Cal-Royal 500 Series Instruction sheet

Other Cal-Royal Door Opening System manuals

Cal-Royal

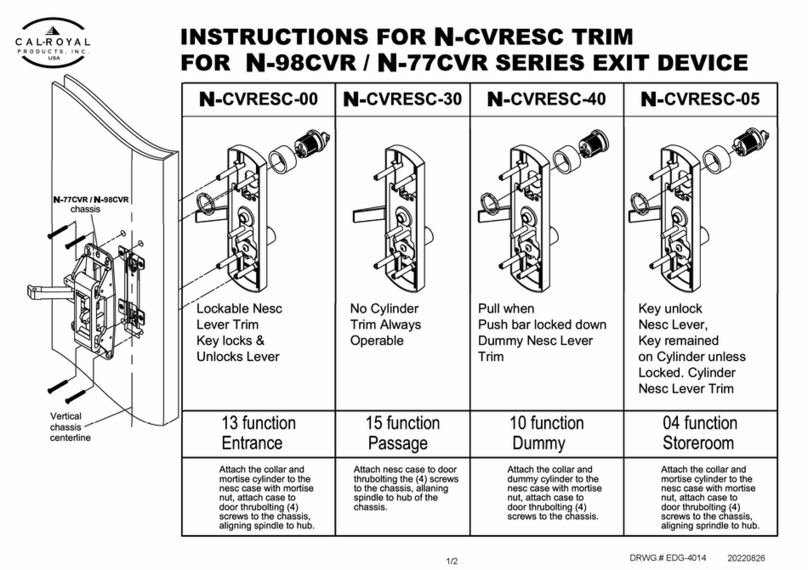

Cal-Royal N-CVRESC User manual

Cal-Royal

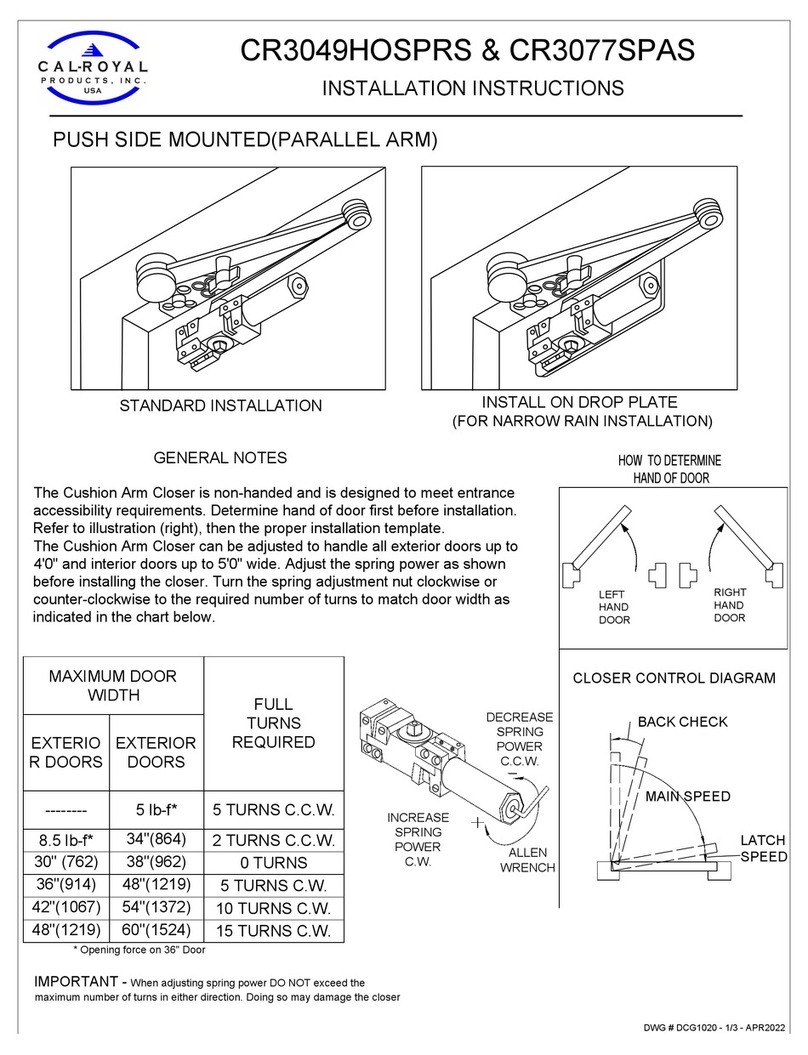

