Cirs 715 User manual

Pediatric Anthropomorphic

Training Phantoms

USER GUIDE

Model 715

900 Asbury Ave • Norfolk, Virginia 23513 • USA • Tel: 757-855-2765 • WWW.CIRSINC.COM

OBJECTIVE

An ideal addition to any imaging department or Radiologic Technology training

program, the CIRS Model 715 Series can assist in the monitoring, training and

improvement of parameters and protocols common to most pediatric imaging

procedures.

SPoRTTM is designed to aid teaching and improvement of patient positioning, col-

limation and anatomical comprehension and it’s wide range of features facilitate

effective instruction of safe, high quality, pediatric imaging.

SPoRTTM can be used in film radiography, CR, DR and Computed Tomography.

DESCRIPTION OF THE PHANTOM

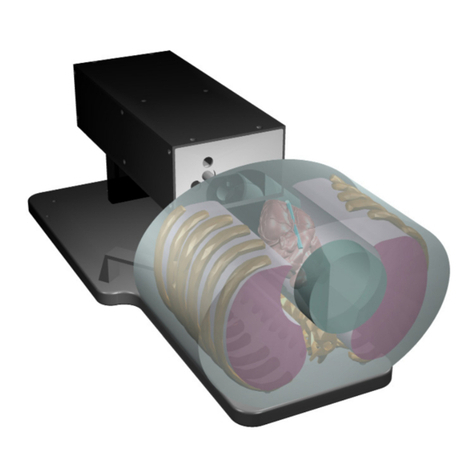

The phantom represents a typical 5-year old in both size and structure, making it

portable and easy to position. The full body with head, arms and legs measures

110 cm (43 inches) tall and weighs 20 kg (44 lb).

Right extremeties are available in extended or flexed configurations. Left arm and

leg are available with or without embedded fractures. The fracture versions contain

the most common pediatric fracture types, including buckle fracture to tibia and

common fracture to fibula; fracture to first metatarsal; radius fracture with open

reduction and hardware and a common fracture to second intermediate phalange.

Components are made from propriety urethane and epoxy materials that mimic

X-ray attenuation properties of human tissues for both diagnostic and therapy

energy ranges (50keV-15MeV). The materials are durable, impact resistant and suit-

able for continuous handling.

