Cirs MRIdian Phantom User manual

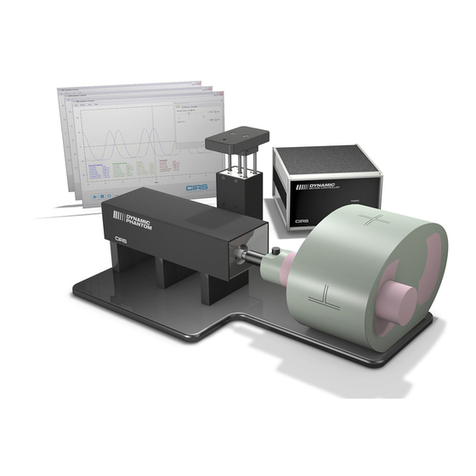

Motion Phantom for MRI Automatic

Tracking and Gating

USER GUIDE

1

Table of Content

Overview…………………………………………………………………...2

Description of Phantom…………………………………….…………...2

Specifications …….……………………………………………………....3

Use of Phantom…………………………………………………………...4

A. Unpacking Instructions …………..…………………………4

B. Assembly Instructions ….…….…..…………………………8

C. Oscilloscope Connection….…….....………………………13

D. Repacking Instructions …………..………………...………17

Care and Handling………………………………………….................19

Warranty………..…………………………………………....................20

Overview

The phantom is to be used to validate the capability of Viewray®

system to track and deliver a gated treatment based on MRI real

time imaging. Dosimetry capabilities of the phantom enhance the

validation of the whole Viewray system from the planning phase

to the final stage of gated treatment delivery. This phantom was

designed in collaboration with Viewray and complies with

Viewray Requirements Specification document RQ-0034 Rev C.

Refer to Viewray protocol FTP-06 Rev B “Functional Test

Procedure” for detailed instructions regarding how to use this

phantom with the MRIdian system.

*Viewray® is a registered trademark (Oakwood Village, OH)

Description of the Phantom

The phantom consists of the following

subassemblies/components:

-Custom Linear actuator (modified CIRS model 008A Linear

actuator as required by input of project 796-01-00).

-Cross bars (front and back) for Actuator indexing to Viewray

system treatment couch.

-Custom Motion Controller box (modified CIRS model 008A

Motion Controller as required by input of project 796-01-00 –

modified firmware) –includes standard 008A communication

cables (USB over Ethernet communication Controller-PC).

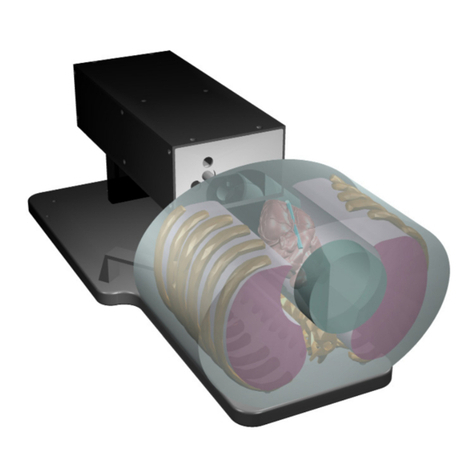

-MRI signal generating Body with static non-deformable targets

and rigid organs at risk. Ion chamber (Exradin A28)**

dosimetry enabled for all targets and OARs. **Other ion chambers

are available. Refer to CIRS cavity codes at www.cirsinc.com/support for

corresponding CV number.

-MRI signal generating Moving Rod with one dosimetry non-

deformable target and non-dosimetry and non-deformable

targets.

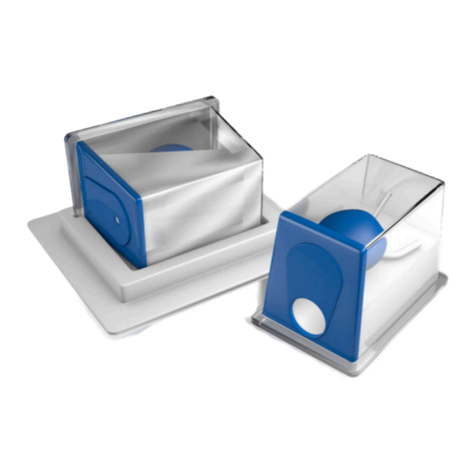

-Supports (front and back) to index MRI Body to Viewray

system treatment couch. Supports allows Viewray Torso Coils

placement around the MRI Body.

-Connector shafts between Actuator –MRI Body

-Shipping cases 2

3

- Accessories

NOTE: The MRI signal generating Body does not include

any ferrous or metallic parts except for the ¼-20 – 1”

long Brass screws used to fasten the couch indexing pegs

to the MRI Body supports. These Brass screws were

selected accordingly with Viewray input for model 008V.

The closest ferrous or metallic parts to the MRI signal

generating Body are the ones from the Custom Linear

actuator.

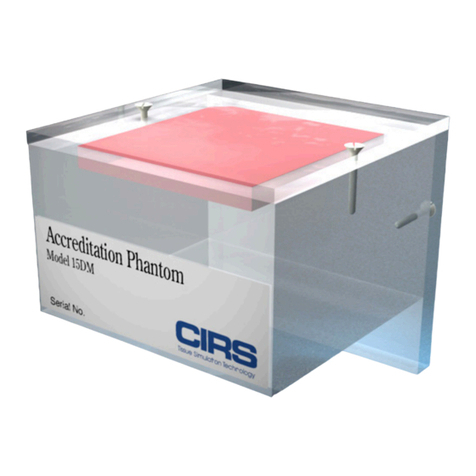

MRI signal generating Body

Dimensions: Ø254mm x 236mm (Gel Volume ~Ø229.3mm x 220mm)

Weight: ≈30 lb.

