Cirs Brachytherapy QA Phantom User manual

Brachytherapy QA Phantom

ZERDINE®Inside

A registered trademark of CIRS

USER GUIDE

U

L

T

R

A

S

O

U

N

D

Q

U

A

L

I

T

Y

A

S

S

U

R

A

N

C

E

Brachytherapy QA

Phantom

Model 045B

900 Asbury Ave • Norfolk, Virginia 23513 • USA • Tel: 757-855-2765 • WWW.CIRSINC.COM

TABLE OF CONTENTS

1 OVERVIEW

1

2 INSTRUCTIONS FOR USE

4

HANDLING AND CARE

��������������������������������������������������������������� 4

GENERAL GUIDELINES FOR PERFORMING MEASUREMENTS

������������������������� 5

ESTABLISHING A BASELINE

��������������������������������������������������������� 6

3 TESTING PROCEDURES

6

UNIFORMITY TESTING

��������������������������������������������������������������� 7

DEPTH OF PENETRATION

������������������������������������������������������������ 7

VERTICAL AND HORIZONTAL DISTANCE MEASUREMENT

����������������������������� 8

ELECTRONIC GRID ACCURACY

������������������������������������������������������� 9

STEPPING MECHANISM ACCURACY

������������������������������������������������� 9

VOLUME MEASUREMENT ACCURACY

����������������������������������������������� 10

NEEDLE ALIGNMENT TESTING

������������������������������������������������������ 12

4 SPECIFICATIONS

13

5 ZERDINE®

14

6 WARRANTY

15

7 APPENDIX: QUALITY ASSURANCE RECORD FOR MODEL 045B

16

1

OVERVIEW

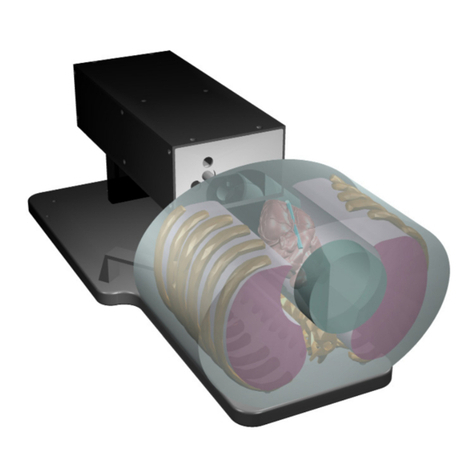

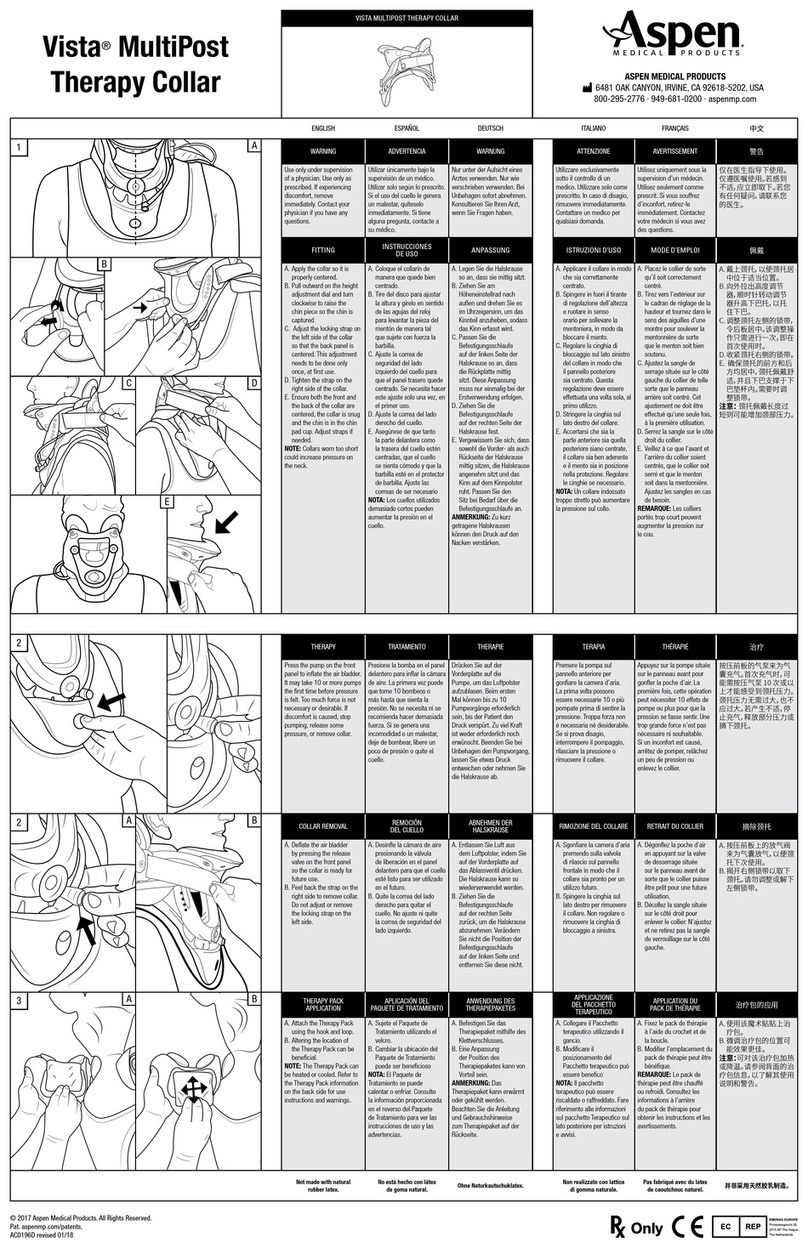

The Model 045B is sturdy, reliable

phantom for testing the imag-

ing performance of side-fire and

bi-plane probes used for trans-

rectal ultrasound imaging in prostate

brachytherapy seed implantation.

The Model 045B phantom offers a

complete solution for implement-

ing a brachytherapy QA program as

recommended by AAPM Task Group

128.1

The phantom is supplied with a water

tank for vertically coupling a trans-

ducer to the scanning membrane.

Brachytherapy needle grid QA can

be accomplished using the space

available inside the water tank as

specified by Goldstein et al.2 The tank

has two angled slots to allow the phantom to be positioned at a 30° angle which

simplifies use with floor-mounted TRUS systems. When testing table-mounted

TRUS systems, the phantom membrane can be oriented vertically. (See page 2

and 3 for images.)

The Model 045B has a series of monofilament targets that will appear as bright dots

or lines on the ultrasound image. These targets are made from monofilament nylon

