Electronic Actuator for 34 Series Pilot Controls

34 Series

MODEL

INSTALLATION / OPERATION / MAINTENANCE

Electronic Actuator for 34 Series Pilot Controls

Thank you for purchasing a 34 Series Electronic Actuated

Pilto Control. With proper maintenance, the actuator will perform

indefinitely and provide very accurate and reliable valve control. It

is built with the latest technology utilizing the highest quality com-

ponents.

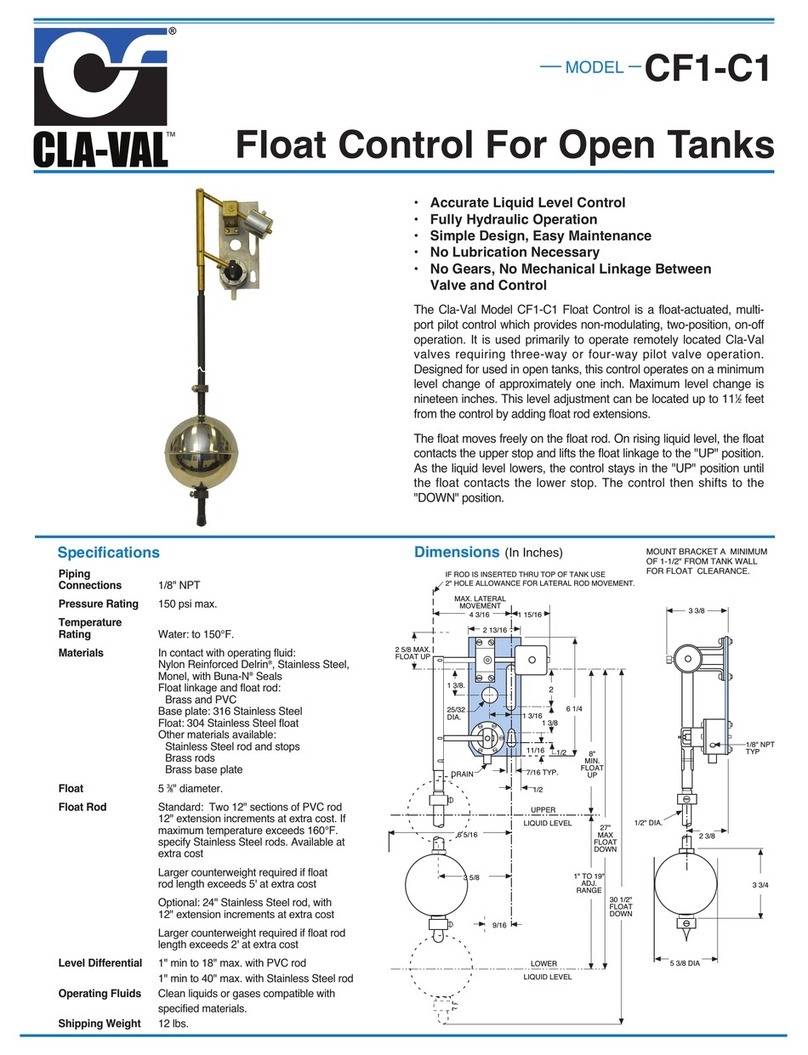

34 Series Controls

The 34 Series Actuated Pilot Controls for 300 Series Valves

consist of a hydraulic pilot subassembly and 130VC-3 Actuator.

The Cla-Val Model CD S-34, CRA-34, CRD-34, CMC-34, and

CRL-34 pilot controls are factory set to full adjustment range of the

pilot subassembly. The 34 Series Actuator accepts a 4 - 20 mA

remote command set point or dry contact closure and positions

spring-loaded hydraulic pilot subassembly as it maintains set point

of pressure or flow rate. The pilot subassembly is automatically lin-

ear between the limit settings.

34 Series Control Operation

A.) The 34 Series actuator allows 34 Series Controls to be

used in valve remote control applications where a simple change

of pilot set-point is needed. SCADA instrumentation provides set-

point control and verification communication based on this scale.

The actuator can also be controlled by simple contact closure.

B.) Other suitable valve remote control applications are

where 4 - 20 mA command input signal is calibrated to specific

high and low range values. SCADA instrumentation provides set-

point control and verification communication based on system

dynamic conditions and valve’s re-ranged scale. Using a laptop

computer, the 34 Series actuator is calibrated in the field to specific

minimum and maximum pressure or flow control settings that are

in direct proportion to 4 - 20 mA command signal. Once values are

established, the valve will be linear between limits and set-point

will not exceed limits throughout the 4 - 20 mA signal range. For

example, when actuator is calibrated to 4 mA = 50 psi to 20 mA =

100 psi, a 12 mA command signal will result in a 75 psi set point.