Materials: Body Housing –Acrylic;

Body and Body targets –CIRS proprietary gels

MRI signal generating Moving Rod

Dimensions: Ø63mm x 290mm ((Gel Volume ~Ø57mm x 254mm)

Weight: ≈4 lb.

Materials: Rod Housing –Acrylic;

Rod and Rod target –CIRS proprietary gels

Specifications

4

Use of the Phantom

A. Unpacking Instructions

Before you open the case check the three Drop ‘N’ Tell

indicators on the right side of the case. (Drop ‘N’ Tell

shipping damage indicator shows when a case has been

dropped in transit and contains potential damaged goods.

The sensor displays a red arrow when applied before

shipping. If the container receives a shock exceeding 25 G

force, the sensor display arrows will change to blue. If the

sensor has been activated and is blue, a claim may need to

be filed with the carrier. If activated, take extra care in

inspecting the components as they are unpacked, assembled

and tested. Note: If there is any damage to the packaging

case, containers, foam, and components, or operation,

immediately contact the carrier and the phantom

supplier, and keep all packaging for carrier inspection.)

5

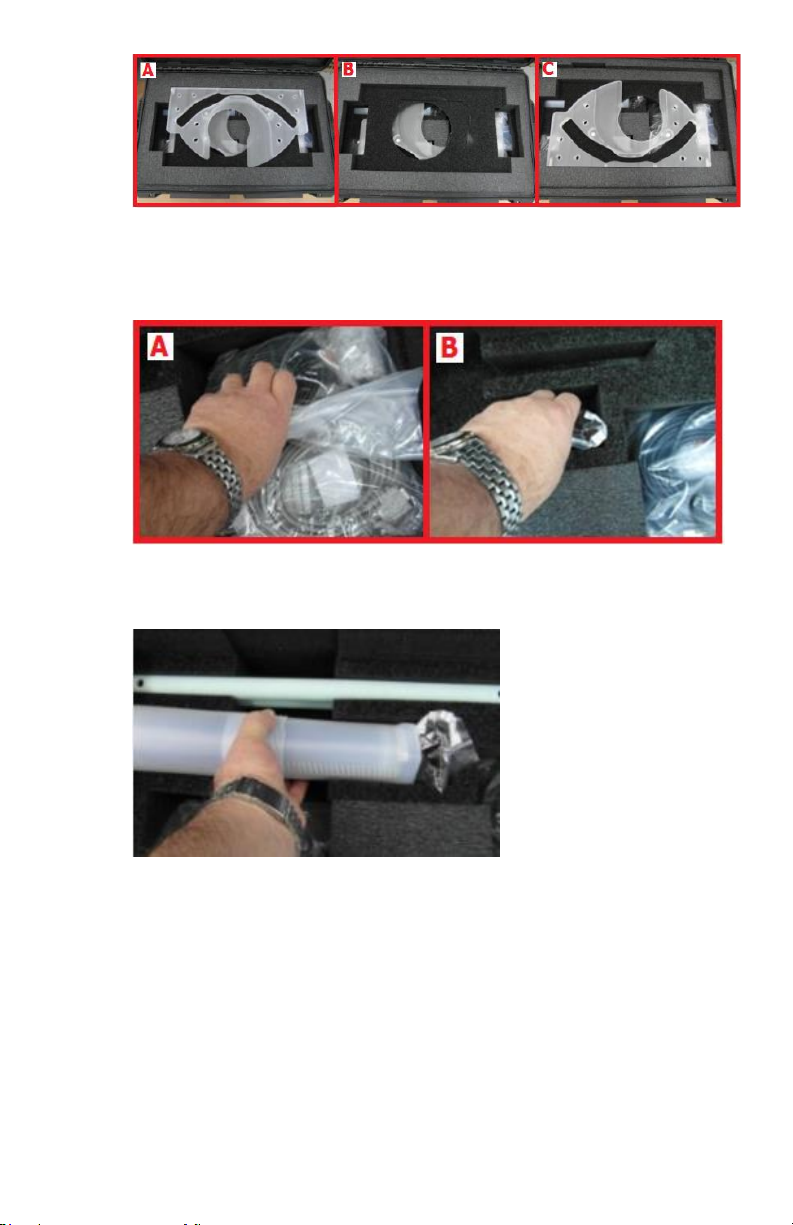

1. Remove MRI Body/Torso Coils supports and set them

aside. Pay attention to the foam trays that accommodate

these parts as they are fragile.

2. Remove cables and accessories bags from case and set

them aside.

