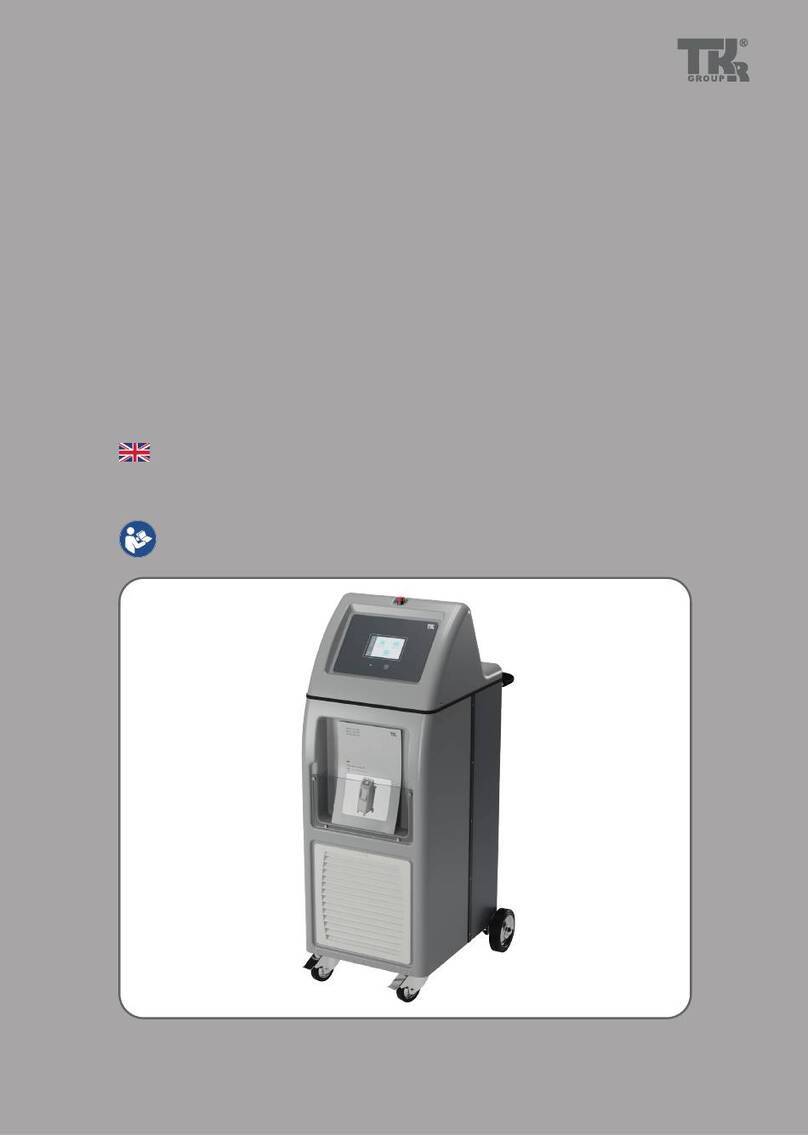

Circontrol Raption 150 Compact CCS User manual

Service Manual

Raption 150 Compact

Raption 150 Compact

Service Manual

COPYRIGHT INFORMATION

This document is copyrighted, 2022 by Circontrol, S.A. All rights are reserved.

Circontrol, S.A. reserves the right to make improvements to the products

described in this manual at any time without notice.

No part of this manual can be reproduced, copied, translated or transmitted in

any form or by any means without the prior written permission of the original

manufacturer. Information provided in this manual is intended to be accurate

and reliable. However, the original manufacturer assumes no responsibility for

its use, or for any infringements upon the rights of third parties that may result

from its use.

All other product names or trademarks are properties of their respective owners.

0101

How to service

your Raption

1 — So, Hello! 01

A - Important safety instructions 02

B - Work in a safe environment 03

C - Personal Protective Equipment (PPE) 05

D - Recommended tools 06

2 — Features 07

A - Overview 07

B - Dimensions 08

C - Components overview 09

3 — Control devices 21

A - PC Screen (HMI) 21

B - Mode 4 board 24

C - CCS board 27

4 — Protection devices 29

A - MCCB/Disconnector 30

B - RCD 31

C - MCBs 32

D - RCBOs 33

E - Transient surge protector 34

F - Isolation protection device 35

02

Raption 150 Compact Service Manual

5 — Other components 39

A - Heater system 40

B - Ventilation system 42

C - RFID reader 43

D - DC meter 44

E - Uninterruptible power supply (UPS) 45

F - Power supplies 46

G - Contactors 47

H - Teltonika RUT 240 48

6 — Other optional components 49

A - RFID Reader - Legic 49

B - Omnidirectional tilt switch 51

7 — Troubleshooting & Errors 53

A - Troubleshooting introduction 53

B - Log files 57

C - Decoding the error 59

D - Error code in remote 69

E - Communications errors 71

F - OCPP errors 72

G - Power modules errors 76

03

8 — Maintenance 77

A - CCS holder adjustment 81

9 — Annexes 83

10 — Technical data 85

11 — Need help? 87

Raption 150 Compact Service Manual

01

This manual provides service and maintenance information for Circontrol Charge

Point, which has been designed and tested to allow electric vehicle charging, specified

at IEC 61851 standards.