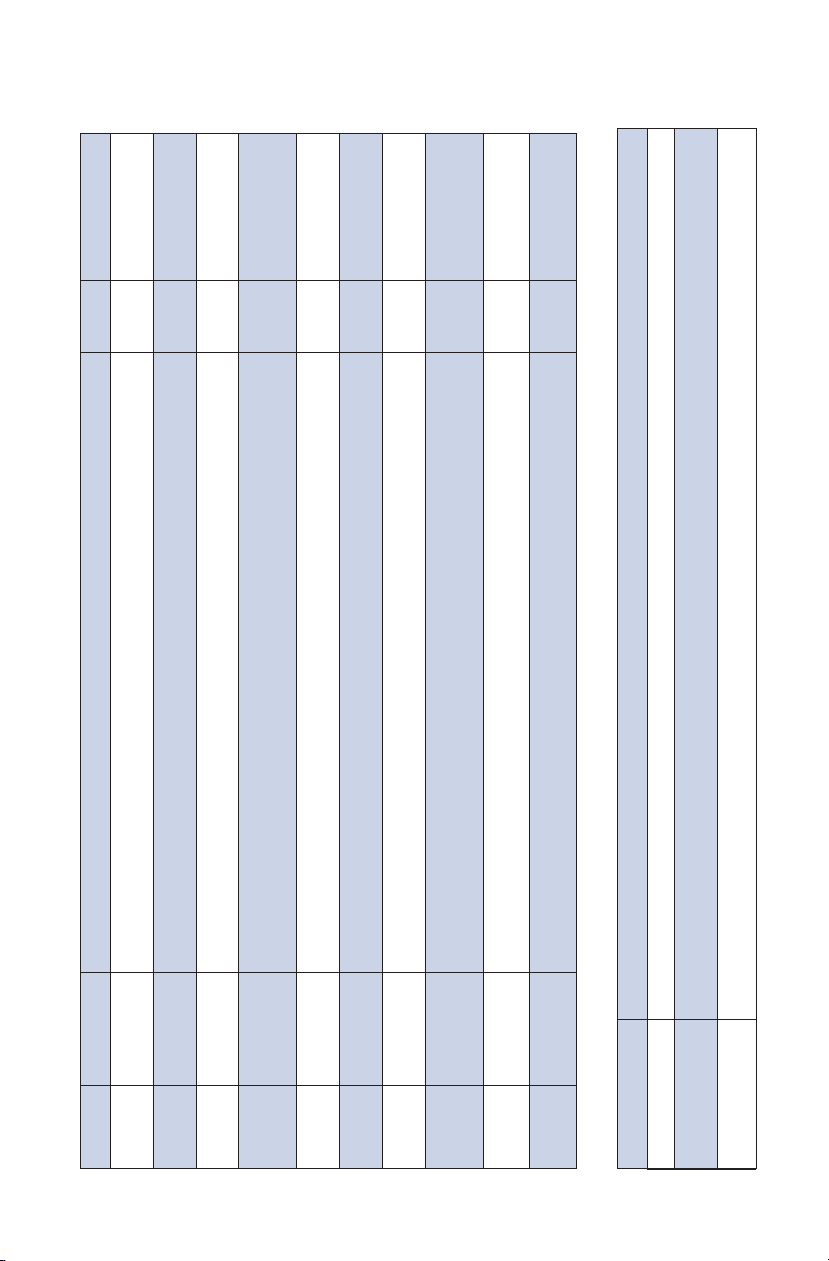

The Model 715 series consists of six sectional phantoms available separately or as

a complete set. Complete set includes head, trunk, right and left arms with natural

and oblique hand positions and right and left legs with natural and plantar flexion

foot positions.

SPECIFICATIONS AND OPTIONAL ACCESSORIES

MODEL DESCRIPTION

9508 Optional custom carry case for entire 715 (not including optional large positioning stand).

715-S-1 Optional large positioning stand for head, torso and appendages. Includes positioning stand, "HEAD" and "TRUNK" base/ quick-release plates, (2)

long thumb screws, (2) short thumb screws, (4) unattached quick-release plates, and allen wrench.

038-20 SRS Frame Support Cups, Set of 4 (compatible with 715-HN)

PART NO. DESCRIPTION INCLUDES WEIGHT DIMENSIONS

715-HN

Head

Skull, Homogeneous Brain, Sinus, Cavities, Ear Canals, C1-C7 Spine, Spinal Disks, Deciduous

and Descending Teeth with enamel and dentin, Small positioning stand for use with head only

2.75 kg 21 cm H x 14 cm W

x 17 cm D

715-T

Trunk

Chest, Rib Cage, Spine, Spinal Disks, Lungs, Bronchial Tree to third bifurcation, Lung Vascula-

ture, Trachea, Scapula, Clavicles, Top Third of Humerus, Pelvis,

Top Third of

Femur

9.85 kg 44.5 cm H x 24 cm

W x 14 cm D

715-A-R

Right Arm

Elbow in natural position, Full bone structure, Oblique hand position 0.7 kg 37 cm L x 8 cm W x

7cm D

715-A-

R-90

Right Arm

Flexed 90

Degrees

Elbow flexed 90 degrees, Full bone structure, Oblique hand position 0.7 kg

32 cm L x 8 cm W

x 13 cm D

715-A-L

Left Arm

Elbow in natural position, Full bone structure, Natural hand position 0.7 kg 37 cm L x 9 cm W

x 5 cm D

715-A-

L-FX

Left Arm with

Fractures

Elbow in natural position, Full bone structure, Natural hand position, R

adius fracture with open

reduction and hardware, Common fracture to second intermediate phalange

0.7 kg 37 cm L x 9 cm W

x 5 cm D

715-L-R

Right Leg

Knee in natural position, Full bone structure, Relaxed foot position 2.50 kg 42.5 cm L x 9 cm W

