Cirs ATS539 User manual

USER GUIDE

U

L

T

R

A

S

O

U

N

D

Q

U

A

L

I

T

Y

A

S

S

U

R

A

N

C

E

Multi-Purpose Phantom

Model ATS539

900 Asbury Ave • Norfolk, Virginia 23513 • USA • Tel: 757-855-2765 • WWW.CIRSINC.COM

TABLE OF CONTENTS

1 OVERVIEW

1

2 INSTRUCTIONS FOR USE

2

HANDLING AND CARE

��������������������������������������������������������������� 2

GENERAL GUIDELINES FOR PERFORMING MEASUREMENTS

������������������������� 2

ESTABLISHING A BASELINE

��������������������������������������������������������� 3

3 TESTING PROCEDURES

4

UNIFORMITY TESTING

��������������������������������������������������������������� 4

DEPTH OF PENETRATION

������������������������������������������������������������ 4

BEAM PROFILE/FOCAL ZONE/LATERAL RESPONSE WIDTH

��������������������������� 5

VERTICAL DISTANCE MEASUREMENT

������������������������������������������������ 7

HORIZONTAL DISTANCE MEASUREMENT

��������������������������������������������� 8

AXIAL AND LATERAL RESOLUTION

��������������������������������������������������� 9

ELEVATIONAL RESOLUTION

��������������������������������������������������������� 10

GRAYSCALE CONTRAST SENSITIVITY

����������������������������������������������� 11

LOW-CONTRAST TARGET DETECTABILITY

������������������������������������������� 12

DEAD ZONE ASSESSMENT

���������������������������������������������������������� 13

4 SPECIFICATIONS

15

5 WARRANTY

18

6 APPENDIX: QUALITY ASSURANCE RECORD FOR MODEL ATS539

19

1

OVERVIEW

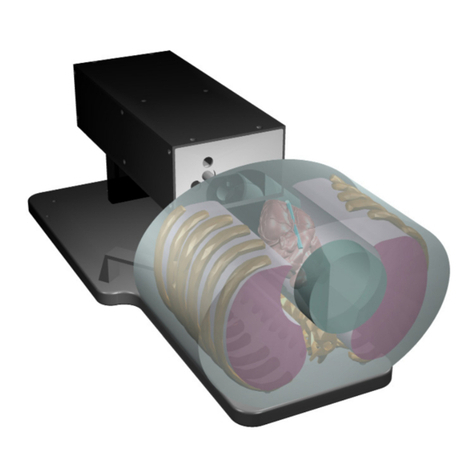

The Model ATS539 Multipurpose

phantom is an easy, comprehensive

means of evaluating imaging systems

over most clinical imaging frequen-

cies (approximately 2-20 MHz).

The phantom is designed with a

combination of monolament line tar-

gets for distance measurements and

tissue mimicking target structures of

varying sizes and contrasts. Cystic-

like target structures are positioned

in-line vertically, thereby permitting an

entire target group to be displayed in

one view. Due to the acoustic similar-

ity of the background material and

the target structures, artifacts caused

by distortion, shadowing or enhance-

ment have been eliminated. Six gray

scale targets ranging in contrast from

+15 to -15 dB are provided to evalu-

ate the system's displayed dynamic

range and gray scale processing

performance. All ATS urethane phan-

toms are guaranteed for the useful

life of the phantom, dened as 10

years.

CIRS is certied to ISO 13485:2016 standards. We have an in-house test facility to

measure acoustic properties of materials. In addition, ultrasound imaging systems

are used to inspect each phantom. Every ultrasound phantom that CIRS distributes

has passed thorough testing during manufacture and completion to ensure the

highest quality product available. A Certicate of Compliance is issued with each

phantom.

Additional guidance on establishing a quality assurance program can be found in

the accreditation programs established by the ACR and AIUM at www.acr.org or

www.aium.org.

