Cirs Dynamic Phantoms 008A User manual

IMAGE ACQUISITION • TREATMENT PLANNING • DOSE DELIVERY

USER GUIDE

Dynamic Phantoms

Model 008A, 008A-20,18023-A, 18043-A

900 Asbury Ave • Norfolk, Virginia 23513 • USA • Tel: 757-855-2765 • WWW.CIRSINC.COM

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . 5

Model 008A, 18023-A & 18043-A Assembly Procedure . . . . . . . . . 6

Removal of Ball Cube. . . . . . . . . . . . . . . . . . . . . . . 7

Model 008A, 18023-A & 18043-A Cables and Connections . . . . . . . . 8

4D CT QA Insert Set Up . . . . . . . . . . . . . . . . . . . . . .9

Setup notes for Dynamic Phantoms with controller connecting to a PC using

an Ethernet connection . . . . . . . . . . . . . . . . . . . . . 10

CIRS Motion Control Software . . . . . . . . . . . . . . . . . . 12

Model 008A Specications . . . . . . . . . . . . . . . . . . . 13

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table of Contents

3

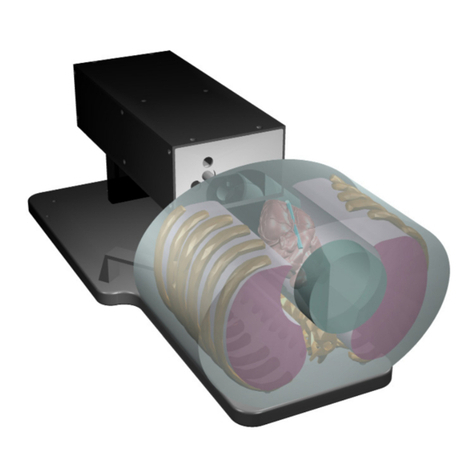

The CIRS Dynamic Phantoms are precision instruments for investigating and mini-

mizing the impact of tumor motion inside the lung (Model 008A Dynamic Thorax

and 008A-20). These phantoms provide known, accurate and repeatable three-

dimensional motion for guided radiation therapy.

The phantom bodies represent an average human thorax/pelvis in shape, propor-

tion and composition.

Model 008A works with a lung-equivalent rod containing a spherical target with

or without various detectors that is inserted into the lung-equivalent lobe of the

phantom. The body is connected to a motion actuator box that induces three-di-

mensional target motion through linear translation and rotation of the lung equiva-

lent rod. Motion of the rod itself is radiographically invisible due to its matching

density with the surrounding material. The target and its motion, given its density

difference, can be resolved. A programmable motion controller is used to drive

the motion actuator.

Model 008A-20 includes only the thorax body and third-axis actuator.

Model 18023-A shares some components with the CIRS Model 008A Dynamic

Thorax Phantom. As with the Model 008A, target and surrogate motion are inde-

pendently controlled with CIRS Motion Control Software. The graphical user in-

terface provides an unlimited variety of motions while the key differences between

the Model 18023-A and the CIRS Model 008A include the length of phantom

body, location of the moving rod within the lung, and the inclusion of ribs.

Model 18043-A contains a cylindrical spine insert. The spine insert is trabecular

bone-equivalent and accommodates a lm cube with cylindrical critical struc-

ture and dosimetric lm for assessment of spinal cord sparing. The insert can be

manually rotated within the phantom body.The 18043-A lung has higher density

than the 008A lung. The 18043-A lung equivalent insert also accommodates a

lm cube with a spherical soft tissue target and dosimetric lm.

Overview

Key Features

• Complex 3D tumor motion

within the lung

• Sub-millimeter accuracy and

reproducibility

• Motion software enables

different cycles, amplitudes and

wave forms

• Tissue equivalent from 50 keV

to 15 MeV

• TLD, MOSFET, micro-chamber

and film can be placed within

the tumor volume

4

GENERAL SAFETY NOTICE

Warnings and Cautions are identied throughout this user guide to alert users of dangerous conditions that are created when instructions are

not followed. Operation and maintenance personnel must observe all safety regulations. For the purposes of this manual, cautions are identied

as situations that can cause damage to the phantom and internal electronics. Warnings are dened as conditions that can cause injury to the

operator.

WARNING:

HIGH VOLTAGES CAPABLE OF CAUSING DEATH ARE USED IN THIS EQUIPMENT. USE EXTREME CAUTION

WHEN OPERATING AND SERVICING THE CONTROLLER. DEENERGIZING THE CONTROLLER BY USING THE

POWER SWITCH DOES NOT REMOVE THE 110-250 VAC POWER EXCITATION FROM THE CONTROLLER.

THESE VOLTAGES REMAIN PRESENT IN THE CONTROLLER POWER SWITCH AND POWER CONNECTOR UN-

LESS IT IS DISCONNECTED.

WARNING:

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY WHEN USING THE MOTION CONTROLLER, FOL-

LOW THESE BASIC PRECAUTIONS:

• There are no user-serviceable parts inside. Refer servicing to qualied service personnel.

• Use only a grounded 3 prong electrical outlet when connecting this product to a power source. If you do not know

whether the outlet is grounded, check with a qualied electrician.

• Do not remove ground prong.

• Do not install or use this product near water, or when you are wet.

• Operate the product securely on a stable surface.

• Set up the product in a protected location where no one can step on or trip over the power cord and the power cord can

not be damaged.

• It is recommended that the customer install an AC surge arrestor in the AC outlet to which the Controller is connected.

This is to avoid damaging the equipment by local lightning strikes and other electrical surges.

• To prevent overheating, do not block the fan on the rear panel or the ventilation holes located on the rear panel

and bottom of the Controller.

CLEANING

You can clean the phantom with a soft cloth dampened with water and mild detergent. Do not use disinfectants or solvent-based cleaners or

sprays.

Safety

SAFETY PRECAUTIONS

Below is a list of specic safety precautions detailed in this user guide. Please review these precautions carefully and use care while handling the

phantom.

CAUTION:

PHANTOM ASSEMBLY REQUIRES TWO PEOPLE. ONE PERSON FOR STABILIZING AND A SECOND FOR AS-

SEMBLING THE PHANTOM. FAILURE TO STABILIZE THE BASE PLATE CAN ALSO RESULT IN DAMAGE TO THE

PHANTOM.