x 18 cm D

715-L-R-

90

Right Leg

Flexed 90

Degrees

Knee flexed 90 degrees, Full bone structure, Relaxed foot position 2.50 kg

34 cm Lx 9 cm W x

19 cm D

715-L-L

Left Leg

Knee in natural position, Full bone structure, Plantar foot flexion 2.50 kg

51.5 cm L x 9 cm W x

18 cm D

715-L-

L-FX

Left Leg with

Fractures

Knee in natural position, Full bone structure, Plantar foot flexion

Buckle fracture to tibia and

common fracture to fibula; Fracture to first metatarsal

2.50 kg

51.5 cm L x 9 cm W x

18 cm D

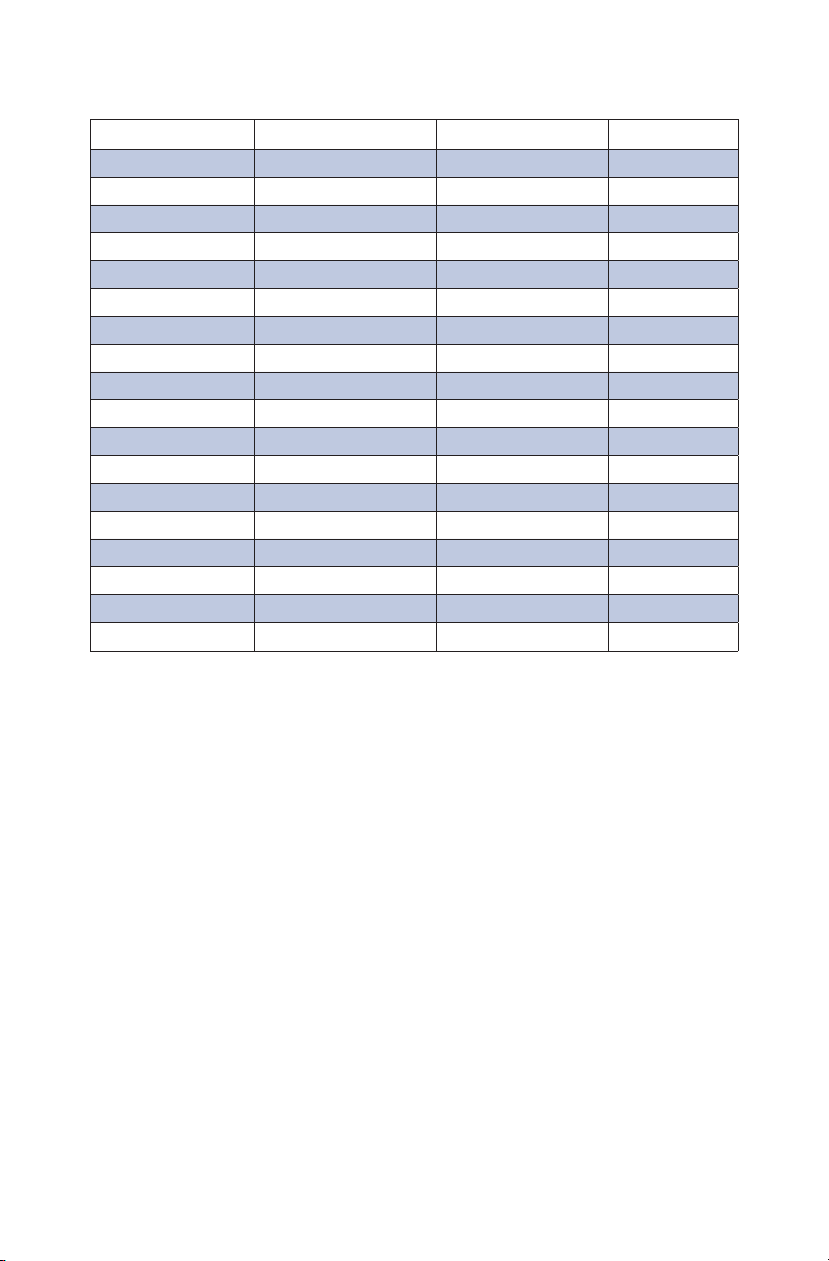

SOFT TISSUE

ENERGY- MEV REF. MUSCLE CIRS RATIO, %

0.04 0.2804 0.2548 90.87

0.06 0.2146 0.2121 98.84

0.08 0.1913 0.1940 101.41