Cal-Royal CR3049HOSPRS User manual

Cal-Royal

Cal-Royal 900 Series User manual

Cal-Royal

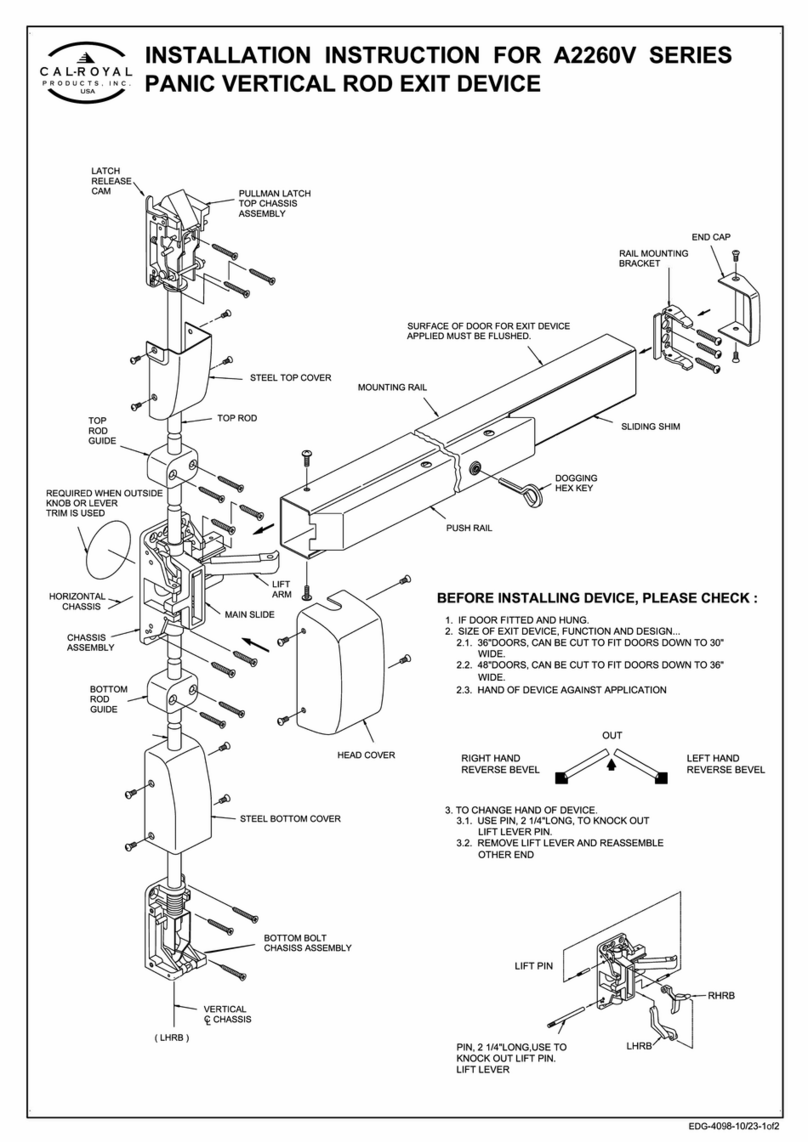

Cal-Royal A2260V Series User manual

Cal-Royal

Cal-Royal 8600 User manual

