1

Overview

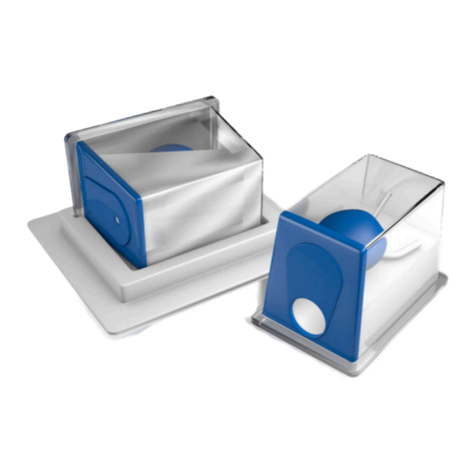

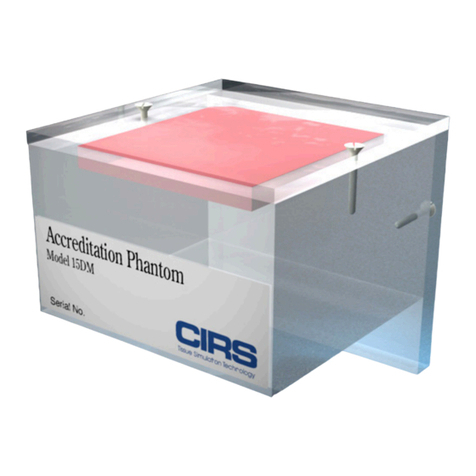

The Model 049 and 049A Elasticity

QA Phantoms are elasticity reference

tools developed for both shear wave

and compression elastography. The

phantoms contain targets of known

stiffness relative to the background

material and range in stiffness, diam-

eter and depth.

Both phantoms are made of CIRS'

proprietary Zerdine®hydrogel poly-

mer, which has been formulated to

produce lesions of differing Young’s

modulus. To maximize phantom

lifetime, this gel is contained in a rugged ABS plastic housing with a Saran-based

laminate membrane.

The Model 049 Elasticity QA Phantom contains 10 mm and 20 mm diameter

spheres of varying hardness relative to the background material. The spheres are

located at depths of 15 mm and 35 mm respectively and will appear hyperechoic to

the background using standard B-mode imaging.

The Model 049A contains sets of stepped cylinders that vary in diameter from 1.6

mm to 16.7mm. The stepped cylinders in each set are located at depths of 3 cm

and 6 cm. Each set has a different hardness relative to the background material and

will appear almost isoechoic to the background using standard B-mode imaging.

CIRS is certified to ISO 13485:2016 standards. We have an in-house test facility to

measure acoustic properties of speed, attenuation and relative contrast. In addi-

tion, two ultrasound systems are used to visually inspect each phantom. As a result,

every ultrasound phantom is subjected to rigorous testing both during manufacture

and upon completion. The user may observe very minor imperfections within the

product such as: very slight inhomogeneities with the background speckle pattern

and only seen under certain conditions or a very small air bubble in a place that

does not impact utility or integrity of the phantom. Any such anomalies have been

determined, by CIRS engineers, to not impact the quality, performance or usability

of the product and are deemed “aesthetic imperfections”. The embedded lesions

may contain random inhomogeneities. Such inhomogeneities may prove useful in

demonstrating the ability of sonoelastography techniques to discriminate subtle

differences in material properties. A Certificate of Compliance is issued with each

phantom.

Models 049 & 049A are

Suitable for:

• Determining dynamic range

• Checking system performance

over time

• Training and demonstrating of

system features

• Research and development