5

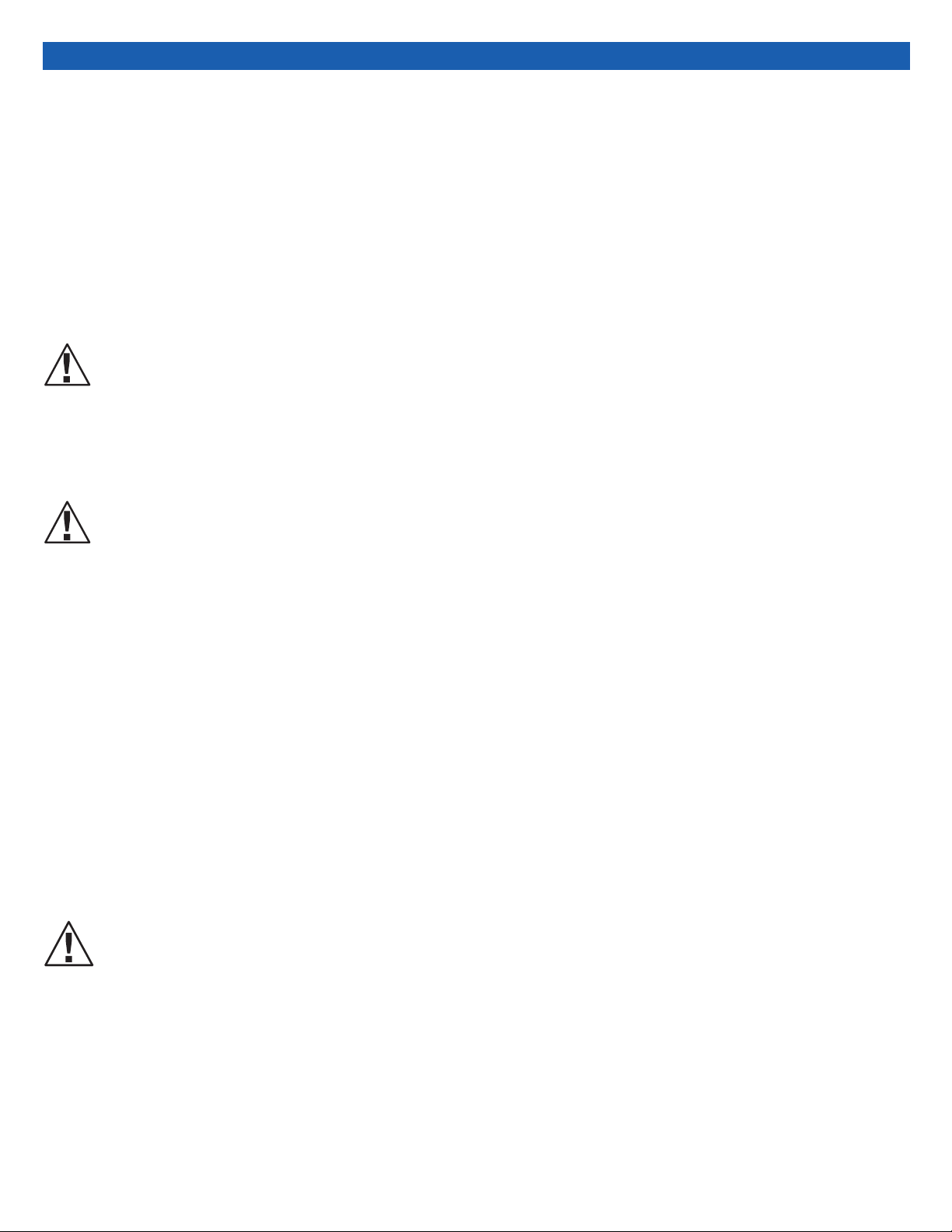

1. Before you open the case check the

three Drop ‘N’ Tell indicators on the

right side of the case.

Unpacking Instructions

Model 008A, 18023-A and 18043-A

4. Remove motion controller from case

and set aside.

3. Pull phantom body from case.

6. Remove the actuator base plate

assembly from case. 7. Inspect the list of parts before assembly.

Refer to specications on page 13. Verify

all parts received. (Parts and packaging

may vary.)

5. Remove cables.

(Optional computer is available).

2. Remove wall partition from the case and

set aside.

Drop ‘N’ Tell shipping damage indicator

shows when a case has been dropped

in transit and contains potential dam-

aged goods. The sensor displays a red

arrow when applied before shipping. If

the container receives a shock exceeding

25 G force, the sensor display arrows will

change to blue. If the sensor has been

activated and is blue, a claim may need

to be led with the carrier. If activated,

take extra care in inspecting the compo-

nents as they are unpacked, assembled

and tested.

Note: If there is any damage to the

packaging case, containers, foam,

and components, or operation, Im-

mediately contact the carrier and the

phantom supplier, and keep all pack-

aging for carrier inspection.

6

Model 008A, 18023-A & 18043-A Assembly Procedure

1. Place base plate with actuator assembly

on table. Carefully move base plate to

overhang table. This allows access to

holes for attaching phantom body.

2. Position phantom body on base plate as

shown. The rod hole must be on same

side and aligned with the rod holder.

3. Place one screw through bottom of base

plate and screw into phantom. Continue

until all screws are in place. Snug but do

not tighten screws to allow minor align-

ment adjustments in steps 6 and 7.

4. Insert lung rod thru hole in phantom

body. Ensure that screw hole on lung rod

is aligned with screw hole on actuator

rod.

5. Use thumb screw to secure lung rod to

actuator rod. 6. Push lung rod towards the motor box.

Visually check gap around the rod. It

should appear consistent. If not, adjust

body left and right until gap is consistent

around rod.

7. Repeat step 6 with rod extended out.

Check gap on the motor box side of

body as well. Adjust phantom body to

achieve best t. Finish tightening the

screws on underside of phantom.

8. 3rd axis actuator is shipped in the

horizontal position. 9. Move 3rd axis gating device to vertical

position by loosening screws and

repositioning as shown.

CAUTION:

PHANTOM ASSEMBLY REQUIRES 2 PEOPLE. ONE PERSON FOR STABILIZING AND A SECOND FOR ASSEMBLING THE PHANTOM.

FAILURE TO STABILIZE THE BASE PLATE CAN RESULT IN DAMAGE TO THE PHANTOM.