Cal-Royal

Cal-Royal 7760V Series User manual

Cal-Royal

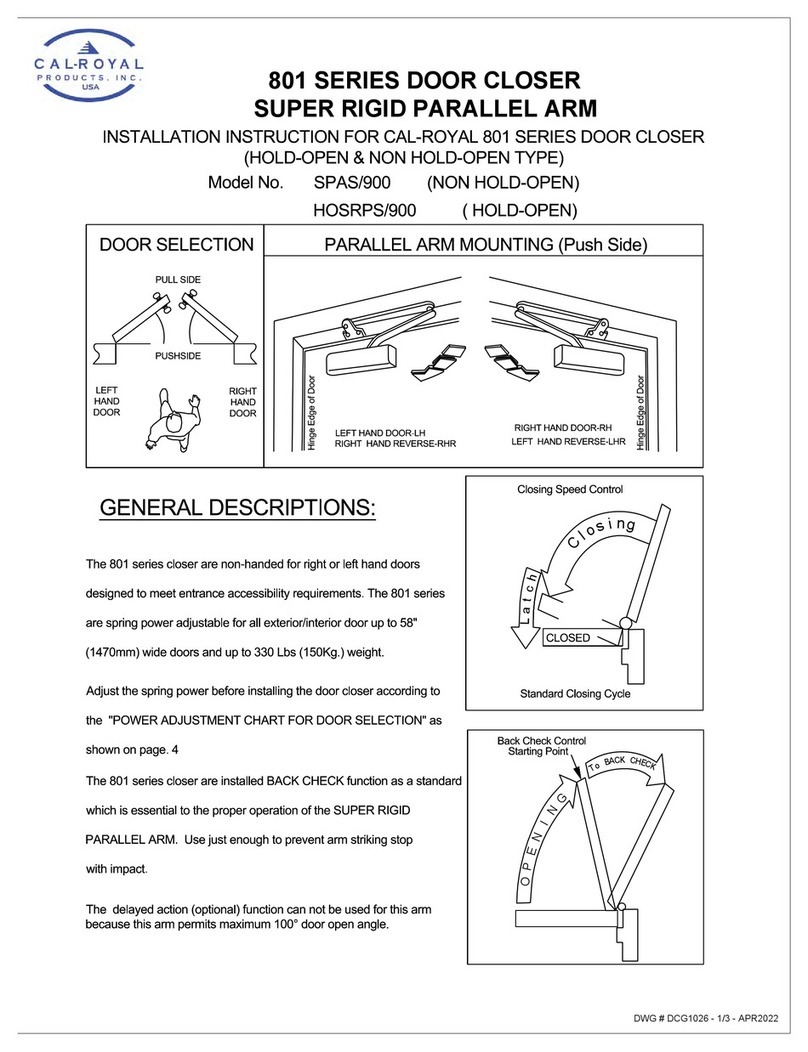

Cal-Royal CR801 Series User manual

Cal-Royal

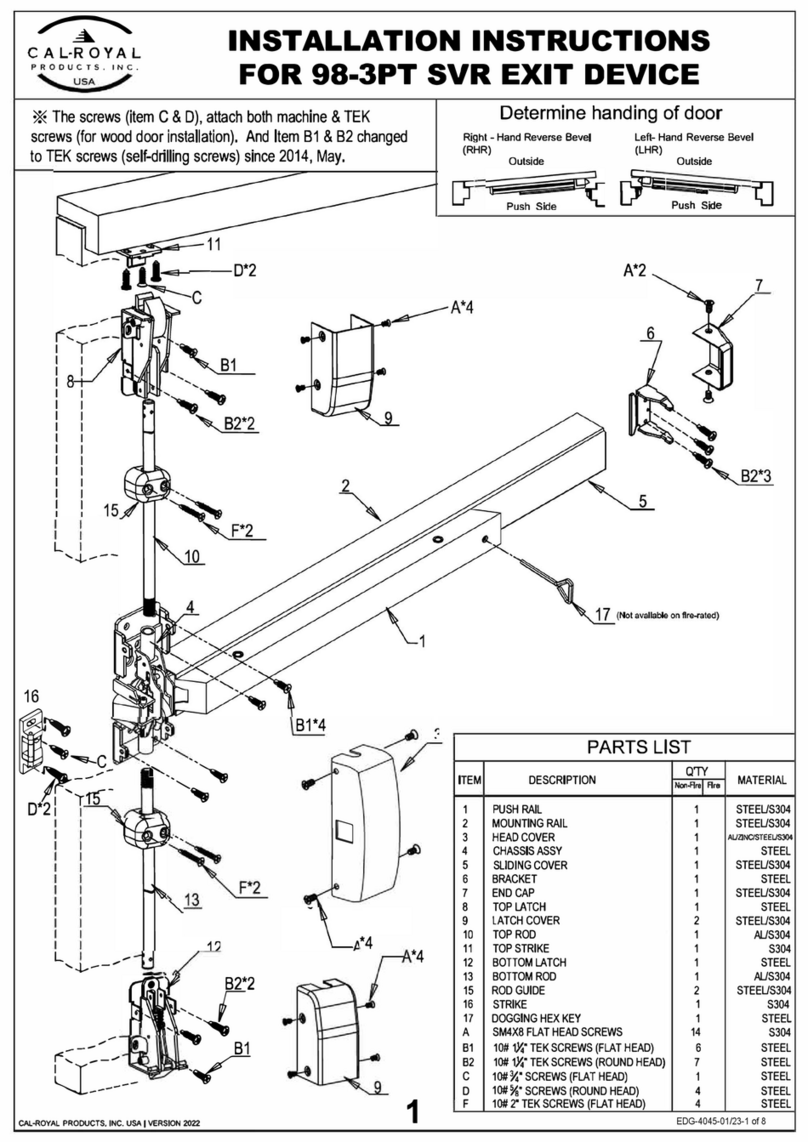

