USER INFORMATION

User Information shall be provided to the user of the product.

NFPA Standard 1983 recommends separating the User Information from the equipment and

retaining the information in a permanent record. The standard also recommends making a

copy of the User Information to keep with the equipment and that the information should be

referred to before and after each use.

Additional information regarding auxiliary equipment can be found in NFPA 1500, Standard

on Fire Department Occupational Safety and Health Programs and NFPA 1983, Standard

on Life Safety Rope and Equipment for Emergency Services.

INSPECTION

Inspect the equipment according to your department's policy for inspecting life safety

equipment. The equipment should be inspected after each use by an inspector that meets

your department's training standard for inspection of life-safety equipment. Record the date

of the inspection and the results in the equipment log or on a tag that attaches to the

equipment. Each user should be trained in equipment inspection and should do a cursory

inspection before each use.

The service life of equipment used for rescue depends greatly on the type of use and the

environment of use. Because these factors vary greatly, a precise service life of the equipment

cannot be provided. Moisture, ice, salt, sand, snow, chemicals and other factors can prevent

proper operation or can greatly accelerate wear and may damage the electronics.

Inspect the equipment for cracks, dents, elongation of the swivels, corrosion or excessive

wear. Verify that the swivels rotate freely and that the axle bolts have not loosened. If any

significant damage is observed, the equipment should be removed from service. Minor

nicks or sharp spots may be smoothed with emery paper.

If the equipment is dropped or impact loaded, it should be inspected by a qualified inspector

prior to being returned to service. In most cases, a visual inspection will not be able to

determine if the equipment has been damaged. Based on the history of the incident, if there

is any doubt regarding the safety of the equipment, it should be removed from service and

retired. You should occasionally apply a known force to verify the Enforcer is accurate.

Be aware during use; stop and check if forces don’t seem reasonable. The Enforcer unit

should be returned to the manufacturer for calibration when needed. Contact Customer

Support at 800 235 5741 for more information.

USING THE ENFORCER

To measure the force applied to a rope system at a given point, connect the Enforcer

between two components of the system. An example would be for monitoring the tension

in the trackline of a highline system.

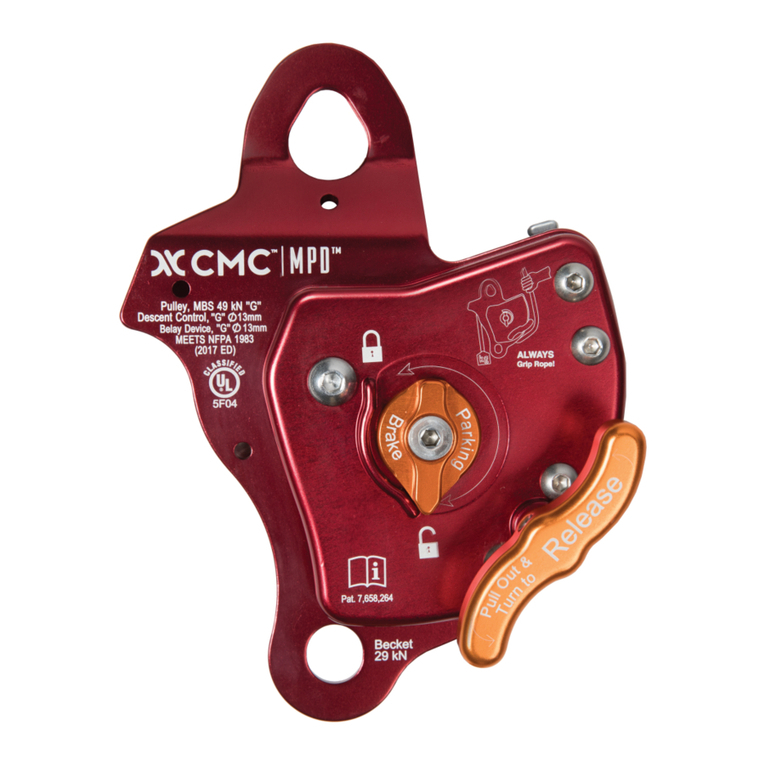

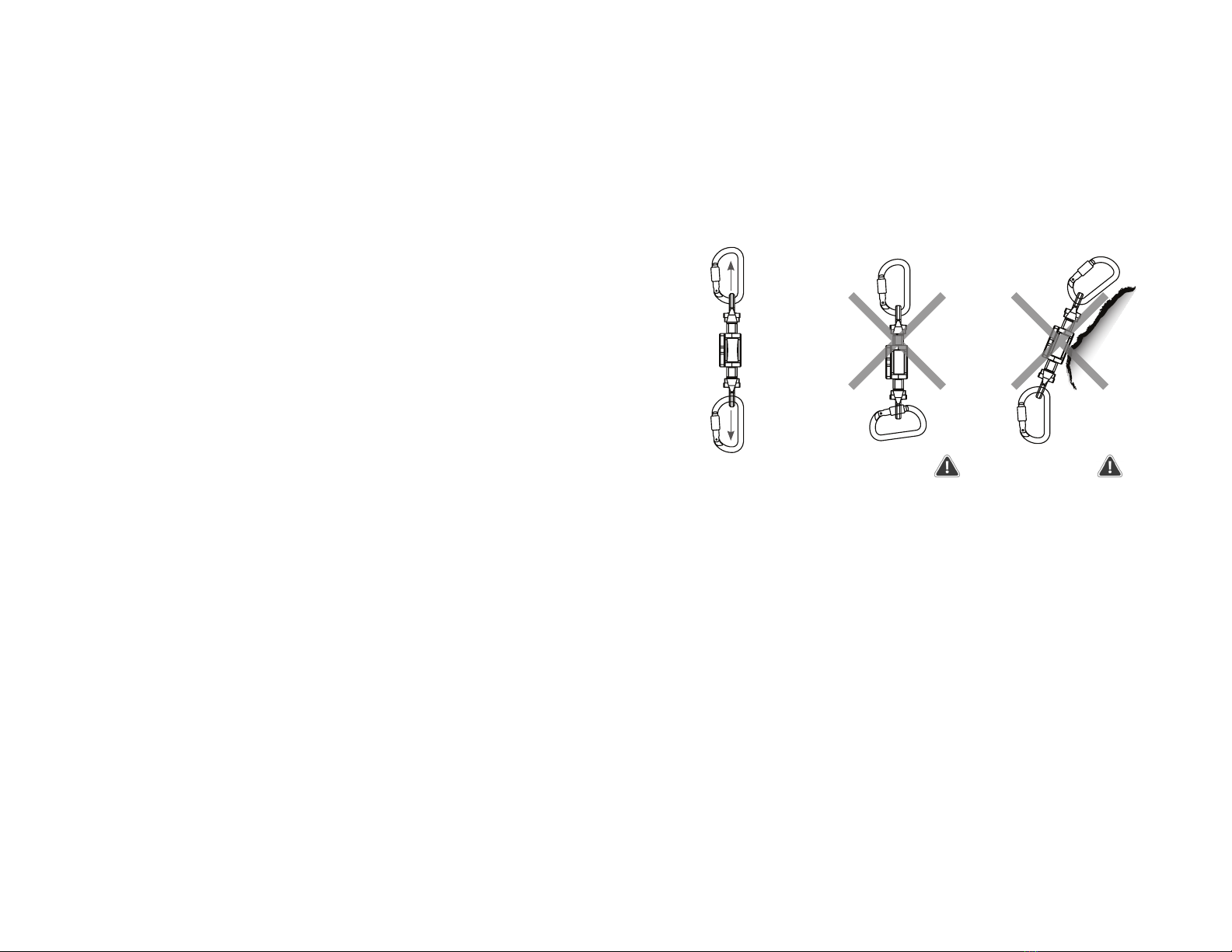

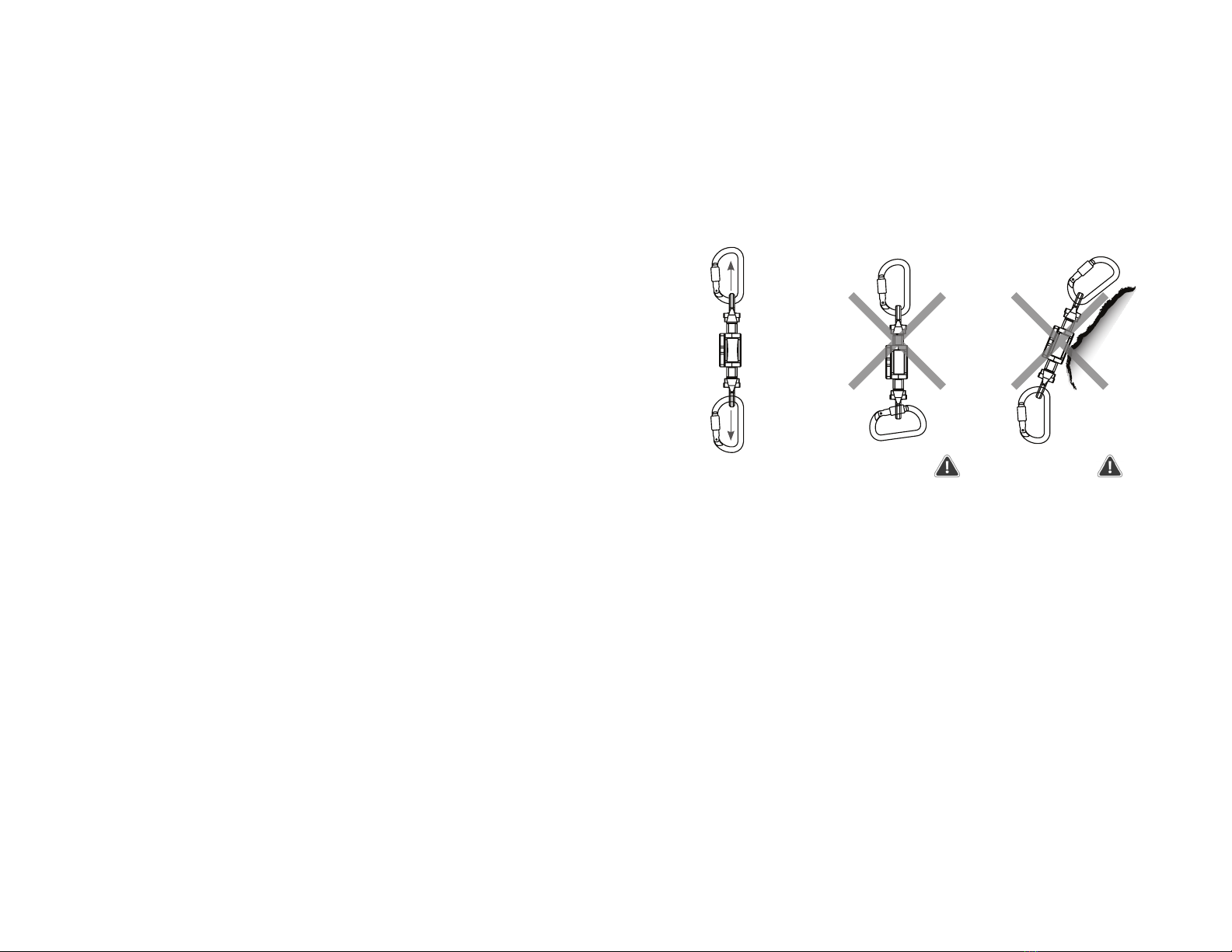

Ensure the Enforcer is free to align with the load (Figure 1) and does not bind or lever

against connectors (Figure 2) or terrain/obstructions (Figure 3). Verify compatibility

with other components of your system. Incompatible connections can cause detachment,

breakage, etc.

The Enforcer is rated to 50 kN (11,240 lbf), but the electronics may be damaged at loads

over 20 kN (4,496 lbf) and at loads over 20 kN the display will permanently indicate

OVERLOADED. In this case the Enforcer should not be used in life safety applications.

It is recommended that you establish your own Working Load Limit (WLL) depending

on your use.

Refer to the Quick Reference Guide provided for instructions on how to operate each

of the Load Cell functions, including Bluetooth connectivity to a mobile device. For

the most current version of the reference card, please visit cmcrescue.com/enforcer

or call Customer Support at 800 235 5741.

Structural components of the Enforcer are very rugged, and the electronics are durable,

but it can be damaged by dropping. The electronics are resistant to light moisture, but not

waterproof. The unit should be protected from rain or other direct water exposure. If it must

be used in such conditions wrap it in clear plastic, making sure it dries out completely

later. If you use the Enforcer in drop or strength testing, protect it from hitting something

if breakage will occur.

Figure 1 OK Figure 2 NO Figure 3 NO