Key Tests with Model

ATS539

• Uniformity

• Depth of Penetration

• Beam Prole/ Focal Zone/

Lateral Response Width

• Vertical Distance Measure-

ment

• Horizontal Distance Measure-

ment

• Axial and Lateral Resolution

• Elevational Resolution

• Contrast Resolution

• Grayscale Contrast Sensitivity

• Dead Zone Assessment

For more information on these tests, see

"Testing Procedures" starting on page 5

2

INSTRUCTIONS FOR USE

HANDLING AND CARE

For best results the phantom should be kept clean at all times and stored at room

temperature. In particular a build-up of dried coupling gel on the scan surface

should be avoided. The phantom may be cleaned with warm water using a lint free

cloth. Particularly stubborn stains and dirt may be removed with a mild household

cleaner. The use of petroleum solvents should be avoided since they may adversely

react with the rubber-based material.

GENERAL GUIDELINES FOR PERFORMING MEASUREMENTS

To evaluate the performance of diagnostic ultrasound imaging systems, the Model

ATS539 has a combination of monolament line targets and tissue-mimicking cylin-

drical targets of varying sizes and contrasts.

The following are general steps for imaging all targets:

• Some wires will appear as short lines rather than dots. When using the

electronic calipers, always take measurements from a point on one echo

to the same point on the next (i.e., center to center). Otherwise, errors may

be introduced.

• If a convex probe is used, center the target within the scan plane in order to

minimize degradation and distortion introduced on the outer edges of the

probe.

• When assessing vertical distance measurements, DO NOT press on the

scanning surface. Pressure on the scanning surface causes the wires

to become temporarily displaced, making vertical distance measure-

ments inaccurate.

• When assessing horizontal distance accuracy, ensure that the scan plane is

perpendicular to the horizontal target group. Rotation of the probe will result

in inaccurate distances.

• Always be sure the phantom is scanned while at room temperature. A

phantom just received may be colder or hotter than room temperature de-

pending on where it was stored during shipping. Temperature affects the

speed of sound and, ultimately, the perceived measurements. The phantom

should be stored at room temperature for at least 24 hours before use to

ensure its core temperature is correct.

• The most accurate measurements will be made with the phantom 22˚C ±

1˚C (70˚F–73˚F).

3

ESTABLISHING A BASELINE

Before performing routine quality assurance measurements, establish:

1. System settings for each measurement:

System setup can have a dramatic impact on the results obtained from quality as-

surance measurements. You must establish and record what system settings

should be used for each of the quality assurance tests. These same settings

should be used each time the test is performed. If not, then the conclusions

drawn may not be valid. CIRS recommends that you use the most commonly

used settings for the type of probe tested- i.e. the liver preset values for an abdominal

probe- which are called a "normal" technique in the sections that follow.

2. Baseline measurements:

The rst set of measurements taken will be the baseline measurements for the

combination of system settings and phantom. Record the system settings and

phantom serial number used to acquire each measurement along with

your measurement results. On subsequent scans, refer to the baseline results

to determine if the ultrasound system has drifted to an unacceptable level. It is

each facility's responsibility to establish the magnitude of drift allowed

before corrective action is warranted.

3. Allowable deviation from baseline measurements:

The difference between the original baseline measurements and subsequent

measurement should be calculated and recorded. At some point the difference

will be large enough that some action is required (call service, replace system,

etc.). Each facility needs to determine the action level for each test. You should

refer to the user’s manual of your ultrasound scanner and note the stated

accuracies of the system’s general imaging measurements. These stated ac-

curacies may greatly inuence the conclusion made when evaluating the ultra-

sound system. For example, if the measurement accuracy for your system

is 10% for distances up to 2 cm, the scanner may detect 2.0 cm as being any

where from 1.8 cm to 2.2 cm and still be functioning properly. The user is

responsible for establishing action levels.

4. Frequency of system assessment:

How often each system is evaluated is also up to each facility to determine.

CIRS recommends at least annually.

Reference the accreditation programs established by the ACR and AIUM at

www.acr.org or www.aium.org for further guidance on establishing a QA program.

4

TESTING PROCEDURES

The following sections outline procedures for routine quality control tests with the

Model ATS539. It may be useful to refer to the target map, shown in the Specica-

tions section of page 14, when reviewing these procedures.

UNIFORMITY TESTING

Uniformity is dened as the ability of the machine to display echoes of the same

magnitude and depth with equal brightness on the display. This is a good test to

ensure all crystals within the transducer are functioning.

1. Apply coupling gel to the scanning surface or ll the water trough with tap water.

2. Position the transducer on the scanning surface in a region with a minimum

number of targets.