wire with a diameter of 0.4 mm and a positional accuracy of ±0.2 mm. There are

also three volumetric targets. These targets are made from Zerdine that has a differ-

ent contrast relative to the background material.

CIRS is certified to ISO 13485:2016 standards. We have an in-house test facility to

measure acoustic properties of speed, attenuation and relative contrast. In addition,

two ultrasound systems are used to visually inspect each phantom. As a result,

every ultrasound phantom is subjected to rigorous testing both during manufacture

and upon completion. A Certificate of Compliance is issued with each phantom.

For further guidance on establishing a quality assurance program, you may want to

reference the accreditation programs established by the ACR and AIUM. You can

access this information at www.acr.org or www.aium.org. If additional information

is required, please call CIRS technical service at 1-800-617-1177.

1. Pfeiffer, Douglas, et al., AAPM Task Group 128: Quality assurance tests for prostate brachytherapy ultrasound systems.

Med. Phys., vol. 35 (12), pgs. 5471-5489, December 2008.

2. Goldstein, A., Yudelev, M., Sharma, R.K. and Arterbery, E. (2002), Design of Quality Assurance for Sonographic Prostate

Brachytherapy Needle Guides. Journal of Ultrasound in Medicine, 21: 947-954. doi:10.7863/jum.2002.21.9.947

Consistency Measure-

ments with the Model

045B

• Uniformity

• Depth of Penetration

• Vertical distance measurement

accuracy

• Horizontal distance measurement

accuracy

• Electronic Grid Accuracy

• Stepping Mechanism Accuracy

• Volume Measurement Accuracy

• Needle Alignment Testing

2

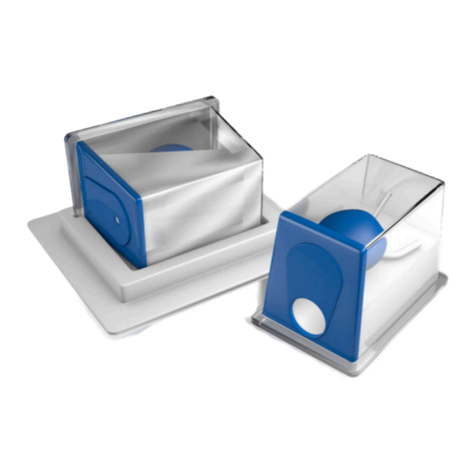

Phantom is placed vertically in water tank for testing. Tank needs to be filled with

water prior to use.

3

Phantom can be positioned at 30-degrees for compatibility with floor

mounted brachytherapy systems.

4

INSTRUCTIONS AND USE

HANDLING AND CARE

With proper care, the Model 045B will withstand years of normal use. Below are

some guidelines to follow.

The scanning surface is the most important item on the phantom to protect. It can

withstand normal scanning pressure but DO NOT press on the scanning surface

with your fingernails or any other sharp objects. If the scanning surface becomes

damaged, seal the phantom in an airtight container and IMMEDIATELY contact

RMA Request form to 757-857-0523.