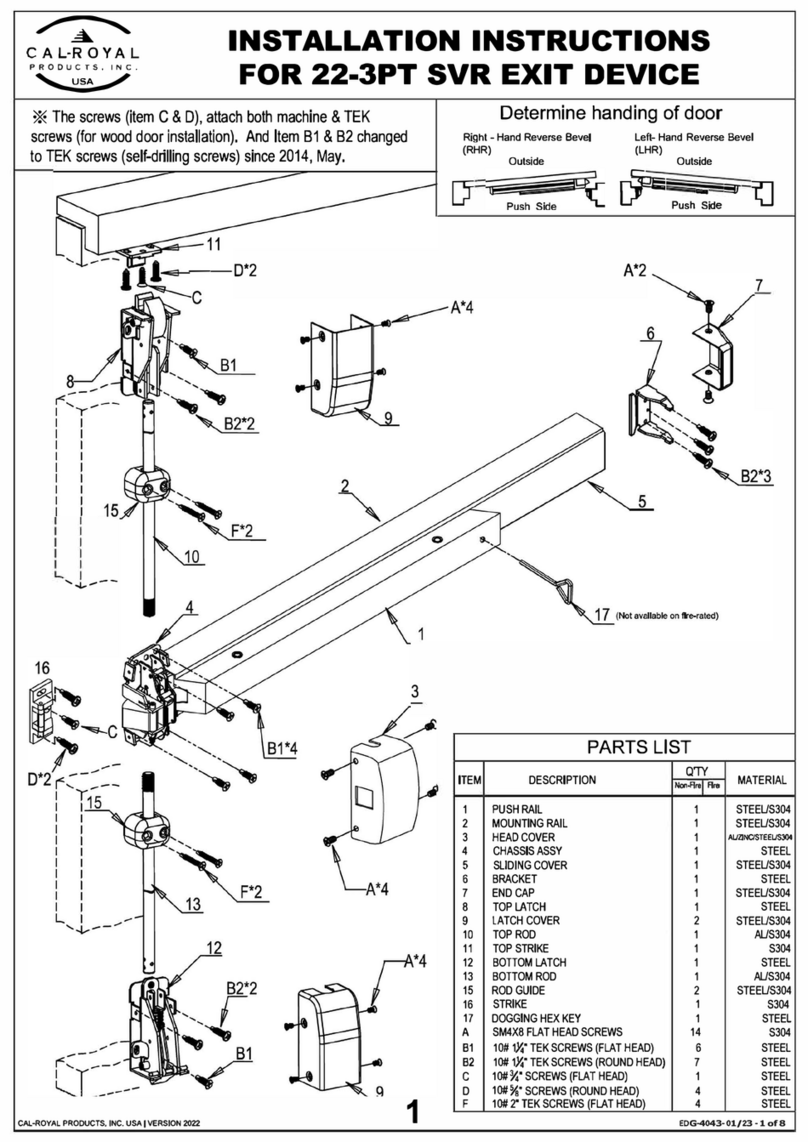

Cal-Royal 98-3PT User manual

Cal-Royal

Cal-Royal N-FMR7700 Series User manual

Cal-Royal

Cal-Royal 8600 User manual

Cal-Royal

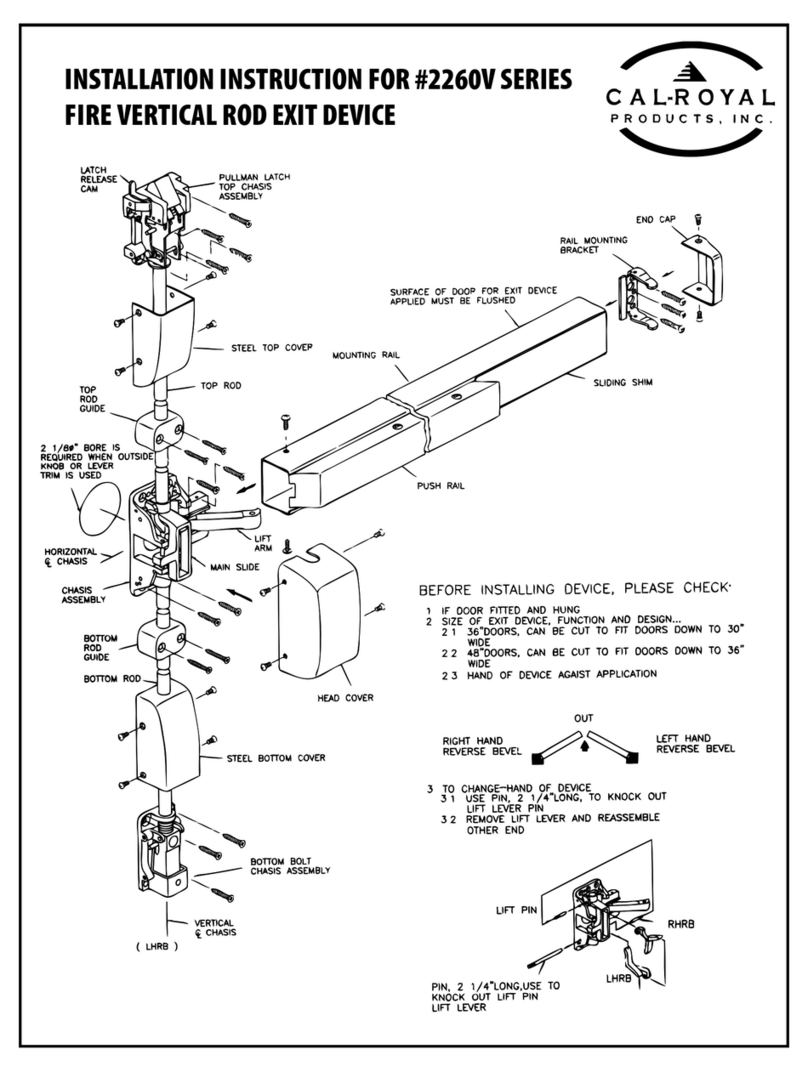

