Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500239-01 Printed in U.S.A. Form 50KC-4-6-03SI Pg 1 3-2020 Replaces: 50KC-4-6-02SI

Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation.

CONTENTS

Page

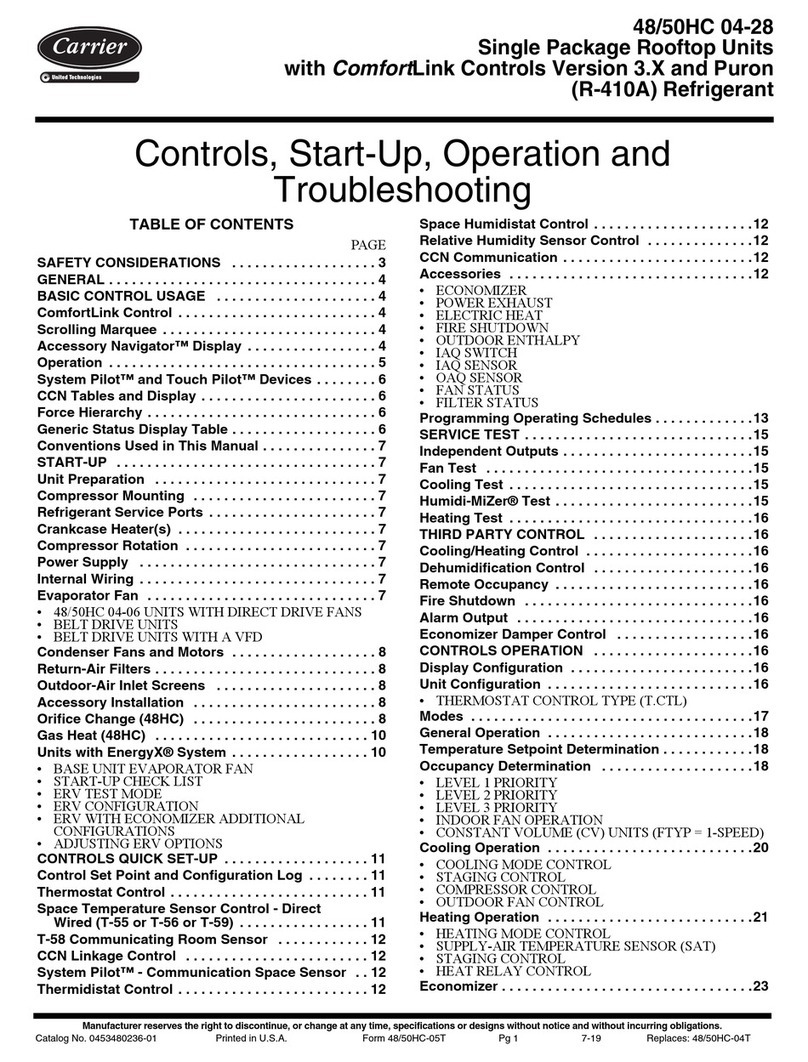

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . 1

Model Number Nomenclature and Dimensions . . . . 2

Rated Indoor Airflow (cfm) . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Jobsite Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Step 1 — Plan for Unit Location . . . . . . . . . . . . . . . 10

• ROOF MOUNT

Step 2 — Plan for Sequence of Unit Installation . . 10

• CURB-MOUNTED INSTALLATION

• PAD-MOUNTED INSTALLATION

• FRAME-MOUNTED INSTALLATION

Step 3 — Inspect Unit . . . . . . . . . . . . . . . . . . . . . . . . 10

Step 4 — Provide Unit Support . . . . . . . . . . . . . . . . 10

• ROOF CURB MOUNT

• SLAB MOUNT (HORIZONTAL UNITS ONLY)

• ALTERNATE UNIT SUPPORT (IN LIEU OF CURB OR

SLAB MOUNT)