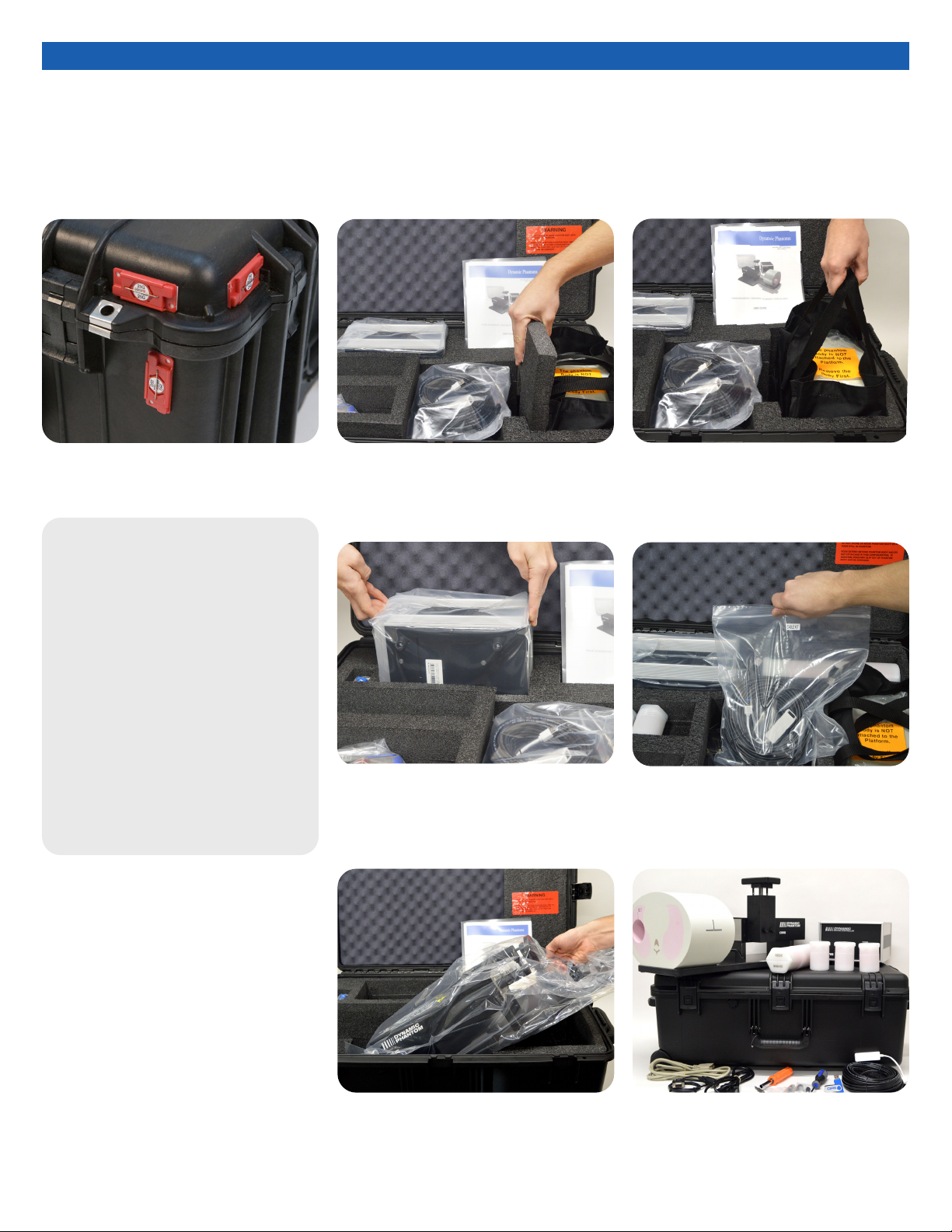

Removal of Ball Cube Insert (Optional)

1. CIRS has provided a Ball Cube Removal Tool. Please note

precautions on Ball Cube insert packaging.

2. Insert Ball Cube Removal Tool into back of Target Moving Rod

at insertion point as shown above. 3. Gently push forward until Ball Cube is removed. Do not use

other tools for this purpose as they may damage the surface of

the Ball Cube which is fragile.

5. Use a screw driver to tighten the 4 nylon screws on the

cup.

4. The Model 18023-A and 18043-A rods connect to the motion

actuator with cup holders. Insert the lung rod thru the hole of

the phantom body. If the body is properly aligned the rod will

slip into the cup. Ensure that the pin hole on the rod is aligned

with the pin inside the cup.

