3

Safety Reminders

Instruction Book

This appliance should only be used for

it’s intended purpose as described in

these instructions.

Ensure that you fully understand these

instructions before operating this appli-

ance.

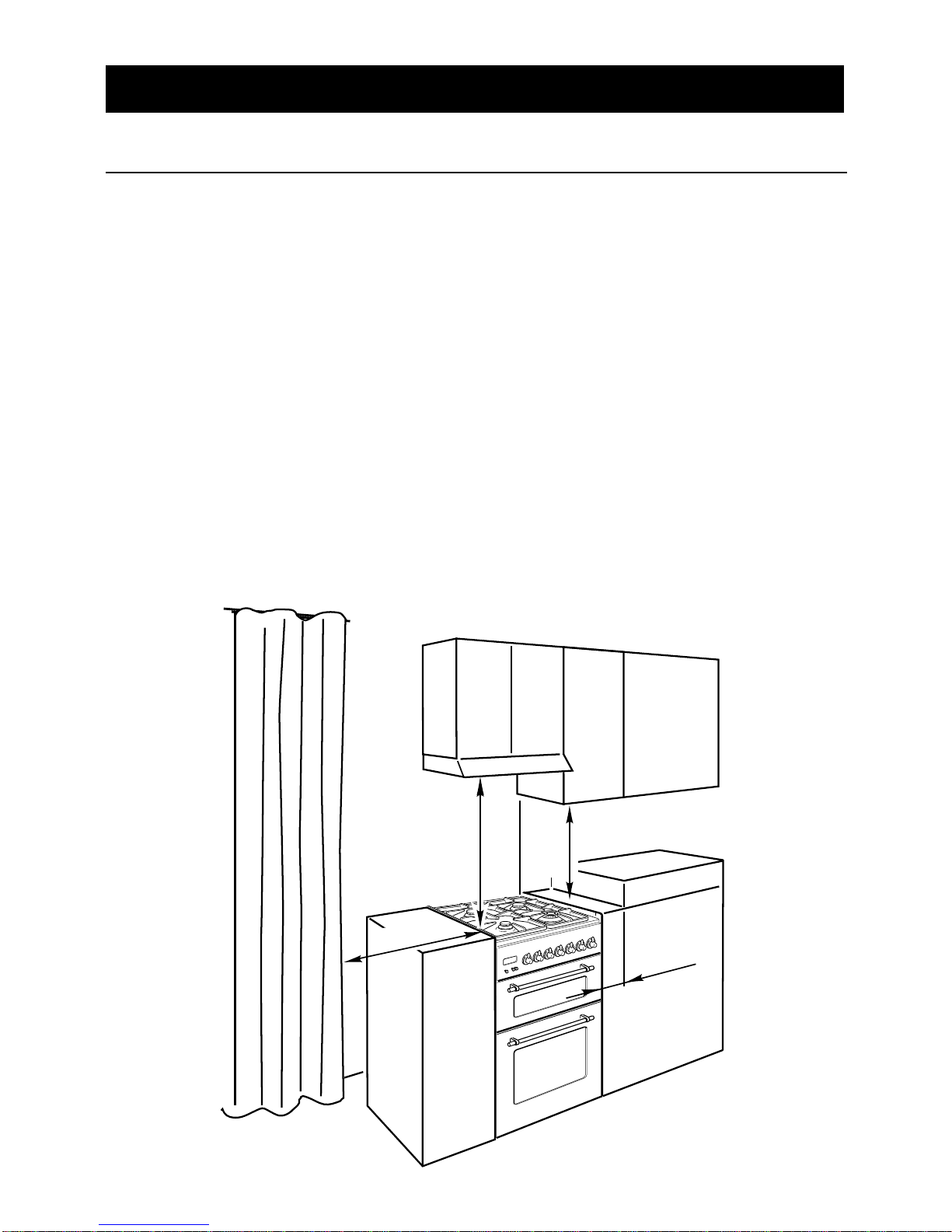

Space Requirements

Ensure that the specified ventilation

space around the appliance is not

obstructed.

Food Splashes

Always wipe clean the oven after use.

Food splashes can carry on cooking next

time and may become a fire hazard.

Hot Surfaces

It is important to remember that the sur-

faces of cooking appliances get hot dur-

ing use and retain the heat for some time

after switching off.

It is therefore advisable to keep small

children away from the appliance.

The Grill and Top oven element

are exposed, so take great care when

placing food in the oven or removing it.

Use the grill pan handles or gloves.

DO NOT line the oven, grids, trays etc.

with aluminium foil as this could adverse-

ly affect the heating elements and it

could also damage the interior surfaces.

DO NOT place flammable materials in

the oven.

Faults

Do not continue to use this appliance if it

appears to be faulty.

After Use

After use, ensure that the hob knobs are

in position ●(off), and close the main

gas delivery valve or the gas cylinder

valve.

Switch the oven controls off.

Always switch off at the isolating switch

before cleaning the appliance, or

attempting any maintenance task.

CAPLE Service

To ensure the continued safe and effi-

cient operation of this appliance, we rec-

ommend that any servicing or repairs are

carried out only by an authorised CAPLE

SERVICE ENGINEER.

Before Use

Check that all accessories have been

removed from the oven interior.

Set the temperature to the maximum

position using the temperature control

knob.

Leave on for approximately 30 min-

utes. This will burn off any protective

coating applied to the oven during

manufacture.

The kitchen should be well ventilated

during this time as there may be an

odour given off.

When cool, wash the accessories and

the oven with warm water and mild

detergent.