INTRODUCTION

Three years of extensive research have resulted in the most advanced triathlon bicycle ever created. Not only engineered to carry you to victory, your P5X has been

designed to support all of your service, nutrition and training requirements seamlessly. Although Cervélo strongly recommends that your bicycle be assembled by your

Cervélo retailer, please take time to familiarize yourself with this assembly guide, as this bicycle contains unique components, and requires an understanding of the

disassembly process for travel.

We thank you for making the choice to purchase your Cervélo P5X, and we hope that you enjoy the many hours you will spend with us.

This document has been prepared to guide you through the assembly of the unique features of the P5X, but is intended only as a supplement to the assembly

instructions offered by your component manufacturer. Please pass these instructions to the consumer along with the completed bicycle.

TABLE OF CONTENTS

Version 2 - 2017-06-07

Introduction ......................................................................................................1

Frame Features ................................................................................................2

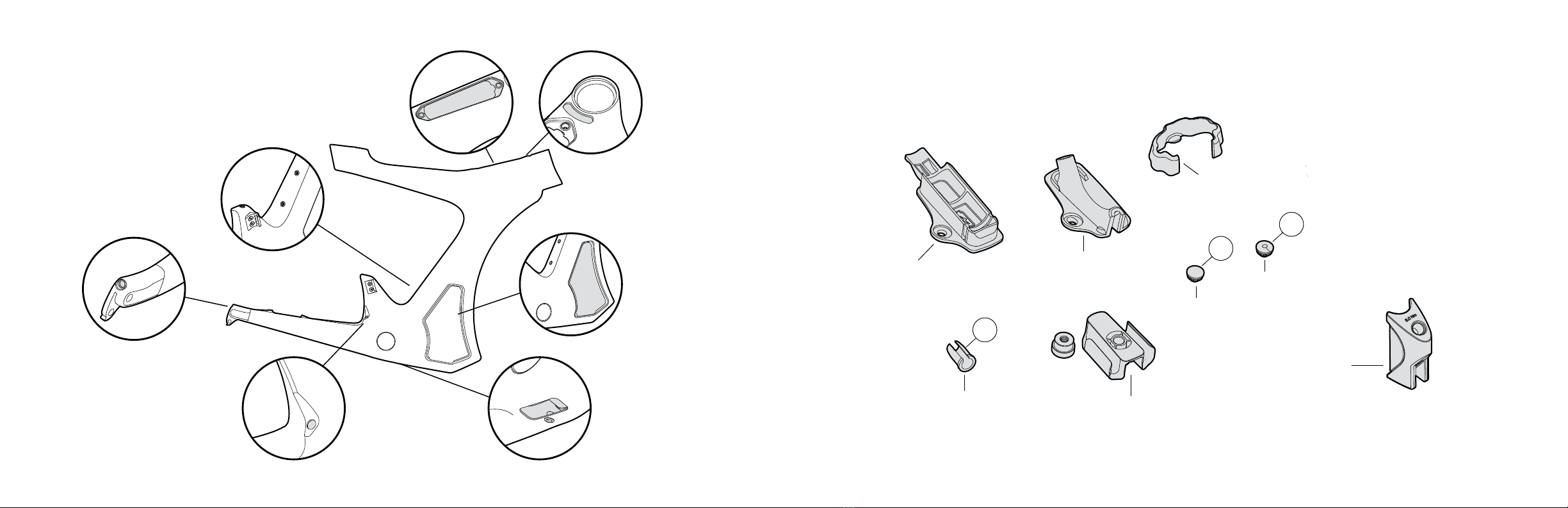

Small Parts .......................................................................................................3

Frame Storage Cases.......................................................................................4

Aerobar Components Overview .......................................................................5