8

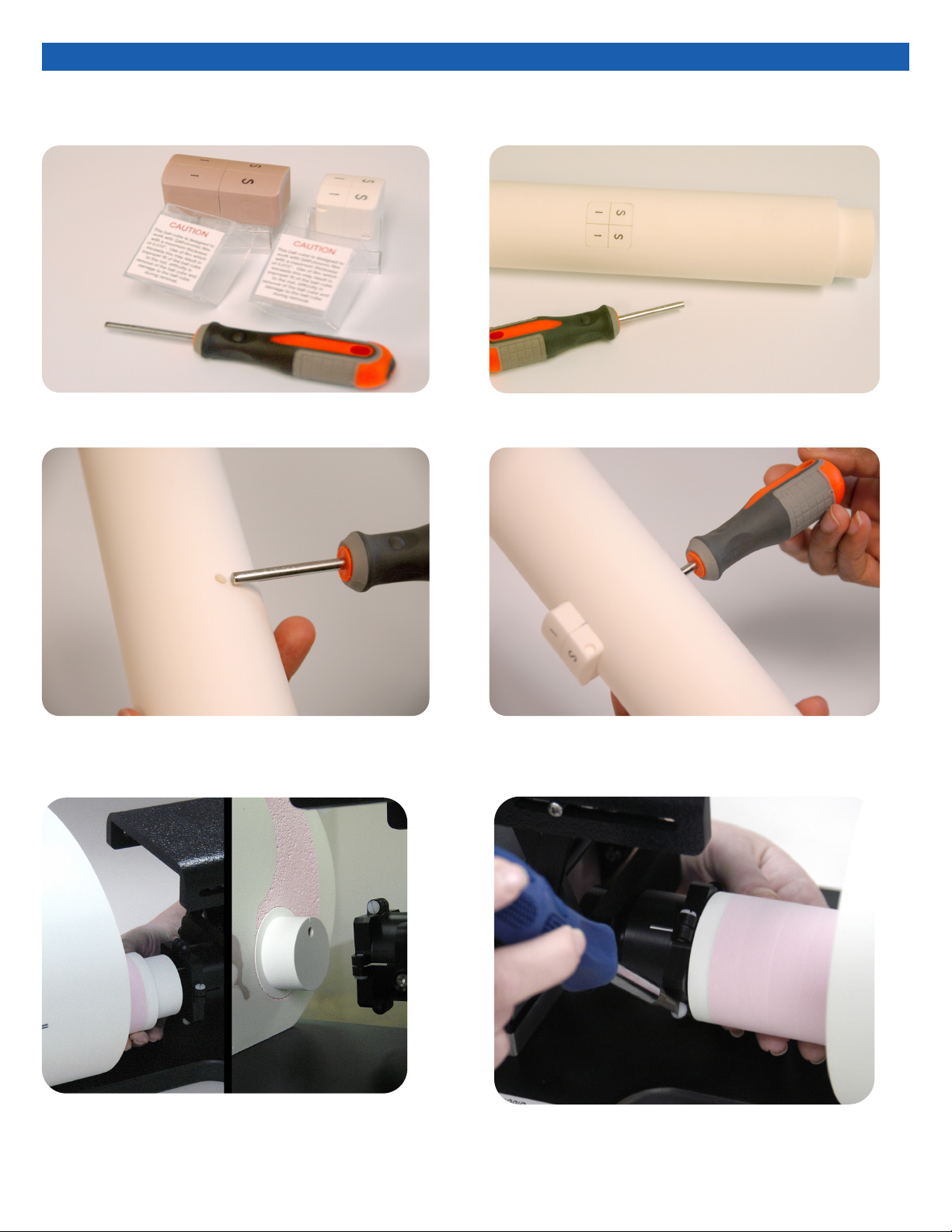

3. Attach ethernet cable to back of

controller.

4. Plug power cord into the back of

controller. Plug other end of

power cord into the wall outlet.

1. Plug the Cable DB25 m/m to back of

controller and to back of actuator.

5. The controller and actuator powered

and ready for use.

2. Plug the Cable DB9 m/m which

leads from gating device to back

of actuator.

Model 008A, 18023-A & 18043-A Cables and

Connections

A. Adjustable legs kit (See B and C for

mounting) B. Prior to attaching phantom body, care-

fully lay base plate with actuator in its

side. Attach solid black post to un-

derside of base plate as shown.

C. Secure remaining 4 adjustable feet to

base plate as shown.

WARNING:

FOLLOW THE CABLE CONNECTION STEPS AS THEY ARE PRESENTED IN THIS USER GUIDE.

CONNECTING THE CABLES WITH THE CONTROLLER “POWER ON” CAN SERIOUSLY DAMAGE THE PHANTOM’S ELECTRONICS.

9

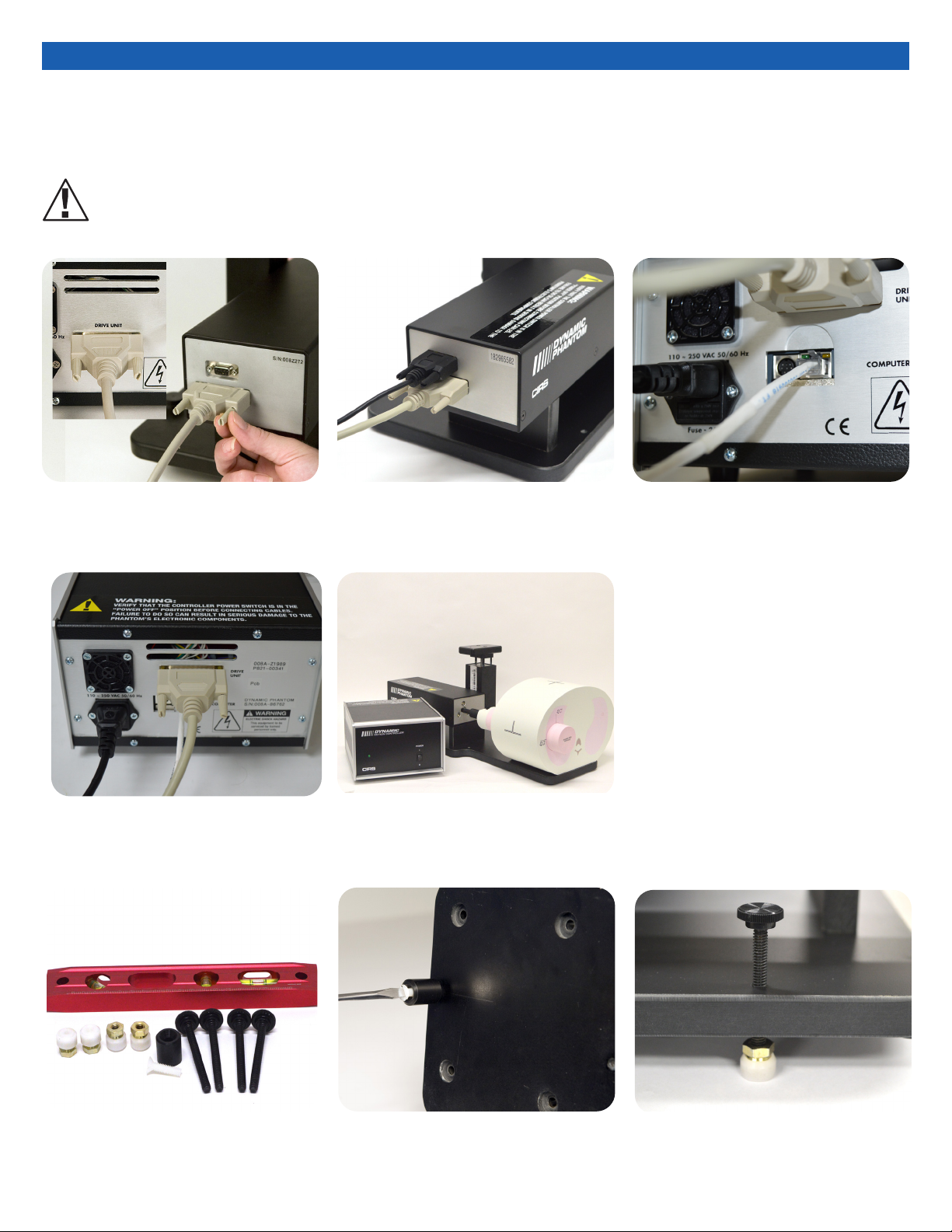

1. Insert the 4D CT QA moving rod into the

rod holder and secure using nylon

screws.

Insert the 4D CT QA static cylinder into

the phantom’s horizontal hole and se-

cure using the rubber gasket.