This document has different sections describing electrical components inside the

Charge Point and a step-by-step maintenance procedure.

It is mandatory to follow the basic security information supplied in this manual to

ensure safe and proper installation.

Failure to follow safety instructions may involve personal injury, equipment damage

and danger of death. CIRCONTROL is not responsible for events arising from such

breach.

ELECTRIC RISK

- This symbol indicates a potentially hazardous situation which, if not

avoided may result in a risk of fire, serious injury or death.

- The Charge Point must be disconnected from any power source before

performing any maintenance, repair or electrical manipulation inside.

ATTENTION!

- Follow the instructions preceded by this symbol, if not respect them or

perform them correctly, may result in minor or moderate injury to the

user, damage to equipment, damage to facilities or other property.

- Handling the equipment can cause injuries as result of the dimension

and weight.

1

Read carefully all the instructions before doing any

maintenance work inside the Charge Point.

THE FOLLOWING SYMBOLS ARE USED FOR IMPORTANT

SAFETY INFORMATION IN THIS DOCUMENT

02

So, hello!

• Read all the instructions before using

and configuring the Charge Point.

• Do not use the Charge Point for anything

other than electric vehicle charging

modes are expected in IEC 61851.

• Do not modify the Charge Point. If

modified, CIRCONTROL will reject all

responsibility and the warranty will be

void.

• Comply strictly with electrical safety

regulations according to your country.

• Do not normally make repairs or

manipulations with the unit energised.

• Only trained and qualified personnel

should have access to the electrical

parts inside the Charge Point.

• Check the installation annually by

qualified technician.

• Remove from service any item that

has a fault that could be dangerous for

users (broken connectors, caps that

don’t close...).

• UseonlyCircontrolsuppliedspareparts.

• Do not use this product if the enclosure

or the EV connector is broken, cracked,

open, or shows any other indication of

damage.

• Adaptors or conversion adapters and

cord extensions set are NOT allowed to

be used.

• Avoid contact with energized electrical

circuits.

• Disconnect the power source before

servicing or repairing electrical

equipment.

• Use only tools and equipment with non-

conducting handles when working on

electrical devices.

• Never use metallic pencils or rulers, or

wear rings or metal watchbands when

working with electrical equipment.

• Enclose all electric contacts and

conductors so that no one can

accidentally come into contact.

• When it is necessary to handle

equipment that is plugged in, be sure

hands are dry and, when possible,

wear nonconductive gloves, protective

clothes and shoes with insulated soles.

• Never handle electrical equipment

when hands, feet, or body are wet or

perspiring, or when standing on a wet

floor.

AImportant safety instructions

03

Raption 150 Compact Service Manual

It is recommended to be very cautious and work safely to control all potential electrical

hazards.

So, the safety rules shown below classify the work to be done depeding on the present

electrical risk, that helps to control risks of injury or death from workplace hazards.

ELECTRICAL RISK

SITUATION EQUIPMENT SITUATION DESCRIPTION

Work without voltage Disconnected -

Live working Equipment connected

without load

Equipment connected

under load (up to 1000 V)

Acting on live elements or

at a distance of less than

70 cm from live elements.

Below the established

safety distance.

Proximity Equipment connected

without load

Equipment connected

under load (up to 1000 V)

Distance greater than 70

cm to live elements.

Steps to be followed during the development of the tests

- Work without voltage unless it is strictly necessary.

- If it is necessary to access the equipment while it is connected (with or without load),

measures should be taken to ensure that all conductive elements are properly protected

by appropriate polycarbonates or insulating enclosures.

- If it cannot be guaranteed that ALL live parts of the equipment are protected by

polycarbonates, live working shall be carried out.

- Guarantee safety distance between risk elements (cabinets, dispensers, wallboxes...)

and the work table (computers, readers, testers).

- Wide and safe access from the door of the box to the work areas. There should always

be a safe escape route.

- Minimise the presence of cables in working areas and put cable protectors.

- Remove all the elements that are not essential for carrying out the tests.

- Have the necessary safety signs to be used as required.

BWork in a safe environment

04

Work without voltage

Live working

It is essential to carry out the following steps in order to successfully perform the

required tests:

1. Disconnect the installation from its source.

2. Check for absence of voltage.

3. Test preparation by placing all the necessary measuring instruments and closing

the doors totally or partially (as much as possible).

4. Energise the installation.

5. Performance of tests making the necessary readings and checks on the tests

STAYING OUTSIDE THE 70 CM PROXIMITY DISTANCE.

6. Lock the installation so that no one authorised has access to the inside part.

Tests MUST be stopped in case of rain, wind or

thunderstorm.

The tests must only be carried out when it is not possible to apply the previous protocol,

only when it is essential to make connections/disconnections with the equipment

connected.

Beforehand, an analysis of the entire installation in which work have to be done must

be carried out in order to protect all live parts with polycarbonates.

It is important that the protective polycarbonate must always be installed after the

connection has been made.

Insulating tools must always be used.