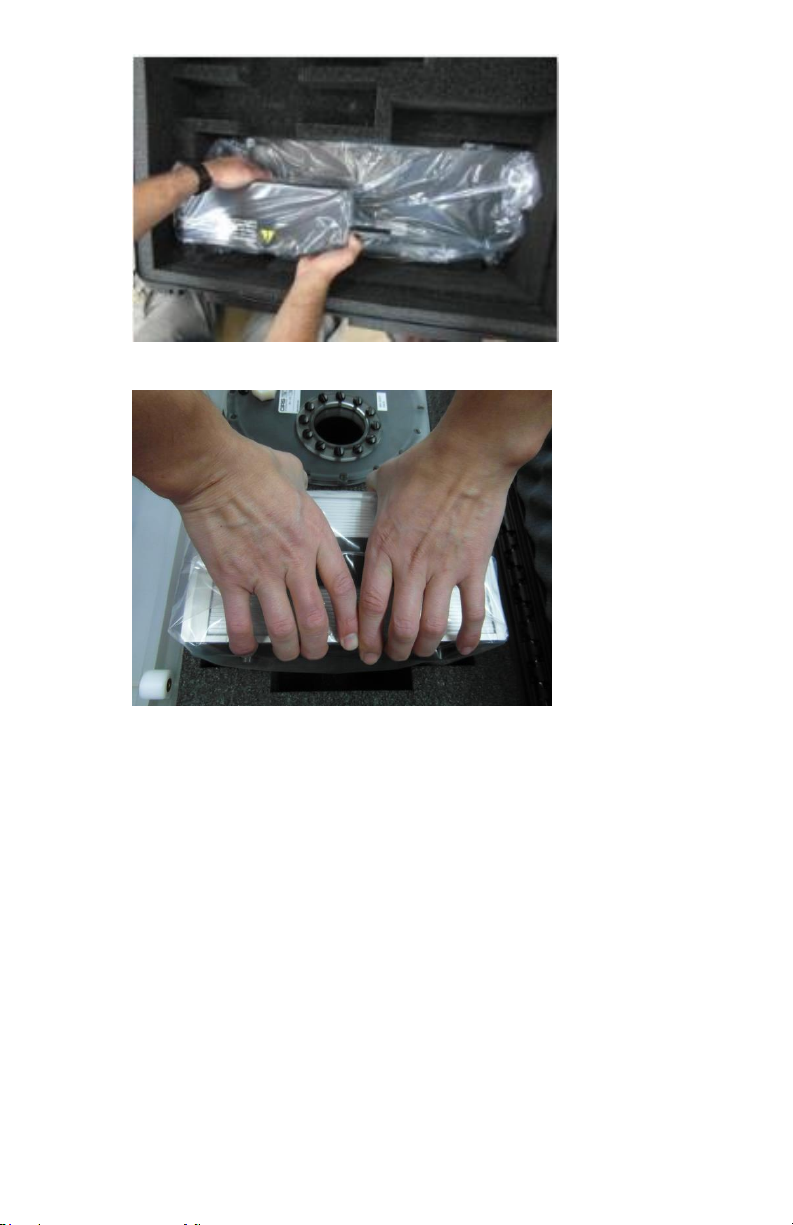

3. Remove MRI Moving Rod and set it aside.

6

4.

Pull base and the actuator assembly from case and set it aside.

5.

Remove Motion Controller box from case and then MRI Body

Carrying Handle, which is shipped inside of one of the

removal cutout of the MRI Body.

7

6.

Carefully take the MRI Body out from the case and set it aside

in a horizontal position laying it on the straight edges of the

body’s ends.

7.

Remove the remaining hardware from the case and set it

aside.

8

B. Assembly Instructions

1.

Assemble the MRI Body/Viewray Torso Coils supports and

MRI Body crossbars using the alignment pins and

corresponding holes (circled in blue) and secure in place with

the black ½-13 hex nylon screws. Pair the MRI Body/Viewray

Torso Coils support with the corresponding MRI Body

crossbar, which can be identified by their labels (circled in

red).

Note: Throughout this user manual “Front” and “Back” (for

both MRI Body and actuator) are referring to such that

“Back” is the furthest from the observer when the phantom

is on the couch with the MRI Body toward the gantry and

the observer at the end of the couch. Also, to aid in correct

assembly of the phantom’s parts the

identification/matching labels are affixed only on

observer’s right side.

9

2.

After indexing the two MRI Body/Viewray Torso Coils

support - MRI Body crossbar subassemblies to the Viewray

couch ( following the naming convention explained before)

place the MRI Body between them as shown above.

Make sure the body slides inside the two supports and is

guided by the walls of the recess pockets so that it locks on

the flat faces of the MRI Body’s ends (see below).

10

To place the MRI Body on the support use the handle and the

straps like shown below (make sure the body do no slips from

the straps; carry the body as much as possible in a horizontal

position with the straps/handle position in a vertical

line/plane with the body’s top laser marks).

3. Position the Linear actuator on the other end of the couch.

The crossbars alignment pins and actuator base plate holes

facilitate a quick alignment between the Linear actuator and

MRI Body (see pictorial A). Secure the linear actuator against

tripping using the adjustable legs, which should push against

the couch (see circled in blue in pictorial C; screw the

adjustable legs through the actuator base plate and into the

toggle pads, which are found in the accessories bag).