Static position on a preliminary CT scan

4D CT QA Insert (Model 008A option)

3. Run phantom Homing (automatic when

powered on). Perform a preliminary CT

scan in “home” position without motion

in order to verify alignment of moving

ducial to static grid ducials. The 4D CT

QA Moving Rod position may need to be

adjusted to ensure proper alignment.

Adjustments can be made by changing

“Start Position” in the Advanced Motion

Parameters window.

2. For IS and AP tests, position static cylin-

der with square end mark at 9 o’clock

using level or machine square.

For IS and LR tests, position static cylin-

der with square end mark at 12 o’clock

using level or machine square.

4. Static grid ducials have an increment of

5 mm and provides maximum displace-

ment of +/- 15 mm in IS direction and

+/- 10 mm in LR or AP directions. Set

motion amplitudes within these limits

in increments of 5 mm:

• For IS: IS per your choice, LR and

AP= 0, start angle 0 or 90 degrees

• For LR: IS= 0, LR per your choice,

AP= 0, start angle 0 degree

• For AP: IS= 0, LR= 0, AP per your

choice, start angle 90 degree

5. Run phantom and perform 4D CT imag-

ing. Obtain test results from the 4D CT

sorted images. Report results as the

difference (in mm) between the moving

and static ducials when positioned at

0% and 50% phases.

6. If the moving ducial starting position is

aligned with the static ducial during pre-

liminary static CT scan, then the results

of 4D CT binning can be checked for the

maximum and minimum amplitudes,

respectively 0% and 50% phases. Since

both static and moving ducials measure

1 mm in diameter, misalignments as

small as 0.5 mm can be easily visualized.

The software measurement tool allows

precise evaluation of these misalign-

ments. If a discrepancy is discovered,

check equipment and/or adjust treat-

ment safety margins.

7. Due to its regular size and cylindrical

shape, the moving rod can be used for

motion artifact evaluation. The plunger

that carries the moving ducial is cylin-

drical in shape (45.7 mm diameter x

20.0 mm long) and can be used to

investigate artifacts, volumes, and

shapes during different breathing mo-

tions, including patient-specic motion

proles.

Left: Linear Phase 0% at 10 mm amplitude

Right: Rotation Phase 50% lateral 5 mm amplitude

Left: IS and AP Tests, Right: IS and LR Tests

CIRS Motion Software Advanced Motion Param-

Moving Rod and plunger with ducial

10

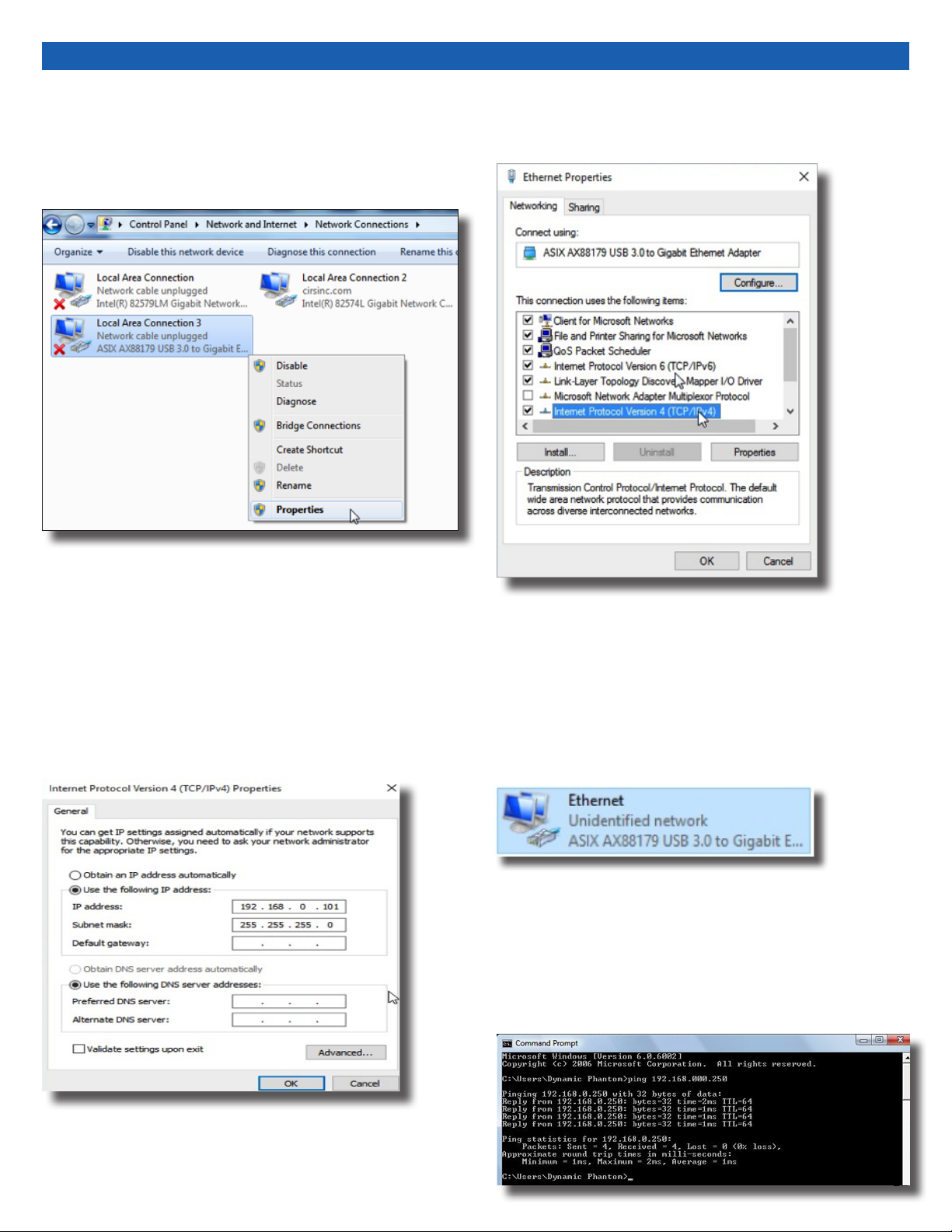

The following are the recommended steps to install the “USB to Network Adapter” that was shipped with this phantom. The new Net-

work Connection must be setup as a Static IP address in order for the PC to communicate with the motion controller of the phantom.

Setup notes for Dynamic Phantoms with controller

connecting to a PC using an Ethernet connection:

Note: The provided “USB to Network Adapter” can act as Plug and

Play device on some PC but CIRS recommends doing the installation

of the driver as outlined above.

