INTRODUCTION

Welcome to the Cervélo family, and congratulations on your decision to ride an R Series bicycle. The ultra-lightweight engineering of your Cervélo R Series

classic road bikewill help you attackany climbs,and enjoy speed and control on descents. The understated design allows performance to shine through with a

settled ride that lets you respond to the road.

As with the ownership of any high-performance vehicle, it is important to familiarize yourself with its features and service requirements.Please read this manual

before assembly or use.

This document has been prepared to guide you through the assembly of the unique features of the R Series, but is intended only as a supplement to the

assembly instructions offered by your component manufacturer.

Version 1 - 2017-02-07

TABLE OF CONTENTS

Introduction ......................................................................................................1

Frame Features ................................................................................................2

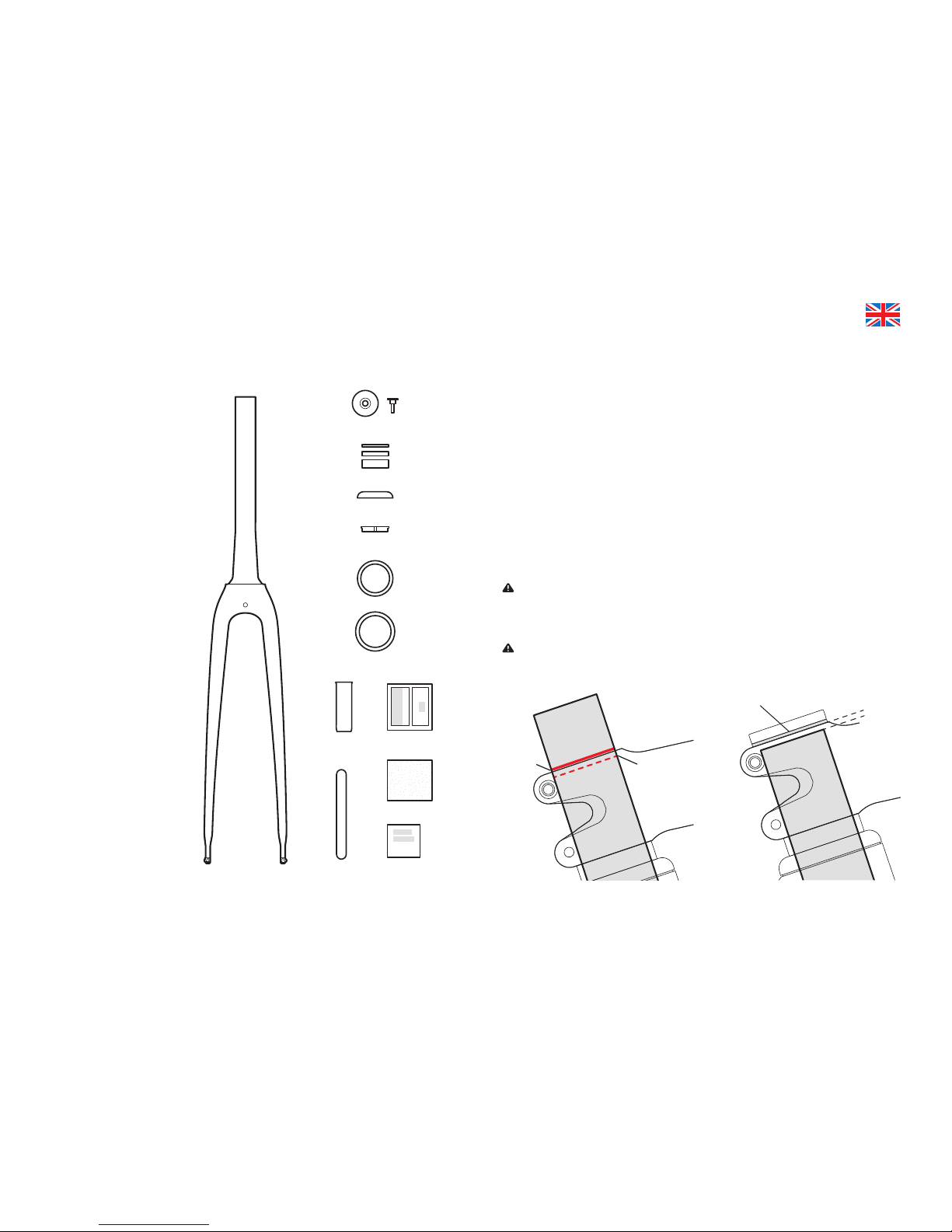

Fork Preparation...............................................................................................3