0.10 0.1777 0.1822 102.53

0.20 0.1426 0.1478 103.65

0.40 0.1104 0.1147 103.89

0.60 0.0932 0.0969 103.97

0.80 0.0818 0.0851 104.03

1.00 0.0736 0.0765 103.94

2.00 0.0514 0.0534 103.89

4.00 0.0354 0.0365 103.11

6.00 0.0288 0.0295 102.43

8.00 0.0252 0.0256 101.59

10.0 0.0230 0.0233 101.30

20.0 0.0188 0.0185 98.40

30.0 0.0177 0.0171 96.61

El. Density, x1023, cm-3 3.621 3.616 99.86

Density, gcm-3 1.10 1.103 -

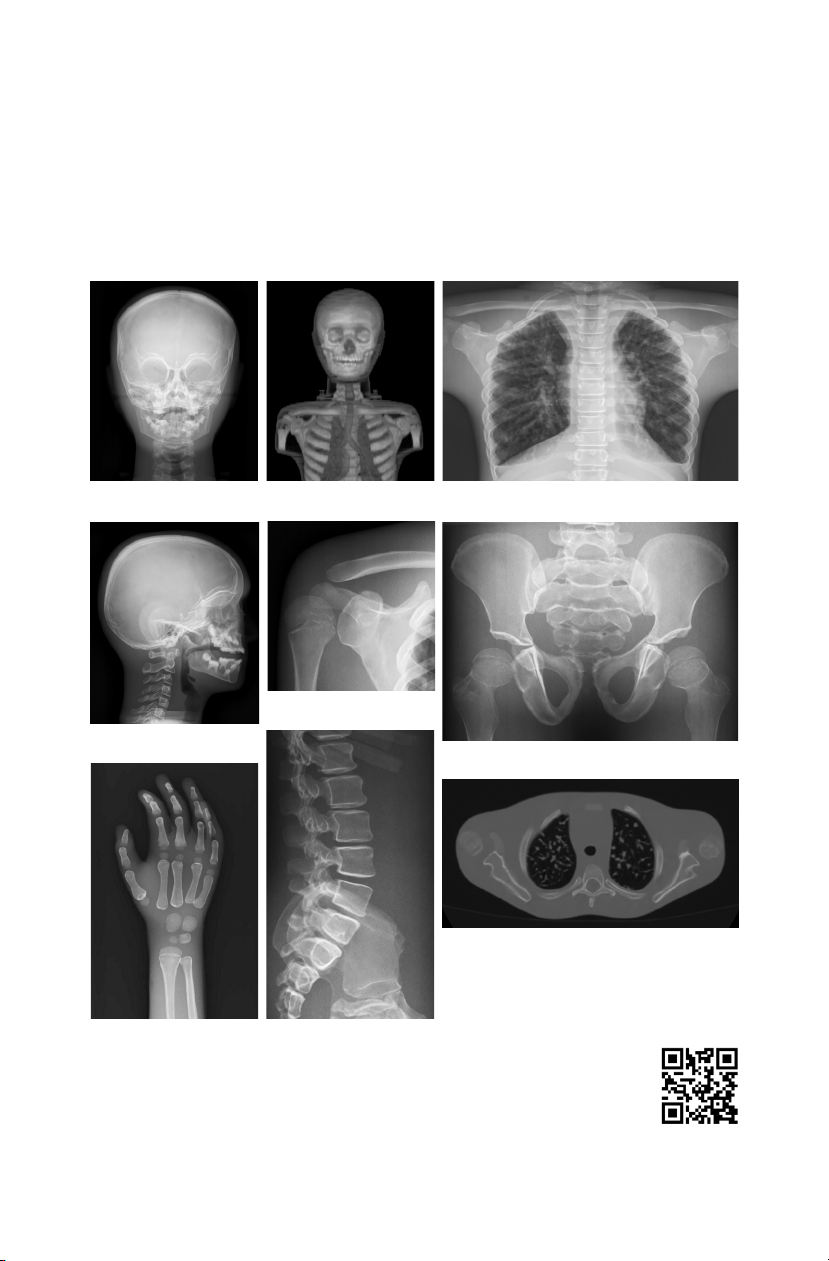

USE OF THE PHANTOM

The phantom should be used as a training aid for positioning techniques, colloma-

tion, and anatomical comprehension. Simply scan phantom using the same x-ray

technical factors as would be used on a lean patient.