3. Adjust the instrument settings (gain, TGC, output, etc.) as for a “normal”

technique. Record these settings for use on subsequent testing.

4. Align the probe so that the targets are maximized.

5. Freeze the image and obtain a hard copy.

6. Observe the general appearance of the phantom. Note if all regions at the

same depth are displayed with the same intensity across the image.

7. Record your observations.

DEPTH OF PENETRATION TESTING

The ability of an imaging system to detect and display weak echoes from small ob-

jects located at specied depths (penetration) is referred to as sensitivity. Clinically,

weak reecting echoes are commonly produced from internal structures of organs.

Denition of these structures can be extremely important in the interpretation of the

ultrasound ndings. Sensitivity can be affected by the pulser/receiver section of the

system, the degree of focusing of the transducer, attenuation of the medium, depth

and shape (geometry) of the reecting object, and electromagnetic interference from

the local surroundings. Testing is performed as follows:

1. Place the phantom on a clean, at surface with #1 scanning surface positioned

for use

2. Apply an adequate amount of low viscosity gel or water to the scan surface. If

water is used, ll the scanning well slowly to avoid introduction of air bubbles.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline values

for "normal" scanning. If the bottom of the phantom is seen, lower the gain

settings until the bottom of the image goes entirely black. Record these settings

on the quality assurance record. These settings should be used for subsequent

testing.

5

Note: In addition to the above, this test should also be performed with output levels

set at the highest and lowest settings. This enables any changes in output to be

more easily detected.

4. Position the transducer over the 8 mm group of anechoic targets.

5. Freeze image and obtain a hard copy.

6. Examine the image to determine the last or deepest target structure displayed.

Using the electronic calipers or the timing markers measure the depth of this

target.

7. Document the depth measurement on the quality assurance record.

Results:

The depth of penetration should not shift by more than 1.0 cm, when using this

phantom at same instrument settings and transducer. If a discrepancy occurs cor-

rective action should be considered by the individual Ultrasound Department.

BEAM PROFILE, FOCAL ZONE AND LATERAL RESPONSE WIDTH

The focal zone is the region surrounding the focal point in which the intensity and

the lateral resolution is the greatest. Clinically, structures examined within the focal

zone will provide the best diagnostic information obtainable. The focal zone can be

affected by changes in the pulsing/receiving section of the imaging system or dam-

age to the transducer. Testing is performed as follows:

1. Place the phantom on a clean, at surface with #1 scanning surface positioned

for use.

2. Apply an adequate amount of low viscosity gel or water to the scan surface. If

water is used, ll the scanning well slowly to avoid introduction of air bubbles.

6

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline

values for "normal" scanning. If the bottom of the phantom is seen,

adjust the gain settings until image goes entirely black. Record these settings

on the quality assurance record. These settings should be used for subsequent

testing.

4. Position the transducer over the vertical group of line targets on the phantom,

until a clear image is obtained. Freeze the display and obtain a hard copy.

NOTE: A line rather than a dot is produced on the display. The length of the line is

indicative of the width of the beam. Therefore, targets inside the focal zone form a

shorter line than those outside of the focal zone. Adjustments in the gain settings

will change the length of the line targets displayed.

5. For a variable focused transducer, scans with several different focal zone

settings should be performed. Dynamically focused transducers may not

display changes in the width of the line targets. However a change in the

intensity can be observed upon adjustment of the transmitting focus of the

transducer.

6. Using the hard copy, draw a line connecting the ends of the echoes received

from the line targets (both sides), the line should form a smooth curve. This will

illustrate the shape of the sound beam. Now locate the narrowest portion,

this is the focal zone. Measure the width of the beam and the depth at this

point.

7. Document the depth of the focal zone and the measurement of the focal width

on the quality assurance record.

Results:

The location of the focal zone should agree with the manufacturer's specica-

tions and should not change with time. This applies to both xed and dynamically

focused systems. If changes occur corrective action should be considered.

