3

Appliance conformity

– The appliance complies with European Directives EEC 89/336,

92/31 and 93/68 relative to electromagnetic compatibility.

– All our appliances are designed and constructed in compliance

with European standards EN 60 335-1 and EN 60 335-2-6

and their subsequent amendments, in conformance with the

requirements of the European Low Voltage Directive EEC

73/23 and 93/68.

– The oven accessories that can come into contact with food are

constructed using materials that conform to European

directive EEC 89/109 of 21/12/88.

– The appliances are constructed in compliance with European

gas directives EEC 90/396, EEC 93/68 and European

standards EN 30-1/EN 30-2.

– The conformity to the standards is proved by symbol CE

applied.

This booklet is valid only for the country of installation

indicated on the back cover and on the appliance itself.

Carefully keep this booklet for future reference.

TO THE OWNER OF THE COOKER

Retain this owner’s manual for future reference.

TO THE INSTALLER:

Leave this owner’s manual with the cooker.

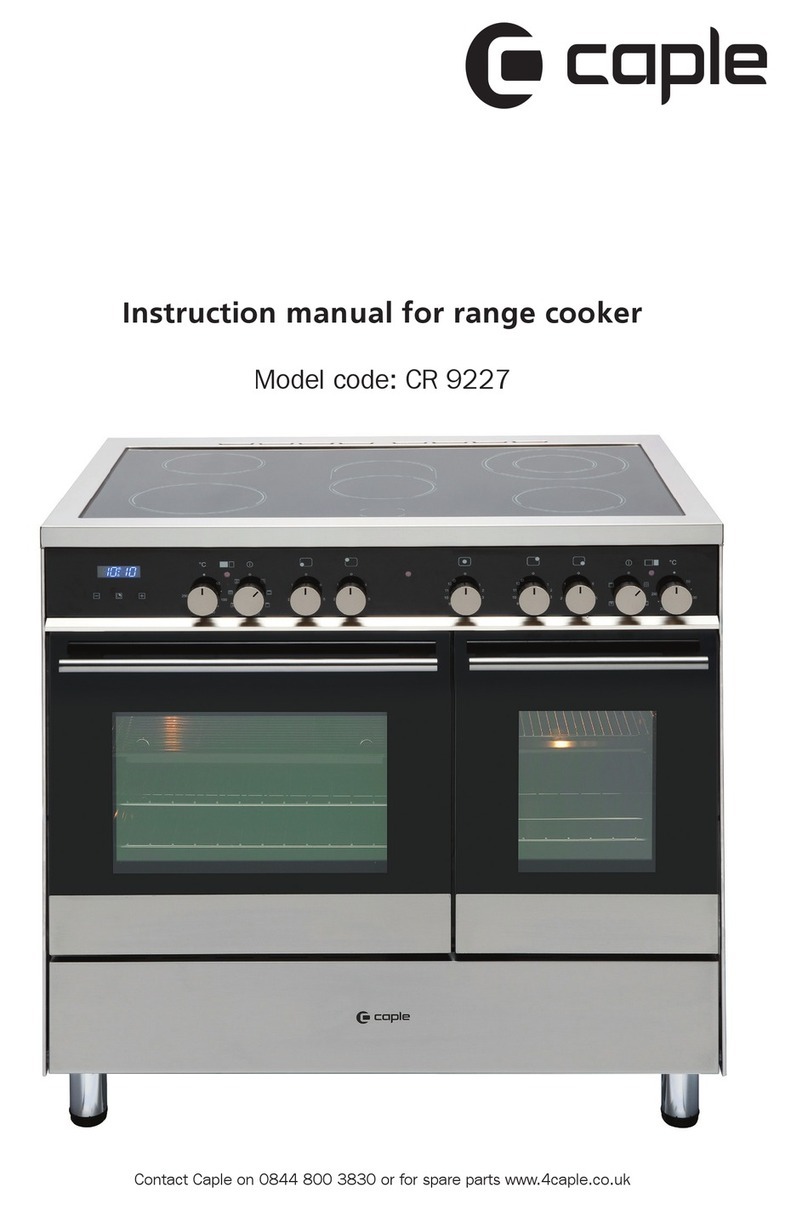

The cooker model and its technical data (power, supply voltage,

etc.) appear on the data plate affixed to the inner side of the

Plate Warming Door. The factory settings are indicated on the

label affixed beside the data plate.

“THIS COOKER GUARANTEE IS FOR DOMESTIC

USE ONLY”

This booklet gives valuable instructions covering the installation,

servicing and use of your cooker.

Important

After using the cooker, it is advisable to:

– Always check that the control knobs are in the “ ” position.

– Also close the gas cylinder valve (if LPG is used) or the supply

cock (if natural gas is used).

– Periodically inspect the rubber hose. If it shows any signs of

wear it must be replaced: never repair the gas hose.

Contact your qualified installer.

FOR YOUR SAFETY

The installation must be performed by a competent installer,

properly qualified as required by local regulations. Any rewiring

required of the household electrics in order to install the

cooker should only be carried out by a Qualified Electrician. The

manufacturer declines all responsibility for any type of

damage resulting from failure to observe the regulations, or

from negligent installation of the cooker.

For repairs, always call in an authorised Technical Service Centre

and insist on the use of original spare parts.

Caution: When in use parts of the cooker become very hot (e.g.

the burners) and remain hot for a long period of time. Use of

oven gloves is recommended whilst using your cooker. Children

should be kept away from the appliance.

– Make sure there is adequate air circulation around the cooker.

Poor ventilation reduces the amount of oxygen in the room. If in

doubt, consult the installer. In the interest of hygiene and

safety, the cooker should always be kept clean.

– Deposits of grease or other foods can catch fire. Carefully

supervise the cooking of oils or fat.

– When you first use your cooker it may give off a slight odour

but this will stop after a little use.

– This product has been designed for domestic cooking only and

should not be used for other purposes (such as heating a

room).

– Avoid installing the cooker close to flammable materials (e.g.

curtains, drapes, etc...)

– Operate the cooker with the type of gas specified on the

adhesive label placed in the inner side of the Plate Warming

Door.

– Before cleaning or servicing the appliance, disconnect it from

the electricity supply by unplugging it or by using the main

circuit breaker.

Please note: The connection hose and the chain are part of the

installation not part of the cooker. They should be provided by

your installer and are available at most builders merchants.

THIS MANUAL CONTAINS:

• User’s instructions

• Cooking guide

• Installation instructions

• Servicing instructions