The CMC Rescue and CMC ProSeries®Rescue

Harnesses are designed for multi-purpose use in fire/

rescue, industrial, and rope access work applications.

The harness’ light weight and ease of donning and doffing

appeal to emergency responders who must act quickly.

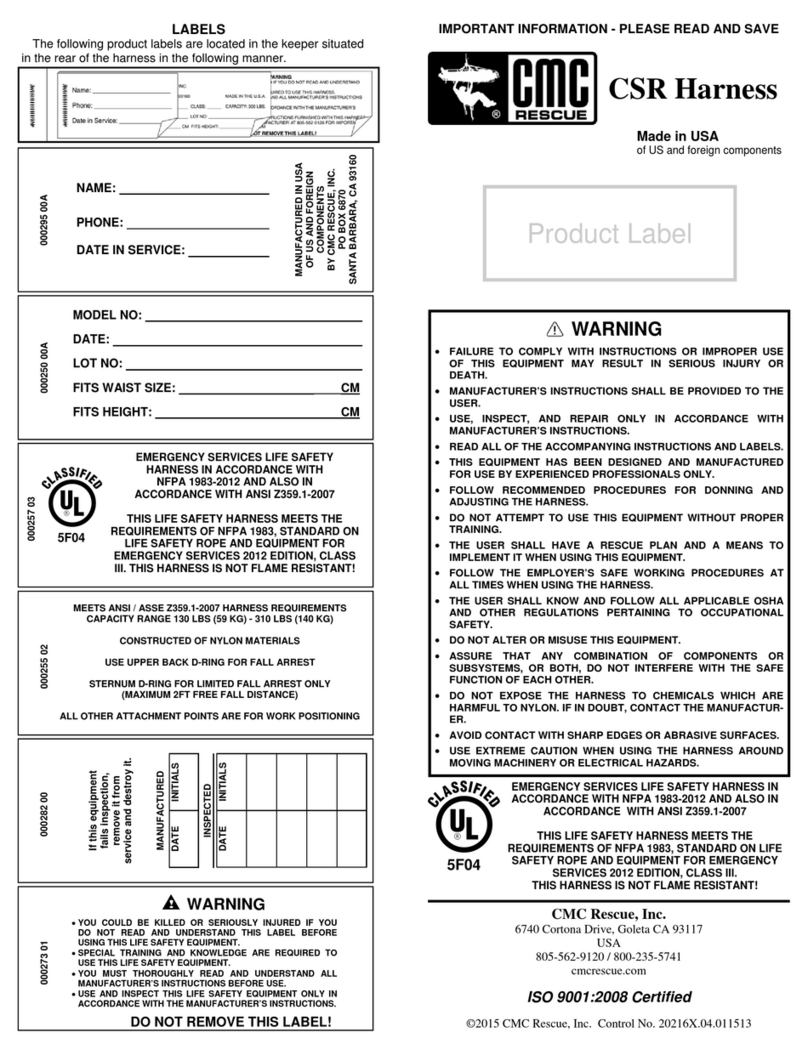

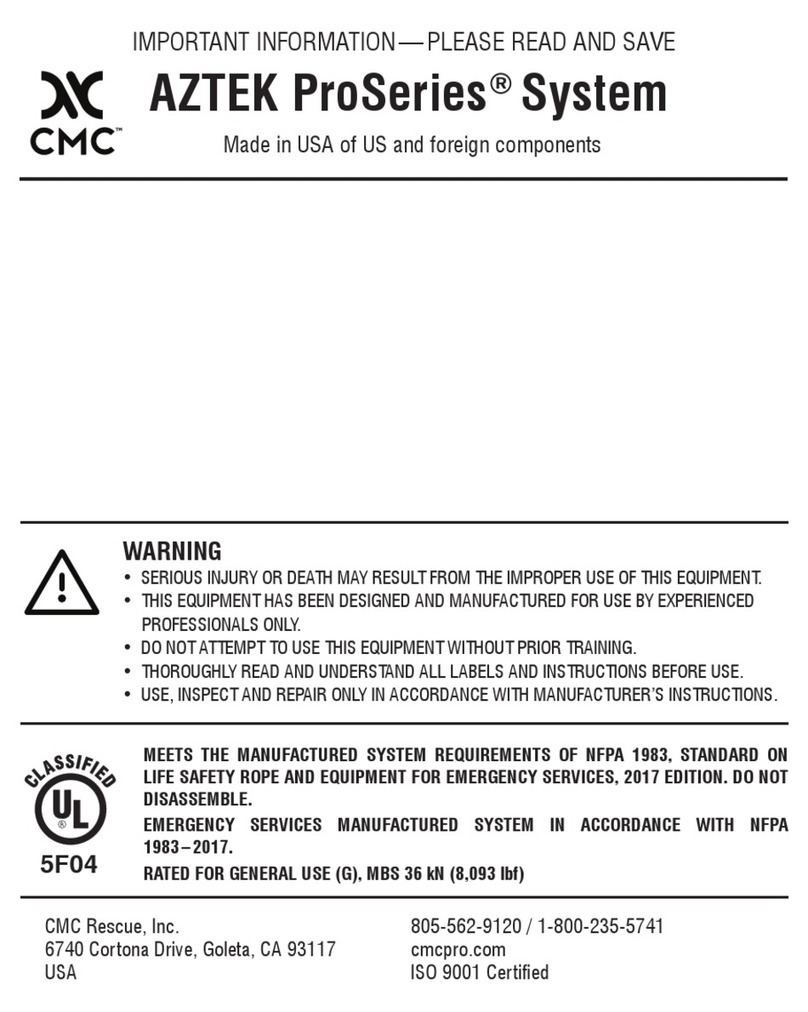

HARNESS CERTIFICATION AND USE

Rescue and work harnesses from CMC Rescue are

designed to comfortably support the wearer, creating a

safe work platform. Because our harnesses are used

when working at heights, they are also built with the

strength to catch a fall. Depending on the intended use

(rescue, rope access or fall protection) harnesses are

tested to specific standards set by the applicable industry.

Rescue: NFPA 1983 - 2012 provides specifications for a

rescue harness. All front and back D-ring connection

points are dynamically and statically tested to this

standard.

Rope Access Work: A harness selected for rope access

work needs comfort and support very similar to a rescue

harness, which is not available in a harness designed

solely for fall arrest applications. Depending on the

applicable regulations, fall protection may also be

required. When so labeled, CMC Rescue harnesses

are independently certified to meet ANSI Z359.1-2007.