7

VERTICAL DISTANCE MEASUREMENTS

Vertical distance measurements obtained along the axis of the sound beam. The

accurate representation of the size, depth and volume of a structure is a critical

factor in a proper diagnosis. Most imaging systems use depth markers and/or

electronic calipers to obtain these measurements. The phantom is scanned and a

distance measurement obtained using the timing markers and/or electronic cali-

pers. The resulting measurement is then compared to the known distance between

the line targets in the phantom. The accuracy of vertical distance measurements is

dependent upon the integrity of the timing circuitry of the imaging system. Testing is

performed as follows:

1. Place the phantom on a clean, at surface with scanning surface #1 positioned

for use

2. Apply an adequate amount of low viscosity gel or water to the scan surface. If

water is used, ll the scanning well slowly to avoid introduction of air bubbles.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline values

for "normal" scanning. If the bottom of the phantom is seen, adjust the

gain settings until the image goes entirely black. Record these settings on the

quality assurance record. These setting should be used for subsequent testing.

4. Position the transducer over the vertical group of line targets until a clear image

is obtained. Freeze the display.

5. Using the electronic calipers or the timing markers measure the greatest

distance that can be clearly imaged between line targets.

6. Document the measurement obtained on the quality assurance record.

Results:

Vertical Spacing: 1.0 cm center to center ± 0.1 mm

If a discrepancy occurs which is greater than 1.0 mm, corrective action should be

considered by the individual Ultrasound Department.

8

HORIZONTAL DISTANCE MEASUREMENTS

Horizontal distance measurements are obtained perpendicular to the axis of the

sound beam. Proper diagnosis is dependent upon the accurate representation of

the size and volume of a structure being examined. Most imaging systems use

distance markers and/or electronic calipers to obtain these measurements. The

phantom is scanned and a distance measurement obtained. The resulting mea-

surement is then compared to the known distance in the phantom. The accuracy

of the horizontal distance measurements is dependent upon the integrity of the

transducer, the output intensity and the resolution of the imaging system. Testing is

performed as follows:

Note: The Model ATS539 Multipurpose phantom provides two scanning surfaces

used to evaluate horizontal measurement calibration. Linear array scanning sys-

tems should use #1 scanning surfaces. Sector scanning systems should use #3

scanning surfaces.

1. Place the phantom on a clean, at surface

2. Apply an adequate amount of low viscosity gel or water to the scan surface. If

water is used, ll the scanning well slowly to avoid introduction of air bubbles.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline values

for "normal" scanning. If the bottom of the phantom is seen, adjust

the gain settings until the image goes entirely black. Record these settings

on the quality assurance record. These settings should be used for subsequent

testing.

4. Position the transducer over the horizontal group of line targets until a clear

image is obtained. Freeze the image.

5. Using the electronic calipers or the timing markers measure the greatest

distance that can be clearly imaged between line targets displayed.

Note: Some sector scanners have distance markers on the outside edges of the

sector image with no other indicators available. Hand-held calipers must be used

for distance measurements within the

image on the monitor.

6. Document all of the measurements

on the quality assurance record.

Results:

Interval Spacing: 2.0 cm ± 1 mm

Depths: 5.0 cm ±.1 mm (Scan surface

#1) 5.0 cm ±.1 mm (Scan surface #3)

9

AXIAL AND LATERAL RESOLUTION TESTING

Resolution is the minimum reector separation between two closely spaced objects

which can be imaged separately. If a system has poor resolution capabilities, small

structures lying close to each other will appear as one image, causing improper

interpretation of the ultrasound ndings.

Resolution along the axis of the sound beam is referred to as Axial Resolution. Axial

Resolution is affected by the pulsing section of the imaging system and the condi-

tion of the transducer.

Resolution perpendicular to the axis of the sound beam is termed Lateral Resolu-

tion. Lateral Resolution is dependent upon the beam width, increased beam width

will reduce the Lateral Resolution.

The Model ATS539 provides four scanning surfaces to evaluate axial-lateral resolu-

tion at four given depths. Target locations in the phantom are referenced from the

center of the array at target point 5.

The line targets are spaced at 5.0, 4.0, 3.0, 2.0 and 1.0 mm intervals both axially

and laterally. The last point of the axial array target group is also the rst target point

in the lateral array group. Testing is performed as follows:

1. Place the phantom on a clean, at surface with scanning surface #1 positioned

for use.