11

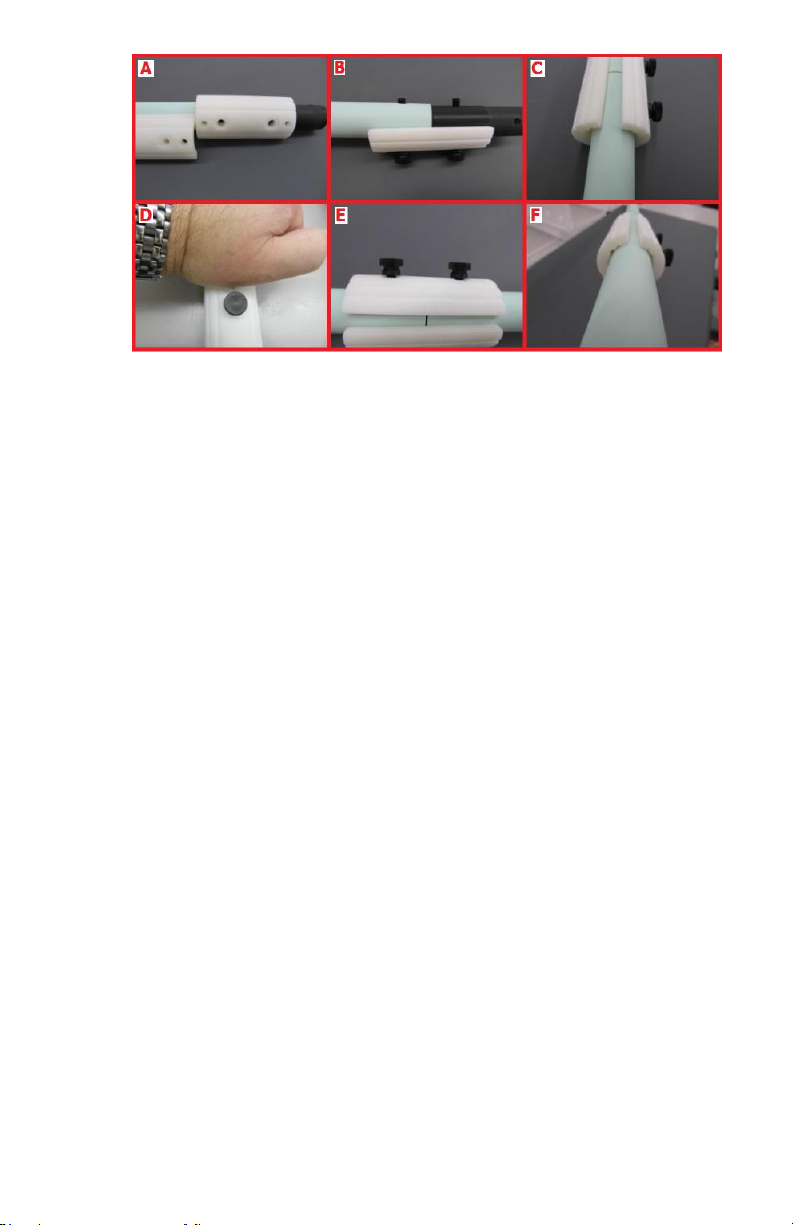

4.

Connect the shafts together and to the actuator push rod

following the sequence from the above pictorials.

The recommended procedure is:

-Identify the top connector bridge (white nylon pieces)

with un-threaded large holes (pictorial A) and align the

holes of shafts/Absylux connectors with the conical posts

of the said bridge (pictorial B).

-Pass two ¼-20 -1.5” long nylon thumb screws through the

holes of top connector bridge and shafts/Absylux

connectors then screw them in the bottom connector

bridge as shown in pictorial C.

-If it becomes hard to screw the thumb screws one can

press the whole assembly against a hard flat surface with

the bottom connector bridge down (pictorial D) until a

result like shown in pictorial E is obtained.

-Tight the thumb screws so that both the top and bottom

connector bridges touch the shafts/Absylux connectors.

Do not over tight.