Cal-Royal 2260V Series User manual

Cal-Royal

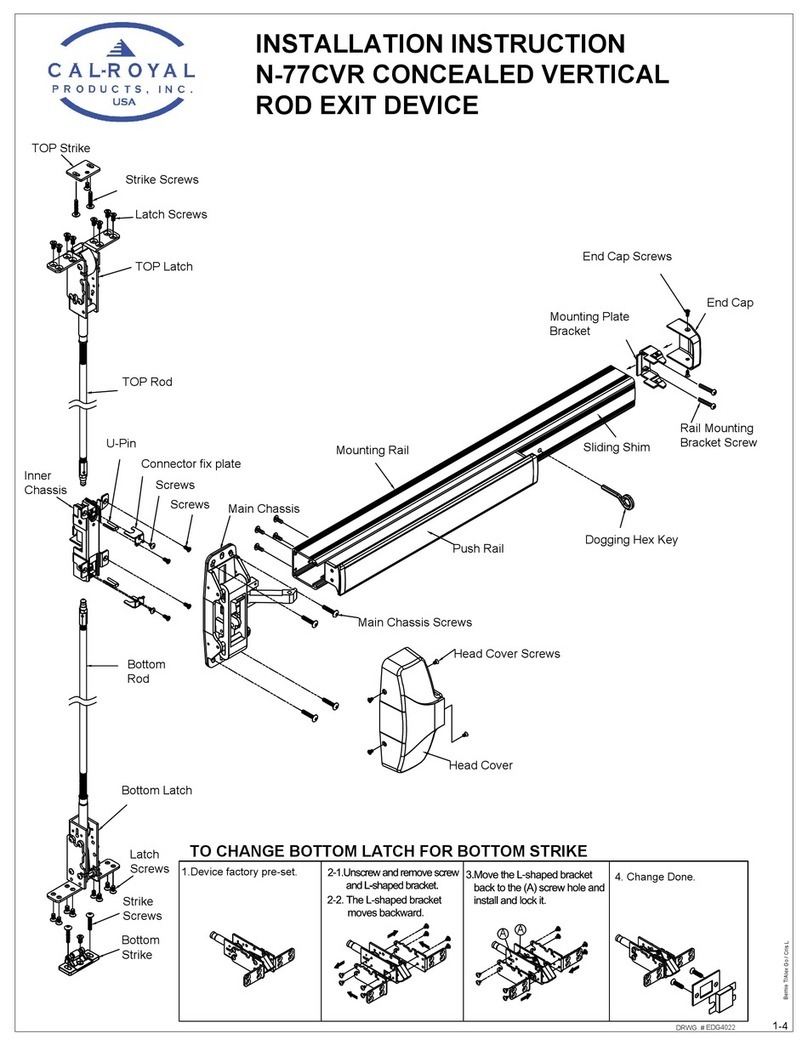

Cal-Royal N-77CVR User manual

Cal-Royal

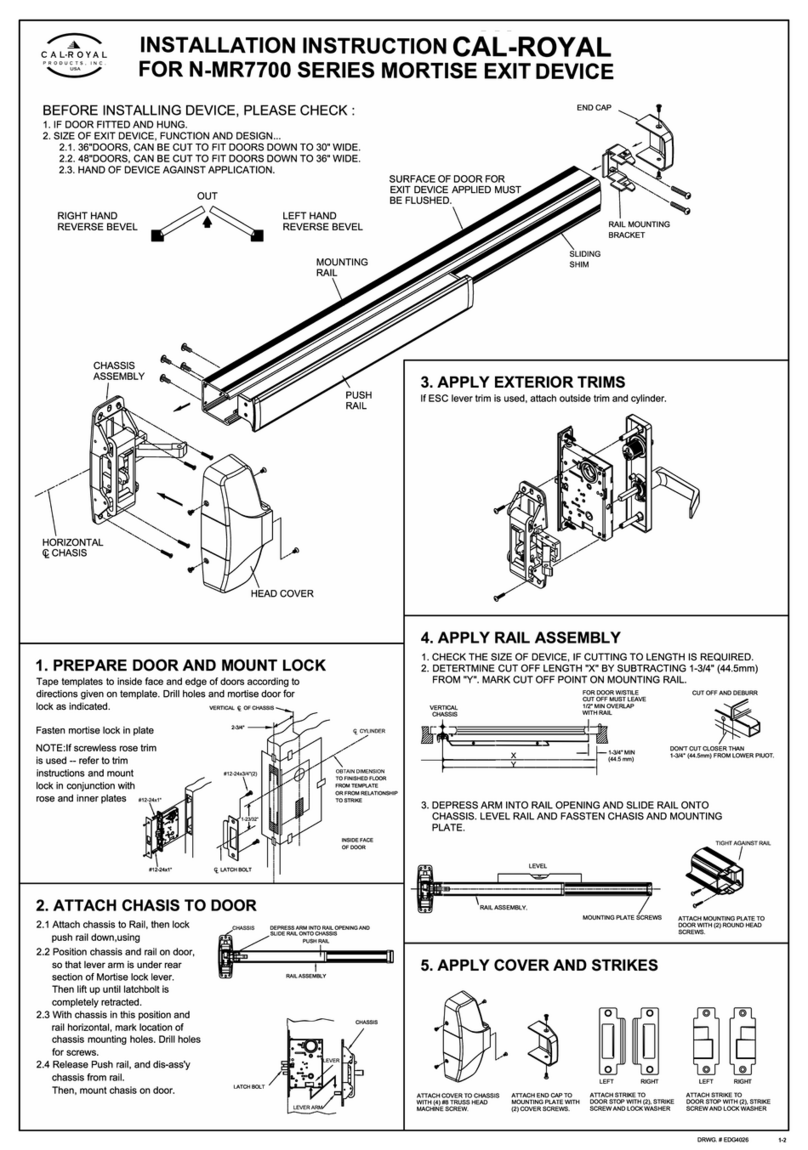

Cal-Royal N-MR7700 Series User manual

Cal-Royal