34 Series Actuator Hardware Set-up

BEFORE running actuator or software program, complete the

following hookup steps:

Use good field wiring practices for low voltage DC analog instrumen-

tation wiring (use 20-gauge twisted pair shielded wire minimum).

Avoid potential ground loops. Avoid over tightening wiring connector

fasteners.

The enclosure is rated IP-68 (similar to NEMA 6P) submersible for

short periods of time. It is not intended for continuous underwater

use. Consult Cla-Val factory technical support if you have questions.

The ten-wire ten meter cable is permanently attached to 34 Series

actuator and should be terminated in suitable junction box or

directly into an above grade RTU or similar device. Care should be

used when attaching to wires to avoid damage. Installation of suit-

able protection from lightning is highly recommended.

There are no user serviceable parts inside the actuator and tam-

pering or opening it will void the warranty. The ten-wire actuator

cable is permanently attached. Internal damage not covered by

warranty will occur if cable is removed.

FIELD WIRING STEPS:

Terminate wires only applicable to your application. For example,

minimal wiring requirements for power and remote set point are:

1.) Attach 12 to 24 VDC power to 34 Series Actuator cable.

Black wire is for (-) negative; Red wire is for (+) positive. Provide

minimum 500 mA supply.

2.) Attach 4 to 20 mA analog Remote Command Input (from

SCADA system or loop calibrator) to 34 Series Actuator cable.

Yellow is positive and Grey is negative.

Download Wiring Diagram from website (www.cla-val.com)

3.) After wiring is complete and actuator is powered, it can be

used with 4 - 20 mA remote command input signal scaled to factory

default pilot control adjustment range (Operation A, above).

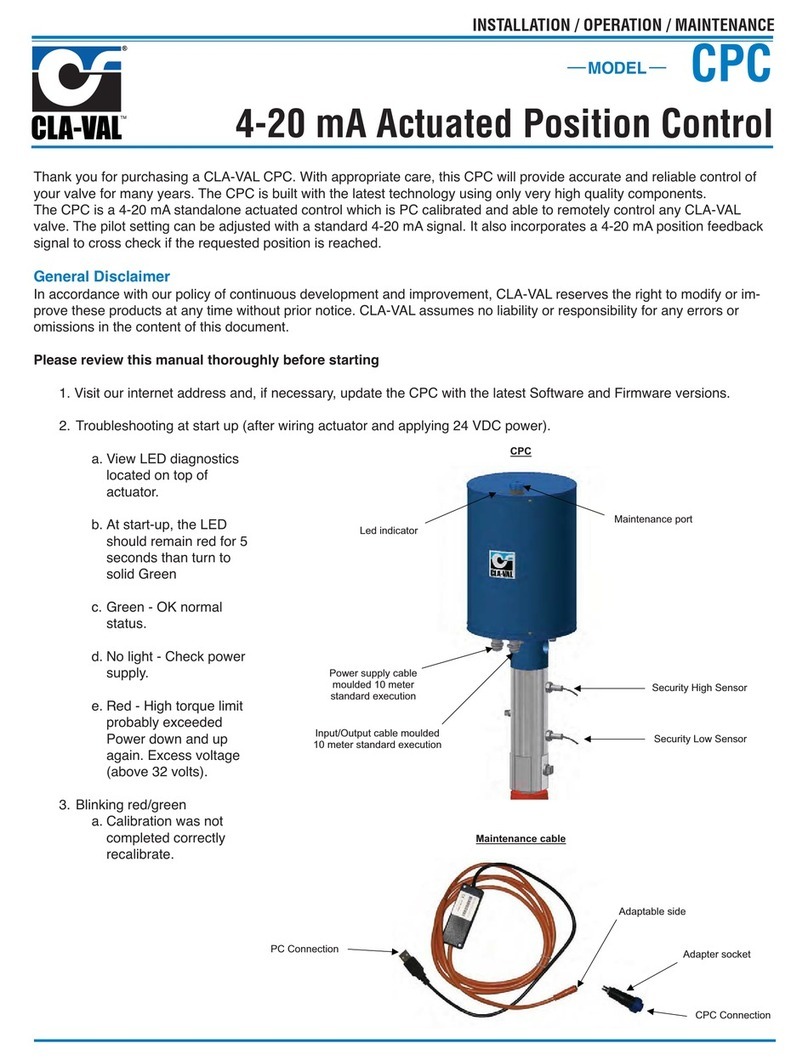

Troubleshooting Actuator Set-up

1.) The actuator LED will remain red for approximately 30

seconds after power on, and then will switch to green indicating

actuator is OK and that internal start-up test is complete.

2.) The actuator LED blinks red if there is a problem. After

resolving the problem, reset the actuator by turning power off for

ten seconds then on again.

3.) The actuator blinks red and green if still in the calibration

mode. It will be necessary to finish calibration.

Terminal strip not

supplied for

Illustration

purpose only

*DO NOT WIRE 24 VDC POWER

*