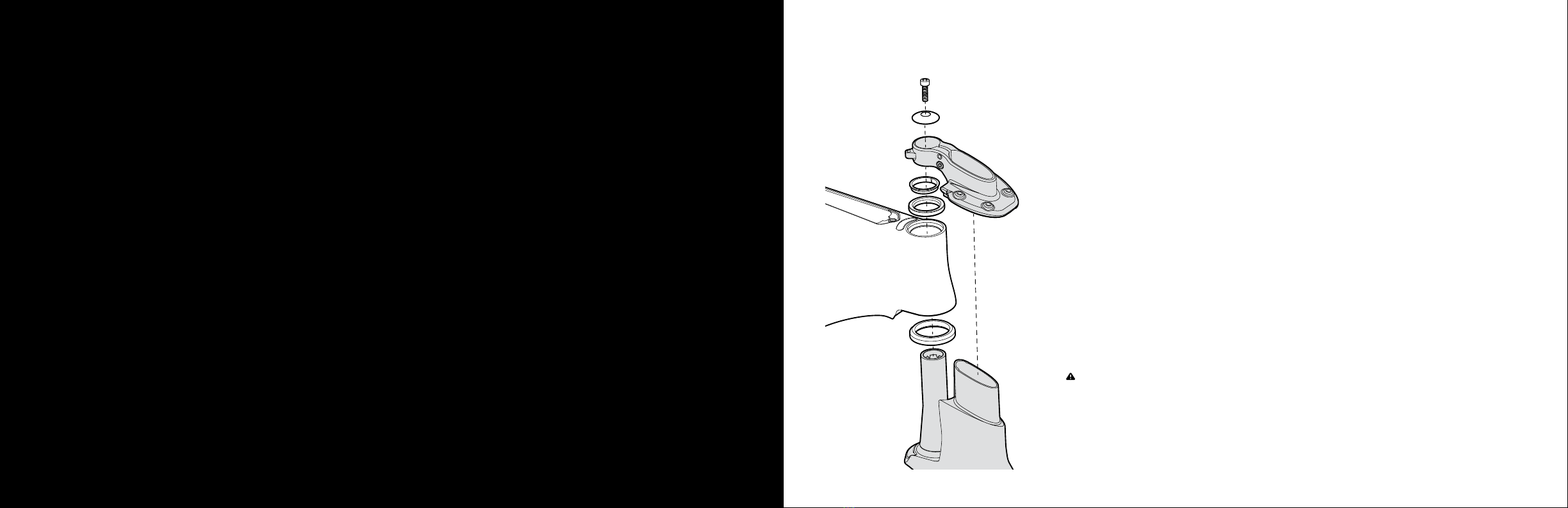

Fork Installation ................................................................................................7