Step 5 — Field Fabricate Ductwork . . . . . . . . . . . . . 11

• FOR UNITS WITH ACCESSORY ELECTRIC HEATERS

Step 6 — Rig and Place Unit . . . . . . . . . . . . . . . . . . 11

• POSITIONING ON CURB

Step 7 — Convert to Horizontal and Connect

Ductwork (when required) . . . . . . . . . . . . . . . . . . 12

Step 8 — Install Outside Air Hood . . . . . . . . . . . . . . 13

• ECONOMIZER HOOD PACKAGE REMOVAL AND

SETUP - FACTORY OPTION

• ECONOMIZER HOOD ASSEMBLY

Step 9 — Units with Hinged Panels Only . . . . . . . . 14

Step 10 — Install External Condensate Trap

and Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Step 11 — Make Electrical Connections . . . . . . . . . 15

• FIELD POWER SUPPLY

• UNITS WITH FACTORY-INSTALLED NON-FUSED

DISCONNECT

• UNITS WITHOUT FACTORY-INSTALLED NON-

FUSED DISCONNECT

• ALL UNITS

• CONVENIENCE OUTLETS

• FACTORY OPTION THRU-BASE CONNECTIONS

• UNITS WITHOUT THRU-BASE CONNECTIONS

• FIELD CONTROL WIRING

• THERMOSTAT

• UNIT WITHOUT THRU-BASE CONNECTION KIT

• HEAT ANTICIPATOR SETTINGS

Electric Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

• SINGLE POINT BOXES AND SUPPLEMENTARY

FUSES

• SINGLE POINT BOXES WITHOUT FUSES

• LOW-VOLTAGE CONTROL CONNECTIONS

Humidi-MiZer® Control Connections . . . . . . . . . . . 21

• HUMIDI-MIZER – SPACE RH CONTROLLER

Economi$er® X (Factory Option) . . . . . . . . . . . . . . .23

• SYSTEM COMPONENTS

• SPECIFICATIONS

• INPUTS

• OUTPUTS

• ENVIRONMENTAL

• ECONOMIZER MODULE WIRING DETAILS

• INTERFACE OVERVIEW

• SETUP AND CONFIGURATION

• ENTHALPY SETTINGS

• CHECKOUT

• TROUBLESHOOTING

Control and Power Wiring Diagrams . . . . . . . . . . . .34

Smoke Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

• ADDITIONAL APPLICATION DATA

PremierLink™ Controller (Factory Option) . . . . . . .42

RTU Open Controller (Factory-installed Option) . .42

Controller Options . . . . . . . . . . . . . . . . . . . . . . . . . . .42

• LOW AMBIENT

Step 12 — Adjust Factory-Installed Options . . . . . .43

• SMOKE DETECTORS

• ECONOMI$ER IV OCCUPANCY SWITCH

Step 13 — Install Accessories . . . . . . . . . . . . . . . . .43

Step 14 — Check Belt Tension . . . . . . . . . . . . . . . . .43

• BELT FORCE — DEFLECTION METHOD

• BELT TENSION METHOD

Evaporator Coil Metering Devices . . . . . . . . . . . . . .44

Pre-Start and Start-Up . . . . . . . . . . . . . . . . . . . . . . . .44

UNIT START-UP CHECKLIST. . . . . . . . . . . . . . . . CL-1

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified service personnel should install, repair, or

service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of

cleaning coils and filters and replacing filters. All other operations

should be performed by trained service personnel. When working

on air-conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit, and other safety

precautions that may apply.

Follow all safety codes, including ANSI (American National

Standards Institute) Z223.1. Wear safety glasses and work gloves.

Use quenching cloth for unbrazing operations. Have fire

extinguisher available for all brazing operations.

It is important to recognize safety information. This is the safety-

alert symbol . When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal

injury.

Understand the signal words DANGER, WARNING, CAUTION,

and NOTE. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices, which may result in minor personal

injury or product and property damage. NOTE is used to highlight

50KC04-06

Single Package Rooftop Cooling Only

with Puron®(R-410A) Refrigerant