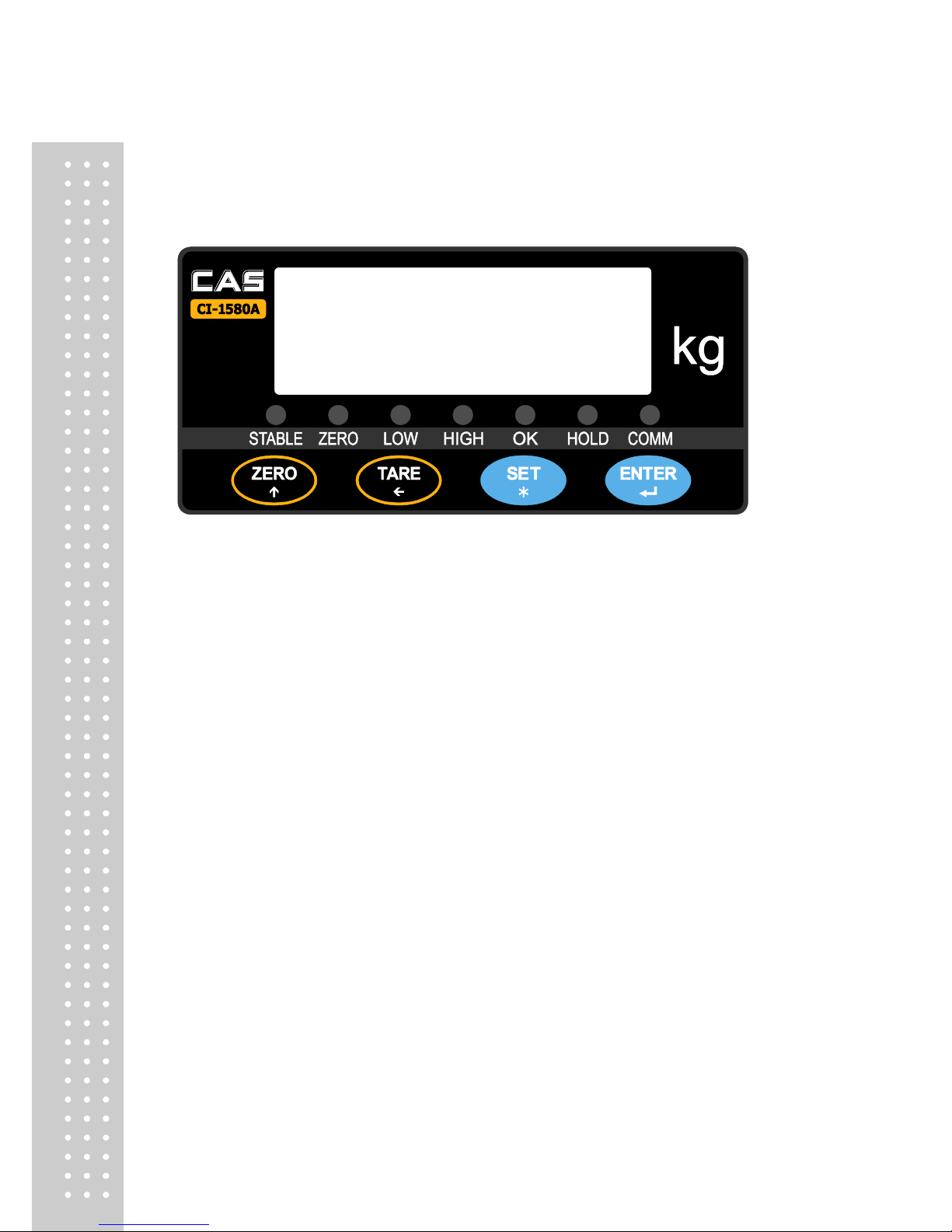

1.Introduction

■Introduction

This product as an indicator for weighing instruction and control is designed for the most

suitable use of any meters (packer, weigh separator, platform scale, various tensile and

compression test equipment)that can be applied in the widest way throughout industries.

This product ensures communications with external devices such as computers as it basically

installs an RS-232C port.

In addition, this product can be conveniently used for the weighing control as it basically has

three relay outputs necessary for control (applicableonly if there is relay out).

Please utilize all the functions in this product sufficiently as you can use the device properly

with good knowledge of this manual before you use this product.

■Features

·Measurestoscreenoffexternalnoises

·Built-inself-diagnosisandself-recoveryfunctionsfromfailure

·Externalresolution:1/20,000

·Electrostaticdatamemory

·2built-inexternalrelayinputterminals(zero,tare/tareremoval)

·Datamemory

·24VofinputpowersupplycanbeusedwiththeuseofDCpowersupplyregardlessof

polarity(500mA<TransType>ormoreisrecommended)

·FAC(FullAutoCalibration)methodforcalibration

·EquivalentinputmethodforCalibration

·BasicinstallationofRS-232C

·Option:RS-422/485

·Option:I/V-OUT