1. To install the necessary driver, unzip the “USB-to-Network

Adapter” folder found on the provided USB drive or download

the zipped folder from the CIRS website. Archive to a known

location and select autorun.

3. Follow the on screen steps and acknowledge all the mes-

sages related to driver’s installation. Once the driver installa-

tion is nished, plug the “USB-to-Network Adapter” into

your PC’s USB port and acknowledge the Windows installa-

tion message. Exit the “USB-to-Network Adapter Software”

menu by clicking Exit.

4. From the Control Panel, open the Network and Sharing Cen-

ter and then select “Change adapter settings”.

2. Let your Windows OS select the most appropriate driver by

selecting “Install Driver”.

11

6. Select Internet Protocol Version 4 (TCP/IPv4) and click on prop-

erties

5. Providing that the installation of the “USB-to-Network Card”

was successful, the newly installed Network Adapter should

show as “ASIX AX88179 USB 3.0 to Gigabit Ethernet Adapter”.

Select it’s Properties using the right mouse click menu as

shown below.

7. In the internet Protocol Version 4 (TCP/IPv4) properties window,

change from default “Obtain an IP address automatically” to

“Use the following IP address:” Enter “192.168.0.101” as the

IP address and “255.255.255.000” as the Subnet mask.

Note: If an IP address conict occurs because IP address

192.168.0.101 is already assigned to another Net

work Adapter, the user can try any other IP address between

192.168.0.102 and 192.168.0.249.

8. Once the IP address is entered, click OK. Connect the PC to

the Controller using the provided Ethernet cable by inserting

one end of the cable in the controller’s Ethernet port and the

other one in the “USB-to-Network Adapter”. Power on the

controller. To check that the PC to controller connection was

successful, ensure the icon of the “ASIX AX88179 USB 3.0 to

Gigabit Ethernet Adapter” in the Control Panel matches the

image below. Network Connection can be renamed using the

right mouse click menu.

9. A more in depth check of the PC-to-controller communication

connection can be done by running a “ping command” in Com-

mand Prompt as seen in the image below. To ping the controller,

type “ping 192.168.0.250” and press enter. Ping certies

IP-level connectivity to another TCP/IP device. If you receive

Ping statistics for IP address 192.168.0.250 (controller IP ad-

dress) the communication connection between the PC and

controller was successful.

12

CIRS MOTION CONTROL SOFTWARE SYSTEM

REQUIREMENTS

Windows XP® / Vista / Windows 7/ Windows 8/ Windows 10

(32 and 64 Bit)

Pentium 3® or equivalent

512 MB RAM, 2 MB of available disk space

INTRODUCTION

CIRS Motion Control is an application which allows you to control

the movement of the CIRS Model 008A Dynamic Thorax Phantom

and model 008PL Dynamic Platform. With CIRS Motion Control, you

can quickly set up a movement based on a library of pre-dened

motions, including Sin, Cos4, Cos6, Sawtooth, Sharkn, Hyster-

esis ( Model 008A only) and Continuous Drift, Transient Excursion,

Persistent Excursion, High-Frequency Excursion, or you can import

custom motion data from any tab-delimited or comma- separated

text le. CIRS Motion Control also allows you to save any motion

to easily access the same parameters for repeated calibration and

testing.

INSTALLATION

The CIRS Motion Control application requires the Trio PC Motion

library, which allows the computer to recognize the Trio controller

board in the Dynamic Phantom or Platform. To install the Trio PC

Motion library, double-click Trio_PC_Motion_ActiveX_2_6_15_Setup

and follow the steps in the InstallShield Wizard.

To install CIRS Motion Control, double-click MotionControl-

Setup or Setup and follow the steps in the Setup Wizard. The

Microsoft.NET Framework Version 3.5 is required for the ap-

plication to run.

GENERAL USE

The CIRS Motion Control Software is preinstalled on the optional

computer. Help can be launched from Help Menu. A copy of the

software is included on a USB drive.

CIRS does not support 3rd party equipment. Please refer to the

included documents for warranty and service information for the

ACER brand computer (computer optional).

The software automatically creates a log le where data about wave-

form parameters are saved. The log le is usually located under the

current user in the Application Data folder. A Windows OS search

function can be used to nd the log le. Searching hidden les and

folders should be enabled.

The log le provides a record of the motion history of the device and

can be used as objective evidence that proper QA was performed.

CIRS Motion Control Software

SOFTWARE USER MANUAL & SOFTWARE UPGRADES

CIRS Motion Control software has an online user manual. After

software installation, a copy may be viewed and downloaded using

either the “Check for Updates” button from Help Menu and selecting

“Motion Control User Manual.pdf” or by pointing a web browser to

the CIRS Software Updates webpage: http://www.cirsinc.com/Mo-

tionControlUpdates/Motion_Control_User_Manual.pdf

If the end-user is ofine during use of the phantom, it is recom-

mended that a copy of the CIRS Motion Control User Manual is

downloaded and saved. Once a copy of the manual is saved in a

known location, the PDF document can be opened and viewed in a

window separate from the CIRS Motion Control software window to

aid in phantom set up and use.

The user manual is regularly updated to incorporate new information

based on the addition and/or modication of features as well as end-

user feedback.

CIRS recommends that the end-user routinely check the CIRS Soft-

ware Update webpage using the “Check for Updates” button from

Help Menu. This page indicates the current software version. The

latest free software upgrade is posted as soon as it becomes avail-

able. Instructions for updating the software are also posted. Please

note, when updating WIndows operating system, the controller may

need to be updated as well, requiring return to CIRS. See https://

www.cirsinc.com/software/motion-control/ for more information.

