5

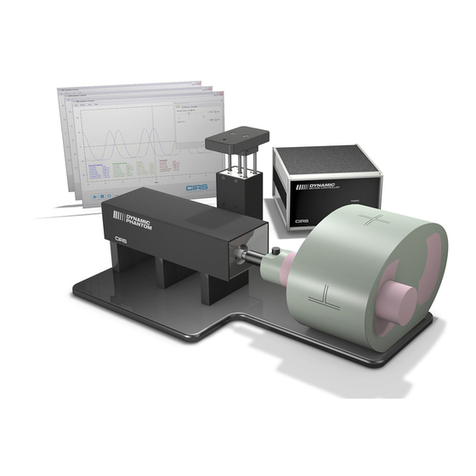

CIRS MOTION CONTROL SOFTWARE SYSTEM

REQUIREMENTS

Windows XP® / Vista / Windows 7/ Windows 8/ Windows 10

(32 and 64 Bit)

Pentium 3®or equivalent

512 MB RAM, 2 MB of available disk space

INTRODUCTION

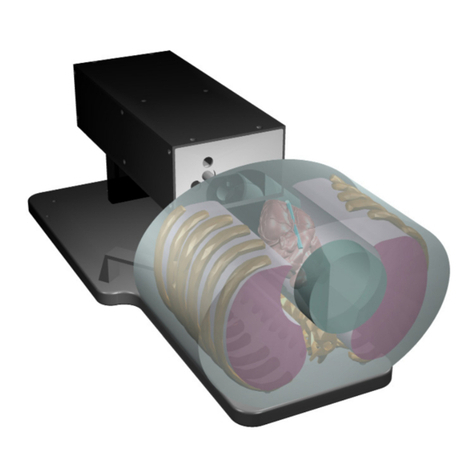

CIRS Motion Control is an application which allows you to control

the movement of the CIRS Model 008A Dynamic Thorax Phantom

and model 008PL Dynamic Platform. With CIRS Motion Control, you

can quickly set up a movement based on a library of pre-defined

motions, including Sin, Cos4, Cos6, Sawtooth, Sharkfin, Hyster-

esis ( Model 008A only) and Continous Drift, Transient Excursion,

Persistent Excursion, High-Frequency Excursion, or you can import

custom motion data from any tab-delimited or comma- separated

text file. CIRS Motion Control also allows you to save any motion

to easily access the same parameters for repeated calibration and

testing.

INSTALLATION

The CIRS Motion Control application requires the Trio PC Motion

library, which allows the computer to recognize the Trio controller

board in the Dynamic Phantom or Platform. To install the Trio PC

Motion library, double-click Trio_PC_Motion_ActiveX_2_12_0_Setup

and follow the steps in the InstallShield Wizard.

To install CIRS Motion Control, double-click MotionControl-

Setup or Setup and follow the steps in the Setup Wizard. The

Microsoft.NET Framework Version 3.5 is required for the ap-

plication to run.

GENERAL USE

The CIRS Motion Control Software is preinstalled on the optional

computer. Help can be launched from Help Menu. A copy of the

software is included on a CD or USB drive.

CIRS does not support 3rd party equipment. Please refer to the

included documents for warranty and service information for the

ACER brand computer (computer optional).

The software automatically creates a log file where data about wave-

form parameters are saved. The log file is usually located under the

current user in the Application Data folder. A Windows OS search

function can be used to find the log file. Searching hidden files and

folders should be enabled.

The log file provides a record of the motion history of the device and

can be used as objective evidence that proper QA was performed.

CIRS Motion Control Software

SOFTWARE USER MANUAL & SOFTWARE UPGRADES

CIRS Motion Control software has an online user manual. After

software installation, a copy may be viewed and downloaded using

either the “Check for Updates” button from Help Menu and selecting

“Motion Control User Manual.pdf” or by pointing a web browser to

the CIRS Software Updates webpage: http://www.cirsinc.com/Mo-

tionControlUpdates/Motion_Control_User_Manual.pdf

If the end-user is offline during use of the phantom, it is recom-

mended that a copy of the CIRS Motion Control User Manual is

downloaded and saved. Once a copy of the manual is saved in a

known location, the PDF document can be opened and viewed in a

window separate from the CIRS Motion Control software window to

aid in phantom set up and use.

The user manual is regularly updated to incorporate new information

based on the addition and/or modification of features as well as end-

user feedback.

CIRS recommends that the end-user routinely check the CIRS Soft-

ware Update webpage using the “Check for Updates” button from

Help Menu. This page indicates the current software version. The

latest free software upgrade is posted as soon as it becomes avail-

able. Instructions for updating the software are also posted. Please

note, controllers with serial numbers containing P136 may experi-

ence PC communication failuers upon updating Windows OS. If

this occurs, CIRS strongly recommends a motion controller update.

For details on how to upgrade, refer to the model 008A product

brochure.