Cal-Royal N-F77CVR User manual

Cal-Royal

Cal-Royal 801 Series User manual

Cal-Royal

Cal-Royal 22-3PT User manual

Cal-Royal

Cal-Royal N900 Series User manual

Cal-Royal

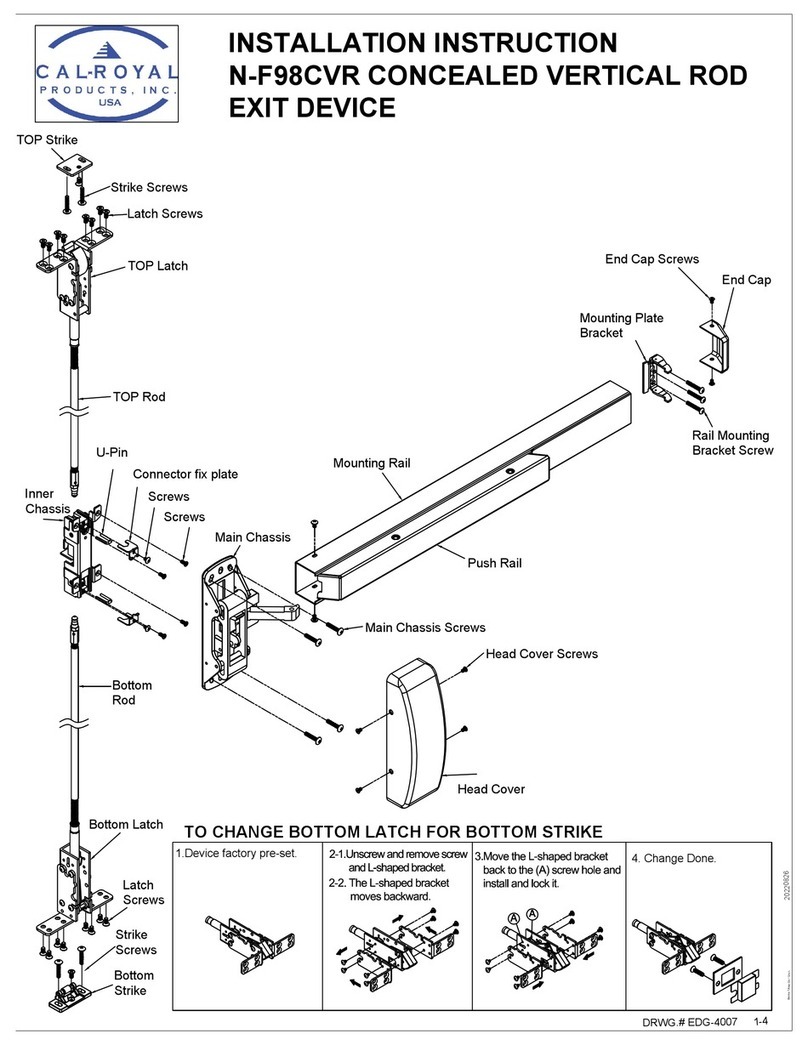

Cal-Royal N-F98CVR User manual

Popular Door Opening System manuals by other brands

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

GEZE

GEZE ECturn user manual

Chamberlain

Chamberlain T user guide