13

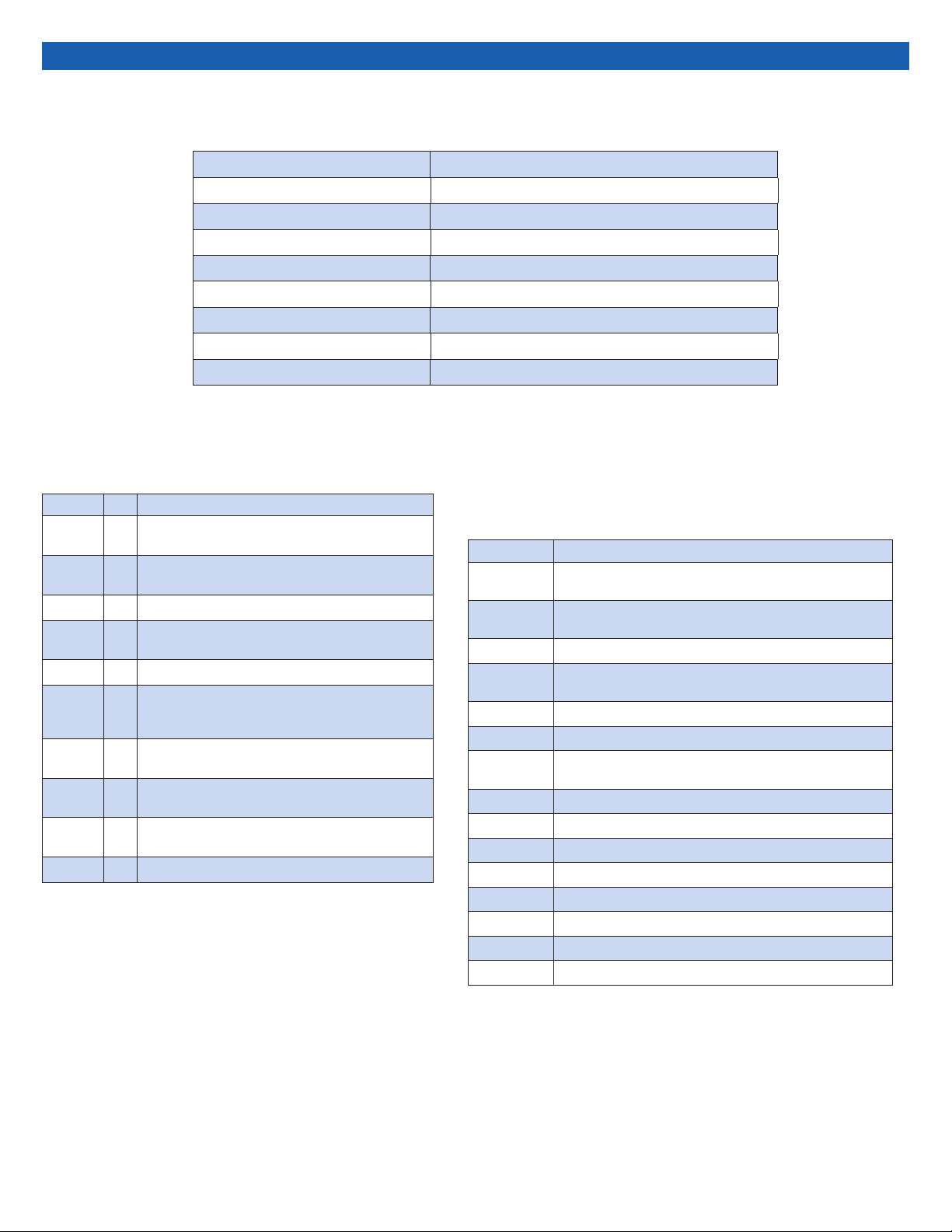

OVERALL DIMENSIONS: 67 cm x 32 cm x 28 cm (26’ x 13’ 11’)

OVERALL WEIGHT: 17.2 kg (37.9 lb)

POWER: 110-250 VAC, 50/60 Hz

AMPLITUDE, IS: ± 25 mm

AMPLITUDE, AP/LR: ± 5 mm

AMPLITUDE, SURROGATE: ± 25 mm

MAX. SURROGATE PLATFORM LOAD 5.4 kg (12 lb)

MOTION ACCURACY: ± 0.1 mm

CYCLE TIME: 1 - ∞ (adjusted based on amplitude)

Model 008A Specications

Part No. Qty Component Description

008A 1 Dynamic Thorax Phantom Body with 3D spine

(Dosimeter & QA rods not included )

1 Dynamic Motion Controller with rmware installed

(110 - 220V, 50 - 60Hz)

1 Actuator base plate assembly

1 3rd axis gating device (mounted to actuator base

plate assembly)

1 CIRS Motion Control Software USB

1 Cable kit: USB 3.0 Gigabit Ethernet Adapter, Net-

work cable CAT5e, 75’, DB 25 male to male cable,

DB 9 male to male cable, Power cord

1 Accessories Kit: 4 in 1 screwdriver, push rod,

fasteners pack, 2 spare fuses

1 Adjustable legs kit: level, 4 adjustable legs with feet,

post with screw

1 User’s guide (PDF user guide and catalog included

on provided USB)

1 Carry Case

OPTIONAL ACCESSORIESINCLUDED WITH MODEL 008A

Note: Customers must complete their order with the purchase of at least one

(1) interchangeable insert option. *Refer to separate CIRS cavity and plug

code list for available chamber cavities.

Part No. Description

008A-05 MOSFET congured lung equivalent rod with set of 3 target

inserts

008A-

06-CV*

MICRO CHAMBER congured lung equivalent rod with set of

3 target inserts

008A-08 Radiochromic lm congured lung equivalent rod

008A-11 GEL DOSIMETRY congured lung equivalent rod with CIRS

Model B-9, Dose Gel Container

008A-12 4D CT QA Device

008A-14 Lung equivalent Imaging Rod with set of 3 target inserts

008A-15 PET/CT congured lung equivalent rod with set of 3 target

inserts

008A-17 Adjustable legs kit

008A-19 Ball Cube congured lung equivalent rod for lm dosimetry

008A-22 SBRT Rod with set of 3 target inserts

008A-24 OSL Dosimetry Rod with 3 cm Target insert

008A-153 Replacement Push Rod

008A-125 Chest plate with reective 11.5 mm tracker balls

008-18 Model 008 upgrade to 008A

008A-253 Cable CAT5E 150 Feet for Dynamic Phantom (008A, 008M,)

14

All standard CIRS products and accessories are warranted by CIRS

against defects in material and workmanship for a period as speci-

ed below. During the warranty period, the manufacturer will repair

or, at its option, replace, at no charge, a product containing such

defect provided it is returned, transportation prepaid, to the manu-

facturer. Products repaired in warranty will be returned transportation

prepaid.

There are no warranties, expressed or implied, including without

limitation any implied warranty of merchantability or tness, which

extend beyond the description on the face hereof. This expressed

warranty excludes coverage of, and does not provide relief for,

incidental or consequential damages of any kind or nature, includ-

ing but not limited to loss of use, loss of sales or inconvenience. The

exclusive remedy of the purchaser is limited to repair, recalibration,

or replacement of the product at manufacturer’s option.

This warranty does not apply if the product, as determined by the

manufacturer, is defective because of normal wear, accident, mis-

use, or modication.

