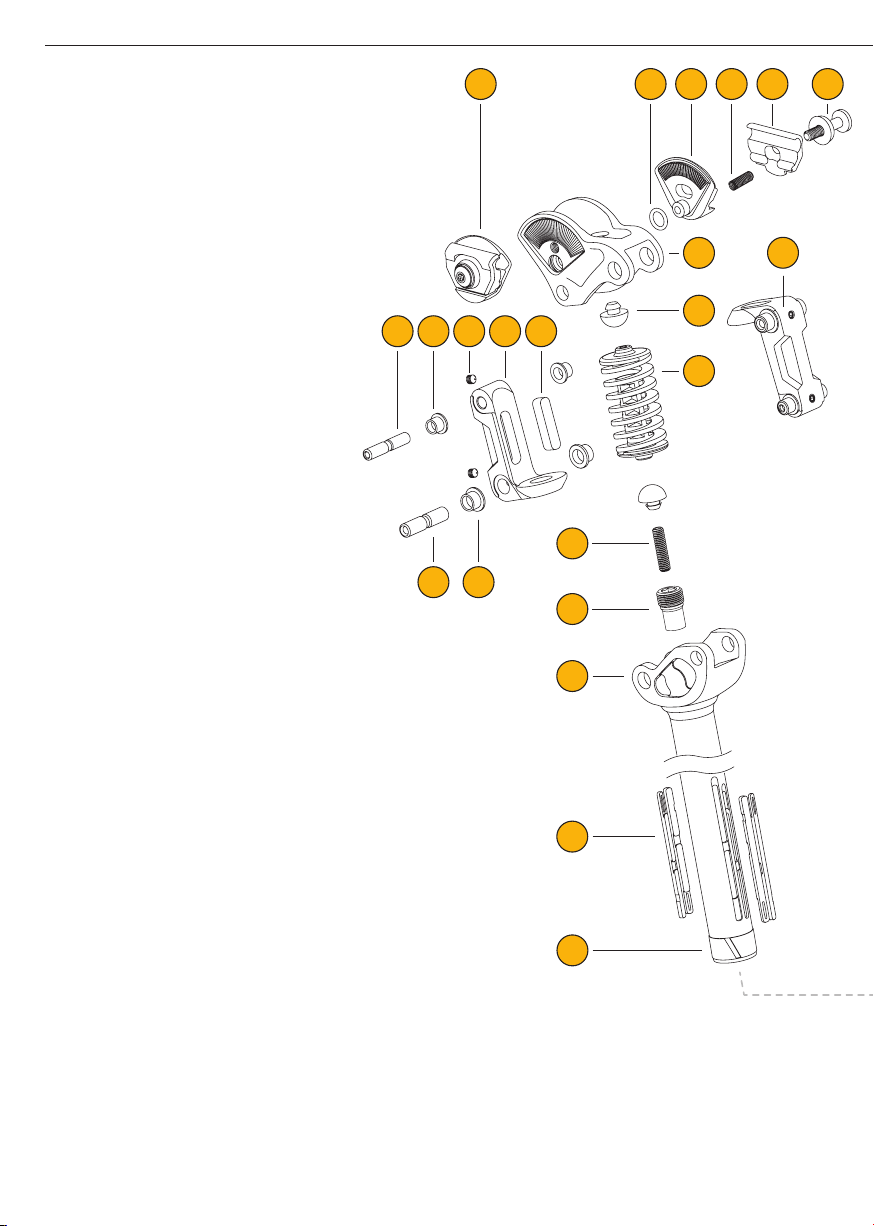

6. Spring elements 05

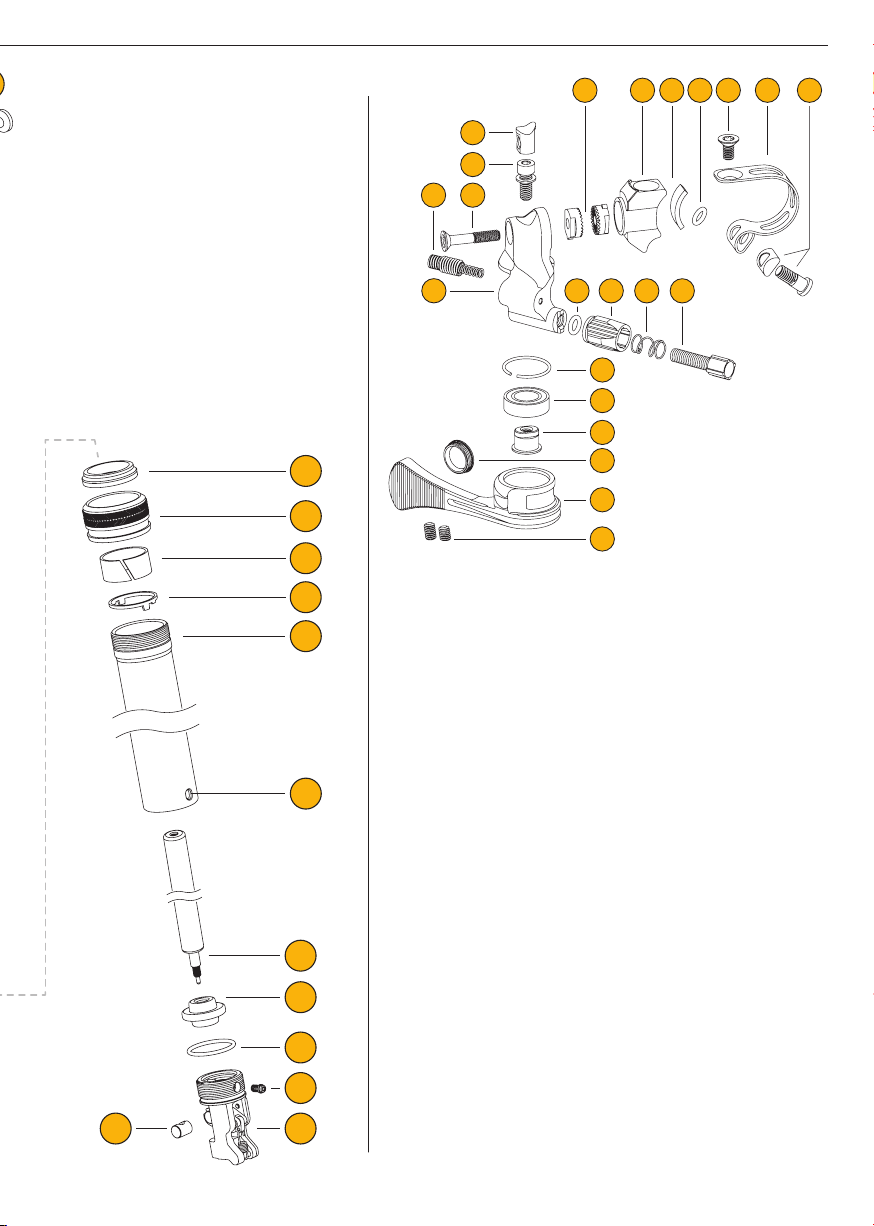

7. Seatpost components / Exploded view 06-07

8. Installation requirements 08-09

9. Installation 10-14

9.1 / 9.2 Tools + preparation 10

9.3 Mounting the remote lever 10-11

9.4 Routing the cable 12

9.5 Connecting seatpost + remote lever 12-14

9.6 / 9.7 Saddle installation / adjustments 15

10. Changing the spring element 16-17

11. Operating the seatpost 18

12. Care / Cleaning 18

13. Warranty / Guarantee 19

14. Maintenance / Service card 19

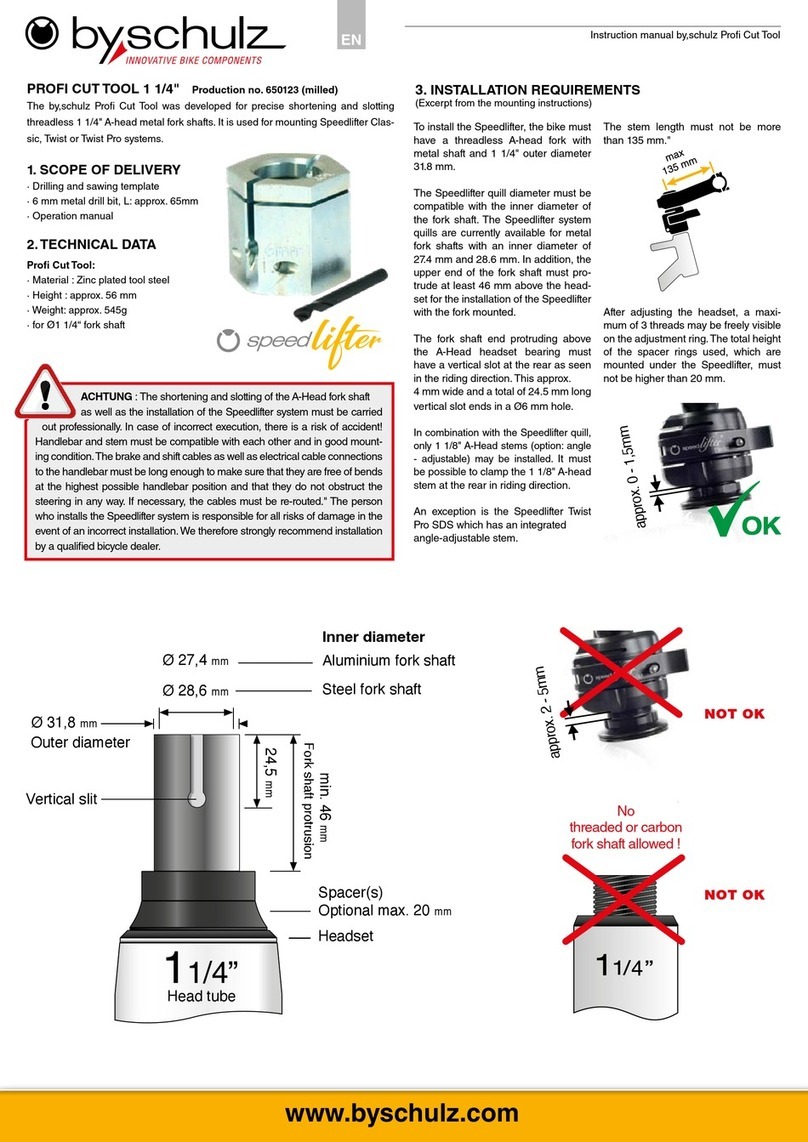

1. USAGE APPROVAL

The adjustable parallelogram suspension by,schulz D.2 ST-

Ri seatpost is for use with bicycles, cargo bikes, pedelecs

and e-bikes up to 45 km / h suitable. It is NOT designed

for extreme loads that occur during downhill, dual slalom

or freeriding, or for riding proles with jumps. The D.2 ST-

Ri seatpost is made of high-strength aluminium, and has

been tested and approved according to the following DIN

standards:

Before the rst ride:

We strongly recommend that you check the roadworthiness

of the bicycle in general, and the operational safety of the

seatpost in particular, before each ride.

First check that the saddle is rmly secured in the saddle

clamp. Also make sure that the seatpost tube is free of

play and rmly connected to the bicycle frame. It must be

clamped in the desired position in such a way that it cannot

be turned or moved in the seat tube. Please note the mini-

mum insertion depth of the seatpost of 100mm.

2. SAFETY INSTRUCTIONS

1. These instructions contain important informa-

tion on the proper assembly, use and maintenance of

the by,schulz D.2 ST-Ri seatpost.Take the listed warning

and safety instructions seriously. Failure to do so may

result in property damage or personal injury, for which

neither the seller nor the manufacturer is liable.

