© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A. Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULTOPWHL0001 12-9-20 www.motorcitywashworks.com 1

ACCELERATOR™ HORIZONTAL TOP WHEEL

INSTALLATION MANUAL

Part # TOPWL360BKS [ . . . . ]

( ALL COLORS )

TABLE OF CONTENTS

Equipment Specifications Page: 1

Equipment Features Page: 1

Suggested Tools and Installation Materials Page: 1

Installation Instructions Page: 2

Electrical Installations Page: 13

Optional Inverter Installations Page: 15

Pneumatic Installations Page: 19

Plumbing Installations Page: 21

Foamer Installation Page: 22

Start-Up Procedures Page: 23

Maintenance Page: 25

Troubleshooting………………………………………………………………………………………………………..Page: 28

Exploded Views………………………………………………………………………………………………………..Page: 31

Warranty………………………………………………………………………………………………………………..Page: 47

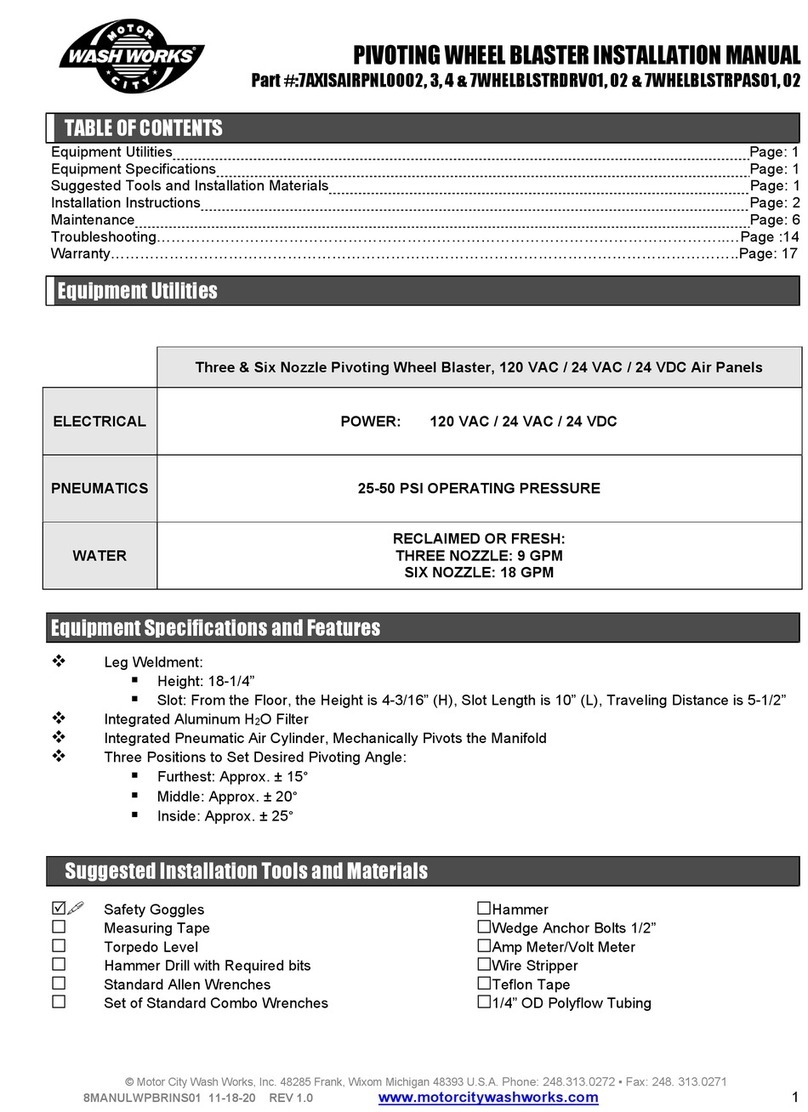