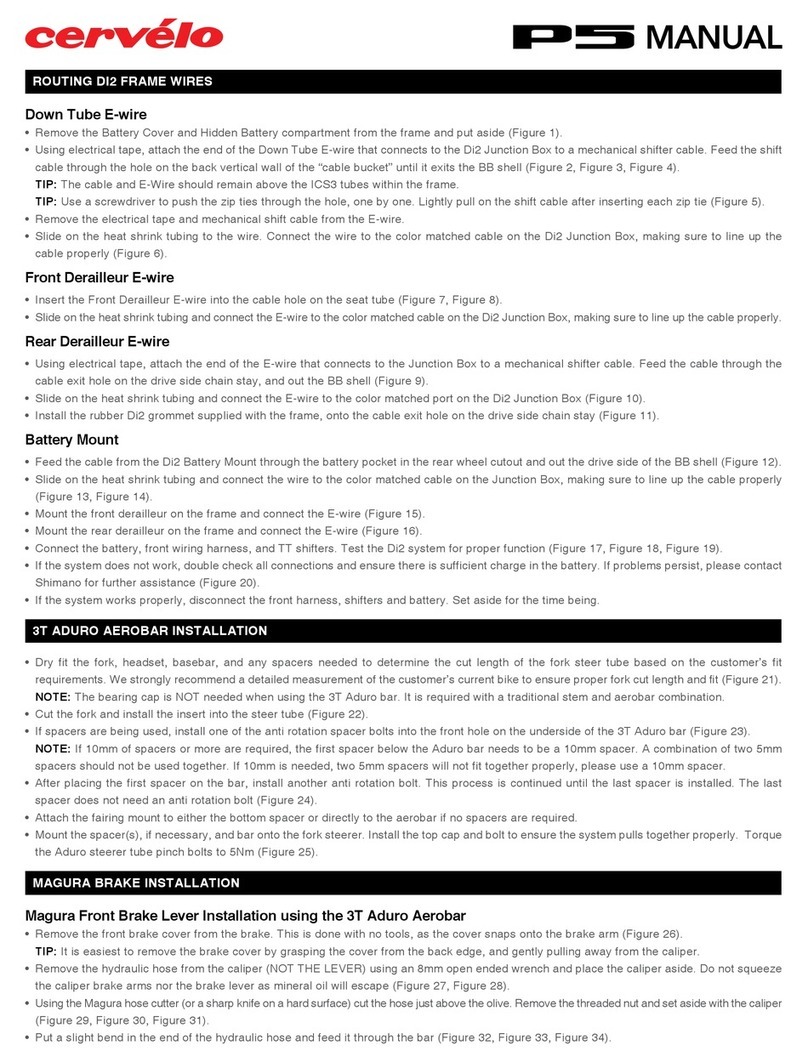

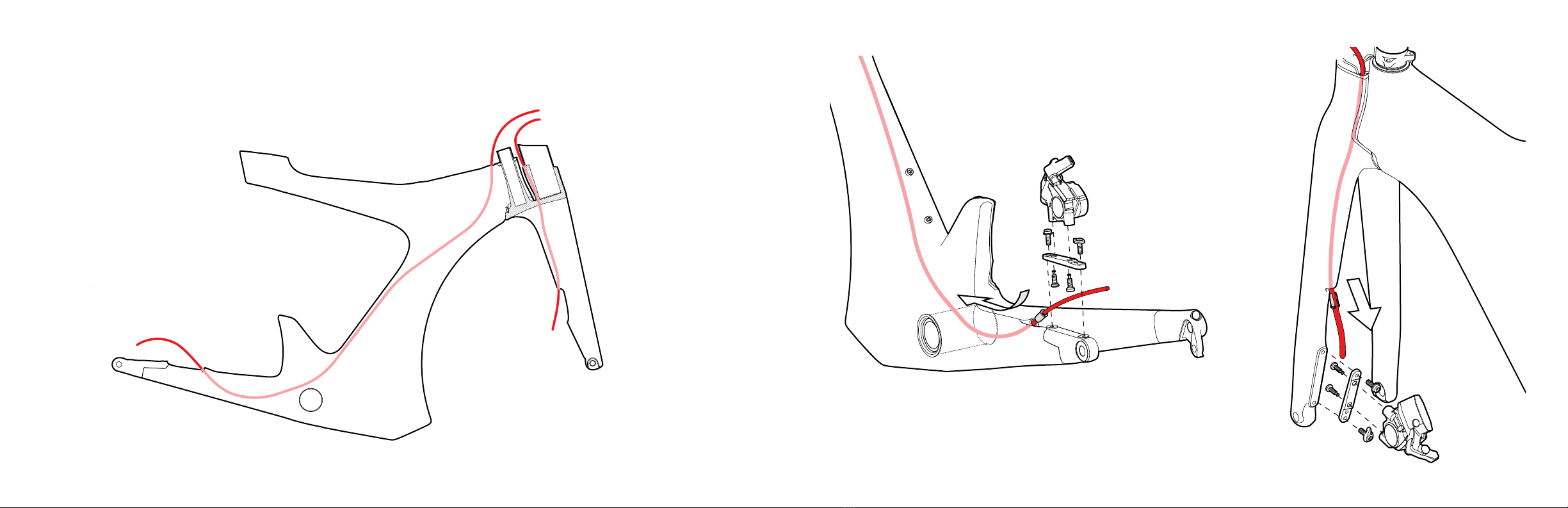

Brake Housing Installation................................................................................8

