Chopin Mixolab 2 User manual

Other manuals for Mixolab 2

1

Table of contents

Other Chopin Laboratory Equipment manuals

Chopin

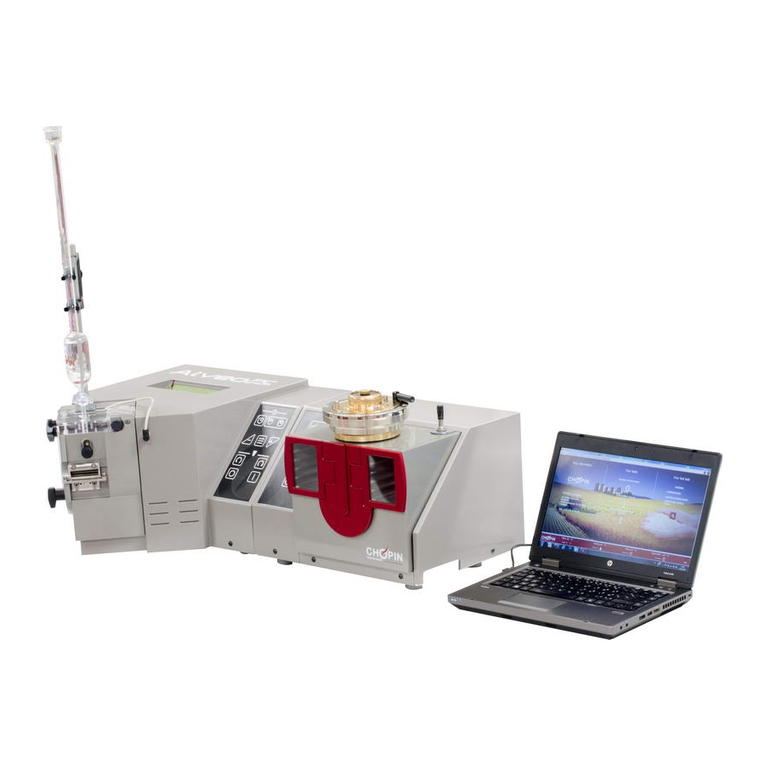

Chopin Alveo PC graph Instruction sheet

Chopin

Chopin Mixolab User manual

Chopin

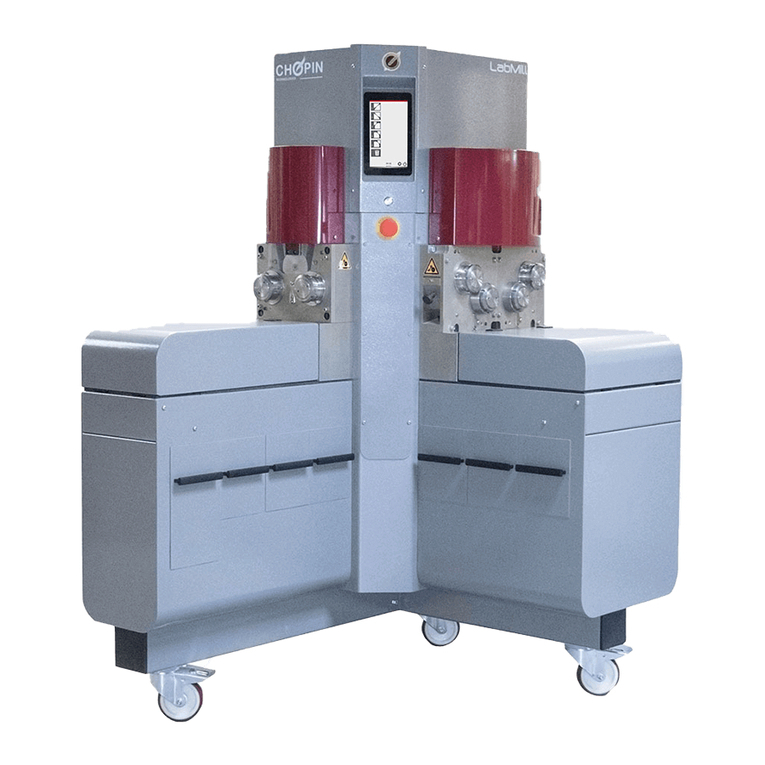

Chopin LabMill Instruction sheet

Chopin

Chopin Mixolab 2 Instruction sheet

Chopin

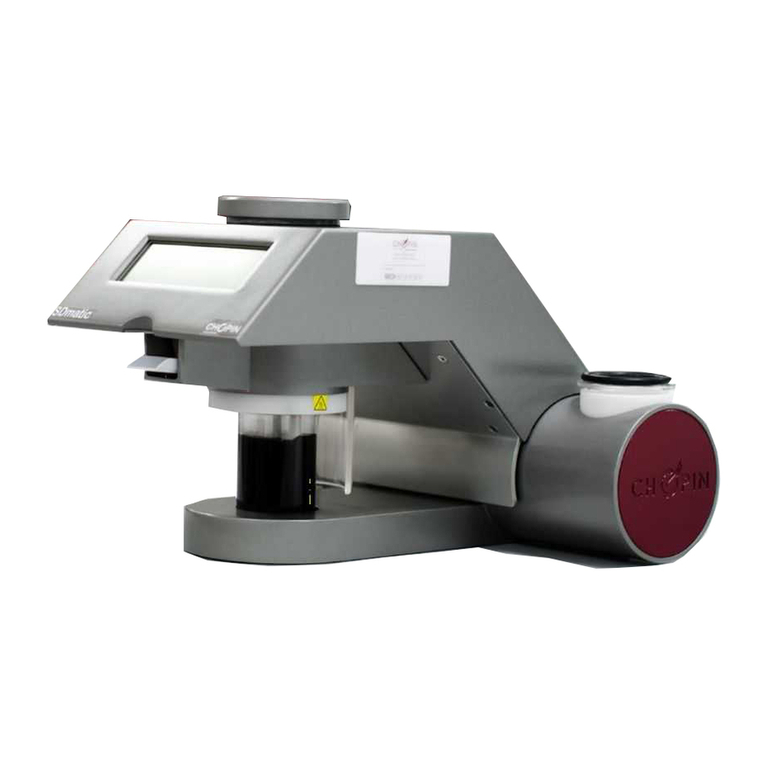

Chopin SDmatic Instruction sheet

Chopin

Chopin RHEO F4 Instruction sheet

Chopin

Chopin AlveoLabgraph Instruction sheet

Chopin

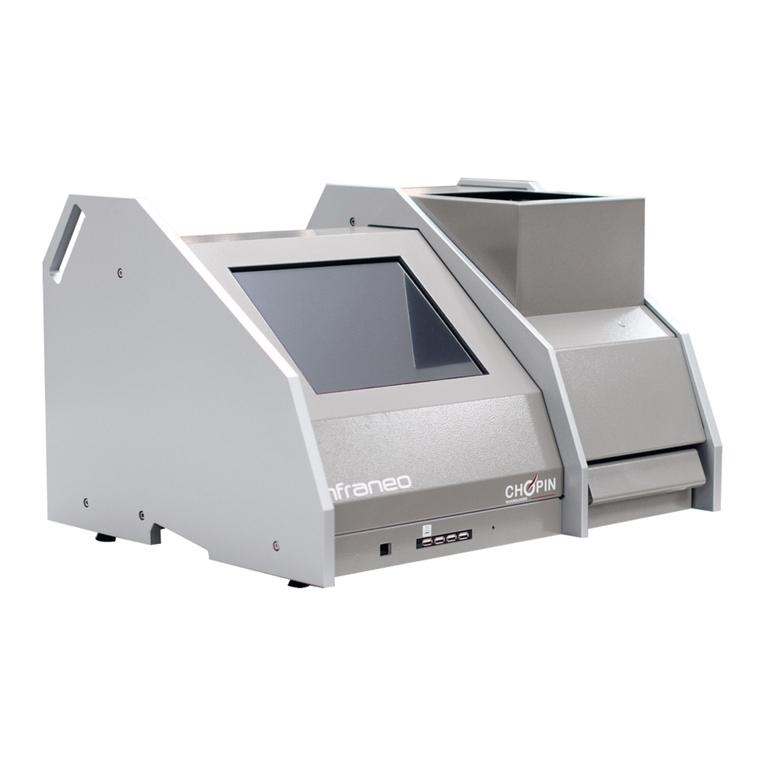

Chopin Infraneo Instruction sheet

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific RC 12BP Plus instruction manual

Hermle

Hermle Z 206 A instruction manual

Knauer

Knauer BlueShadow V6 Service manual

Thermo Scientific

Thermo Scientific Evolution 300 user guide

Datalogic

Datalogic Matrix 220 Product reference guide

Lacor

Lacor 39012 Instructions for use and maintenance

Kyoto Kagaku

Kyoto Kagaku MRI QA Phantom PH-31 instruction manual

Oxford Instruments

Oxford Instruments ANDOR iVac Series Hardware guide

Sarstedt

Sarstedt SC 2700 instruction manual

Grant

Grant GLS Aqua Plus operating manual

Sartorius

Sartorius talent operating instructions

Somark

Somark LABSTAMP quick start guide