The phantom may be cleaned with mild soap and water ONLY. Avoid solvent-

based, alcohol-based, or abrasive cleaning agents.

For longest life, the phantom should be cleaned after each use and stored at room

temperature in the provided zip-lock bag. The primary concern is gel desiccation

due to loss of water vapor through the membrane. In addition, the thermal stresses

associated with a freeze/thaw cycle may cause the gel to crack or damage the

housing integrity, while extreme heat may accelerate water vapor transmission

through the membrane. To minimize desiccation, always store the phantom in a

sealed zip-lock bag or an equivalent air-tight, sealed container.

Inspect your phantom regularly for signs of damage and weight loss. If any notice-

able changes to the phantom are detected, return the phantom IMMEDIATELY for

repair or replacement.

At least once a year, weigh your phantom and compare to original

weight noted on certificate of compliance. If the phantom has lost

or gained more than 1% of its original weight and you notice a dif-

ference in vertical distance measurements, or if the scan surface

appears depressed, call CIRS at (800) 617-1177.

This product contains Zerdine, a non-flowing water-based, poly-

acrylamide material which is fully sealed within the phantom housing.

Zerdine contains trace amounts of the residual monomer acrylamide

CAS#79-06-1. There are no known hazards when the phantom

is used and stored as intended. Zerdine is fully cured and will not

leak from the housing. Damage to the integrity of the housing may

expose the user to trace amounts of acrylamide monomer. The

amount is not sufficient to pose an acute health risk, but it is still

advised to wear protective gloves if handling exposed Zerdine gel

due to the potential long-term hazards of the monomer. It is also

advisable to wash hands and all surfaces with soap and water after

handling exposed Zerdine gel.

5

HANDLING AND CARE (CONTINUED)

Regulations regarding disposal of materials with trace acrylamide

monomer vary by locality. Contact your local authority for instruc-

tions. If assistance is desired in the proper disposal of this product,

including accessories and components, after its useful life, please

return to CIRS.

GENERAL GUIDELINES FOR PERFORMING MEASUREMENTS

It is recommended that all measurements be performed at the most frequently used

imaging arrangements. The importance of these tests is to make sure that system

performance remains constant over an extended period of time. Measurements

may also be used to compare the performance of various setups of the same ma-

chine or to compare different machines in a quantitative manner.

The following are general steps for imaging all targets:

• Some wires will appear as short lines rather than dots. When using the

electronic calipers, always take measurements from a point on one echo

to the same point on the next (i.e., center to center). Otherwise, errors may

be introduced.

• When assessing vertical distance measurements, DO NOT press on the

scanning surface. Pressure on the scanning surface causes the wires

to become temporarily displaced, making vertical distance measure-

ments inaccurate.

• When assessing horizontal distance accuracy, ensure that the scan plane is

perpendicular to the horizontal target group. Rotation of the probe will result

in inaccurate distances.

• Always be sure the phantom is scanned while at room temperature. A

phantom just received may be colder or hotter than room temperature de-

pending on where it was stored during shipping. Temperature affects the

speed of sound and, ultimately, the perceived measurements. The phantom

should be stored at room temperature for at least 24 hours before use to

ensure its core temperature is correct.

• The most accurate measurements will be made with the phantom 22˚C ±

1˚C (70˚F–73˚F).

6

ESTABLISHING A BASELINE

Before performing routine quality assurance measurements, establish:

1. System settings for each measurement:

System setup can have a dramatic impact on the results obtained from quality

assurance measurements. You must establish and record what system

settings should be used for each of the quality assurance tests. These

same settings should be used each time the test is performed. If not, then the

conclusions drawn may not be valid. CIRS recommends that you use the most

commonly used settings for the type of probe tested- i.e. the brachytherapy

preset values which are called a "normal" technique in the sections that

follow.

2. Baseline measurements:

The first set of measurements taken will be the baseline measurements for the

combination of system settings and phantom. Record the system settings and

phantom serial number used to acquire each measurement along with

your measurement results. On subsequent scans, refer to the baseline results

to determine if the ultrasound system has drifted to an unacceptable level. It is

each facility's responsibility to establish the magnitude of drift allowed

before corrective action is warranted.

3. Allowable deviation from baseline measurements:

The difference between the original baseline measurements and subsequent

measurement should be calculated and recorded. At some point the difference

will be large enough that some action is required (call service, replace system,

etc.). Each facility needs to determine the action level for each test. You should

refer to the user’s manual of your ultrasound scanner and note the stated

accuracies of the system’s general imaging measurements. These stated ac-

curacies may greatly influence the conclusion made when evaluating the ultra-

sound system. For example, if the measurement accuracy for your system

is 10% for distances up to 2 cm, the scanner may detect 2.0 cm as being any

where from 1.8 cm to 2.2 cm and still be functioning properly. The user is

responsible for establishing action levels.

