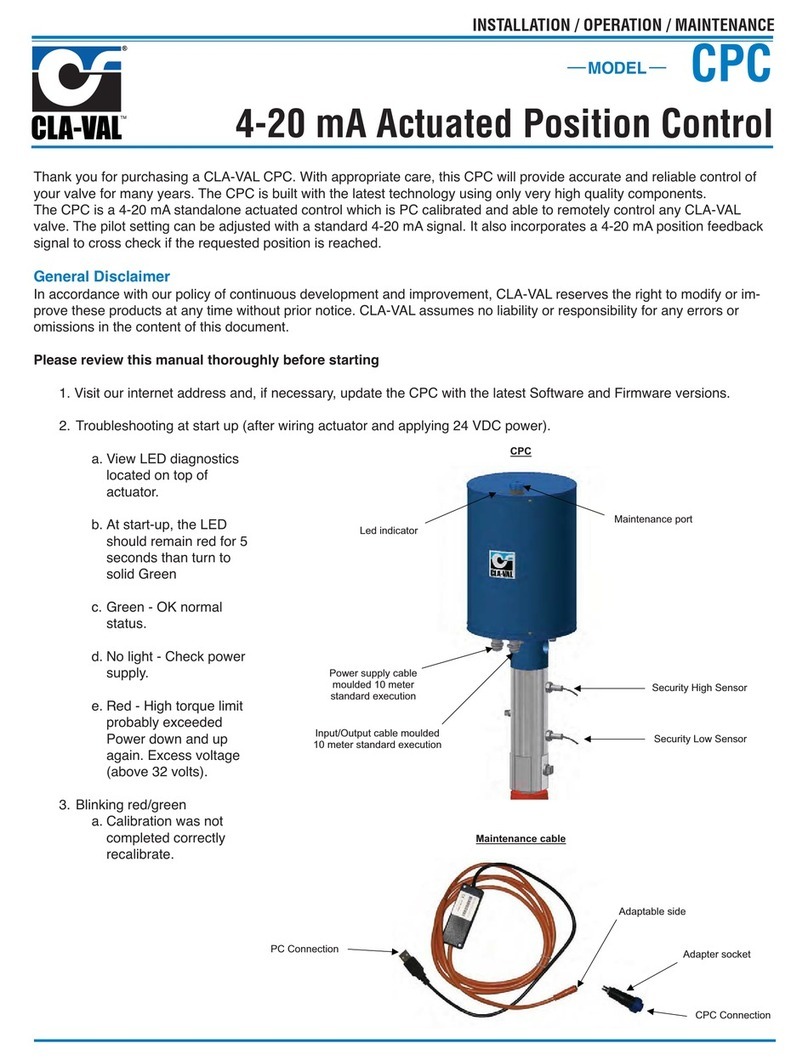

DESCRIPTION

The CRL Pressure Relief Control is a direct acting, spring loaded,

diaphragm type relief valve. It may be used as a self-contained valve or as

a pilot control for a Cla-Val Main valve. It opens and closes within very

close pressure limits.

INSTALLATION

The CRL Pressure Relief Control may be installed in any position. The

control body (7) has one inlet and one outlet port with a side pipe plug (24)

at each port. These plugs are used for control connections or gauge appli-

cations. The inlet in the power unit body (6) is the sensing line port. A flow

arrow is marked on the body casting.

OPERATION

The CRL Pressure Relief Control is normally held closed by the force of the

compression spring above the diaphragm; control pressure is applied

under the diaphragm.

When the controlling pressure exceeds the spring setting, the disc is lifted

off its seat, permitting flow through the control.

When controlling pressure drops below spring setting, the spring returns

the control to its normally closed position.

ADJUSTMENT PROCEDURE

The CRL Pressure Relief Control can be adjusted to provide a relief setting

at any point within the range found on the nameplate.

Pressure adjustment is made by turning the adjustment screw (9) to vary

the spring pressure on the diaphragm. Turning the adjustment screw clock-

wise increases the pressure required to open the valve. Counterclockwise

decreases the pressure required to open the valve.

When pressure adjustments are complete the jam nut (10) should be tight-

ened and the protective cap (1) replaced. If there is a problem of tamper-

ing, lock wire holes have been provided in cap and cover. Wire the cap to

cover and secure with lead seal.

DISASSEMBLY

The CRL Pressure Relief Control does not need to be removed from the

line for disassembly. Make sure that pressure shut down is accompanied

prior to disassembly. If the CRL is removed from the line for disassembly

be sure to use a soft jawed vise to hold body during work.

Refer to Parts List Drawing for Item Numbers.