05

Raption 150 Compact Service Manual

It is mandatory that all technical employees wear the following Personal Protective

Equipment (PPE). It must be used for any electrical task such as the described above.

INSULATING SAFETY SHOES

Class 0: 1000V

Dielectric boots recommended

INSULATING GLOVES

Class 0: 1000V AC/1500V DC

HELMET AND FACE SHIELD

Electrical insulation helmet EN397,

EN50365, ANSI Z89.1 20kV

ANTISTATIC MAT

Class 0: Low voltage 1000V

High voltage 36kV

CPersonal Protective Equipment (PPE)

06

DRecommended tools

LAPTOP

MULTIMETER

MULTI-TOOL

USB-RS485

ETHERNET CABLE

SWITCH

ALLEN TOOLS

TORX-TOOLS

SCREW DRIVERS

RATCHET WRENCH

Raption 150 Compact Service Manual

07

2

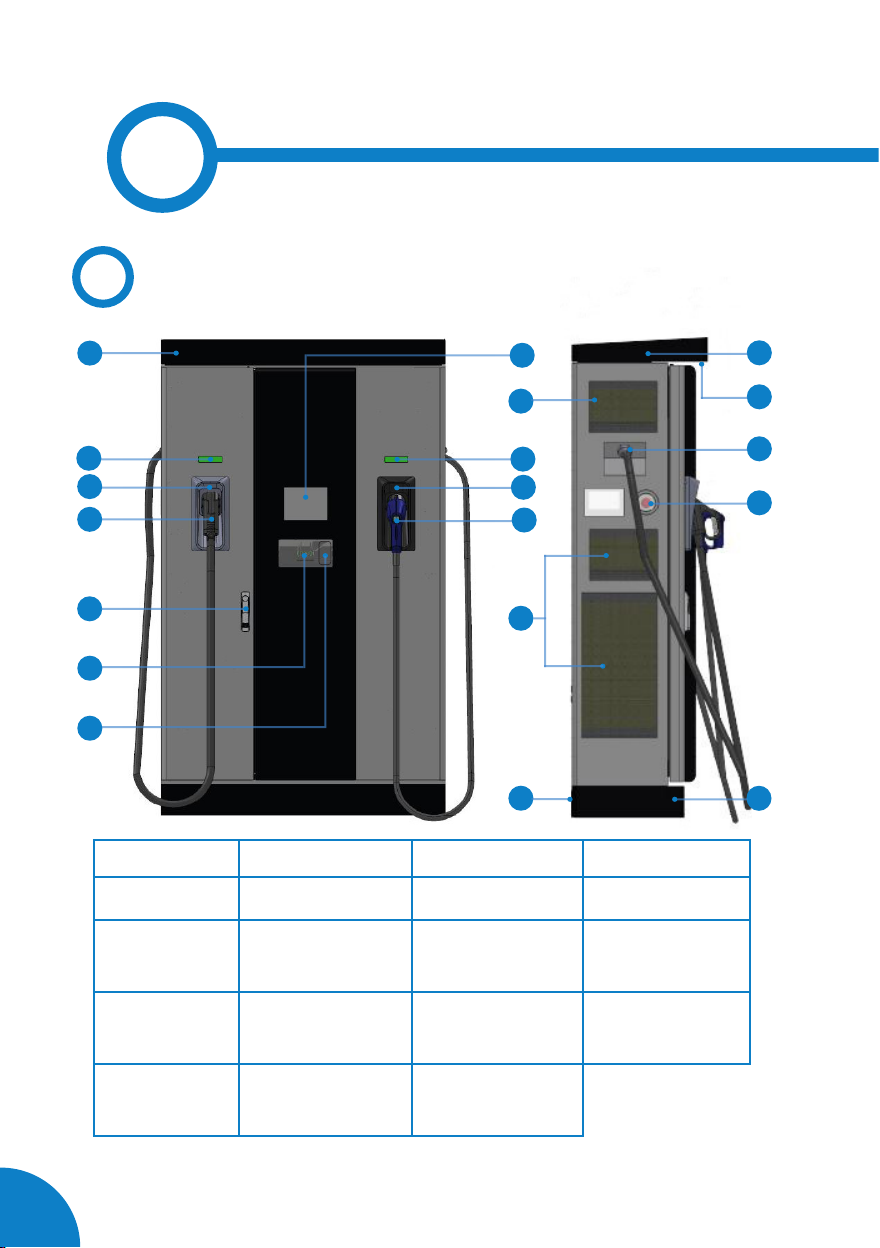

AOverview

Note: Depending on the model, the components can vary.

