3

1 Introduction............................................................................................................................................4

1.1 Instructions...............................................................................................................................................4

1.2 Intended Use............................................................................................................................................4

1.3 Safety Instructions....................................................................................................................................4

1.4 Safety Marking.........................................................................................................................................5

1.5 Environment.............................................................................................................................................5

2 Product Description...............................................................................................................................6

2.1 Important Features...................................................................................................................................6

2.2 Technical Data..........................................................................................................................................6

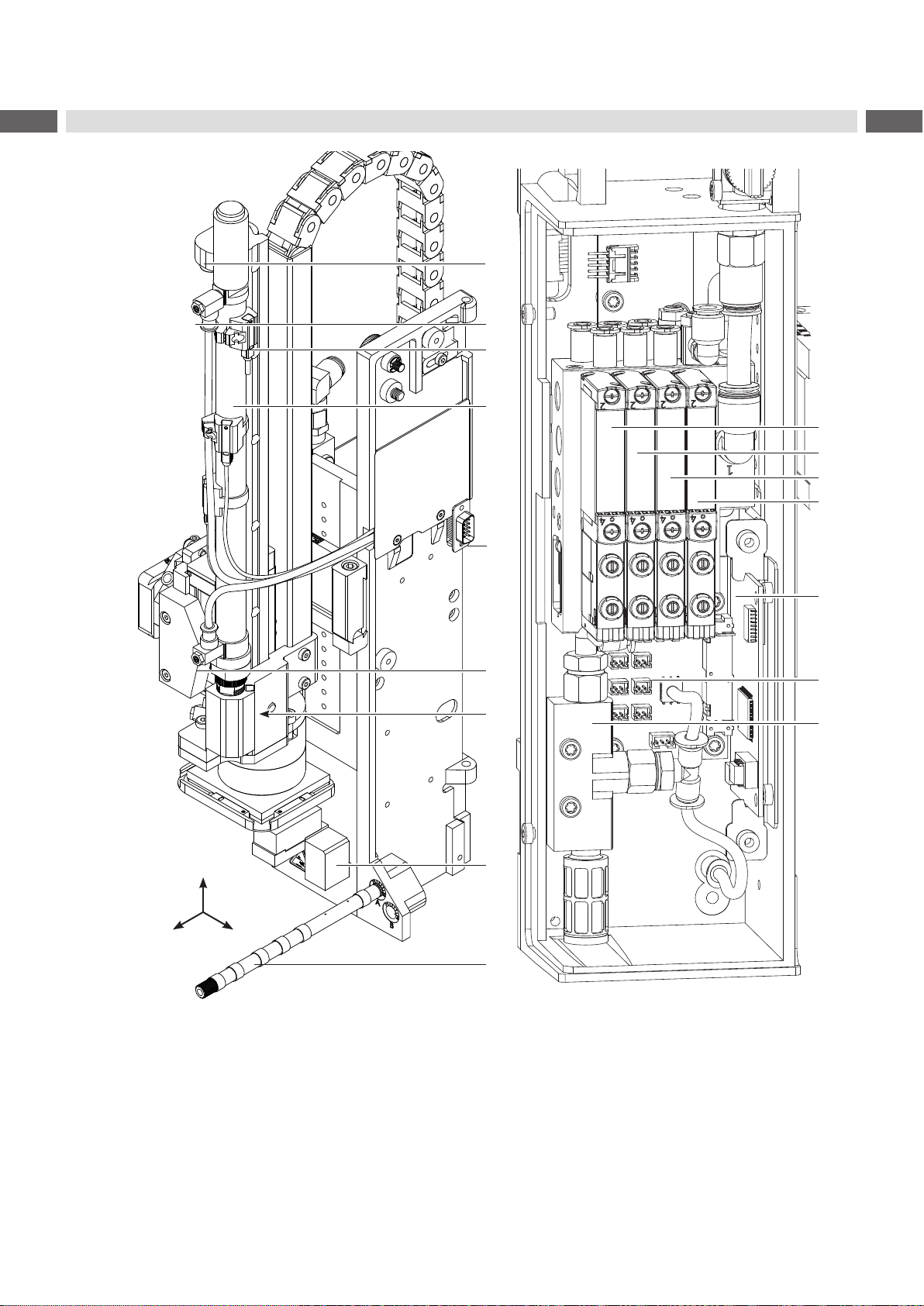

2.3 Overview Without Cover ..........................................................................................................................7

2.4 Contents of Delivery.................................................................................................................................9

3 Operation..............................................................................................................................................10

3.1 Standard Operation................................................................................................................................10

3.2 Cleaning.................................................................................................................................................10

3.3 Movement of the Pad.............................................................................................................................12

4 Error Messages....................................................................................................................................13

4.1 Error Messages of the Printer................................................................................................................13

4.2 Error Messages of the Applicator...........................................................................................................13

5 Installation............................................................................................................................................14

5.1 Factory default Settings .........................................................................................................................14

5.2 Tools.......................................................................................................................................................14

5.3 Mounting and Dismounting the Cover....................................................................................................15

5.4 Transportation Lock................................................................................................................................15

5.5 Mounting the Applicator to the Printer....................................................................................................16

5.6 Mounting the Pad...................................................................................................................................17

5.7 Mounting the Blow Tube.........................................................................................................................17

5.8 Connecting the Compressed Air ............................................................................................................18

6 Adjustments .........................................................................................................................................19

6.1 Adjusting the Pad...................................................................................................................................19

6.1.1 Moving the Pad in Y-Direction..........................................................................................................20

6.1.2 Moving the Pad in Z-Direction..........................................................................................................21

6.2.1 Moving the Pad in X-Direction..........................................................................................................22

6.3 Set Throttle Valves on the Cylinders......................................................................................................23

6.4 Set the Sensors......................................................................................................................................23

6.5 Vacuum Adjustments..............................................................................................................................24

6.6 Adjusting the Blow Tube (Supporting Air)...............................................................................................25

6.7 Adjustment of the Stopper for Blow Mode..............................................................................................27

6.8 Lift Speed of Cylinder Z..........................................................................................................................28

6.9 Sensors on Cylinder Z............................................................................................................................29

6.10 End Position Cushioning........................................................................................................................30

6.11 Adjusting the Options for Z-Direction Movement ...................................................................................30

6.12 Lift Speed of Cylinder R.........................................................................................................................31

6.13 Sensors on Cylinder R...........................................................................................................................31

6.14 Settings of the Rotation Angle of the Cylinder R....................................................................................32

6.15 Labeling from Below - Changing the Spring of the Impact Sensor ........................................................33

7 Conguration........................................................................................................................................34

7.1 Method for Changing the Printer Setup..................................................................................................34

7.2 Conguration Parameters of the Applicator ...........................................................................................35

7.3 Setting the Peel Position........................................................................................................................36

7.4 Activation of Peel-o Mode ....................................................................................................................36

8 Test Operation......................................................................................................................................37

8.1 Test Mode without a Print Job................................................................................................................37

8.2 Test Mode with a Print Job.....................................................................................................................37

9 Drawings...............................................................................................................................................38

9.1 Block Diagram........................................................................................................................................38

9.2 Pneumatic Drawing Type 4214 .............................................................................................................39

9.3 Labeling Position Type 4214 L...............................................................................................................40

9.4 Label Position Type 4214 R ...................................................................................................................41

10 Index......................................................................................................................................................42

Table of Contents