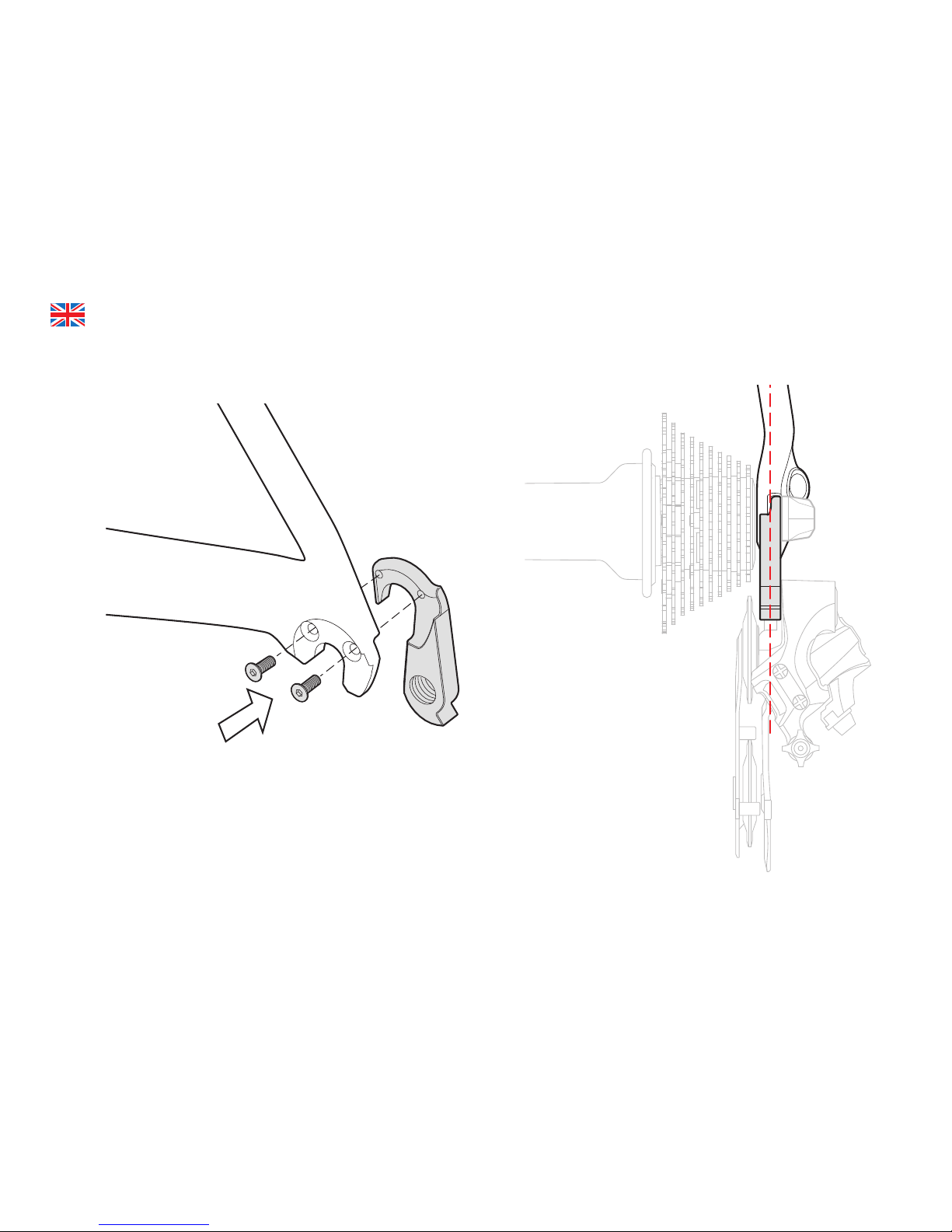

Small Parts .......................................................................................................5

Frame Preparation............................................................................................6