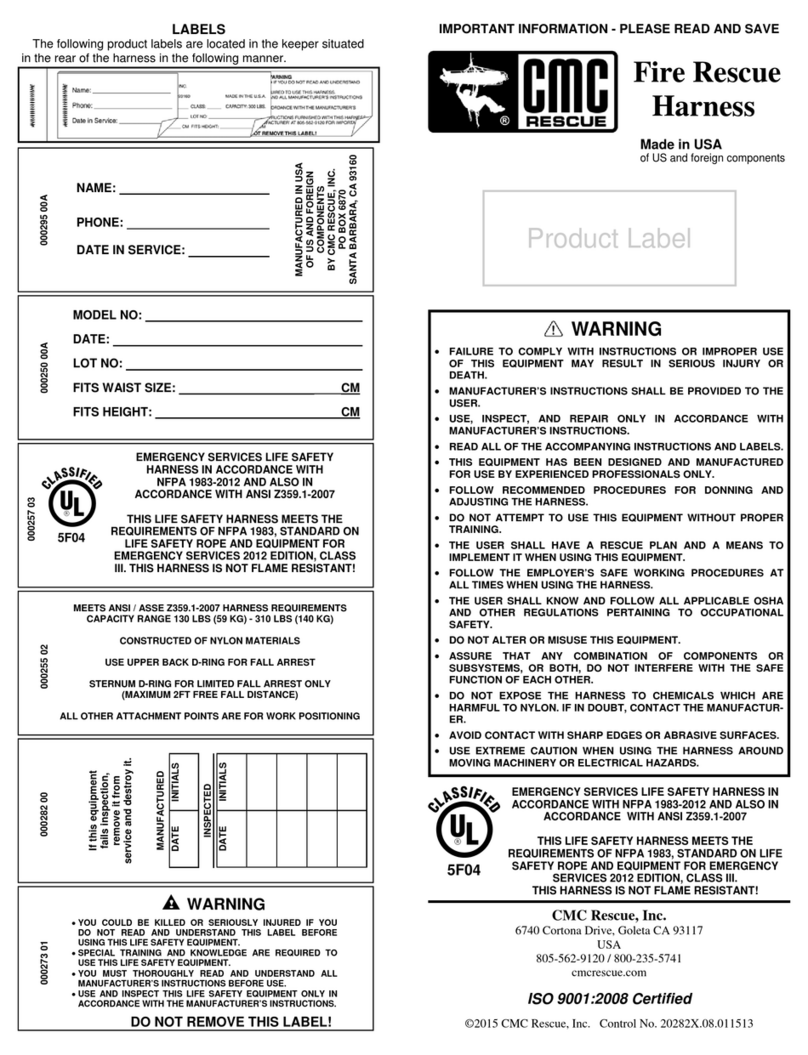

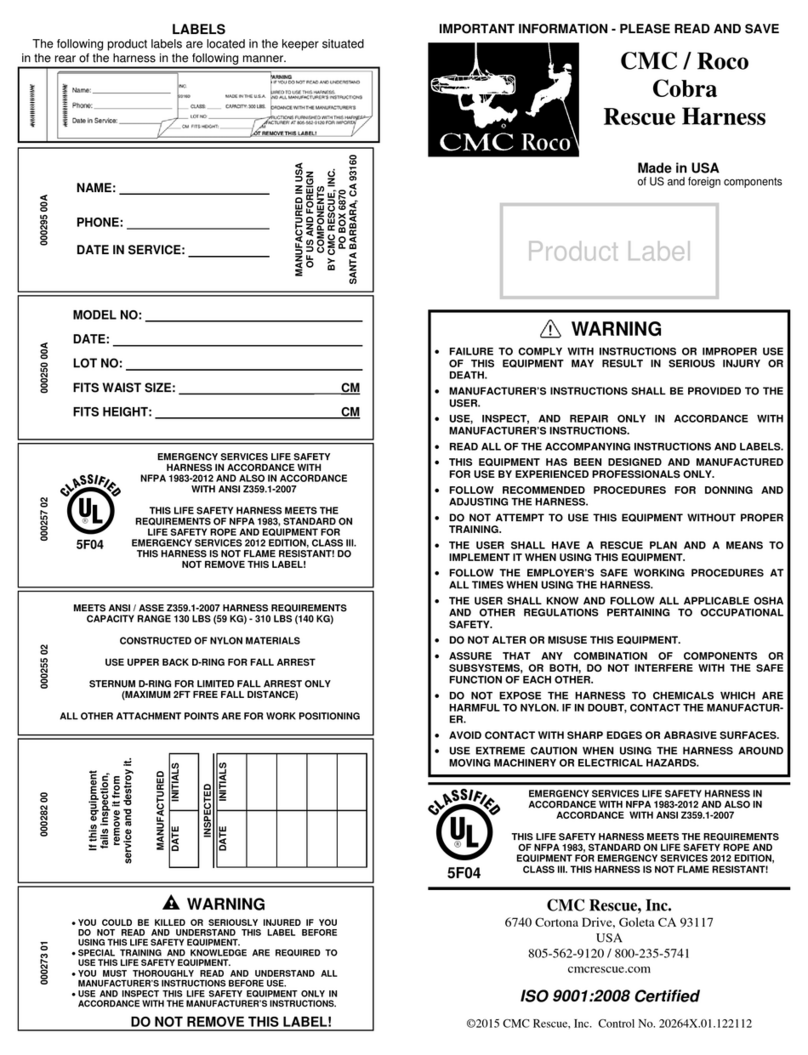

USER INFORMATION

User Information shall be provided to the user of the

product. NFPA Standard 1983 recommends separating

the User Information from the equipment and retaining

the information in a permanent record. The standard also

recommends making a copy of the User Information to

keep with the equipment and that the information should

be referred to before and after each use.

Additional information regarding auxiliary equipment

can be found in NFPA 1500, Standard on Fire

Department Occupational Safety and Health Programs,

and NFPA 1983, Standard on Life Safety Rope and

Equipment for Emergency Services.

INSPECTION

Inspect the equipment according to your department's

policy for inspecting life safety equipment. The equipment

should be inspected after each use by an inspector that

meets your department's training standard for inspection

of life-safety equipment. Record the date of the inspection

and the results in the equipment log or on a tag that

attaches to the equipment. Each user should be trained in

equipment inspection and should do a cursory inspection

before each use.

The service life of equipment used for rescue depends

greatly on the type of use and the environment of use.

Because these factors vary greatly, a precise service life

of the equipment cannot be provided.

When inspecting the equipment, check the webbing for

cuts, worn or frayed areas, broken fibers, soft or hard

spots, or discoloration. Check the stitching for pulled

threads, abrasion, or broken stitches. If any damage is

noted, the equipment should be removed from service.

If the equipment is dropped or impact loaded, it should

be inspected by a qualified inspector prior to being

returned to service. In most cases, a visual inspection will

not be able to determine if the equipment has been

damaged. Based on the history of the incident, if there is

any doubt regarding the safety of the equipment, it should

be removed from service and destroyed.