4. Frequency of system assessment:

How often each system is evaluated is also up to each facility to determine.

CIRS recommends at least annually.

Reference the accreditation programs established by the ACR and AIUM at

www.acr.org or www.aium.org for further guidance on establishing a QA program.

TEST PROCEDURES

The following sections outline procedures for performing routine quality control tests

with the imaging targets contained within the Model 045B. The water tank should

be filled with water and phantom placed inside the tank when performing test proc-

dures. See the following references on page 7 for further test procedure details:

7

Pfeiffer, Douglas, et al., AAPM Task Group 128: Quality assurance tests for prostate brachytherapy ultrasound systems. Med.

Phys., vol. 35 (12), pgs. 5471-5489, December 2008.

Goldstein, A., Yudelev, M., Sharma, R.K. and Arterbery, E. (2002), Design of Quality Assurance for Sonographic Prostate

Brachytherapy Needle Guides. Journal of Ultrasound in Medicine, 21: 947-954. doi:10.7863/jum.2002.21.9.947

UNIFORMITY

Uniformity is defined as the ability of the machine to display echoes of the same

magnitude and depth with equal brightness on the display. This is a good test to

ensure all crystals within the transducer are functioning. Uniformity testing is per-

formed as follows:

1. Position the transducer on the scanning surface in a region with a

minimum number of targets.

2. Adjust the instrument settings (gain, TGC, output, etc.) as for a “normal”

technique. Record these settings for use on subsequent testing.

3. Align the probe so that the targets are maximized.

4. Freeze the image and obtain a hard copy.

5. Observe the general appearance of the phantom. Note if all regions at the

same depth are displayed with the same intensity across the width of the

image.

6. Record your observations.

DEPTH OF PENETRATION TESTING

Depth of penetration, also called maximum depth of visualization or sensitivity, is the

greatest distance in a phantom for which echo signals caused by scattering in the

background material can be detected on the display. The depth of penetration is

determined by the frequency of the transducer, the attenuation of the medium being

imaged and the system settings. It is measured with the aid of the “N” group wire

targets, as follows:

1. Position the transducer above the “N” Group and perpendicular to the wires.

(The wires should appear as dots, not lines).

2. Adjust the instrument settings (gain, TGC, output, etc.) as for a “normal”

technique. Record these settings for use on subsequent testing.

3. Align the probe so that all the vertical targets are displayed at their maximum

intensity level.

4. While actively scanning, look to see where the scatterers within the background

material disappear. Be careful not to confuse electronic noise with the back

ground scatterers. Electronic noise will move; scatterers will remain stationary.

5. Freeze the image.

6. With electronic calipers measure the distance between the scanning surface

and the last identifiable echo due to scattering. Note: The wires may be visible

even though the scatterers are not. Remember to measure the distance to the

scatterers not the last visible wire.

8

7. Record this distance on a record sheet and compare with baseline depth.

VERTICAL AND HORIZONTAL DISTANCE ACCURACY- USING ELECTRONIC CALIPERS

If the displayed grid does not line up with the N-shaped target group or you want

a more precise measure of distance accuracy, electronic calipers may be used.

Vertical distance is defined as the distance along the axis of the beam. Horizontal

distance is defined as the distance along the length of the transducer. Distances

are used to measure areas, volumes, depths, and sizes of objects. The vertical ar-

ray of targets at column B and F on the phantom diagram allow one to assess the

accuracy of the vertical measurements while the horizontal array of targets at row 1

through 5 assess horizontal measurement accuracy. For bi-plane probes, the cross-

ing wires in the z-axis can also be used for horizontal measurements and provide

spacing from 0.5 cm to 5.0 cm.

1. Adjust the instrument setting (gain, TGC, output, etc.) as for a “normal” tech-

nique. Record these settings for use on subsequent testing.

2. Align the probe so the N-shaped target group is maximized.

3. Freeze the image.

4. Using electronic calipers, measure the distances between two wires at various

depths or align the echoes to the ultrasound system display markers for com-

parison.

5. Record measurements.

6. Compare measured values with baseline distances.

7. Repeat steps using horizontal targets in N-shaped group.

VERTICAL AND HORIZONTAL DISTANCE ACCURACY

Vertical distance is defined as the distance along the axis of the beam while

horizontal distance is defined as the distance along the length of the transducer.

Distances are used to measure areas, volumes, depths, and sizes of objects. Using

the “N” target group, the vertical array of targets at column B and F on the phan-

tom diagram allow one to assess the accuracy of the vertical measurements while

the horizontal array of targets at row 1 through 5 assess horizontal measurement

accuracy. For bi-plane probes, the crossing wires in the z-axis can also be used for

horizontal measurements and provide spacing from 0.5 cm to 5.0 cm.