Each user of the phantom may find additional uses and CIRS urges one to share

findings with others when possible and appropriate.

Lateral Skull

3D Reconstruction

Lateral Lumbar Spine

AP Skull AP Chest

AP Pelvis

AP Shoulder

Oblique Hand/Wrist

CT

To download the phantom DICOM data set (Resources) or view the

multimedia gallery, visit: www.cirsinc.com/products/all/36

SOFT TISSUE

POSITIONING STANDS

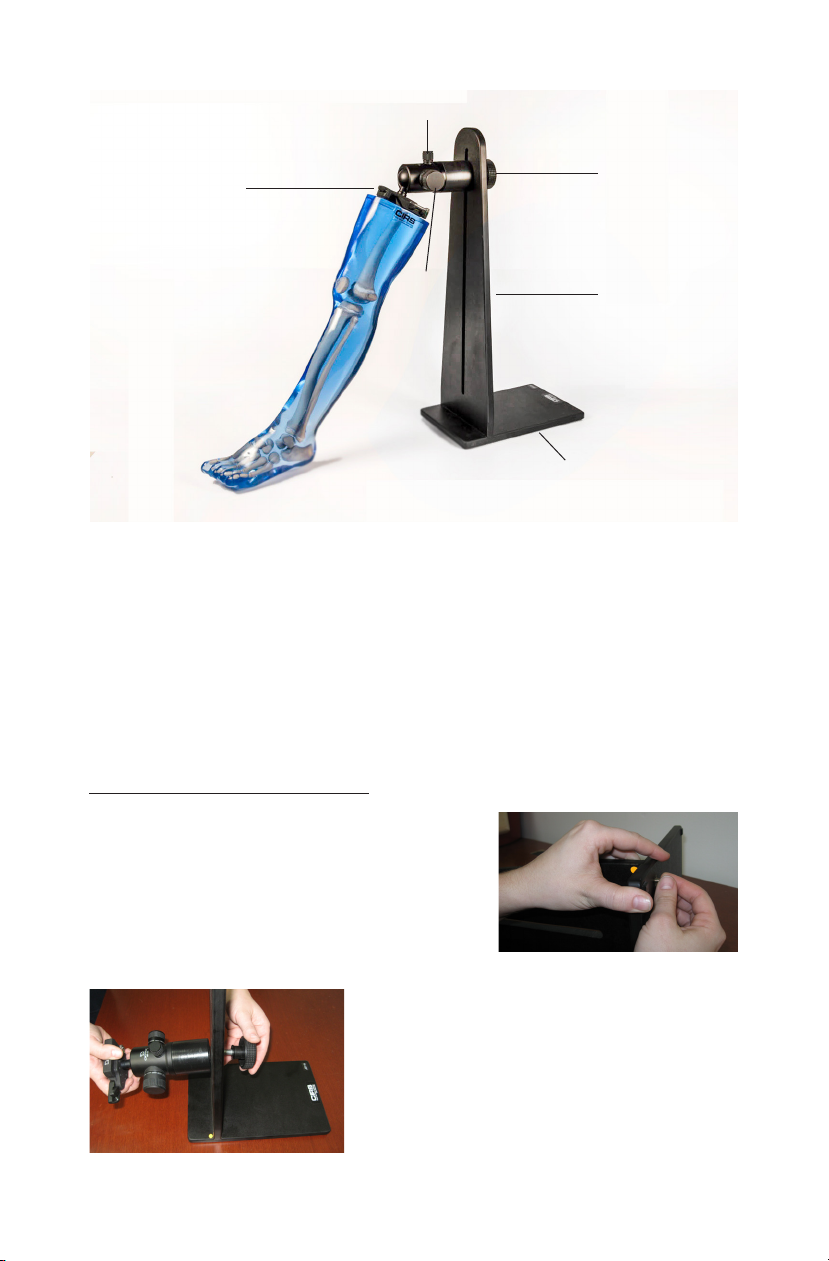

The Model 715 can be used with two positioning stands: a small positioning stand

included and only for use with the head phantom (Model 715-HN), and an optional

large stand (Model 715-S-1) which can be used with all of the components of the

Model 715. These stands are designed to allow users to practice alignment and

positioning for different x-ray views.

SMALL POSITIONING STAND

The Small Positioning Stand (Figure 1) should be fully assembled when you receive

your phantom. The only additional setup required will be to attach the phantom

head to the "HEAD" base plate for positioning.

1. Remove the thumb screws from the "HEAD" base plate.

2. Position the phantom face up and align raised cylinder on the phantom with

the matching cavity on the "HEAD" base plate.

3. Tighten the thumb screws to secure the phantom head to the small positioning

stand and base plate.

To adjust the height of the socket base, turn the large hand wheel on the frame

bracket 1/2 turn counter-clockwise, slide socket base to desired height and secure

position by turning large hand wheel 1/2 turn clockwise. Use the small hand wheel

on socket base to adjust the angle and rotation of the head and neck in relation to

the x-ray couch. For greater stability while using the phantom on stand, use a heavy

object as counterweight.

Figure 1

Thumb Screws

Large Hand Wheel

Small Hand Wheel

"HEAD" Base Plate

LARGE POSITIONING STAND (MODEL 715-S-1)

The optional Large Positioning Stand (Figure 2), can be used with any of SPoRT's

sections. The stand includes unattached quick-release plates for appendages and