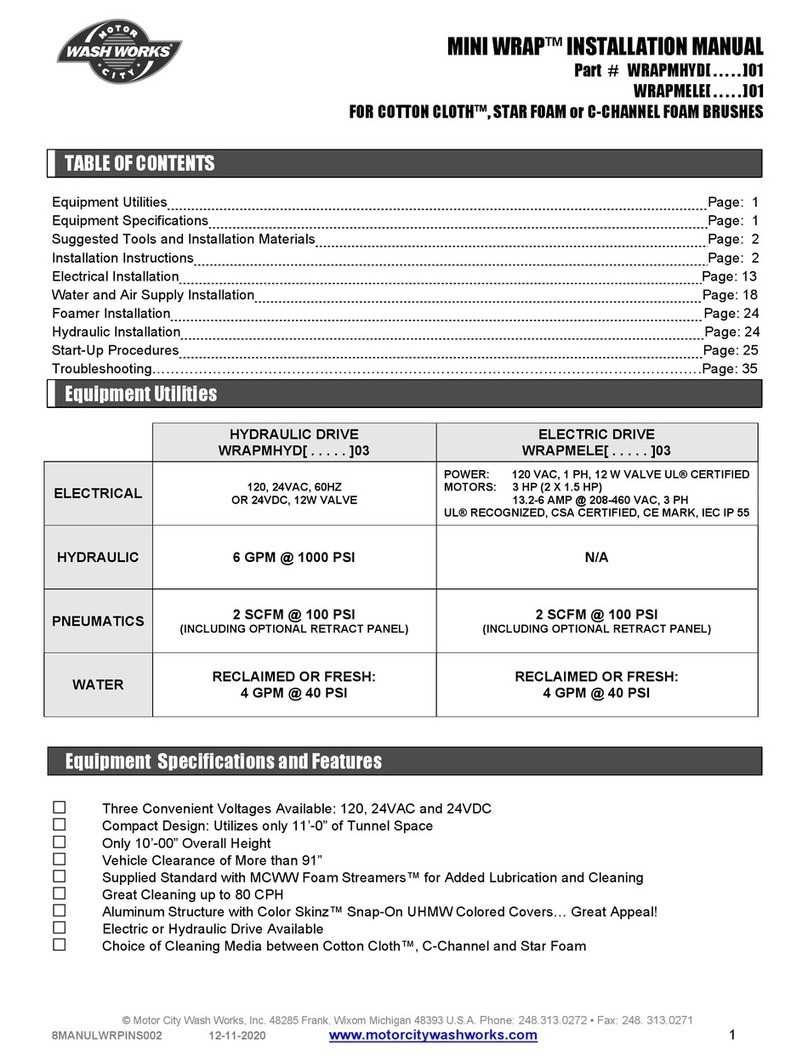

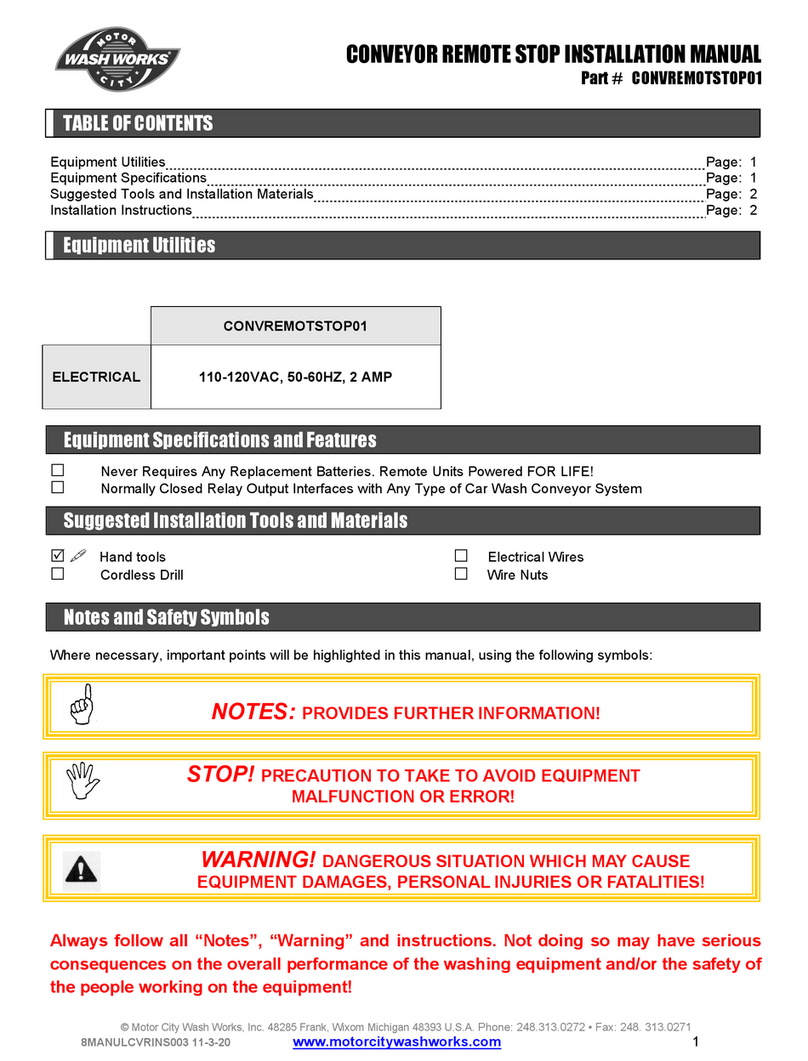

Equipment Specifications

Equipment Features

Aluminum Structure Color Skinz™ Snap On Structure Wrap

Available With Star Foam Wash Material

Less Than 7 Feet of Tunnel Space required

134” Overall Height

Cleans Up to 200 Cars per Hour Line Speed

Built-In Foam Streamer™ for added Show and Proper Lubrication

Suggested Installation Tools and Materials

Hammer Drill with 5/8” Drill Bit (12) Wedge Anchor Bolts 5/8” x 6”

Sledge Hammer Safety Goggles

Set of Standard Combo Wrenches Torpedo Level

Measuring Tape 3/8” Polyflow Tubing

1/2" Polyflow Tubing

ELECTRIC DRIVE

TOPWL360[ . . . . . . . ]

ELECTRICAL

CONTROL: 24VAC, 24VDC, 120 VAC, 3 WATTS UL® CERTIFIED

MOTOR: 1.5 HP 6.6-3.0 AMPS/208-460 VAC 3 PH

UL® RECOGNIZED, CSA CERTIFIED, CE MARK, IEC IP 55

PNEUMATICS 3 SCFM

WATER RECLAIMED OR FRESH:

2 GPM @ 40 PSI