For the most precise assessment of vertical and horizontal distance measurement

accuracy, used the electronic calipers as follows:

1. Adjust the instrument setting (gain, TGC, output, etc.) as for a “normal” tech-

nique. Record these settings for use on subsequent testing.

2. Align the probe so the N-shaped target group is maximized.

3. Freeze the image.

9

VERTICAL AND HORIZONTAL DISTANCE ACCURACY (CONTINUED)

4. Using electronic calipers, measure the distances between two wires at various

depths or align the echoes to the ultrasound system display markers for com-

parison.

5. Record measurements.

6. Compare measured values with baseline distances.

7. Repeat steps using horizontal targets in N-shaped group.

ELECTRONIC GRID ACCURACY

One important aspect for any brachytherapy procedure is accurate placement of

seeds within the prostate. An integral part of seed placement and treatment plan-

ning is the accuracy of the distances measured. By aligning this grid to the “N”

target of the phantom, users can perform a quick check vertical and horizontal

distance accuracy as follows:

1. Adjust the instrument setting (gain, TGC, output, etc.) as for a “normal” tech-

nique. Record these settings for use on subsequent testing.

2. Align the probe so the N-shaped target group is maximized.

3. Secure your transducer and position the stepping/stabilization unit accordingly.

For ease of alignment you may want to place the front surface of the phantom

in contact with the needle template. Adjust the probe/phantom position until

the targets are aligned with the displayed grid. It may be easiest to align the

center target with the center-displayed target and then try to align the rest of

the grid.

4. Proper alignment is achieved when the displayed grid is superimposed on wire

target echoes. The wires may appear larger or smaller than the displayed grid

dots. If the targets appear larger, try to align the centers of the targets with the

displayed grid dots. Depending on the manufacturer of your brachytherapy

system and ultrasound machine, Row 1 on the phantom may or may not repre-

sent Row 1 on the displayed grid. If you have difficulty aligning the targets

with the displayed grid, you can assess horizontal and vertical distance accu-

racy by using the electronic calipers.

5. Record results.

STEPPING MECHANISM ACCURACY

Just as vertical and horizontal distance measurements are important for accurate

seed placement in the x-axis and y-axis, the condition of the stepping mechanism is

critical to accurate seed placement in the z-axis. Perpendicular to the N-shaped tar-

get group are five wires all at the same distance from the transducer, but separated

by 0.5 cm and 1.0 cm in the z-axis.

10

STEPPING MECHANISM ACCURACY (CONTINUED)

1. Adjust the instrument setting (gain, TGC, output, etc.) as for a “normal” tech-

nique. Record these settings for use on subsequent testing.

2. Align the probe so targets are maximized.

3. Insert the transducer towards the back of the scanning cavity and align the

beam with the crossing wire number 6 as indicated on the side of the phantom.

This target will appear as a short line in row 4 above the transducer. Once this

target is visualized, secure the stepping mechanism in place.

4. The next crossing wire (#5) is exactly 1.0 cm from wire #6 in the z-axis. Using

the stepping mechanism, retract the transducer by 1 cm (in most cases this is

two “clicks” on the stepping mechanism). Wire #5 will now be visible if the

mechanism is working. If no wire is visible, the stepper has either retracted the

transducer too much or too little. Manual manipulation of the transducer for-

ward and backward to the target may give you some approximation as to the

degree of error. Note: The accuracy of this assessment is dependent on the

width of the ultrasound beam.

5. Record results.

6. Repeat for various retraction distances as specified in your QA plan.

VOLUME MEASUREMENT ACCURACY

Dose mapping is heavily dependent on accurate assessment of prostate volume.

The Model 045B contains three different calibrated test objects specifically de-

signed to assess volume measurement accuracy. The volume of each test object is

physically measured with a tolerance of ± 0.5cc using Archimedes Principle before

insertion within the phantom. The volumes are recorded on the accompanying

certi-fication sheet. Perimeters which are estimated from the measured volume with

the equations listed below, are also provided. Perimeters stated in the certifications

are only intended to be used nominally. The small and medium volumes are

spherical, but the large volume is egg shaped as seen in figures 1 and 2.

Figure 1 Sphere volumes and perimeters (see certification sheet for actual values in your phantom)

END VIEW

SMALL SPHERE LAYOUT

R9.55mm

END VIEW

MEDIUM SPHERE LAYOUT

R12.7mm

=

4

3!≈3.6

=

4

3!≈8.6

=

2

3!+≈20

=

4

3!≈3.6

=

4

3!≈8.6

=

2

3!+≈20

11

Figure 2 Egg volume and perimeter (see certification sheet for measured values in your phantom)

LARGE EGG LAYOUT

a=14.7mm

b=29.5mmc=14.7mm

=

4

3!≈3.6

=

4

3!≈8.6

=

2

3!+≈20

Volume measurements are performed as follows:

1. Adjust the instrument setting (gain, TGC, output, etc.) as for a “normal” tech-

nique. Record these settings for use on subsequent testing.