combination base/quick-release plates for the head and trunk sections, along with

necessary tools and hardware to attach plates to all SPoRT sections. These plates

must be attached to the section before the section may be positioned using the

Large Positioning Stand.

Assembling Large Positioning Stand

To assemble frame bracket, lay positioning

stand base along the long edge and align

with the upright so that orange stickers

face toward each other. Ensuring that

edges of base and upright are flush, insert

provided screws and tighten with screw

driver. Be sure not to over tighten.

To attach socket base to frame bracket,

unscrew the large hand wheel from socket

base. Slide large hand wheel through frame

bracket and reattach to socket base. This

completes large positioning assembly.

Figure 2 (Tension Knob on Socket Base not shown)

Figure 4

Figure 3

Large Hand Wheel

on Frame Bracket

Upright

Quick-Release Plate

Small Hand Wheel on Socket Base

Base

Locking

knob on

Socket

Base

WARNING: Phantom may fall off table causing injury to operator. Before securing

SPoRT sections on the Large Positioning Stand, place a heavy object on the base

of the stand as a counterweight.

Attaching Prepared SPoRT Section to Large Positioning Stand

All prepared sections attach to the Large Positioning Stand by locking the quick-

release plate to the pre-assembled positioning stand mount on the Large Position-

ing Stand socket base. To lock the quick-release plate into the positioning stand

mount:

1. Unlock the locking lever on the positioning stand mount. Lever will be in 12

o'clock position when unlocked as shown in Figure 6.

2. Orient the section so anterior surface is facing ceiling.

3. Tilt section so quick-release plate is angled to allow posterior edge to make

first contact with posterior edge on the mount.

4. Rotate section to allow entire surface of quick-release plate to make contact

with positioning stand mount. The locking lever will automatically flip to locked

position as shown in Figure 7.