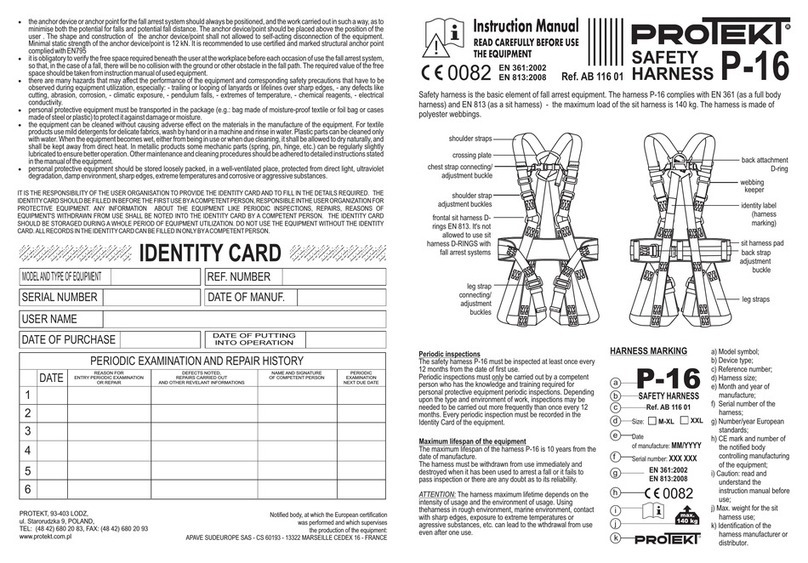

PUTTING ON YOUR HARNESS

1. Loosen the waist and leg adjusting buckles to make

the diameter large enough to pull over your thighs

and hips. Hold the harness by the waist and step

through the waist belt and pull the belt up around your

waist.

2. Adjust the waist strap and leg loops for the most

comfortable fit.

3. Fold the web tails under the Web-Keepers™ and

secure them tightly.

WARNING: Make sure the straps are snug. This

increases the comfort when sitting in the harness and

helps prevent the quick-connect buckles from

disconnecting. When wearing the harness, double-

check the buckles, adjusters, and fit of the harness

immediately prior to relying on it for support.

ATTACHMENT POINTS

• The front waist D-ring is the primary work positioning

attachment point. It allows the user to be in a sitting

position which provides the most comfort and freedom

of movement. The front waist D-ring on the ProSeries

Rescue Harness also serves as an attachment point to

the front of the ProSeries Chest Harness.

• The rear D-ring is intended to provide travel restraint

when working near an edge. The rear D-ring on the

ProSeries Rescue Harness also serves as an

attachment point to the rear of the ProSeries Chest

Harness.

WARNING: To prevent roll out, use only locking

carabiners to attach to D-rings.

USING YOUR HARNESS

CMC harnesses are not intended for rock climbing.

Lead climbing ropes should not be tied into the D-ring or

connected into it with a carabiner.

Do not expose the harness to flame or high

temperatures. Carry the harness where it will be

protected as the harness could melt or burn and fail if

exposed to flame or high temperatures.

The CMC Rescue and ProSeries Rescue Harnesses

are designed for rescue applications in which the wearer

uses the harness primarily for positioning. High impact fall

situations should be avoided. Always keep the safety line

(belay) above the wearer and keep the slack in the safety

line to a minimum.

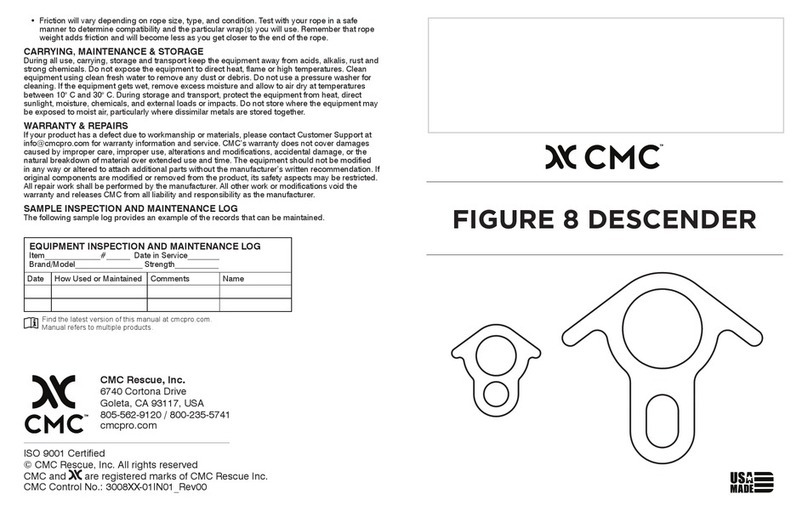

CARRYING, MAINTENANCE & STORAGE

If the harness becomes soiled, it can be washed in cold

water with a mild detergent. CMC Rescue recommends

the use of LifeLine Cleaner. Dry out of direct sunlight. Do

not dry in an automatic dryer. Store in a cool, dry location.

Keep the harness away from acids, alkalis, exhaust

emissions, rust or strong chemicals during storage or use.

REPAIR

All repair work shall be performed by the manufacturer.

All other work or modifications may void the warranty and

releases CMC Rescue, Inc. from all liability and

responsibility as the manufacturer.