2. Apply an adequate amount of low viscosity gel or water to the scan surface. If

water is used, ll the scanning well slowly to avoid introduction of air bubbles.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline values

for "normal" scanning. If the bottom of the phantom is seen, adjust the

gain settings until image goes entirely black. Record these settings on the

quality assurance record. These settings should be used for subsequent

testing.

4. Position the transducer over the axial-lateral resolution group of line targets on

the phantom until a clear image is obtained. Freeze this image.

5. Examine the image to determine if all of the line targets within the group are

clearly displayed as separate target points. Record the closest spaced target

points which can be imaged (refer to specication drawing). Obtain a hard

copy of the display.

6. Document all observations made on the quality assurance record.

7. Repeat the above procedure for the remaining three depths, using scanning

surfaces #2, #3, and #4.

10

AXIAL AND LATERAL RESOLUTION TESTING

Results:

The system's ability to resolve the array targets at all four depths should remain

consistent from week to week when using the same instrument settings and the

Model ATS539 phantom. Compare the test results obtained with a baseline or

previous test. If the current image demonstrates changes in the system's ability to

resolve these targets, corrective action should be considered.

ELEVATIONAL TESTING

A full characterization of system resolution requires measurement of elevational res-

olution, or slice thickness. Slice thickness is typically much coarser than axial and

lateral resolution as most ultrasound transducer arrays are mechanically focused in

the thickness dimensions.

Two methods are described for measuring elevational resolution. The rst method,

rst described by Skolnick(1), uses the vertical wire targets as follows:

1. Apply coupling gel to the scanning surface or ll the water trough with tap

water.

11

2. Adjust the instrument settings (gain, TGC, output, etc.) as for a “normal” tech-

nique. Record these settings for use on subsequent testing

3. Orient the transducer to image the length of the vertical target wires, taking

care to adjust the tilt so that the wires are lined up in a vertical column.

4. Rotate the transducer 45° so that only a partial length of the wires is now vis-

ible.

5. Freeze the image and measure the length of each wire segment with the elec-

tronic calibers.

6. Record the measurements.

GRAYSCALE CONTRAST SENSITIVITY

Gray scale or gray scale processing uses the amplitude of the echoes received to

vary the degree of brightness of the displayed image. The adjustment of the echo

signal required to go from a just noticeable (lowest gray scale level) echo to the

maximum echo brightness is referred to as the displayed dynamic range. Clinically,

gray scale processing and displayed dynamic range allow echoes of varying de-

grees of amplitude to be displayed in the same image.Testing of grayscale contrast

is performed as follows:

1. Place the phantom on a clean, at surface with scan surface #4 positioned for

use.

2. Apply an adequate amount of low viscosity gel or water to the scan surface. If

water is used, ll the scanning well slowly to avoid introduction of air bubbles.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline values

for "normal" scanning. If the bottom of the phantom is seen, adjust the

gain settings until image goes entirely black. Record these settings on the

quality assurance record. These settings should be used for subsequent

testing.

4. Position the transducer over the gray scale target group until a clear image is

obtained.

5. Freeze the image and obtain a hard copy.

6. Examine the image. The targets should appear circular in shape, with clear

sharp edges and vary in the degree of brightness ranging from low to high

levels of contrast. The presence or absence of any shadowing behind the

structures should be noted.

7. All ndings should be documented on the quality assurance record.

12

CONTRAST RESOLUTION

Contrast resolution is an imaging system's ability to detect and display the size,

shape, and depth of an anechoic structure within the test phantom. In practice, the

data obtained will give a direct indication of the minimum size structure the system

is capable of resolving at a given depth.

Denition and ll-in describes the imaging system's ability to detect and display the

shape and echogenic characteristics of a structure. Clinically, a correct diagnosis is

dependent upon the system's ability to differentiate between a cystic or solid struc-

ture versus echo patterns originating from the surrounding normal tissue.

Testing for low-contrast target detectability is performed as follows:

1. Place the phantom on a clean, at surface with scanning surface #1 positioned

for use.

2. Apply an adequate amount of low viscosity gel or water to the scan surface. If

water is used, ll the scanning well slowly to avoid introduction of air bubbles.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline values

for "normal" scanning. If the bottom of the phantom is seen, adjust the

gain settings until image goes entirely black. Record these settings on the

quality assurance record. These settings should be used for subsequent

testing.