2. Check the installation requirements before assembly.

If you do not have the necessary skills and / or tools, we

strongly recommend having the installation carried out

by a specialist dealer

3. Child seats, trailer couplings or luggage carriers must

not be attached to a D.2 ST-Ri seatpost as this can lead

to breakage or damage.

4. To avoid further risks of accidents after a fall with

damage, the seatpost must be checked and replaced

if necessary.

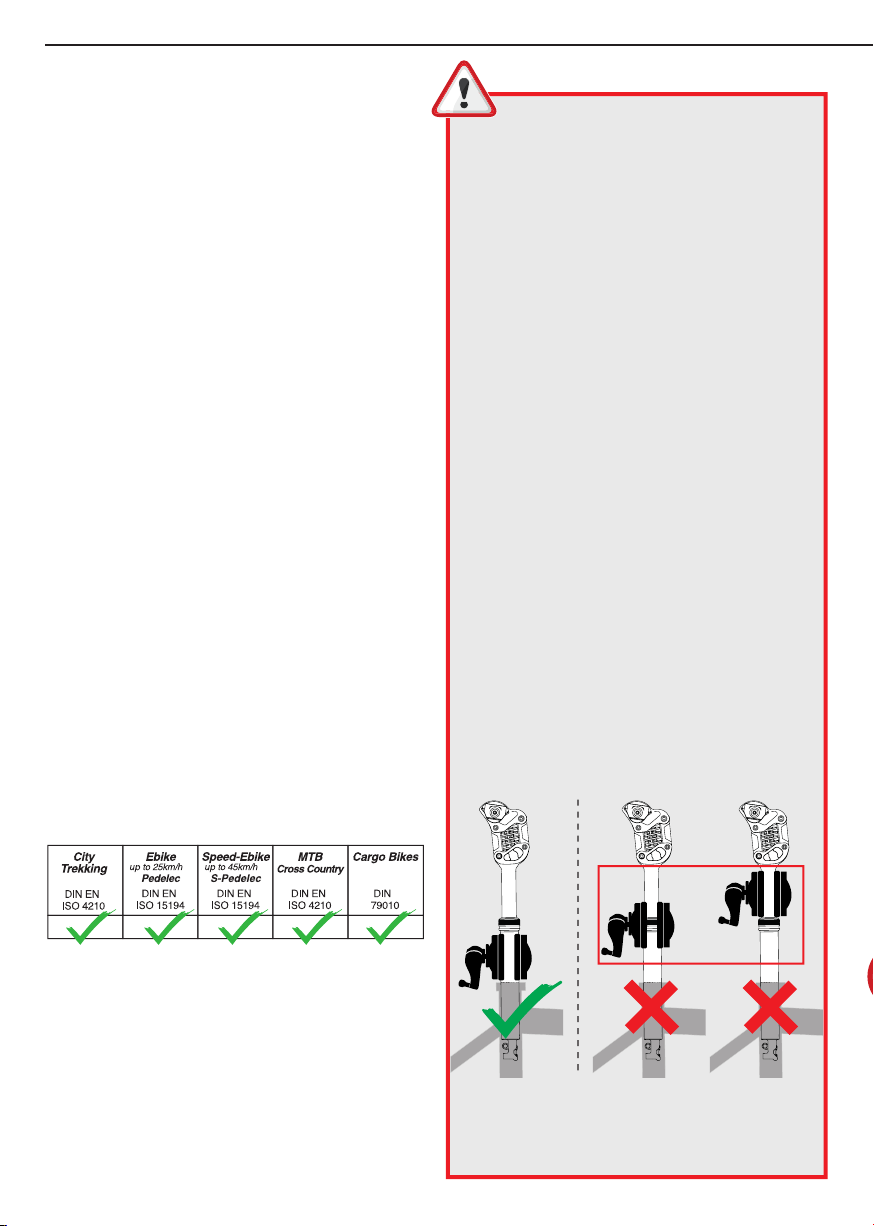

5. Always use the protective neoprene cover to cover

the spring mechanism if a child seat is mounted behind

the seatpost. Without the cover, there is a risk of injury

to children's hands!

