8

EN

8. USE WARNINGS

We recommend following the indications below in order to always work in safety conditions.

•All the operations must be carried out complying strictly with the safety rules of the

country where the device is to be installed.

•It is STRICTLY FORBIDDEN to smoke during the installation or adjustment operations of

the cutting unit.

•The Customer undertakes to comply with and make his staff observe all the rules and

regulations in force concerning safety, prevention of accidents and health in the work

place. Therefore, the Customer assumes the responsibility to strictly follow all the rules and

regulations in force, as well as the special provisions in force in sport and public installations

the Customer declares to know after receiving all the relative necessary information.

•The cutting unit works also without its safety protective device. This protective

device must NEVER be removed.

•Always check the resistance of the material to be cut and the kind of blade which is being used.

•The Customer shall equip his own personnel with all the individual safety protections for

the execution of the works, as well as with the ones which might be prescribed by the

Manufacturer due to specific danger conditions of the plant or of the area where the

personnel must work.

•Do not make any adjustment while the blade is working or while the electric plug is

connected.

•Always pay attention to the electric cable position to prevent it from being cut or damaged

by the blade.

•It is allowed to assemble cutting unit GRT12SX on machines O.E.M. on condition that their

original structure is not modified. Otherwise, the intervention must be certified by Rasor®.

Firstly make sure that the lines are able to feed the cutting unit correctly, in

compliance with the safety rules (for the features required see par. 5).

We suggest installing a magnetothermic safety device before the cutting unit and check

that the ground circuit is effective. Before working on the feeding cables pull the plug out.

Check that electric connections and protections correspond to the driving force and the

plate data values (voltage and current), required by the different electric circuits. By referring

to the CEI 11-27/1 standard all the works carried out by means of electric current must be

performed by a staff, who has been provided with all the devices required by the above-

mentioned standard. For the works carried out under voltage, it is necessary that the

employer certifies the suitability, against formative processes.

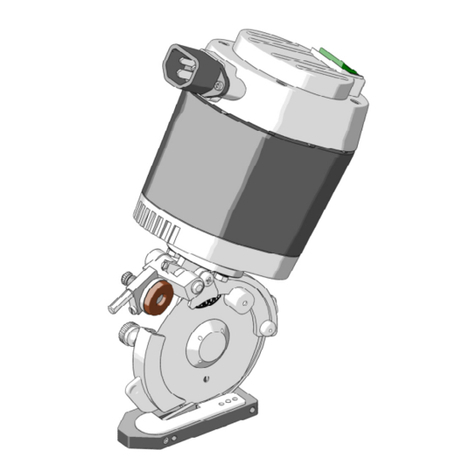

The cutting unit GRT12SX is supplied with electric cable

connected to the connector block located beside the motor

.

The user must connect the cutting unit to the mains (the

cable complies with the CEI 20-22 III Standard). Never change

the length of the cable supplied. If it is necessary, use a longer

cable and replace the one supplied. To connect the new cable

open the cover “A” by unscrewing the 4 cross-slotted screws

“B” (see picture 3). Connect the phase cable to the terminal

board. The minimum section of the connecting cables must be

determined by the operator in charge of the installation.We

recommend to use safety cables and socket IMQ approved.

Check the connection by enabling the cutting unit and verify

the rotation direction. The cutting unit is provided with earthing

WARNING

3

9. ELECTRIC CONNECTION

B

A

B