4. Position the transducer over the anechoic circular target group on the

phantom, until a clear image is obtained.

Results:

This target group varies in echogenicity and provides a good indication of the

performance of the gray scale processing and displayed dynamic range. The test

should be compared with a baseline test using the same instrument settings, to

determine if any change in the characteristics of the target group has occurred with

time. If changes are noted, they should be investigated.

13

DEAD ZONE ASSESSMENT

The dead zone is the distance from the front face of the transducer to the rst

identiable echo at the phantom/patient interface. In the region of the dead zone no

clinical data can be collected. The dead zone occurs because an imaging sys-

tem cannot send and receive data at the same time. The depth of the dead zone

depends upon the frequency and performance of the transducer and the pulsing/

receiving section of the system.

The depth of the dead zone may be measured as follows:

1. Place the phantom on a clean, at surface with scanning surface #1

positioned for use.

5. Freeze the image and obtain a hard copy.

6. Examine the image to determine the rst and last target in each size group

displayed. Record the range of depths visualized for each group. Due to the

conguration of the sound beam small targets in the near eld may not be

imaged.

7. All ndings should be documented on the quality assurance record.

Results:

The targets should appear circular with sharp clearly dened edges, indicating an

abrupt transition from the echogenic to the anechoic region. The targets are an-

echoic and should be free of any internal echoes or ll-in. However, the presence of

internal system noise may manifest itself by producing an observable shade of gray

within the target area.

The specic values determined, while signicant in their own right, are somewhat

less important than stability over time. Performing this test on a routine basis at the

same instrument settings should produce the same results. Any changes should be

investigated.

14

2. Apply an adequate amount of low viscosity gel or water to the scan

surface. If water is used, ll the scanning well slowly to avoid introduction

of air bubbles.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline

values for "normal" scanning. If the bottom of the phantom is

visualized, adjust the gain settings until the image goes entirely black.

Record these settings on the quality assurance record. These setting

should be used for subsequent testing.

4. Scan the phantom until the dead zone target group is clearly displayed.

Freeze this image.

5. This group is composed of 9 line targets. The rst target is positioned

2 mm below the scan surface. Subsequent targets are spaced 1 mm

apart, to a depth of 10 mm.

6. Using the electronic calipers, measure the distance between the rst

target imaged and the echo produced by the scan surface. The resulting

value will be the depth of the dead zone.

7. Document the depth measurement on the quality assurance record.

Results:

If the depth of the dead zone is greater than 10.0 mm, corrective action should be

considered by the individual Ultrasound Department.

15

SPECIFICATIONS

TARGET LAYOUT

PHANTOM

Housing PVC

Outer Dimensions 23.4 x 20.5 x 9.5cm

Scanning Surface 17.5x7.5 cm 14.0 x7.5 cm

Scanning Material Urethane Rubber

Speed of Sound 1450 m/s at 23°

WIRE TARGETS

Material Nylon monolament

Size 6-12mm

Trim this edge only before applying. Align edge to top edge of Phantom.

INSTRUCTIONS:

MATERIAL: IJ-39 Vinyl-Polycarbonate Laminate

COLOR: ALL ARTWORK COLORS BASED ON PANTONE SYSTEM AND CMYK EQUIVALENTS

900 Asbury Ave

Norfolk, Virginia 27613

800-617-1177 / 757-855-2765

PRODUCT LABEL SPECIFICATIONS

APPROVED

NAME:

FILE:

DATE:

PART NO:

APPLICATION:

ATS 539 Multi-Purpose Phantom

RTPC_Target LBL 539_102620

102620

ATS 539

Adobe Illustrator

SCALE:

SIZE:

TRIM TO CROP MARKS

1:1

X

24.7 cm x 22.5 cm

16

NEAR FIELD GROUP

Number of targets: 9

Depth range: 2.0 - 10.0 mm

Spacing: 1.0 mm

VERTICAL DISTANCE GROUP

Number of targets: 17

Depth range: 1.0 - 18.0 cm

Spacing: 1.0 cma

HORIZONTAL DISTANCE: LINEAR PROBES

Number of targets: 5

Depth from Scan Surface #1: 5.0 cm

Spacing: 2.0 cmb

HORIZONTAL DISTANCE: SECTOR SCANNING PROBES

Number of targets: 5

Depth from Scan Surface #1: 13.0 cm

Spacing: 2.0 cmc

AXIAL / LATERAL RESOLUTION GROUPS

Number of Targets: 11

Lateral Displacement: 1.0 mm

Spacing: 4, 3, 2, 1, 0.5 & 0.25 mm

Depth: 7.0, 11.0, 4.0, 16.0 cm

CONTRAST TARGETS (CYSTS)