2. Align the probe so targets are maximized.

3. Retract the probe as far as possible. If the probe is still within the phantom,

move the phantom away from the needle template until only the tip of the trans-

ducer is inside the cavity.

4. Rotate the probe 60 degrees clockwise or counterclockwise depending on what

size mass you wish to visualize.

5. Step the transducer forward until the mass is in view.

6. The volume of each test object should be computed using the methods/soft-

ware provided with the ultrasound system or as performed on a patient.

7. Record measurements.

8. Repeat steps for each volume within phantom.

VOLUME MEASUREMENT ACCURACY (CONTINUED)

12

NEEDLE ALIGNMENT TEST

Needle alignment testing of the brachytherapy system is important to ensure

potential accuracy in guiding radioactive seeds respective of the overlay grid on the

sonographic image.

1. Fill the water tank with water. Remove the phantom from the water tank or

position the transrectal probe into an area that only images the water bath.

2. The transrectal probe needs to be arranged vertically so that needles are held

parallel to the probe’s long axis.

3. Adjust the system settings as for a “normal” technique. Record these settings

to use on subsequent testing.

4. Place brachytherapy needles through the brachytherapy template grid. The

needles should pass into the water bath.

5. Measurements are performed to assess the displacement between echoes

of the needles and the on-screen grid. Use the caliper tools on the imaging

system to measure the difference between the template position indicated on

the sonographic image and the needle “flash” or echo.

6. Record measurements. Record template grid positions of needles to use on

subsequent testing.

7. Compare measured values with baseline or clinically acceptable deviations.

13

Brachytherapy

QA Phantom Model 045A

TOP

FRONT

LEFT RIGHT

20 cc

4 cc

9 cc

20 cc

9 cc

4 cc

0.5 cm

1 cm

0.5 cm

1 cm

1 cm

Brachytherapy

QA Phantom Model 045A

TOP FRONT

LEFT

RIGHT

20 cc

4 cc

9 cc

20 cc

9 cc

4 cc

0.5 cm

1 cm

0.5 cm

1 cm

1 cm

Brachytherapy

QA Phantom Model 045B

TOP FRONT

LEFT RIGHT

20 cc

4 cc

9 cc

20 cc

9 cc

4 cc

0.5 cm

1 cm

0.5 cm

1 cm

1 cm

Brachytherapy

QA Phantom Model 045A

TOP FRONT

LEFT

RIGHT

20 cc

4 cc

9 cc

20 cc

9 cc

4 cc

0.5 cm

1 cm

0.5 cm

1 cm

1 cm

Front view shows the N wire target group while the side views show the Cross Axis

wire targets.

Volumes are rounded to the nearest cubic centimeter. Please refer to phantom certi-

fication for measured volume.

PHANTOM HOUSING

Material 1/4” White PVC

Outer Dimensions 14 x 11 x 7.5 cm

SCANNING SURFACE

Material Saran-based laminate

WATER TANK

Material 3/16” White ABS

BACKGROUND MATERIAL

Material Zerdine

Speed of Sound 1540 m/s

Other Compatible with harmonic imaging

WIRE TARGETS

Material Nylon monofilament

Diameter 0.10 mm

TARGET LAYOUT

SPECIFICATIONS

Scan surface

Scan surface Scan surface

14

“N” GROUP

Number of targets 13

Depth range 2.0 cm to 6.0 cm

Vertical distance between targets 10.0 mm

Horizontal distance between targets 10.0 mm

CROSS-AXIS GROUP

Number of targets 5

Depth Row 3

Horizontal distance between targets 5.0 mm, 10.0 mm

CALIBRATED VOLUMES

Material Zerdine

Speed of Sound 1540 m/s

Attenuation Coefficient 0.5 dB/cm-MHz

Contrast ~+9 dB

Nominal Volumes 4 cc (S), 9 cc (M), 20 cc (L)

ACCESSORIES

Certificate of Compliance, Water Tank

Model 045B User Guide & Technical Information, QA Worksheet

NOTES

All dimensions without tolerances are nominal

All measurements made at 22˚C ± 1˚C

ZERDINE®

The Model 045B is constructed from a patented, solid elastic material developed

at CIRS called Zerdine. Zerdine, unlike other phantom materials on the market, is

not affected by changes in temperature. It can be subjected to boiling or freezing

conditions without sustaining significant damage. Zerdine is also more elastic than

other materials and allows more pressure to be applied to the scanning surface

without subsequent damage to the material. At normal room temperatures, Zerdine

will accurately simulate the ultrasound characteristics found in human liver tissue.