12

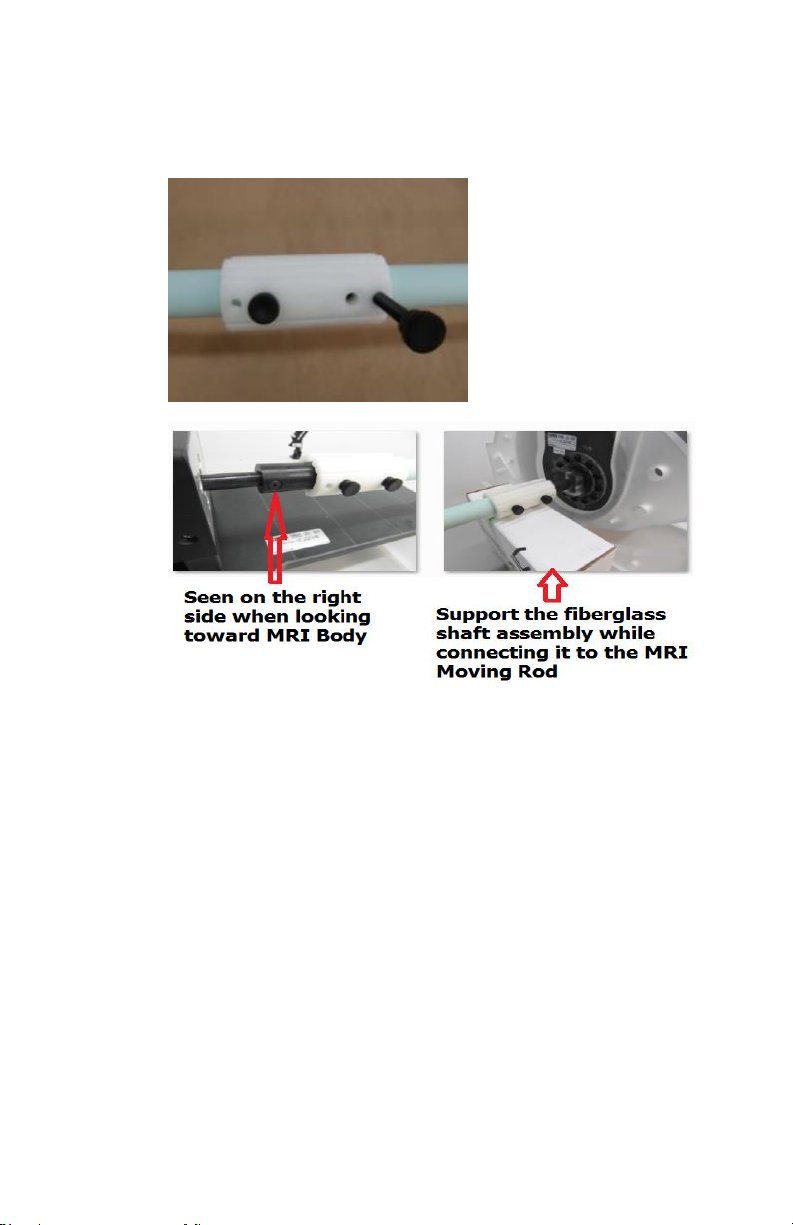

Note: If there is a need to remove the bridge connectors and

they seem to be locked on the shafts use the thumb screws to

push against (by screwing them in the outer treaded holes)

the shaft, which will un-lock them (see below).

5. For proper alignment of actuator with MRI Moving Rod

follow the assembly steps shown above.

13

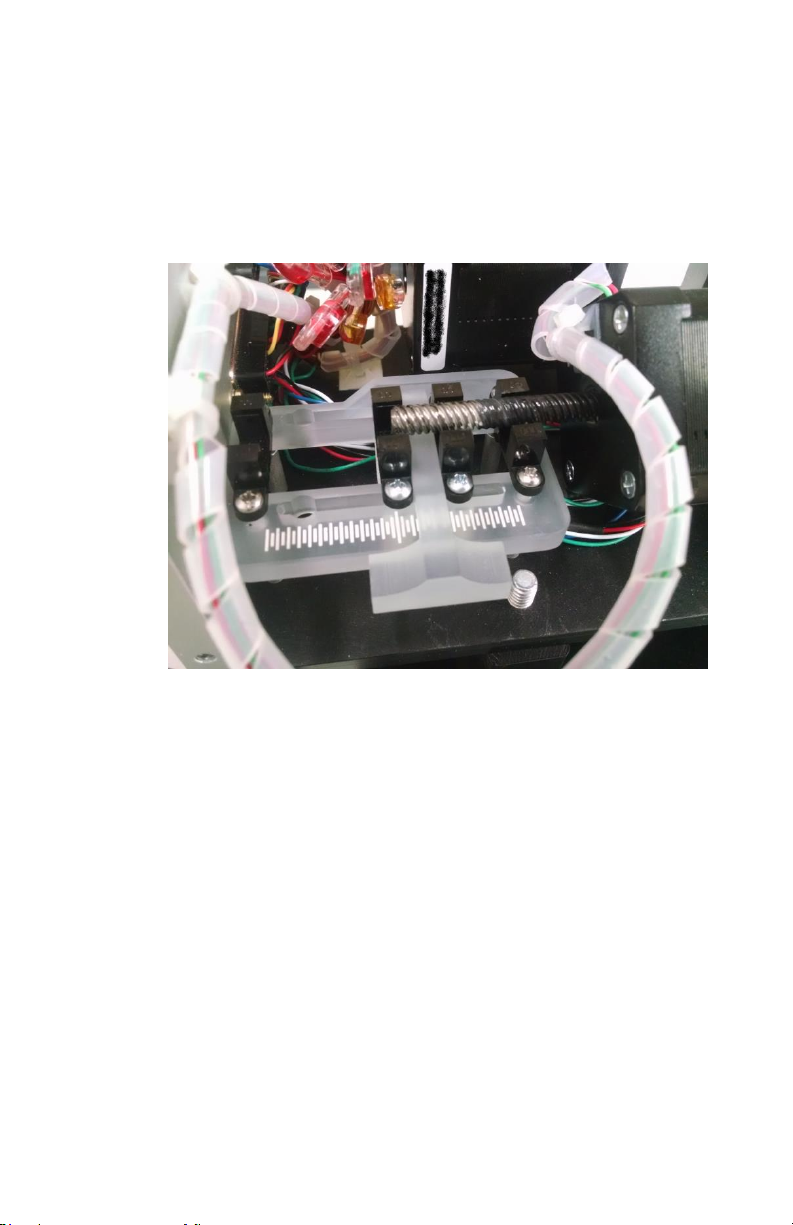

C. Oscilloscope Connection

The phantom is equipped with a special feature that allows

the end user to check whether there is latency between the

position of the MRI moving target and the release of the beam

based on MRI imaging of the this target.

To accomplish this task the phantom is equipped with:

I. An assembly containing two optical switches, which is

housed inside of the main linear actuator of the phantom.

When the lead screw of the linear motor crosses the

optical switches it provides two electrical signals that can

be analyzed on an oscilloscope. The signal from each

individual optical switch is a square wave as shown

below.

14

II. Cable that allows analyzing two signals at once, on

channel 1 and 2 of an oscilloscope respectively.