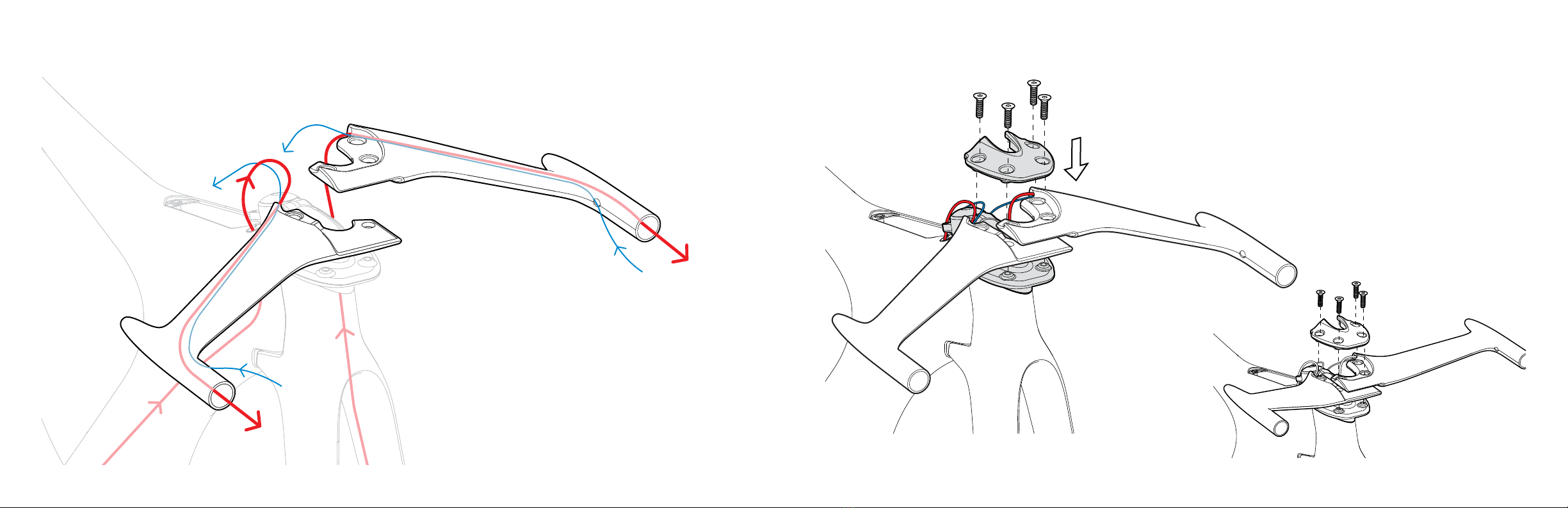

Basebar Wiring...............................................................................................10

Basebar Installation........................................................................................11

Riser Assembly...............................................................................................12

Extension and Pad Mount..............................................................................13

Arm Cup and Pad Installation ........................................................................14

Multi-Bend Extensions ...................................................................................15

Aerobar Assembly Installation........................................................................16

Electric Cable Routing....................................................................................17

Stem Cover Installation ..................................................................................19

Mechanical Cable Routing .............................................................................21

Smartpak Installation......................................................................................23

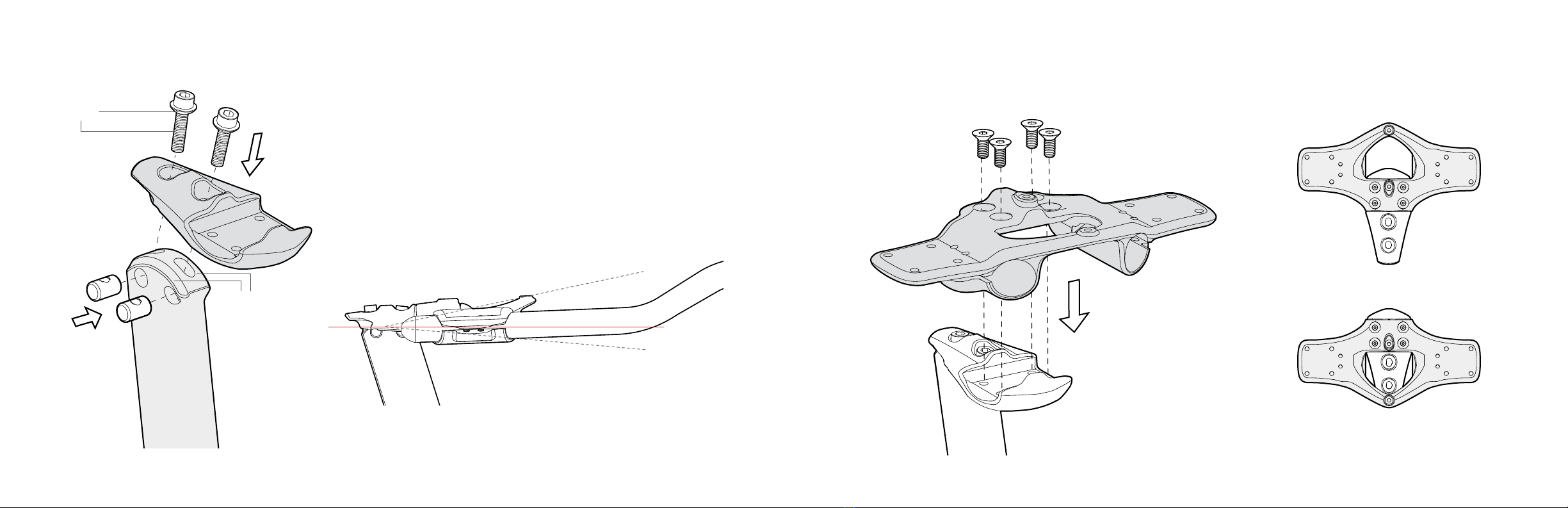

Speedcase Installation ...................................................................................25

Internal Routing Guide Installation .................................................................26

Stealthbox Installation....................................................................................27

Seat post Assembly ......................................................................................28

Cutting Seat Post ..........................................................................................30

Through-Axle Wheel Installation.....................................................................31

Appendix: P5X Fork Owner's Instructions .....................................................33