Specific proprietary fabrication procedures enable close control over the homoge-

neity of Zerdine and the reliability of its acoustic characteristics from batch to batch.

The speed of sound in Zerdine can be adjusted between 1430 and 1650 meters

per second. The acoustic attenuation can be adjusted between 0.05 dB/cm-MHz

and 1.50 dB/cm-MHz. The relation between the acoustic attenuation, A, and the

acoustic frequency, F, is of the form A = AoFnwith values of the power coefficient,

n, in the range of 0.8 to 1.10, indicating the proportional increase of the acoustic

attenuation with frequency. Backscatter characteristics can be adjusted through

the addition of predetermined amounts of calibrated scatter material. Zerdine can

be molded into very intricate shapes, and the material can be cured in layers allow-

ing the production of “multi-tissue” phantoms. Zerdine, like most other phantom

materials, will desiccate if unprotected; thus, all phantoms must be stored properly.

If stored in the case provided, your phantom should last many years.

15

WARRANTY

All standard CIRS products and accessories are warranted by CIRS against defects

in material and workmanship for a period as specified below. During the warranty

period, the manufacturer will repair or, at its option, replace, at no charge, a product

containing such defect provided it is returned, transportation prepaid, to the manu-

facturer. Products repaired in warranty will be returned transportation prepaid.

There are no warranties, expressed or implied, including without limitation any im-

plied warranty of merchantability or fitness, which extend beyond the description on

the face hereof. This expressed warranty excludes coverage of, and does not pro-

vide relief for, incidental or consequential damages of any kind or nature, including

but not limited to loss of use, loss of sales or inconvenience. The exclusive remedy

of the purchaser is limited to repair, recalibration, or replacement of the product at

manufacturer’s option.

This warranty does not apply if the product, as determined by the manufacturer,

is defective because of normal wear, accident, misuse, or modification.

NON-WARRANTY SERVICE

If repairs or replacement not covered by this warranty are required, a repair estimate

will be submitted for approval before proceeding with said repair or replacement.

RETURNS

If you are not satisfied with your purchase for any reason, please contact Customer

Service or your local distributor prior to returning the product. Visit https://www.

cirsinc.com/distributors/ to find your local distributor. Call 800-617-1177, email

attempt to remedy the issue via phone or email as soon as possible. If unable to

correct the problem, a return material authorization (RMA) number will be issued.

Non-standard or “customized” products may not be returned for refund or ex-

change unless such product is deemed by CIRS not to comply with documented

order specifications. You must return the product to CIRS within 30 calendar days

of the issuance of the RMA. All returns should be packed in the original cases and

or packaging and must include any accessories, manuals and documentation

that shipped with the product. The RMA number must be clearly indicated on the

outside of each returned package. CIRS recommends that you use a carrier that

offers shipment tracking for all returns and insure the full value of your package so

that you are completely protected if the shipment is lost or damaged in transit. If

you choose not to use a carrier that offers tracking or insure the product, you will be

responsible for any loss or damage to the product during shipping. CIRS will not be

responsible for lost or damaged return shipments. Return freight and insurance is to

be pre-paid.

WITH RMA NUMBER, ITEMS MAY BE RETURNED TO:

CIRS

Receiving

900 Asbury Ave,

Norfolk, Virginia, 23513 USA

PRODUCT WARRANTY PERIOD

Model 045B - Brachytherapy QA

Phantom 48 Months

16

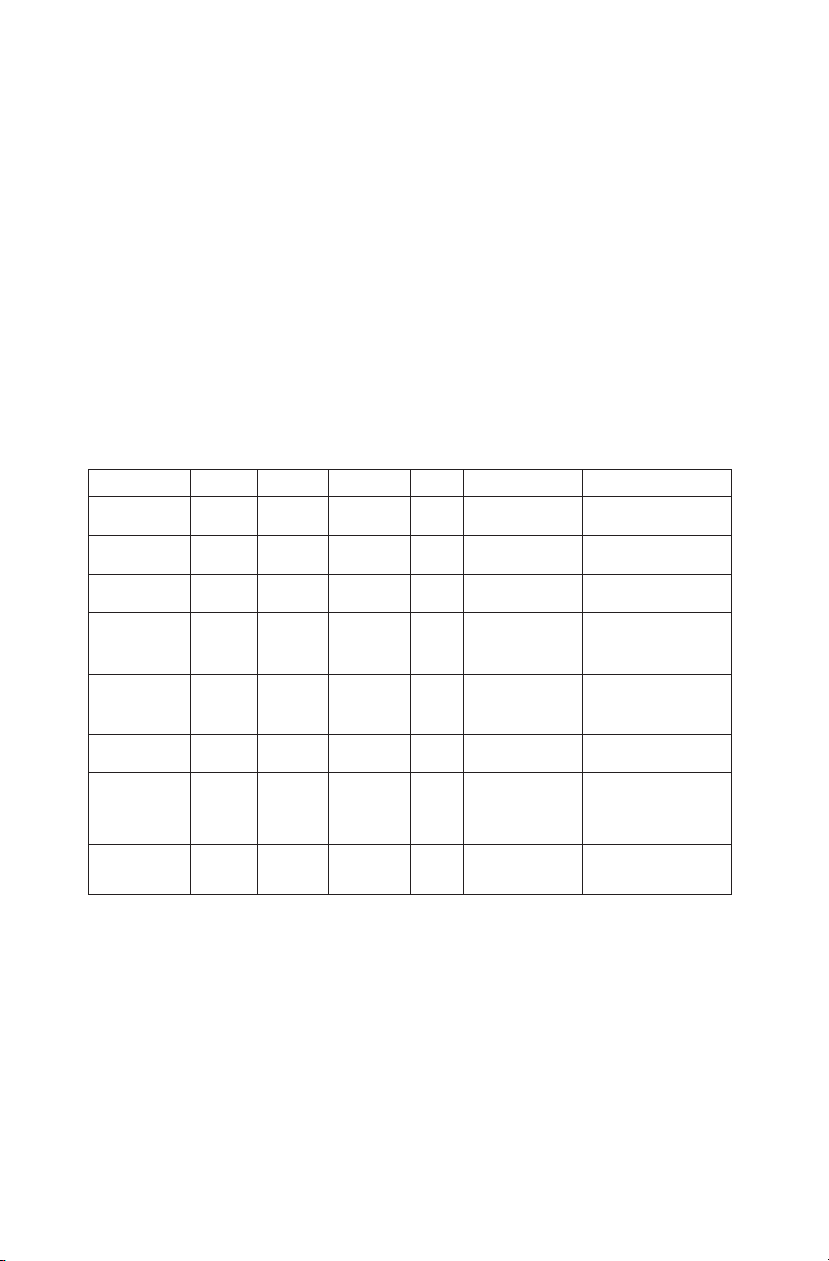

APPENDIX 1: QUALITY ASSURANCE RECORD FOR MODEL 045B

MODEL 045B

BRACHYTHERAPY QA PHANTOM

QUALITY ASSURANCE RECORD

Parameter Actual

Value

Baseline

Value

Measured

Value Drift Corrective

Action Comments

Uniformity

Depth of

Penetration

Small Volume

Vertical and

Horizontal

Distance

Electronic

Grid

Accuracy

Stepping

Mechanism

Volume

Measurement

Accuracy

Needle

Alignment

Test

Miscellaneous Checks

Check for damage on the following items: (space provided for comments)

· Transducer (cord, housing, & face)_______________________________________

· System (cord, knobs, wheels)____________________________________________

Clean the following items: (Space provided for comments)

· Transducer__________________________________________________________

· Monitor_____________________________________________________________

· Keyboard & Knobs____________________________________________________

· Air lters____________________________________________________________

· Misc._______________________________________________________________

Directions for Use:

1. Use this form to plan and record your quality assurance program.

2. Use one form for each transducer.

3. For Baseline measurements ll out system settings and baseline measurements.

4. Use comments section to indicate changes in system settings for a particular measurement and other

observations.

5. Use a photocopy of baseline form for subsequent test results (one for each test date).

MODEL 045A

BRACHYTHERAPY QA PHANTOM

QUALITY ASSURANCE RECORD

Name:_____________________ Date:________________________ Phantom Info:

________________

Baseline System I.D.___________________

____________________________

Date:______________________ Transducer I.D.________________

____________________________

System Settings

Overall Gain:________________ Post Processing:________________ Depth of

Field:________________

TGC Settings:_______________ Dynamic Range:________________

Power:______________________

Focal Points:________________ Preprocessing:_________________

Other:_______________________

Parameter

Actual

Value

Baseline

Value

Measured

Value

Drift

Corrective

Action

Comments

Vertical

Distance

Horizontal

Distance

Small

Volume

Medium

Volume

Large

Volume

Stepping

Mechanism

Uniformity

Other

17

©

2020 Computerized Imaging Reference Systems, Inc. All rights

reserved.

Specifications subject to change without notice.

Publication: 045B UG 102620

Computerized Imaging Reference Systems, Inc. has

been certified by UL DQS Inc. to (ISO) 13485:2016.

Certificate Registration No.10000905-MP2016.

COMPUTERIZED IMAGING

REFERENCE SYSTEMS, INC.

900 Asbury Ave

Norfolk, Virginia 23513 USA

Toll Free: 800.617.1177

Tel: 757.855.2765

Fax: 757.857.0523

Email [email protected]

www.cirsinc.com

Technical Assistance

1.800.617.1177

This manual suits for next models

1

Table of contents

Other Cirs Medical Equipment manuals