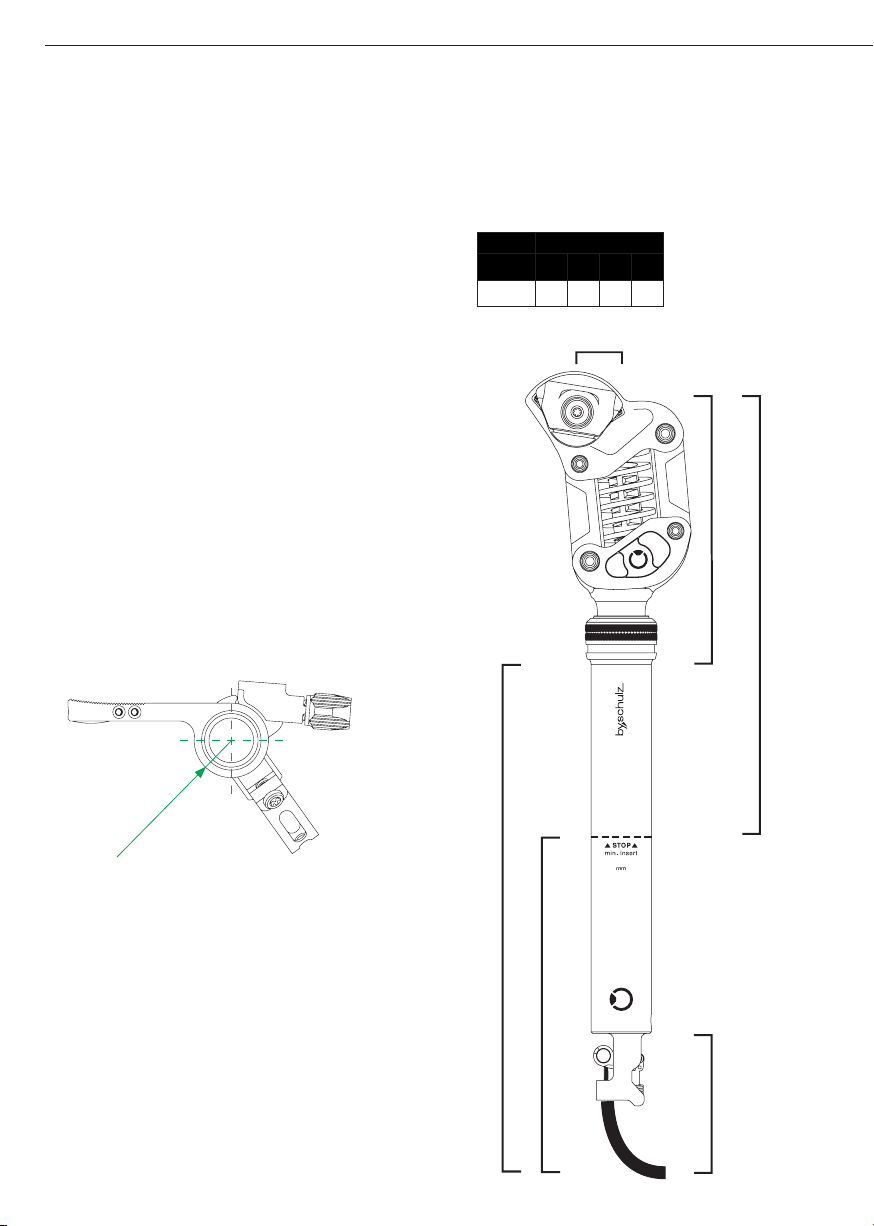

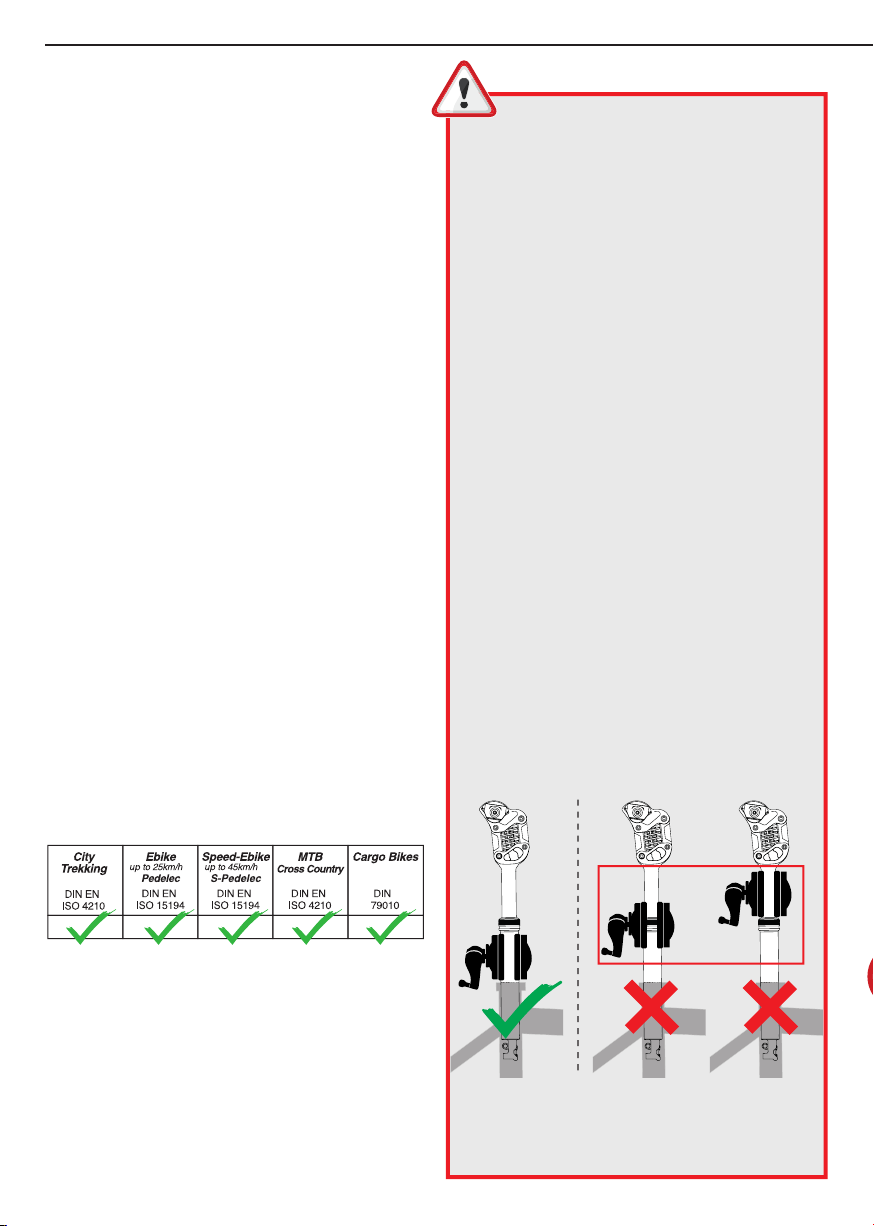

6. The D.2 ST-Ri seatpost is not to be used for trans-

port with car bike racks where the bike is attached to the

saddle. Fastening to the seatpost may only be done as

shown in Fig. 2.1!

7. Clamping systems of mounting stands may only be

attached to the outer seatpost tube below the screw ring,

or to the frame of the bicycle. The inner seatpost tube

and the area of the screw ring are not suitable for this

purpose (Fig. 2.1).

Incorrect attachment can cause damage to the seat-

post, and void the warranty!

Fig. 2.1