1

3

2

5

6

4

10

12

8

11

13

14

9

19

17

16

15

7

18

1- Cover 2- CCS light beacon 3- CCS holder 4- CCS connector

5- Handle 6- RFID reader 7- Card payment 8- Touch screen

9- Air inlet Unit 10- CHAdeMO light

beacon

11- CHAdeMO holder 12- CHAdeMO

connector

13- Power M. air

inlet

14- Decorative rear

panel

15- 4G Antenna 16- Courtesy light

17- Exit cable 18- Emergency button 19- Decorative front

panel

08

Features

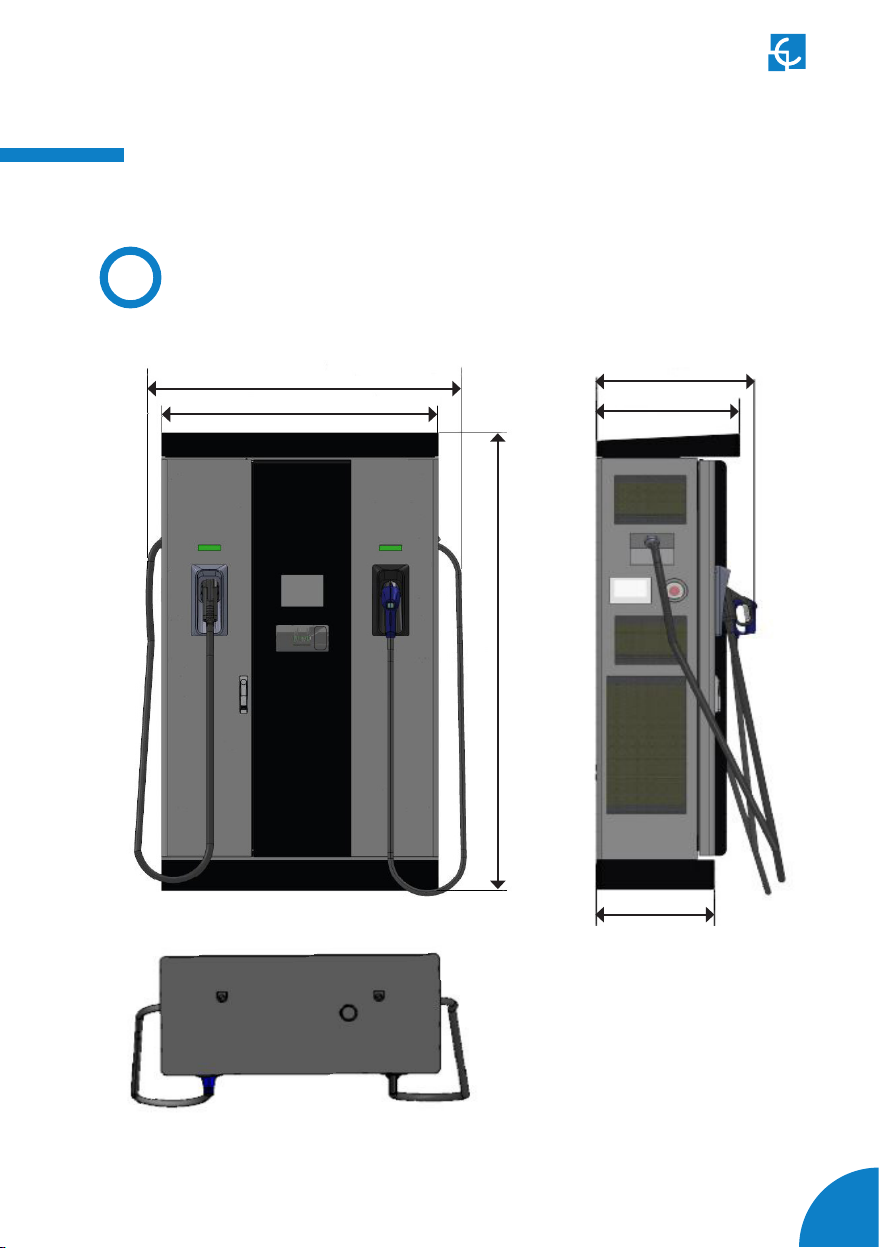

BDimensions

1290

1140

1910

550

610

460

Measures in mm

Raption 150 Compact Service Manual

09

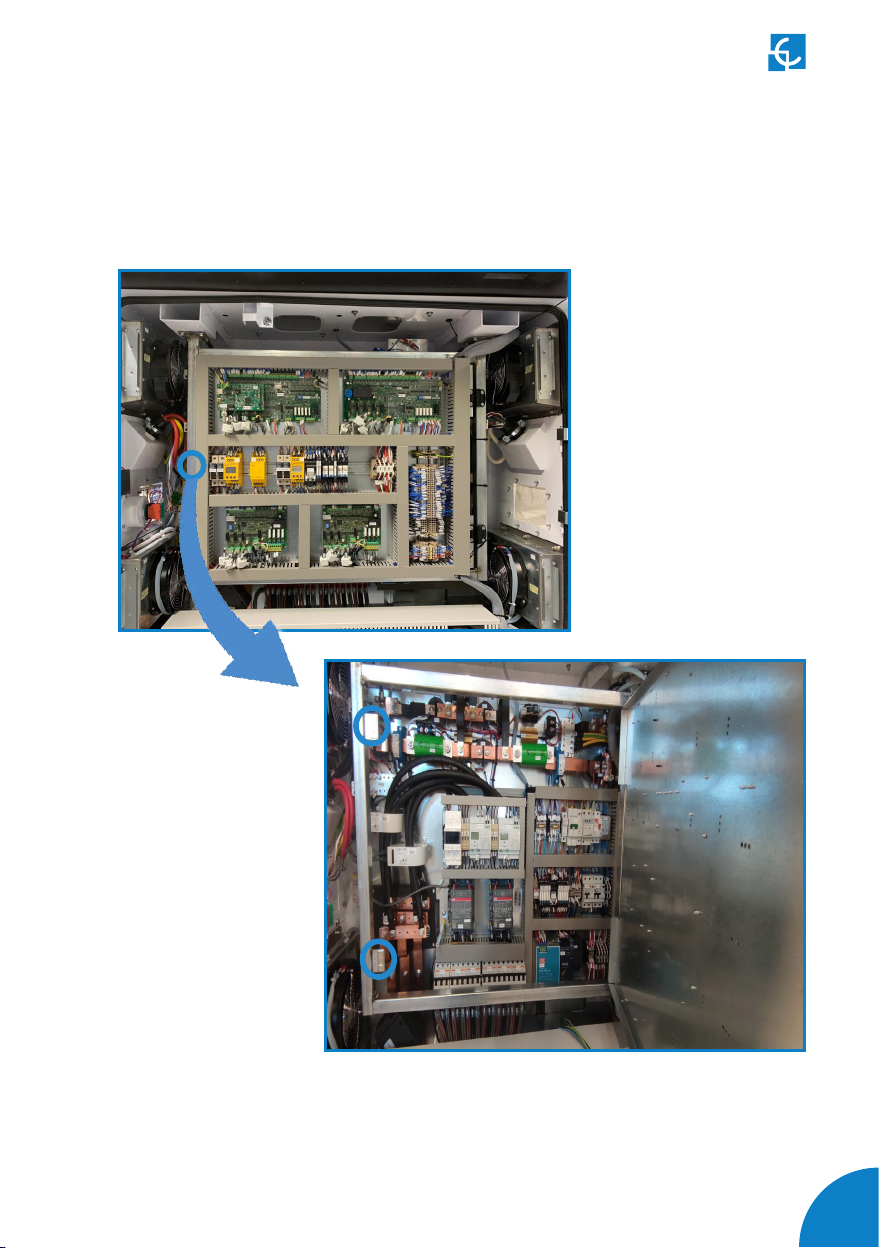