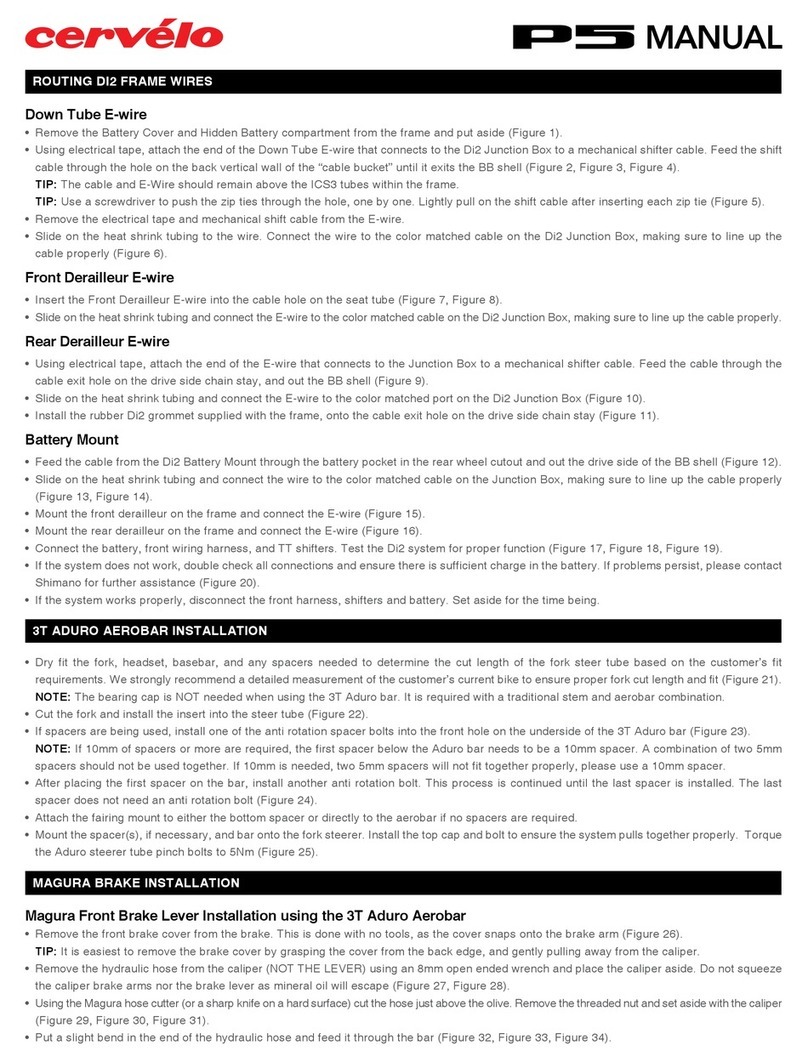

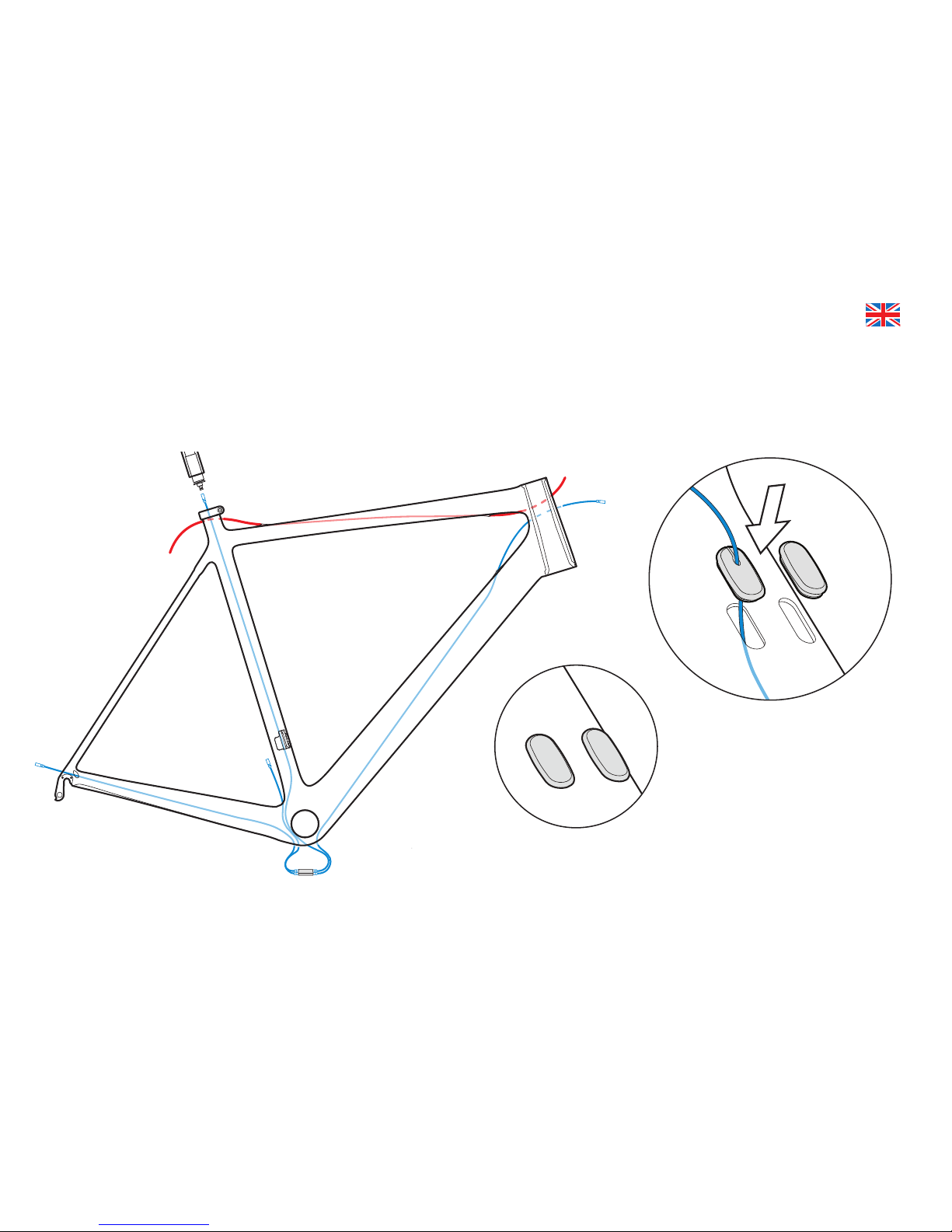

Mechanical Cable Routing ...............................................................................7

Electric Cable Routing......................................................................................9

Seatpost Assembly & Installation...................................................................11

Frame Protection Installation..........................................................................13

Tire Clearance ................................................................................................14