To do adjustments to the signal that is provided by the optical

switches and to analyze them on an oscilloscope follow the following

steps:

15

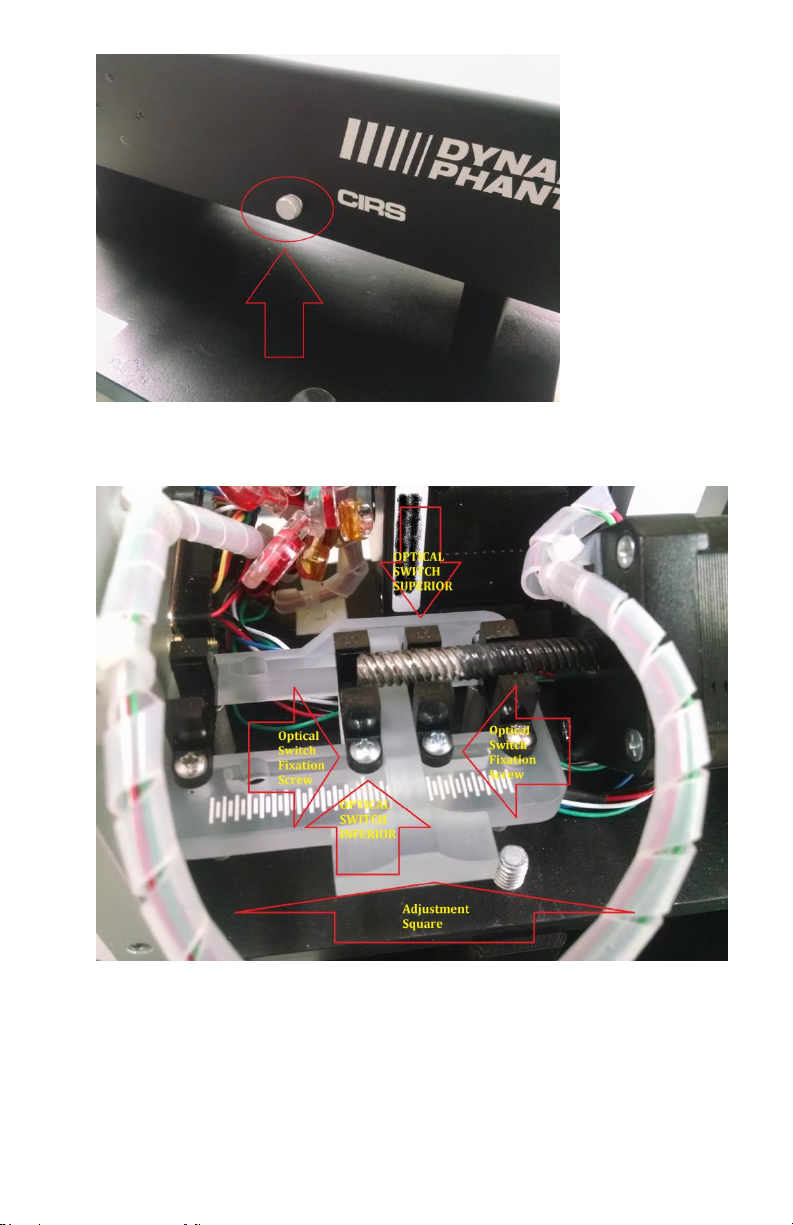

1. Open the cover of the actuator box by unscrewing the aluminum

thumb screws (see above) and remove it.

2. Unscrew the Optical switch fixation screw of the two inner

Optical Switches and adjust the distance between them according

to your research study. Use the Adjustment Square to align the

Optical Switches at 90ºwith respect the slots of the assembly

support.

16

Note: The position of the outer two Optical Switches is not

adjustable. Do not unscrew their fixation screws. These two

Optical Switches are used for safety limits of the travel of the

linear motion and for the homing sequence.

3. Close the cover of the actuator box by hand tightening the

aluminum thumb screws.