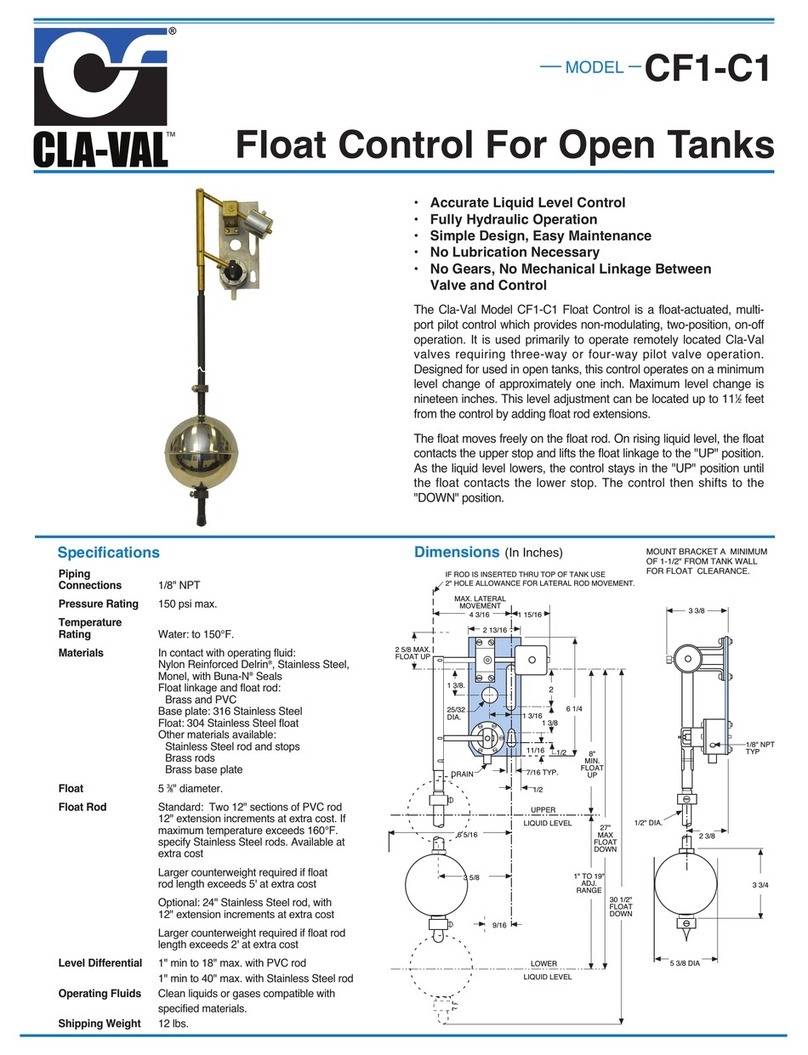

1. Remove cap (1), loosen jam nut (10) and turn adjusting

screw counterclockwise until spring tension is relieved.

2. Remove the eight screws (4) holding the cover (3) and

powerunit body (6). Hold the cover and powerunit together

and place on a suitable work surface.

See NOTE under REASSEMBLY.

3. Remove the cover (3) from powerunit body (6). The spring

(12) and two spring guides (11).

4. Remove nut (13) from stem (19) and slide off the belleville washer

(14), the upper diaphragm washer (15) and the diaphragm (16).

5. Pull the stem (19) with the disc retainer assembly (21) through the

bottom of powerunit. The lower diaphragm washer (17) will slide off

of stem top.

6. Remove jam nut (23) and disc retainer assembly (21) from stem.

Use soft jawed pliers or vise to hold stem. The polished surface of

stem must not be scored or scratched.

7. The seat (22) need not be removed unless it is damaged. If removal

is necessary use proper size socket wrench and turn counterclockwise.

Note: Some models have an integral seat in the body (7).

INSPECTION

Inspect all parts for damage, or evidence of cross threading. Check

diaphragm and disc retainer assembly for tears, abrasions or other dam-

age. Check all metal parts for damage, corrosion or excessive wear.

REPAIR AND REPLACEMENT

Minor nicks and scratches may be polished out using 400 grit wet or dry

sandpaper fine emery or crocus cloth. Replace all O-rings and any dam-

aged parts.

When ordering replacement parts, be sure to specify parts list item num-

ber and all nameplate data.

REASSEMBLY

In general, reassembly is the reverse of disassembly. However, the fol-

lowing steps should be observed:

1. Lubricate the O-Ring (18) with a small amount of a good grade of

waterproof grease, (Dow Corning 44 medium grade or equal).

Use grease sparingly and install O-ring in powerunit body (6).

2. Install stem (19) in powerunit body (6). Use a rotating motion with

minimum pressure to let stem pass through O-ring.

Do Not Cut O-Ring.

3. Install O-ring (5) at top of stem (19). Place lower diaphragm

washer (17) on the stem with the serrated side up. Position

diaphragm (16), upper diaphragm washer (15), with serration down,

and belleville washer (14) with concave side down.

4. Position powerunit body (6) as shown on parts list drawing (top view).

5. Continue reassembly as outlined in disassembly steps 1 through 3.

Pressure Relief Control

CRL

Note: Item (4) Screw will have a quantity of 8 for the 0-75 and 20-200psi

design and a quantity of 4 for the 100-300psi design. Item (25) Screw is

used on the 100-300psi design only. Install item (25), before item (4) for

preload of item (12) spring.

SYMPTOM PROBABLE CAUSE REMEDY

Fails to open. Controlling pressure

too low.

Back off adjusting

screw until valve

opens.

Fails to open with

spring compression

removed.

Mechanical obstruc-

tion, corrosion, scale

build-up on stem.

Disassemble,

locate,and remove

obstruction, scale.

Leakage from cover

vent hole when con-

trolling pressure is

applied.

Diaphragm Damage Disassembly replace

damaged

diaphragm.

Fails to close with

spring compressed.

Mechanical obstruc-

tion.

Disassemble, locate

and remove

obstruction.

Fails to close. No spring compres-

sion.

Re-set pressure

adjustment.

Loose diaphragm

assembly.

Tighten upper

diaphragm washer.

MODEL

INSTALLATION / OPERATION / MAINTENANCE

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O.

Box

1325

•Newport

Beach,

CA

92659-0325

•Phone:

949-722-4800

•Fax:

949-548-5441

•E-mail:

[email protected] •Website

cla-val.com

©

N-CRL (R-8/05)