Figure 6 Figure 7

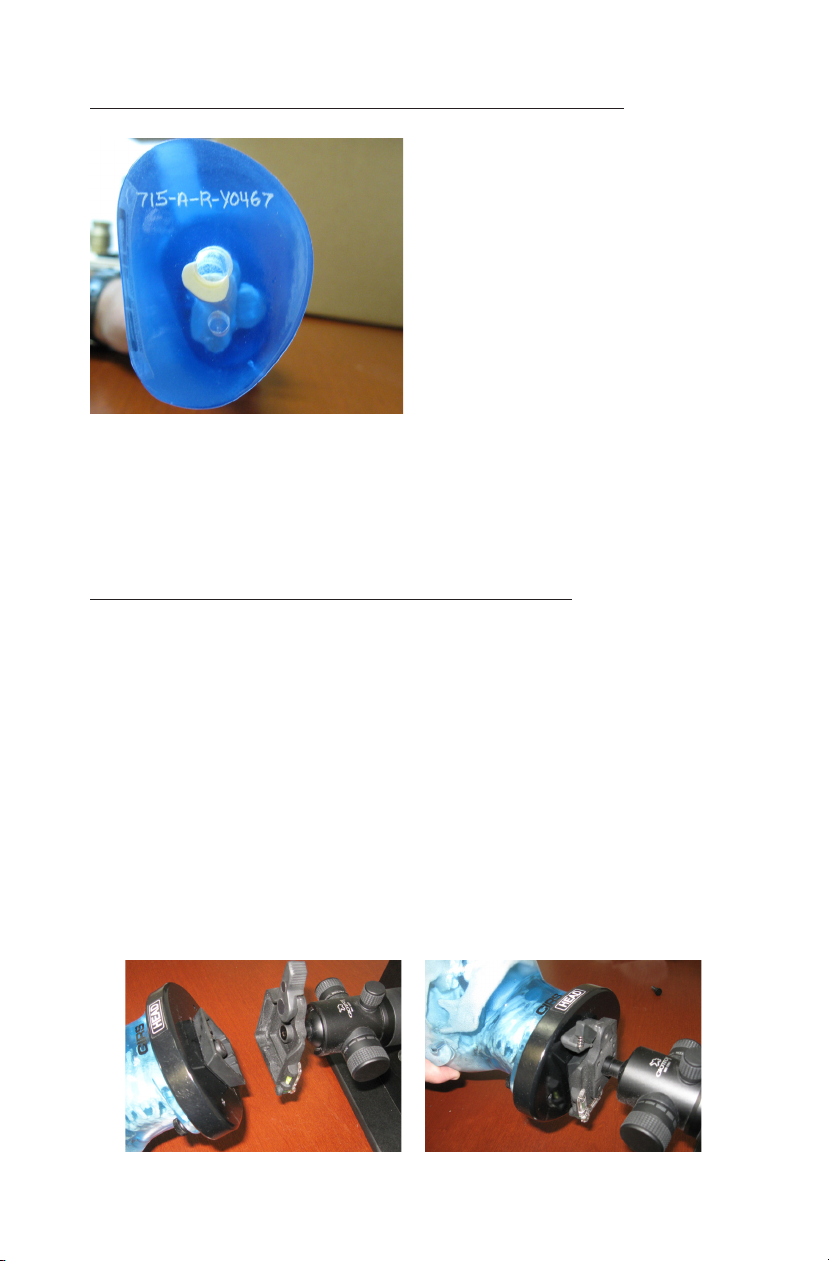

Preparing SPoRT Sections for attachment to Large Positioning Stand

Head & Trunk sections attach to the

Large Positioning Stand using a

combination base/quick-release plate.

This plate must be secured on the

respective section using included thumb

screws. Longer thumb screws are used

on the trunk section. Shorter thumb

screws are used on the head section.

Arm & leg sections attach to the Large

Positioning Stand using a quick-release

plate. This plate must be secured on

the respective section using included

screws. Align the holes in the quick-

release plate with the pre-drilled holes

located on the superior end of each

section (Figure 5). Insert screws and

tighten with included allen wrench.

Figure 5

Using Large Positioning Stand to adjust SPoRT Section Positions

The Large Positioning Stand consists of a frame bracket and socket base. The

large hand wheel on the back of the frame bracket is used to secure the height of

the socket base on the frame bracket. To adjust the height of the socket base,

turn this large hand wheel 1/2 turn counter-clockwise, slide socket base to desired

height and secure position by turning large hand wheel 1/2 turn clockwise.