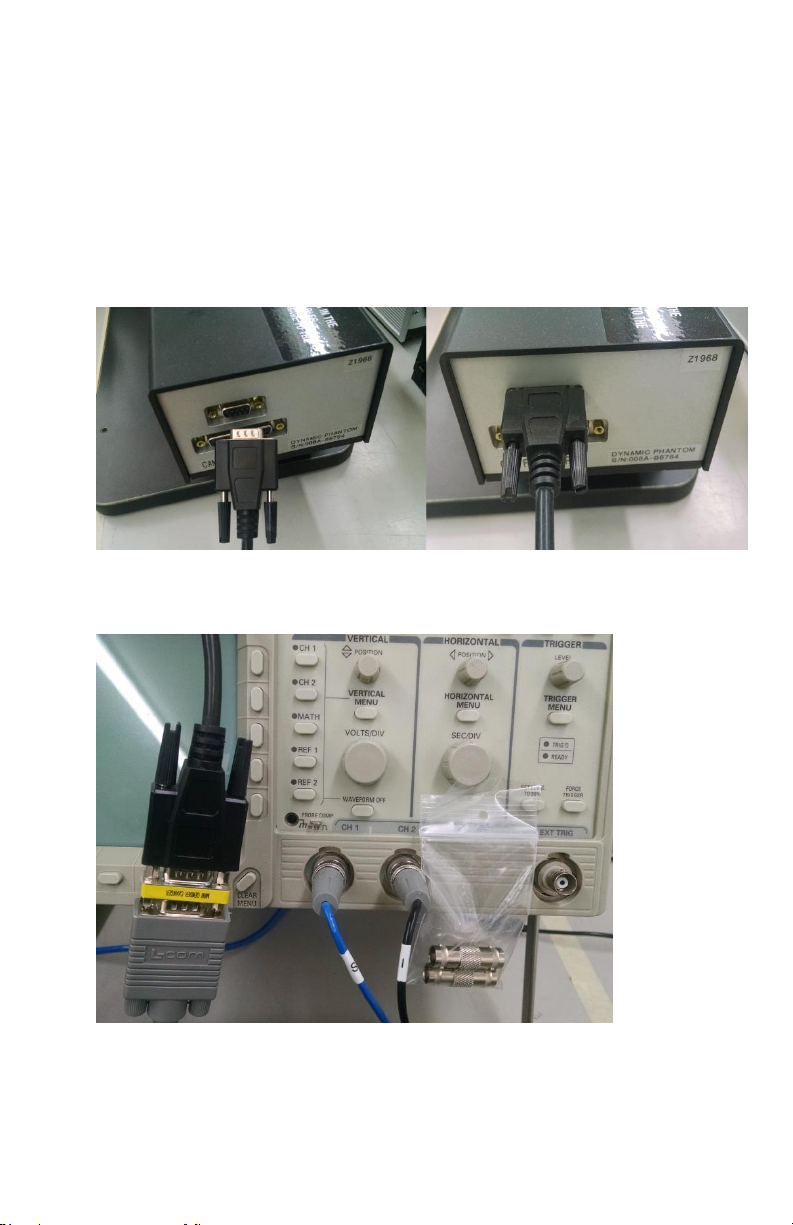

4. Connect one of the provided DB9 shielded cable to the DB9

Female connector at the back of the actuator.

5. Connect the short DB9 to Oscilloscope cable to the DB9 cable that

was connected to the actuator. A DB9 Female to DB9 Female and

extra connectors are provided for convenience.

17

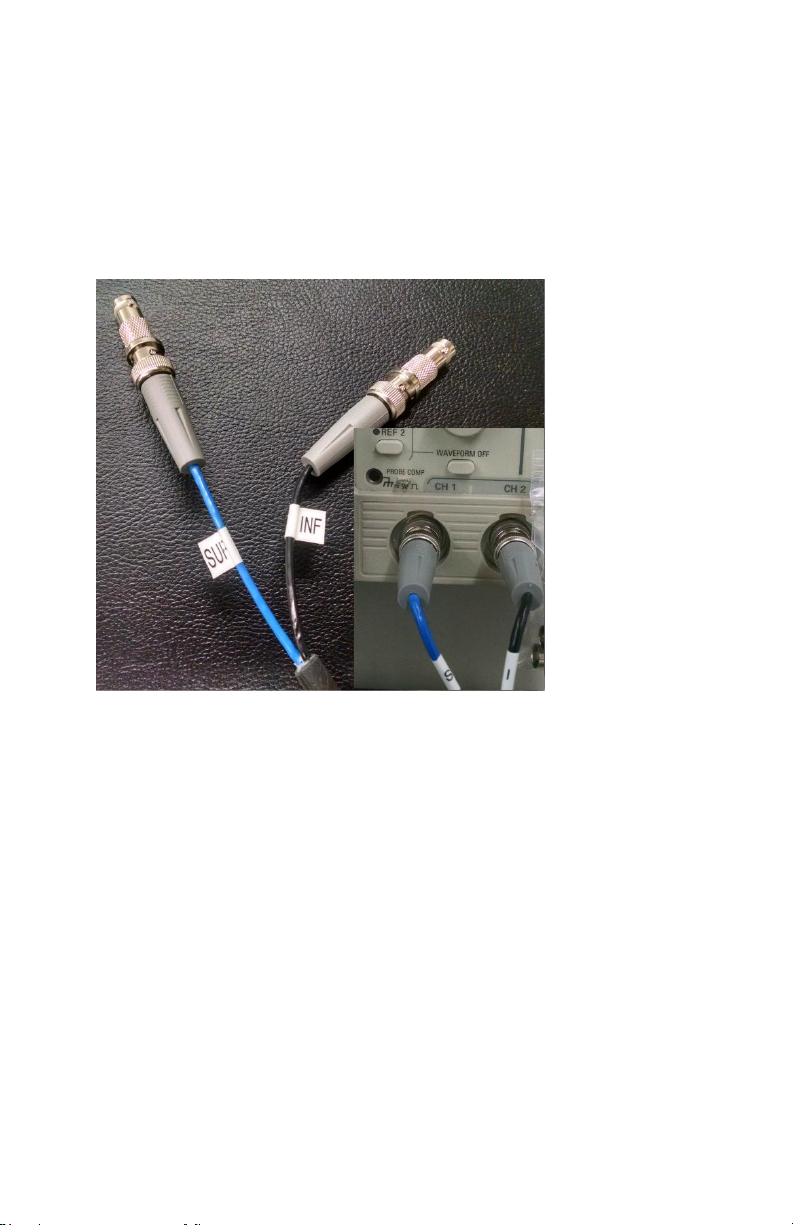

Note: The short DB9 to Oscilloscope cable has its oscilloscope

labeled as SUP for the Optical Switch that is toward the linear

motor and INF for that is toward the back of the actuator due

to the fact that the Phantom is designed for “Supine Head

First”. As shown below it is recommended that SUP signal is

analyzed on Chanel 1 and INF on Chanel 2 of the oscilloscope.

D.. Repacking Instructions

User should try to follow the unpacking steps in a reverse

order.

