Visit www.cla-valpacic.com for more details. Contact the Factory at info@cla-valpacic.com

4

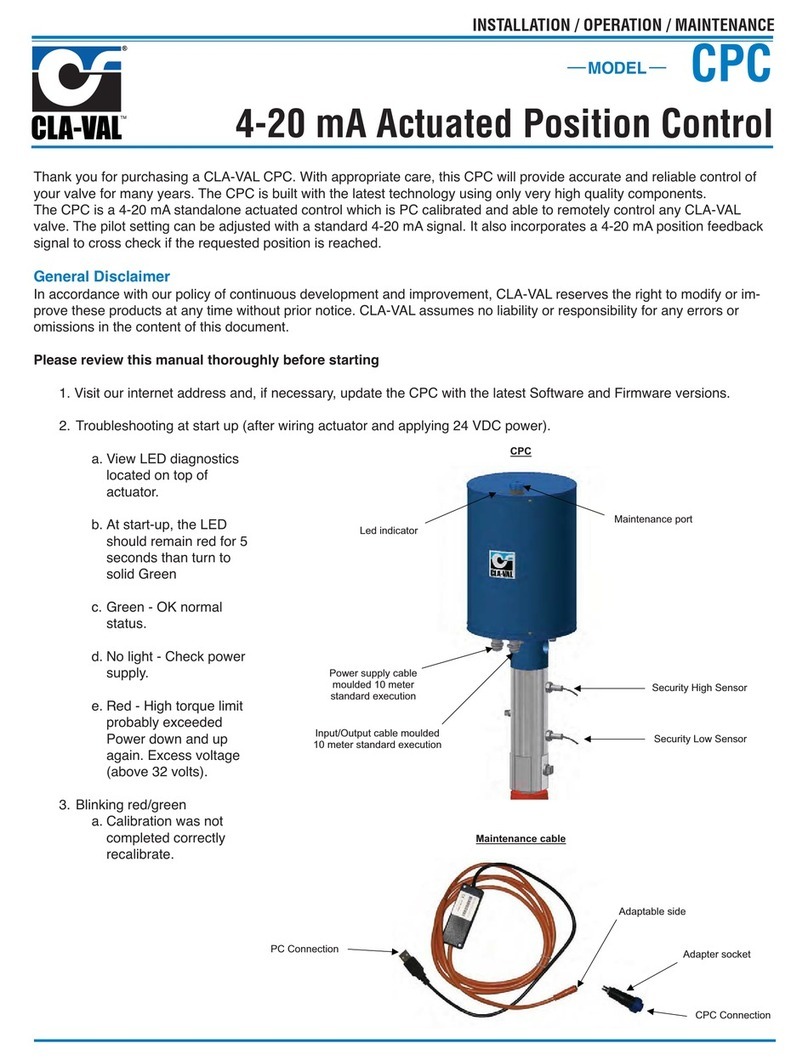

**LED on actuator begins to blink RED & GREEN**

Statically Calibrating the CRD34 Actuator 4-20mA Pressure Range

NOTE! In order to perform a Static Calibration, the current downstream pressure value

must be known plus the spring rating inside the pilot!!

1. Firstly, click ‘Set Range’ on the taskbar to open the calibration screen. A message will appear

warning you that you are going into the calibration mode, click OK.

2. Check the box named; CRD/CRL/CDHS/CDB/CRA

3. Select ‘Static Calibration’ from the drop-down menu and select the pressure units (if required)

4. There is a list of spring pressure ratings denoting the pressure change per each 360 Degree

adjustment of the CRD pilot. Please ensure you know what spring rating is inside the pilot.

5. To work out the number of turns to achieve both high and low pressure from current pressure

value, please see example below.

Using a 1.4 to 7.2 bar spring = 0.8 bar pressure change for every 360-degree turn.

The current downstream pressure is 3 bar and you wish to set the low pressure at 2 bar and high

pressure at 4.2 bar

Formula for low pressure: - Formula for high pressure: -

3 bar – 2 bar = 1.0 bar = 1.25 turns to low 4.2 bar – 3 bar = 1.2 bar = 1.5 turns to high

0.8 bar 0.8 bar