The angle and rotation of the attached SPoRT section is controlled by adjusting the

ball-joint within the socket base. The three hand wheels on the socket base control

this ball-joint.

• The small hand wheel locks the rotation of the entire socket base. Loosen 1/4

turn to adjust rotation.

• The tension knob is a tension knob used to add friction while adjusting the

phantom positioning. Keep this knob tight for well-controlled movement.

• The locking knob will lock/ loosen the ball in the socket. By loosening this

wheel, you will be able to adjust the rotation and the angle of the phantom in

the positioning stand.

CARE AND HANDLING

Solicit help when moving an assembled head and trunk phantom as it may be

heavy and become hazardous if dropped.

The phantom should be stored in a safe place when not in use. The phantom may

be cleaned with mild soap and water.

Technical questions should be referred to CIRS customer service at

(800) 617-1177.

WARRANTY

All standard CIRS products and accessories are warranted by CIRS against defects

in material and workmanship for a period as specified below. During the warranty

period, the manufacturer will repair or, at its option, replace, at no charge, a product

containing such defect provided it is returned, transportation prepaid, to the manu-

facturer. Products repaired in warranty will be returned transportation prepaid.

There are no warranties, expressed or implied, including without limitation any im-

plied warranty of merchantability or fitness, which extend beyond the description on

the face hereof. This expressed warranty excludes coverage of, and does not pro-

vide relief for, incidental or consequential damages of any kind or nature, including

but not limited to loss of use, loss of sales or inconvenience. The exclusive remedy

of the purchaser is limited to repair, recalibration, or replacement of the product at

manufacturer’s option.

This warranty does not apply if the product, as determined by the manufacturer,

is defective because of normal wear, accident, misuse, or modification.

NON-WARRANTY SERVICE

If repairs or replacement not covered by this warranty are required, a repair estimate

will be submitted for approval before proceeding with said repair or replacement.

RETURNS

If you are not satisfied with your purchase for any reason, please contact your local

distributor prior to returning the product. Visit https://www.cirsinc.com/distributors/

to find your local distributor. If you purchased your product direct through CIRS, call

Customer Service at 800-617-1177, email [email protected], or fax an RMA request

form to 757-857-0523. CIRS staff will attempt to remedy the issue via phone or

email as soon as possible. If unable to correct the problem, a return material

authorization (RMA) number will be issued. Non-standard or “customized” products

may not be returned for refund or exchange unless such product is deemed by

CIRS not to comply with documented order specifications. You must return the

product to CIRS within 30 calendar days of the issuance of the RMA. All returns

should be packed in the original cases and or packaging and must include any

accessories, manuals and documentation that shipped with the product. The RMA

number must be clearly indicated on the outside of each returned package. CIRS

recommends that you use a carrier that offers shipment tracking for all returns and

insure the full value of your package so that you are completely protected if the

shipment is lost or damaged in transit. If you choose not to use a carrier that offers

tracking or insure the product, you will be responsible for any loss or damage to the

product during shipping. CIRS will not be responsible for lost or damaged return

shipments. Return freight and insurance is to be pre-paid.

WITH RMA NUMBER, ITEMS MAY BE RETURNED TO:

CIRS

Receiving

900 Asbury Ave,

Norfolk, Virginia, 23513 USA

PRODUCT WARRANTY PERIOD

Model 715 Series - Sectional Pediatric Anthropomorphic

Training Phantom 60 Months

©

2013 Computerized Imaging Reference Systems, Inc. All rights reserved.

Specifications subject to change without notice.

Publication: 715 UG 072220

Computerized Imaging Reference Systems, Inc. has been

certified by UL DQS Inc. to (ISO) 13485:2016. Certificate

Registration No.10000905-MP2016.

COMPUTERIZED IMAGING

REFERENCE SYSTEMS, INC.

900 Asbury Ave

Norfolk, Virginia 23513 USA

Toll Free: 800.617.1177

Tel: 757.855.2765

Fax: 757.857.0523

Email [email protected]

www.cirsinc.com

Technical Assistance

1.800.617.1177

Table of contents

Other Cirs Medical Equipment manuals