Included with Model 008V

18

-(1) Base Plate with Linear Actuator mounted (with 2

Adjustable Legs already mounted)

-(1) MRI Moving Rod

-(2) Motion Transmission Shaft

-(1) MRI Body/Torso Coils Front support

-(1) MRI Body/Torso Coils Back support

-_(1) Bag with mandatory fasteners: 4 x Nylon Socket Head

Cap Screw 1/2"-13 Thread, 1-1/2" Length, Black 6 x

1/4-20 1.5" long Nylon Thumb Screw, 1 x 1/4-20 1" long

Nylon Thumb Screw

-(1) CIRS Motion Control Software USB Drive

-(1) Motion Controller Power cord

-(1) Cable Kit, CAT5e - 75 feet with USB 3.0 Gigabit

Ethernet Adapter

-(1) Oscilloscope Cable [VGA to DB9/4BNC Breakout cable

Male

-(2) DB-25 male to male cable (EMI Shielded)

-(2) DB-9 male to male cable (EMI Shielded)

-(2) Gender Changer DSUB 9POS F-F

-(1) Gender Changer DSUB 25POS F-F

-(1) User’s Guide

- (1) Motion Controller Box

-(1) MRI Body

-(1) MRI Body Carrying handle (with 2 straps already

mounted)

-(1) Linear Actuator Crossbar Front

-(1) Linear Actuator Crossbar Back

-(2) MRI Body Crossbar

- (3 sets) Connection bridges for Motion transmission Shaft

(2 parts per set)

-(1) Connector Motion transmission Shaft-to-MRI Moving

Rod

- (1)Nonsparking (nonmagnetic) Hex L-Key 3/8" Hex Size,

4-1/2" Long

- 10-24x1” (5); Nylon Hex Screw 1/2-13x1.5” (2)

o

19

Care & Handling

Cleaning:

The phantom is manufactured from acrylic. It is recommended

that the phantom only be cleaned with mild soap and water.

Caution: DO NOT USE ANY ABRASIVES, ALCOHOL OR SOLVENTS

ON THE

PHANTOM. These will damage your phantom.

Carrying:

- Short Distances (between couch and plastic storage case) -

Use the provided handle and straps to lift MRI Body from Coils

Support and carry it (horizontal only - see below).

- Long Distances - Use as much as possible the plastic

storage/shipping case. Make sure the MRI Body is fully

secured inside the case by using the appropriate foam blocks

as seen below.

Included with Model 008V

-(2) 2 amp fuses

-(1) Extra fasteners pack (min quantity in brackets): Nylon

Thumb Screw ¼-20x1.5” (6); Nylon Thumb Screw

¼-20x1” (2); Nylon Pan Screw ¼-20x5/8” (2+2 with O-

rings); Nylon Pan Screw 10-24x3/4” (8); Nylon Pan Screw

10-24x1” (5); Nylon Hex Screw 1/2-13x1.5” (2)

Table of contents

Other Cirs Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Otto Bock

Otto Bock Dyna Ankle 50S1 Instructions for use

Physiomed

Physiomed vocaSTIM-Master operating instructions

Bodypoint

Bodypoint BB101M-1 Installation and user instructions

Bunnell

Bunnell LifePulse 204 Quick reference guide

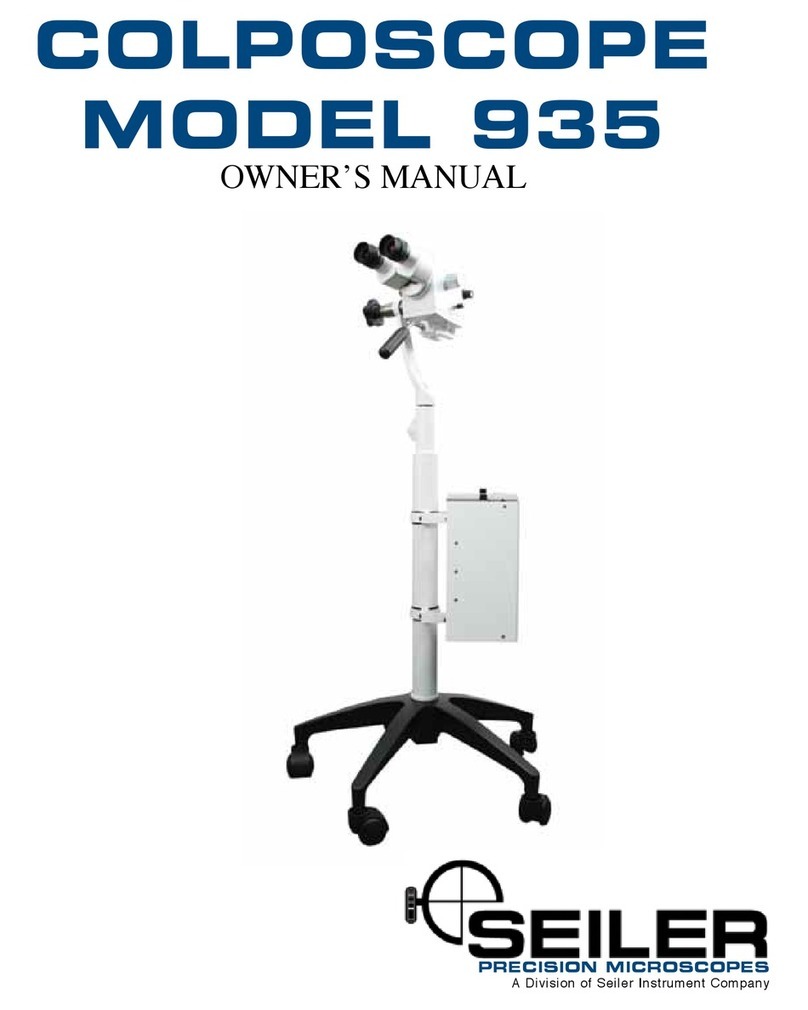

SeilerScope

SeilerScope 935 owner's manual

imtmedical

imtmedical bellavista Quick start manual