Type: Non-echogenic, cylindrical

Number of Groups: 5

Group 2, 3, 4:

Number of targets: 17

Diameter of targets: 2.0, 3.0, 4.0 mm

Depth of Targets: 1.0 - 17.0 cm

Spacing: 1.0 cm

Group 6, 8:

Number of targets: 8

Diameter of targets: 6.0, 8.0 mm

Depth of Targets: 1.0 - 17.0 cm

Spacing: 2.0 cm

a Corrected distance. The physical distance between pins has been adjusted to account for the difference in

sound speed between urethane and tissue.

b Uncorrected distance. Sound speed does not affect horizontal distance measurements when using a linear

probe

c Corrected distance. Sound speed will affect horizontal distance measurements when using a sector scan-

ning probe

17

NOTES

All dimensions without tolerances are nominal

All measurements made at 22˚C ± 1˚C

GRAY SCALE TARGETS

Type: Echogenic, Cylindrical

Number of Targets: 6

Spacing: 2.0 cm (center to center)

Depth: 4.0 cm

Contrast: +15,+6, +3,-3,-6, -15 dB with

respect to background

QTY COMPONENT DESCRIPTION

1Multi-Purpose Phantom

-10-Year Warranty

-User Guide

-Certicate of Compliance

MODEL ATS539 INCLUDES

18

WARRANTY

All standard CIRS products and accessories are warranted by CIRS against defects

in material and workmanship for a period as specied below. During the warranty

period, the manufacturer will repair or, at its option, replace, at no charge, a product

containing such defect provided it is returned, transportation prepaid, to the manu-

facturer. Products repaired in warranty will be returned transportation prepaid.

There are no warranties, expressed or implied, including without limitation any im-

plied warranty of merchantability or tness, which extend beyond the description on

the face hereof. This expressed warranty excludes coverage of, and does not pro-

vide relief for, incidental or consequential damages of any kind or nature, including

but not limited to loss of use, loss of sales or inconvenience. The exclusive remedy

of the purchaser is limited to repair, recalibration, or replacement of the product at

manufacturer’s option.

This warranty does not apply if the product, as determined by the manufacturer,

is defective because of normal wear, accident, misuse, or modication.

NON-WARRANTY SERVICE

If repairs or replacement not covered by this warranty are required, a repair estimate

will be submitted for approval before proceeding with said repair or replacement.

RETURNS

If you are not satised with your purchase for any reason, please contact Customer

Service prior to returning the product. Call 800-617-1177, email [email protected],

or fax an RMA request form to 757-857-0523. CIRS staff will attempt to remedy

the issue via phone or email as soon as possible. If unable to correct the problem,

a return material authorization (RMA) number will be issued. Non-standard or “cus-

tomized” products may not be returned for refund or exchange unless such product

is deemed by CIRS not to comply with documented order specications. You must

return the product to CIRS within 30 calendar days of the issuance of the RMA. All

returns should be packed in the original cases and or packaging and must include

any accessories, manuals and documentation that shipped with the product. The

RMA number must be clearly indicated on the outside of each returned package.

CIRS recommends that you use a carrier that offers shipment tracking for all returns

and insure the full value of your package so that you are completely protected if the

shipment is lost or damaged in transit. If you choose not to use a carrier that offers

tracking or insure the product, you will be responsible for any loss or damage to the

product during shipping. CIRS will not be responsible for lost or damaged return

shipments. Return freight and insurance is to be pre-paid.

WITH RMA NUMBER, ITEMS MAY BE RETURNED TO:

CIRS

Receiving

900 Asbury Ave,

Norfolk, Virginia, 23513 USA

PRODUCT WARRANTY PERIOD

Model ATS539 - Multi-Purpose Phantom 120 Months

Table of contents

Other Cirs Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual