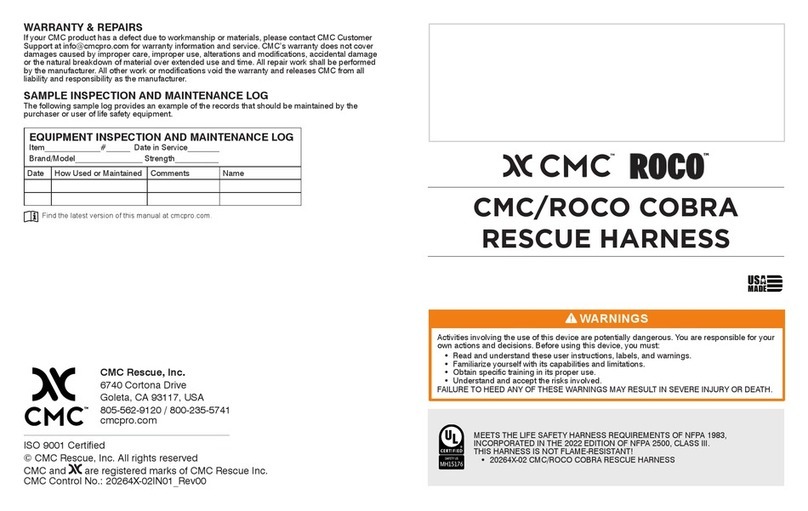

Activities involving the use of this device are potentially dangerous. You are responsible for your

own actions and decisions. Before using this device, you must:

• Read and understand these user instructions, labels, and warnings.

• Familiarize yourself with its capabilities and limitations.

• Obtain specic training in its proper use.

• Understand and accept the risks involved.

FAILURE TO HEED ANY OF THESE WARNINGS MAY RESULT IN SEVERE INJURY OR DEATH.

WARNINGS

Inspect the equipment according to your department’s policy for inspecting life safety equipment.

CMC recommends a detailed inspection by a competent person at least once every 12 months

depending on current regulations and conditions of use. Record the date, inspector name, and

inspection results in the equipment log as well as any other relevant information to track the

usage history.

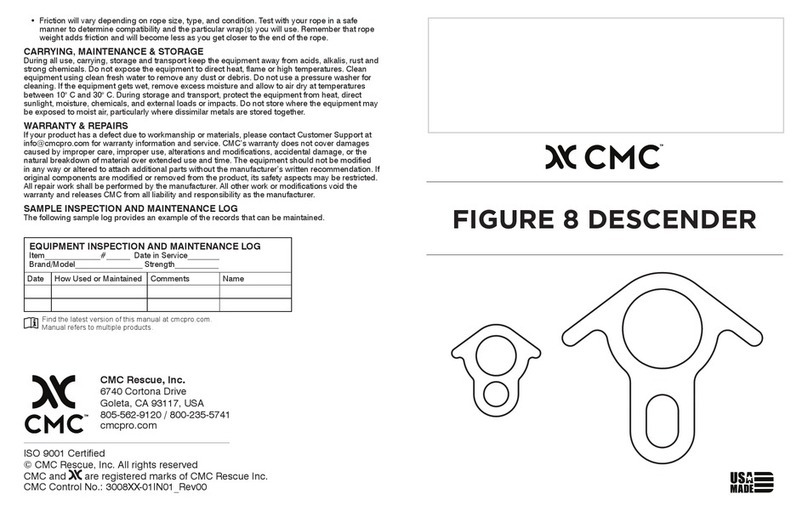

Before each use, the user should:

• Conrm the device is functioning properly.

• Verify the presence and legibility of the product markings.

• Verify there is no excessive wear or indications of damage such as deformation, corrosion,

sharp edges, cracks, or burrs. Minor nicks or sharp spots may be smoothed with emery cloth.

• Check for the presence of dirt or foreign objects that can affect or prevent normal operation

such as grit, sand, rocks, and debris.

During each use, the user should:

• Conrm all pieces of equipment are correctly positioned with respect to each other.

• Monitor the condition of the device and its connections to other equipment in the system.

• Do not allow anything to interfere with the operation of the device or its components.

• Keep foreign objects out of the device.

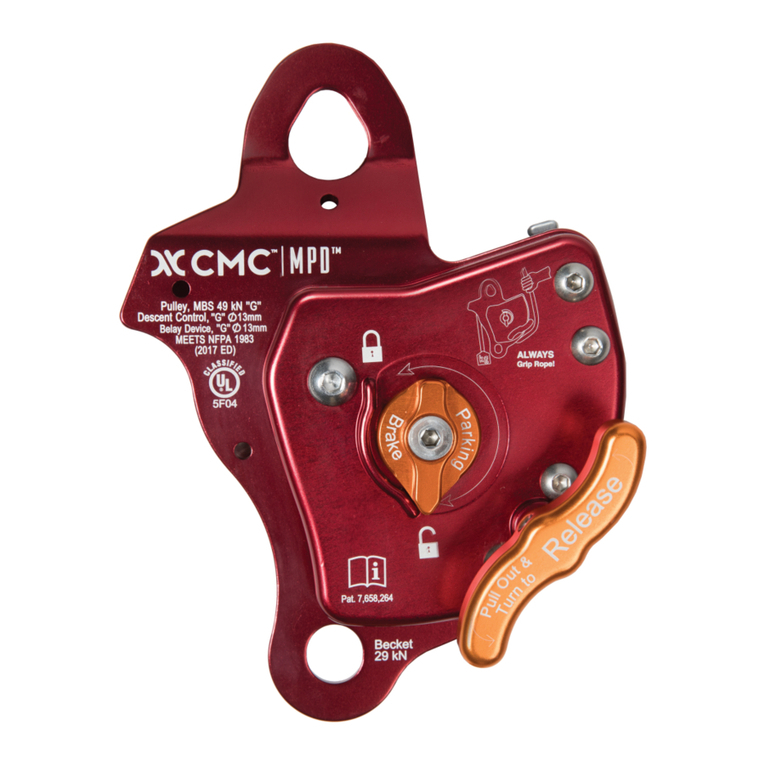

LIMITATIONS AND PROPER USE

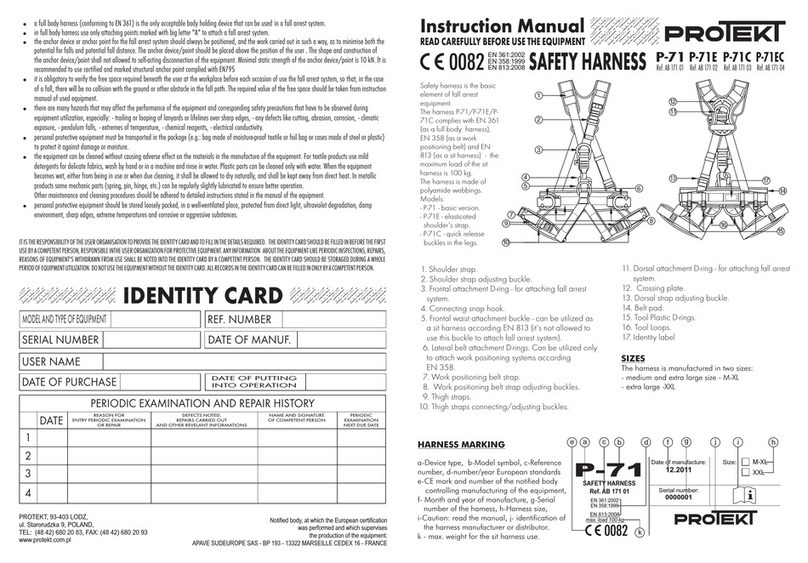

The CMC Ascender is designed for use in personal ascending systems as well as rope systems.

Since the ascender is unidirectional, make sure it is installed in the proper orientation when it

is rigged onto the rope. A function test should be conducted by pulling on the device after it is

connected to the rope to verify that it is grabbing in the desired direction.

• If ascending, the arrow points up towards the secured rope end. If hauling, the arrow points to

the load being raised. For horizontal positioning, the arrow points to the end of the rope that is

secured to what you are using to position yourself.

• Avoid using the Ascender in an application were it could be subjected to a shock or

dynamic load. The rope from the anchor to the grab must always be under tension and slack

must not be allowed to develop because that will greatly multiply the force of any fall. In case of

a fall, you must be able to release the device. This device is not designed to hold severe falls.

• Do not load the Ascender beyond its rated load capacity per NFPA 1983, incorporated in the

2022 edition of NFPA 2500: 5 kN (1,124 lbf) with 11mm (7/16 in) ropes and 11 kN (2,473 lbf) with

13mm (1/2 in) ropes.

• Always be sure cable is in good condition and provides a proper spring action.

• Verify that the jaw operates freely over its whole range of travel and is positioned properly.

• Verify that the setscrews are tight and the axle is secure.

• Tie a stopper knot in the free end of the rope so it can’t accidentally pull through.

• Do not grab the Ascender or the rope above it during a fall as the Ascender may be

inadvertently pulled down the rope without catching.

• In some cases, the Ascender may slip on the rope to dissipate energy, which can reduce rope

damage. In general, smaller diameter ropes will slip at a lower force than larger ropes.

• Test and verify your system and be sure your rope will hold the load you require. Slippage

should never be relied on because rope friction varies depending on age and condition. A new

rope can be much slipperier and more exible than an old rope that has become stiff and fuzzy.

In a shock load or overload scenario, it is possible for a rope grab to damage or cut the rope.

• To prevent roll-out, use only locking carabiners. Do not allow ropes or objects to rub or twist the

sleeve because this could unlock it. Vibration can also unlock a sleeve. Sleeves must be locked

to achieve full strength.

• Must be free to align with the load, any restraint is dangerous. Do not allow any bending force

on the Ascender or it may break or break the connectors.

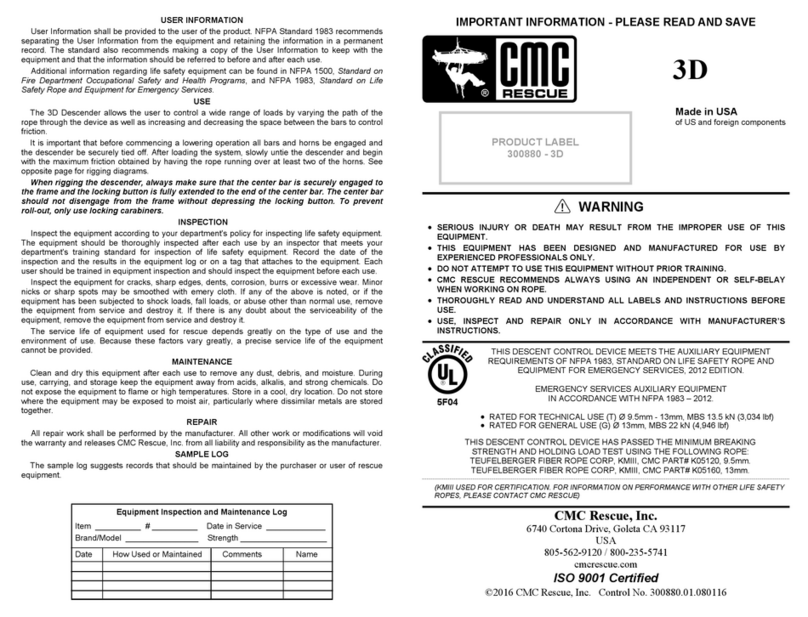

USER INFORMATION

User Information shall be provided to the user of the product. NFPA Standard 1983, incorporated

into the 2022 edition of NFPA 2500 recommends separating the User Information from the equipment

and retaining the information in a permanent record. The standard also recommends making a copy

of the User Information to keep with the equipment and that the information should be referred to

before and after each use.

Additional information regarding life safety equipment can be found in NFPA 1500 and NFPA 1858

and NFPA 1983, incorporated in the 2022 edition of NFPA 2500.

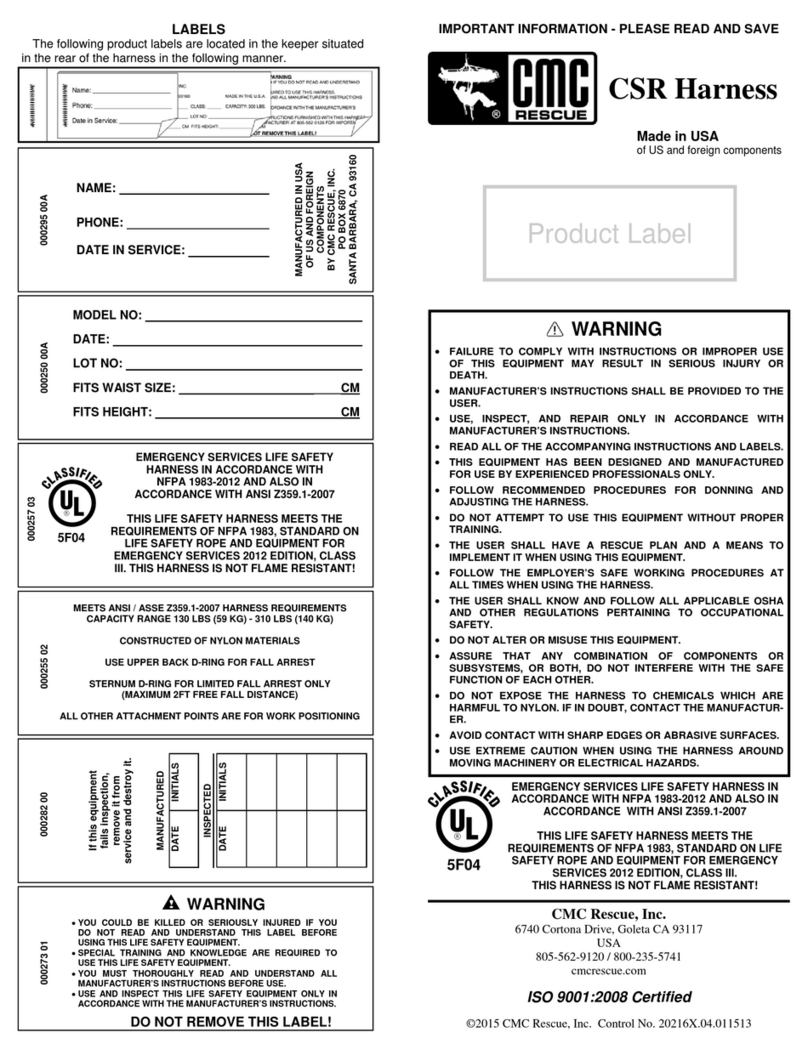

LIFESPAN / INSPECTION / RETIREMENT

CMC does not specify an expiration date for hardware because the service life depends greatly on

how and where it is used. The type of use, intensity of use, and environment of use are all factors in

determining serviceability of the equipment. A single exceptional event can be cause for retirement

after only one use, such as exposure to sharp edges, extreme temperatures, chemicals, or harsh

environments. Remove retired equipment from service and destroy it to prevent further use.

A device must be retired when:

• It fails to pass inspection.

• It fails to function properly.

• It has illegible product markings.

• It shows signs of damage or excessive wear.

• It has been subjected to shock loads, falls, or abnormal use.

• It has been exposed to harsh chemical reagents.

• It has an unknown usage history.

• You have any doubt as to its condition or reliability.

• When it becomes obsolete due to changes in legislation, standards, technique or incompatibility

with other equipment.

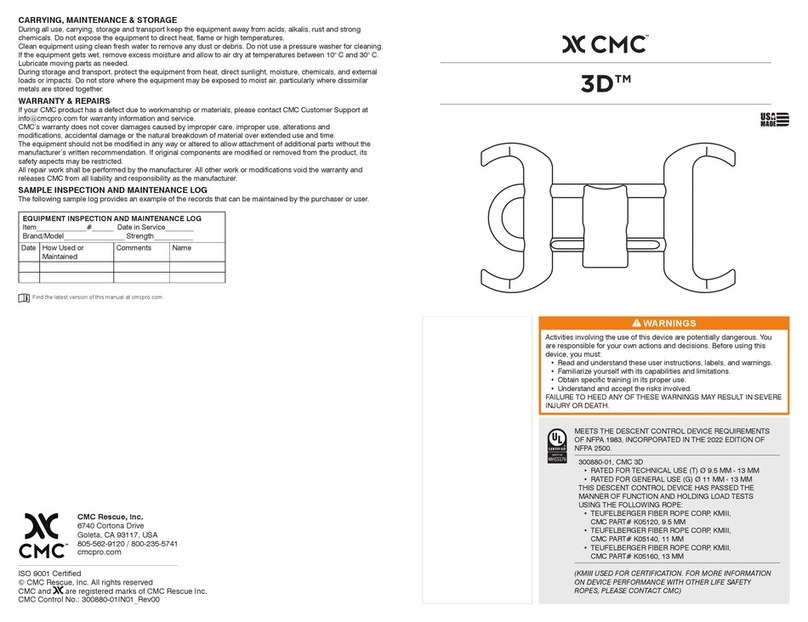

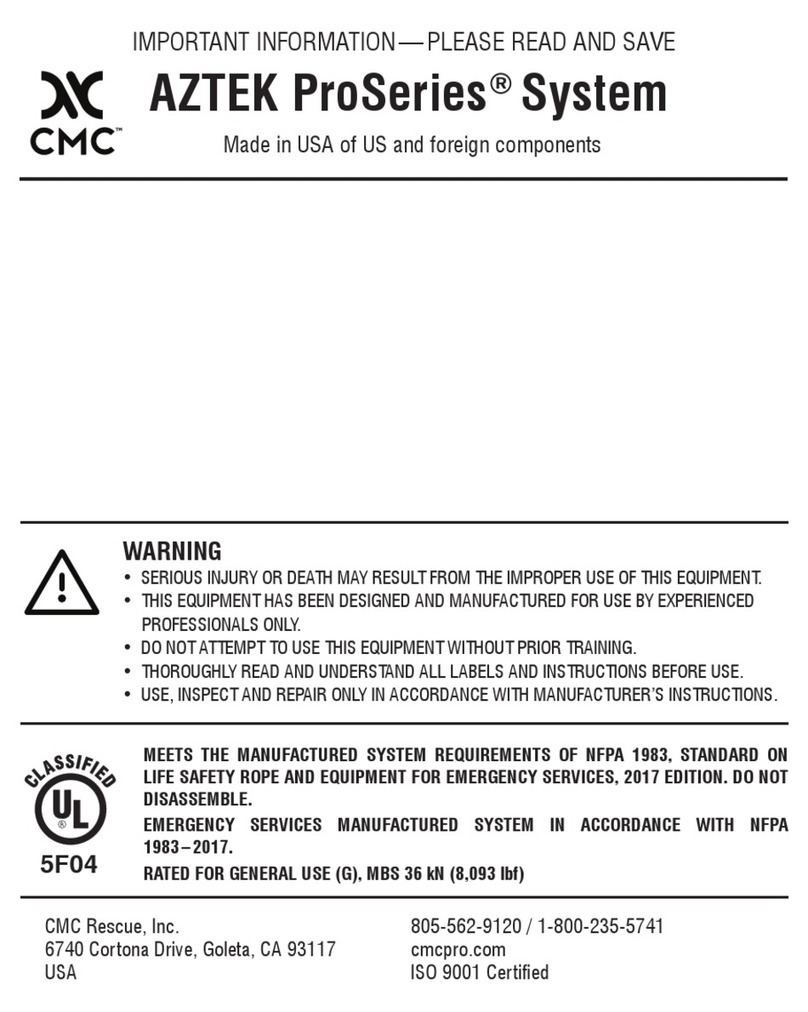

MEETS THE ASCENDING DEVICE REQUIREMENTS OF NFPA 1983,

INCORPORATED IN THE 2022 EDITION OF NFPA 2500.

341103-01 CMC ASCENDER

• RATED FOR TECHNICAL USE (T) Ø 11 MM - 13 MM

• RATED FOR GENERAL USE (G) Ø 13 MM

THIS DESCENT CONTROL DEVICE HAS PASSED THE MANNER OF FUNCTION

AND HOLDING LOAD TESTS USING THE FOLLOWING ROPE:

• CMC STATIC-PRO LIFELINE, PART# 28110X, 11MM

• CMC LIFELINE, PART# 2732X0, 13 MM