7.4 Attaching and detaching a bicycle (VAR PR-72000 clamping arm)

The by,schulz e-Bikelifter BM-60 VA comes with the PR-72000 clamping arm by VAR. This clamping arm can

be swiveled 360°, and is suitable for clamping tubes with diameters from Ø 22 mm up to Ø 80 mm. The two

replaceable rubber clamps with their double cable gap provide a secure grip, and protect components and

paint from scratches. The VAR PR-72000 clamp is approved for loads up to 60 kg. More information about

this clamping arm at

https://www.vartools.uk/clamp-for-professional-repair-stands-c2x36007061

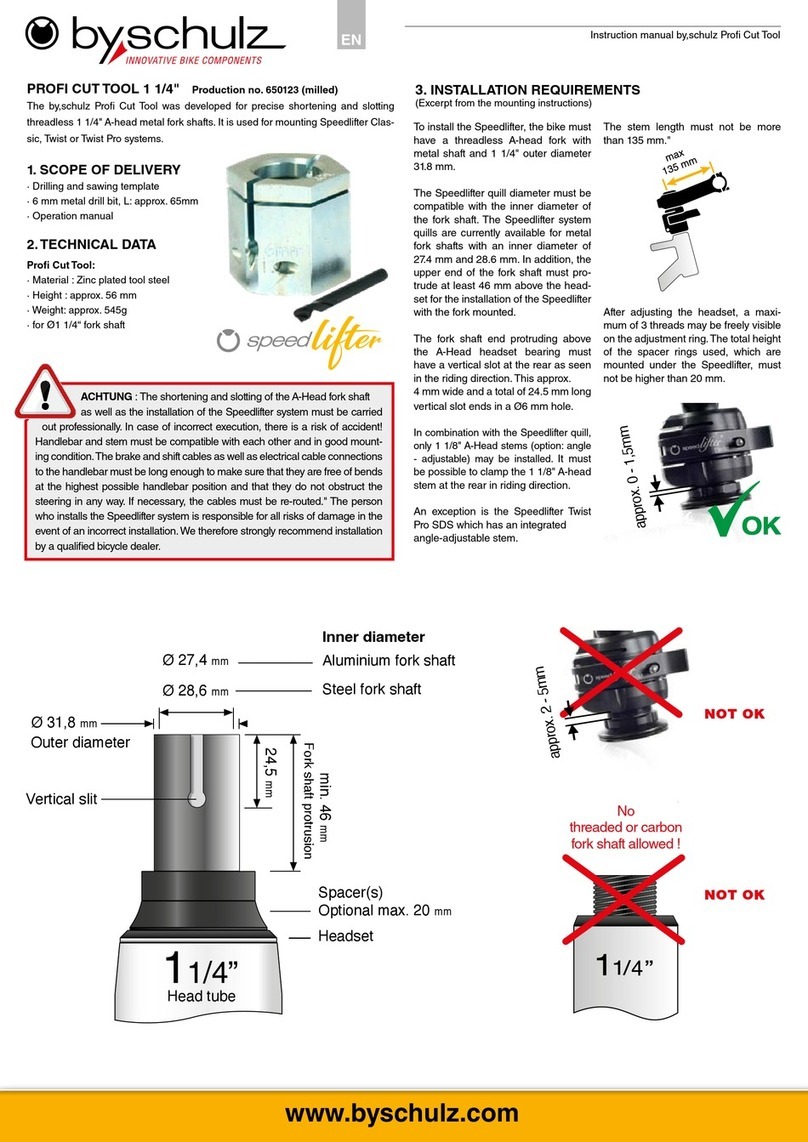

The clamping device consists of two separate parts. The base mounting

plate, which is fixed to the e-Bikelifter, and the interchangeable clamping

arm.

Base mounting plate:

A: Pivot lock lever

B: Allen head screw M5 (Hex 4 mm)

Clamping arm:

C: Rubber clamping jaws

D: Crank for clamping strength fine adjustment with eccentric base

(OPEN)

E: Crank for clamping strength fine adjustment with eccentric base

(CLOSED)

To quickly adjust the clamp to different tube-diameters, the crank has an

eccentric base, which can enter two different conditions. In the „OPEN“

fig. [D] condition, the crank’s knob points towards the clamp, and the

clamping jaws are open. In the „CLOSED“ fig. [E] position it points away

from the clamp, and the clamping jaws are tighter. By simply turning this

crank, the width of the clamp jaw opening can be quickly opened or

closed. Fine adjustment of the opening width, and the clamping force, is

made with the crank. Turning the crank clockwise increases the clamping

force, turning it counterclockwise reduces it.

Beware, that the eccenter has to be in the „CLOSED“ position fig. [E] while

working on a bicycle!

Attaching the bicycle :

1: Place bicycle on the floor in front of the e-Bikelifter.

2: Adjust the sledge to the necessary height, by using the foot switches.

3: Use pivot lock lever fig. [A] of the base mounting plate to rotate the clamping arm and to adjust it to the

clamping situation.

4: Use the crank fig. [E] to adjust the opening of the clamping arm approximately to the diameter of the

tube to be clamped.

5: Turn over crank fig. [E] to the „OPEN“ position fig. [D], to widely open the clamping jaws.

6: Place the clamping area of the bicycle between the clamps fig. [C].

7: Flip the eccentric fig. [D] back to the "CLOSED" position fig. [E] and use the crank to fine-tune the clamp-

ing force. Turn clockwise to tighten the clamping.

Detaching the bike:

1: Lower the sledge by using the foot switch, until the wheels of the bicycle touch the ground.

2: First reduce the clamping force by turning the crank approx. four turns counterclockwise. Now open the

clamping completely by folding the closed eccentric fig. [E] into the open state fig. [D].

3: Then remove the bicycle.

Note when attaching or detaching the bicycle:

lEnsure that the pivot lock lever fig. [A] of the base mounting plate is closed tight, and the

clamping arm can’t rotate.

lTo prevent damage, only attach clamps to parts of the bicycle that are strong enough.

lA slip clutch is preventing damage in case the bike hits the ground while lowering.

lNo obstacles must be on the base plate, when operating the e-Bikelifter.

lMind your limbs while working with the e-Bikelifter.

www.e-bikelifter.com

9