NON-WARRANTY SERVICE

If repairs or replacement not covered by this warranty are required, a

repair estimate will be submitted for approval before proceeding with

said repair or replacement.

PRODUCT WARRANTY PERIOD

Model 008A- Dynamic Thorax

Phantom and accessories 24 Months

Warranty

RETURNS

If you are not satisfied with your purchase for any reason, please

contact your local distributor prior to returning the product. Visit

https://www.cirsinc.com/distributors/ to find your local distributor. If

you purchased your product direct through CIRS, call Customer

Service at 800-617-1177, email [email protected], or fax an RMA

request form to 757-857-0523. CIRS staff will attempt to remedy

the issue via phone or email as soon as possible. If unable to correct

the problem, a return material authorization (RMA) number will be

issued. Non-standard or “customized” products may not be

returned for refund or exchange unless such product is deemed by

CIRS not to comply with documented order specifications. You

must return the product to CIRS within 30 calendar days of the issu-

ance of the RMA. All returns should be packed in the original cases

and or packaging and must include any accessories, manuals and

documentation that shipped with the product. The RMA number

must be clearly indicated on the outside of each returned package.

CIRS recommends that you use a carrier that offers shipment

tracking for all returns and insure the full value of your package so

that you are completely protected if the shipment is lost or damaged

in transit. If you choose not to use a carrier that offers tracking or

insure the product, you will be responsible for any loss or damage to

the product during shipping. CIRS will not be responsible for lost or

damaged return shipments. Return freight and insurance is to be

pre-paid.

With RMA number, items may be returned to:

CIRS

Receiving

900 Asbury Ave,

Norfolk, Virginia, 23513 USA

15

NOTES:

©2013 Computerized Imaging Reference Systems, Inc. All rights

reserved.

All brand names, product names or trademarks belong to

their respective holders.

Specifications subject to change without notice.

Publication: DYNAMIC UG 110320

Computerized Imaging Reference Systems, Inc. has

been certied by UL DQS Inc. to (ISO) 13485:2016.

Certicate Registration No.10000905-MP2016.

COMPUTERIZED IMAGING

REFERENCE SYSTEMS, INC.

900 Asbury Ave

Norfolk, Virginia 23513 USA

Toll Free: 800.617.1177

Tel: 757.855.2765

Fax: 757.857.0523

Email [email protected]

www.cirsinc.com

Technical Assistance

1.800.617.1177

This manual suits for next models

7

Table of contents

Other Cirs Medical Equipment manuals

Cirs

Cirs MRIdian Phantom User manual

Cirs

Cirs ATS 523A User manual

Cirs

Cirs 015DM User manual

Cirs

Cirs Brachytherapy QA Phantom User manual

Cirs

Cirs SHANE 13650001 User manual

Cirs

Cirs ATS539 User manual

Cirs

Cirs 604-GS User manual

Cirs

Cirs 715 User manual

Cirs

Cirs 053S User manual

Cirs

Cirs 008PL User manual

Popular Medical Equipment manuals by other brands

Bolder Surgical

Bolder Surgical CoolSeal GENERATOR user guide

Drive DeVilbiss Healthcare

Drive DeVilbiss Healthcare Samsoft 175 user manual

Adept Medical

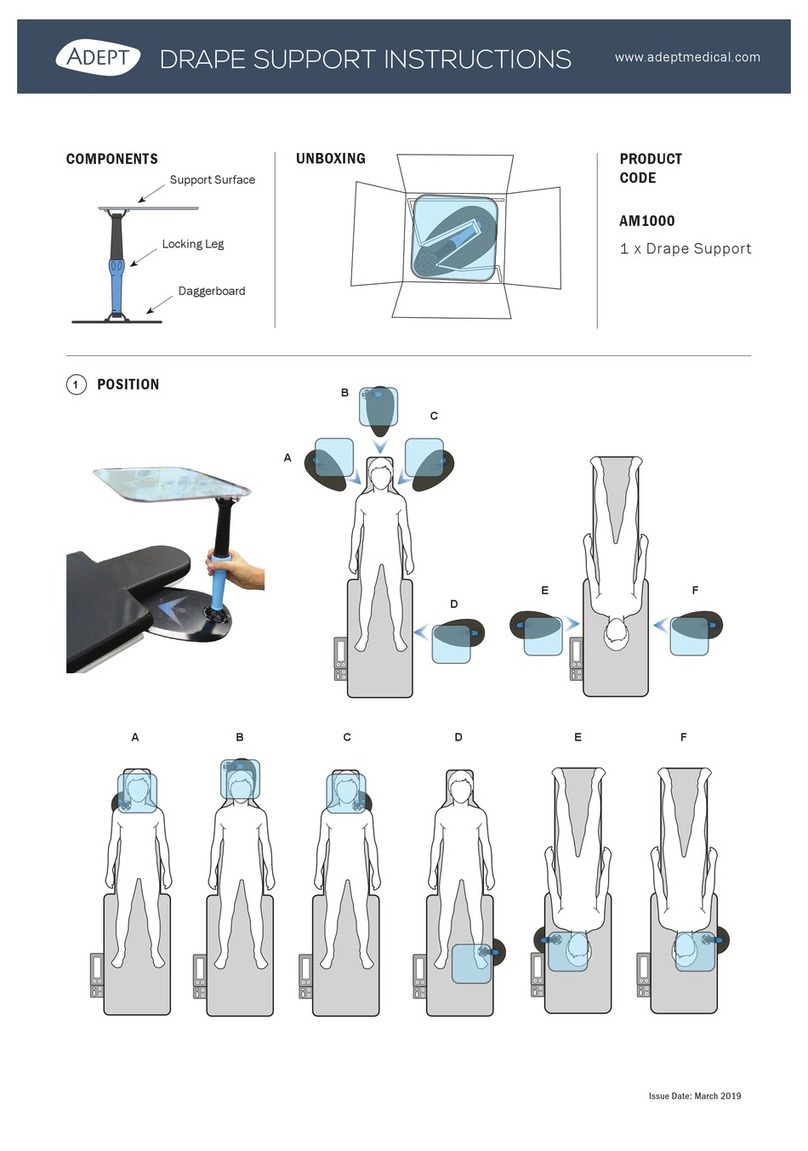

Adept Medical AM1000 instructions

ConMed

ConMed 7-796-18BX Instructions for use

OEC

OEC MINI6600 Periodic Maintenance Procedure

Dräger

Dräger DrugTest 5000 STK Instructions for use