CComponents Overview

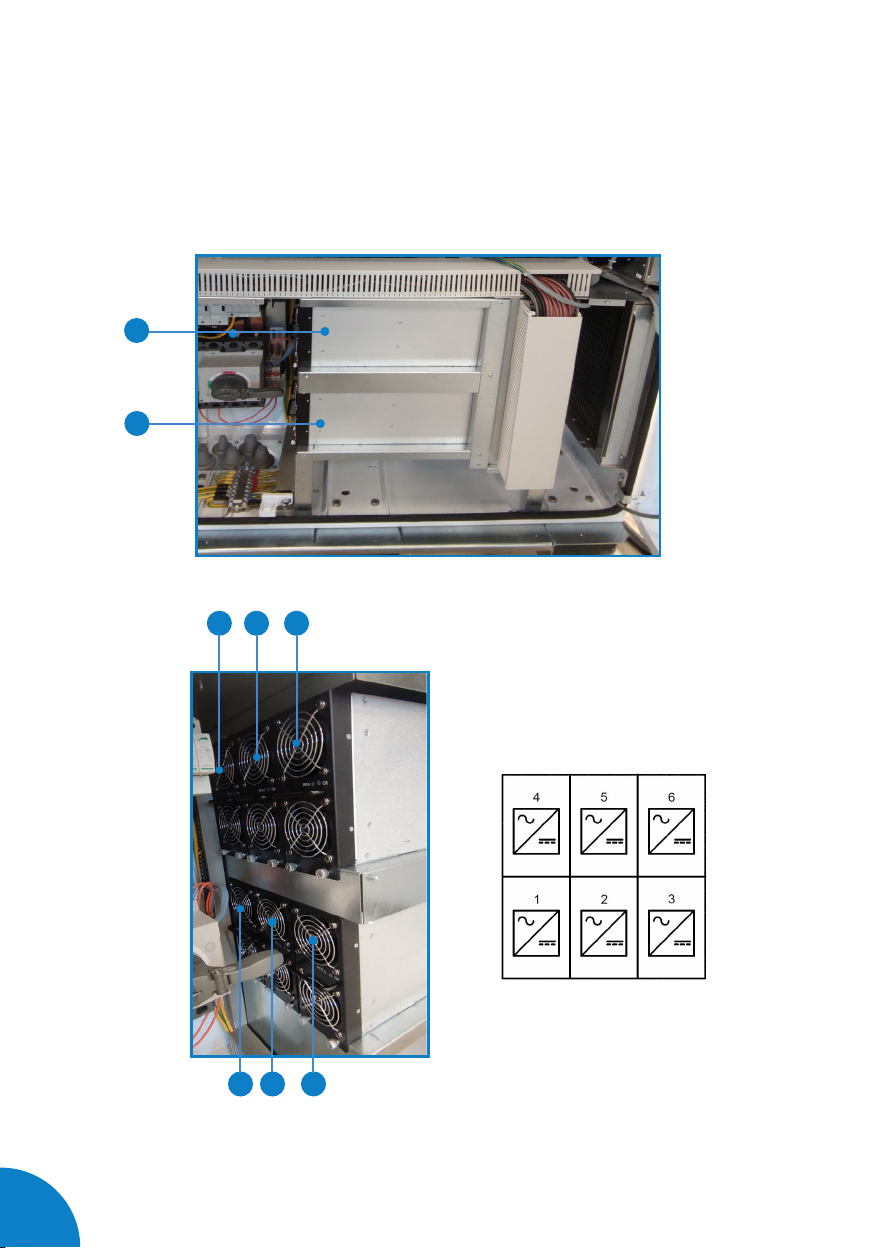

Inside the Charge Point it is possible to differentiate four main parts. In the upper part

there are the electronic boards, the electrical protections and the electrical actuators.

In the medium low part there are located the power modules. Next to them on the left,

there is the power input supply section.

The last important part in the Charge Point are both doors.

Electronic boards,

etc

Power modules

Power supply section

Right door

Left door

10

1 — ELECTRONIC BOARDS, ELECTRICAL PROTECTIONS,

ELECTRICAL ACTUATORS - DOOR OPENING -

Step 2

Pull it back manually until you

have access to the rear layer.

To return to the initial position,

simply close by making the

movement in the opposite

direction.

There are located two magnets

between the layers in order the

door could not be accidentally

opened.

Step 1

Locate the tab in the

mid left of this part and

pull it back.

11

Raption 150 Compact Service Manual

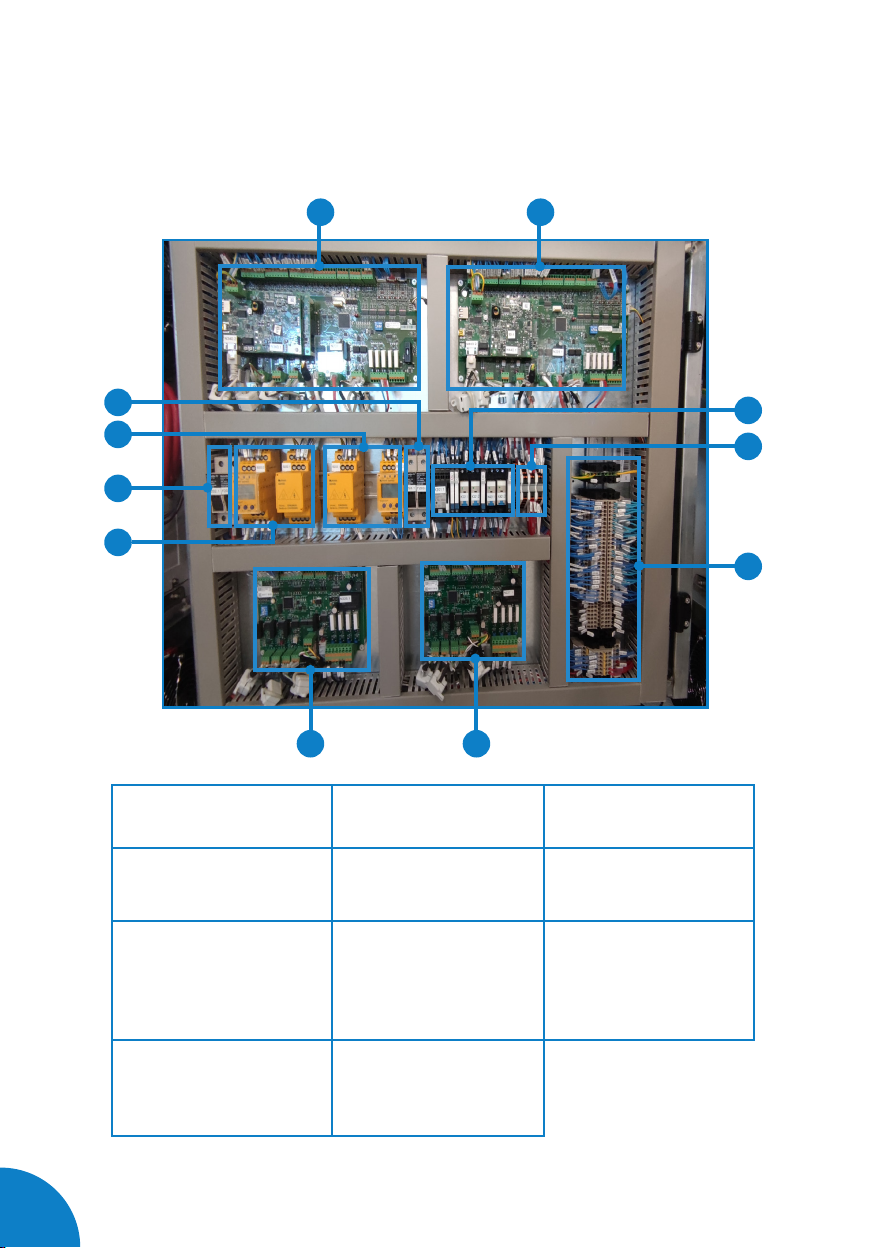

1A — ELECTRONIC BOARDS, ELECTRICAL PROTECTIONS, ELECTRICAL

ACTUATORS - OUTER LAYER COMPONENT OVERVIEW -

7

5

7

11

7

7

7

67

8

2

1

3

4

7

9

1- CHA fuse terminal 6A

(F203.1 /F203.2)

2- Isolation protection

device (B203.1 / B203.2)

3- CCS fuse terminal 6A

(F202.1 / F202.2)

4- Isolation protection

device (B202.1 / B202.2)

5- CCS Mode 4 Control

Board (N226.1)

6- CCS Control board

(N225.1)

7- CHA Mode 4 Control

Board (N228.1)

8- CHA Control board

(N227.1)

9- Relays 24V

(K201.1 / K202.1 / K203.1 /

K321.1 / K321.2 / K350.1 /

K421.1 / K421.2 / K450.1)

10- Distribution supply 12V

(E155.1 / E155.2 / E155.3 /

E155.4)

11- Connection terminal

block

7

10

7

Note: Depending on the model, the components can vary.

12

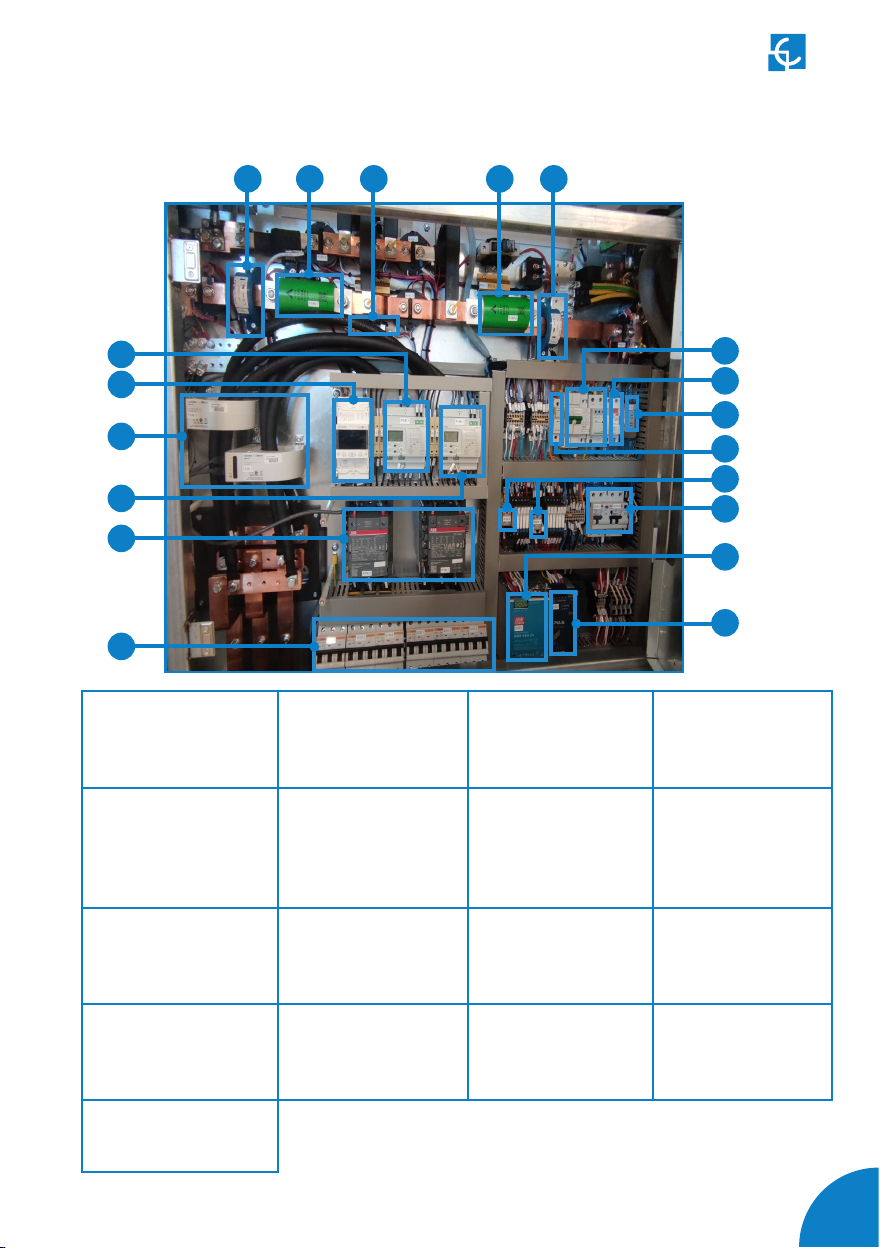

1B — ELECTRONIC BOARDS, ELECTRICAL PROTECTIONS, ELECTRICAL

ACTUATORS - INNER LAYER COMPONENT OVERVIEW -

7

8

3

5

2

1

4

7

10

7

11

7

12

7

15

7

14

1- Three-phase MID

energy meter (P105.1)

2- RCD protection class

B (QD103.1)

3- RCD protection

class B (T105.1 /

T106.1)

4- Three-phase MID

energy meter (P106.1)

5- Contactor for

power modules

(K105.1 / K106.1)

6- Miniature circuit

breaker 3P 50A class C

(Q120.1/Q121.1/Q121.2/

Q122.1/Q123.1/Q123.2)

7- Current transformer

(T140.1 / T140.2)

8- CCS fuse 500A/

CHA fuse 250A (F140.1

/ F140.2)

9- Precharge fuse 2A

(F301.1)

10- Miniature circuit

breaker 2P 20A class C

(Q101.3)

11- RCD 1P+N 25A

30mA class AC

(Q101.4)

12- EMI filter (L101.2)

13- Permanent

overvoltage fuse 25A

(F101.1)

14- Power relay

(K103.2 / K204.1)

15- RCBO 1P 10A class

A (Q109.1 / Q110.2)

16- 24Vdc Power

Supply (G150.1)

17- UPS (G150.3)

7

77

7

7

87

9

Note: Depending on the model, the components can vary.

6

7

16

7

17

7

13

Raption 150 Compact Service Manual

13

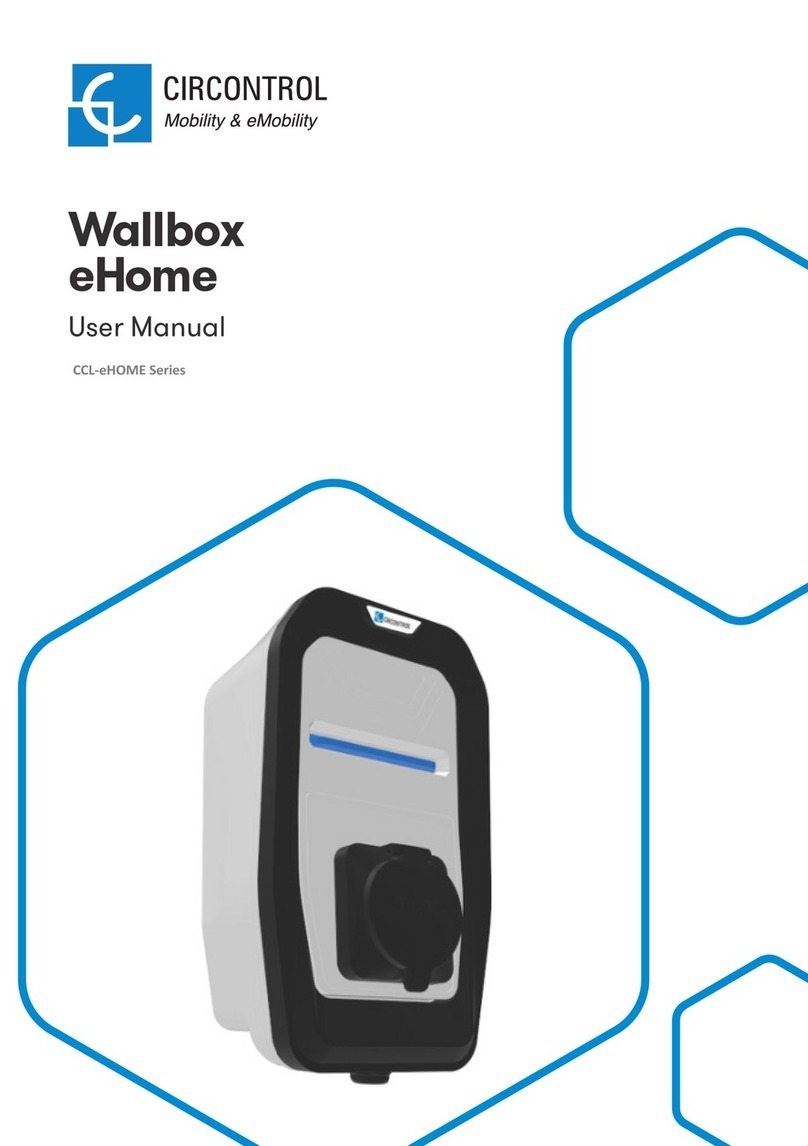

2 — POWER MODULES

7

8

3

4 5

2

Are assembled power modules of 25kW in Raption 51, Raption 52 and Raption 100.

6

1

Power modules layout

(view from left side):

This manual suits for next models

1

Table of contents

Other Circontrol Batteries Charger manuals

Circontrol

Circontrol eVolve T User manual

Circontrol

Circontrol Wallbox eHome CCL-eHOME Series User manual

Circontrol

Circontrol Rapid Series Instruction Manual

Circontrol

Circontrol Wallbox eHome Series User manual

Circontrol

Circontrol eVolve Smart Series User manual

Circontrol

Circontrol CCL-CP1E User manual

Circontrol

Circontrol Post eVolve Series User manual

Circontrol

Circontrol CCL-WBM User guide

Circontrol

Circontrol Raption 150 Series User manual

Circontrol

Circontrol CCS CHA T2C63 User manual