USER INFORMATION

User Information shall be provided to the user of the product. NFPA Standard 1983 recommends separating

the User Information from the equipment and retaining the information in a permanent record. The standard

also recommends making a copy of the User Information to keep with the equipment and that the information

should be referred to before and after each use. Additional information regarding life safety equipment can be

found in NFPA 1500, Standard on Fire Department Occupational Safety, Health, and Wellness Program, and

NFPA 1983, Standard on Life Safety Rope and Equipment for Emergency Services.

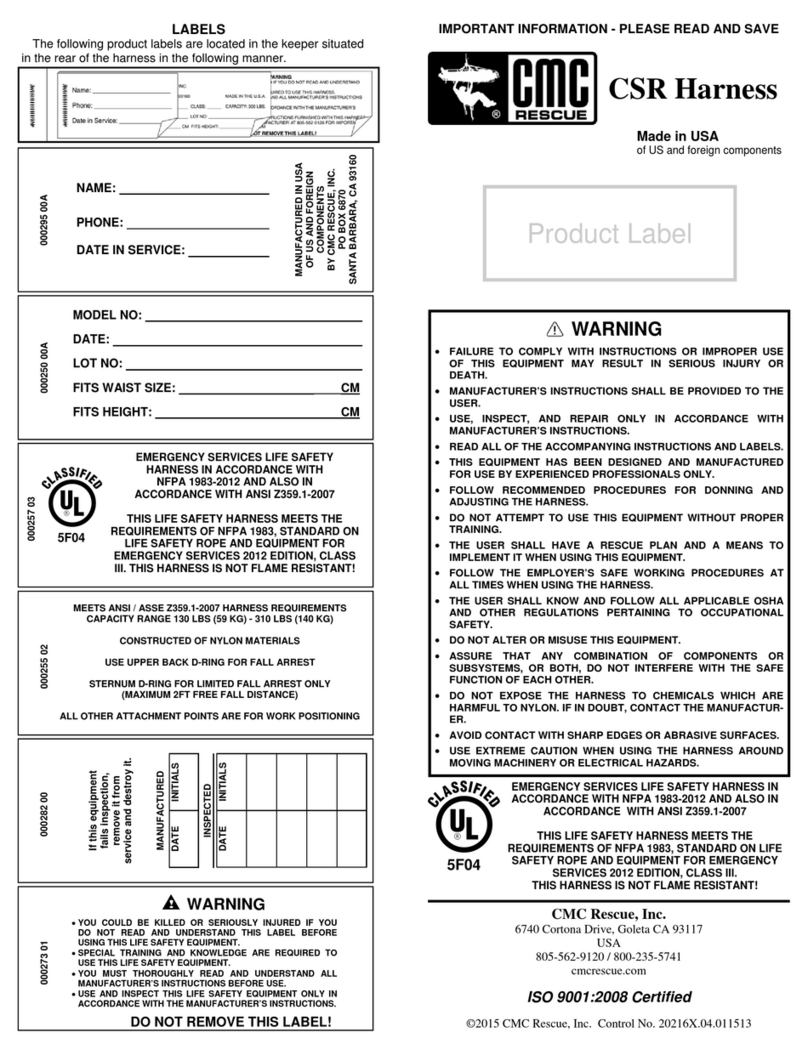

INSPECTION

Inspect the equipment according to your department’s policy for inspecting life safety equipment. Inspect

the equipment prior to entry into service, after each use, and at least once every 12 months. The equipment

should be thoroughly inspected by an inspector that meets your department’s training standard for inspection

of life safety equipment. Keep a record of the date, person performing the inspection and results, as well as

the date of rst use, name of users and any other pertinent information necessary to keep accurate track of

the equipment’s usage history in the equipment log or on a tag that attaches to the equipment. Each user

should be trained in equipment inspection and should inspect the equipment before each use.

Inspect the equipment for cracks, sharp edges, dents, corrosion, burrs or excessive wear. Minor nicks or

sharp spots may be smoothed with emery cloth. If any of the above is noted, or if the equipment has been

subjected to shock loads, fall loads, or abuse other than normal use, remove the equipment from service and

destroy it. If there is any doubt about the serviceability of the equipment, remove the equipment from service

and destroy it. The service life of equipment depends greatly on the type of use and the environment of use.

Because these factors vary greatly, a precise service life of the equipment cannot be provided.

LIMITATIONS AND PROPER USE

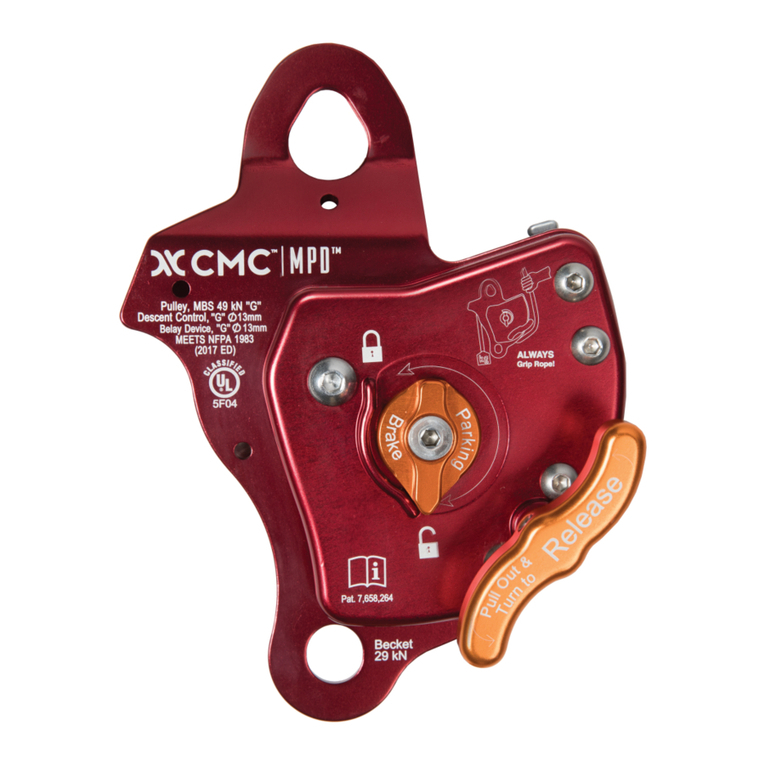

All carabiners are designed to specic performance criteria. Be aware of load limitations, manner used, and

proper technique. Do not overload a carabiner. Carabiners can fail under improper use conditions such as

cross loading, gate open loading, loading other than major axis, applying a shear or torsional load to the

carabiner, etc. If you are not sure of proper application or technique, seek proper training in carabiner use and

technical rope application.

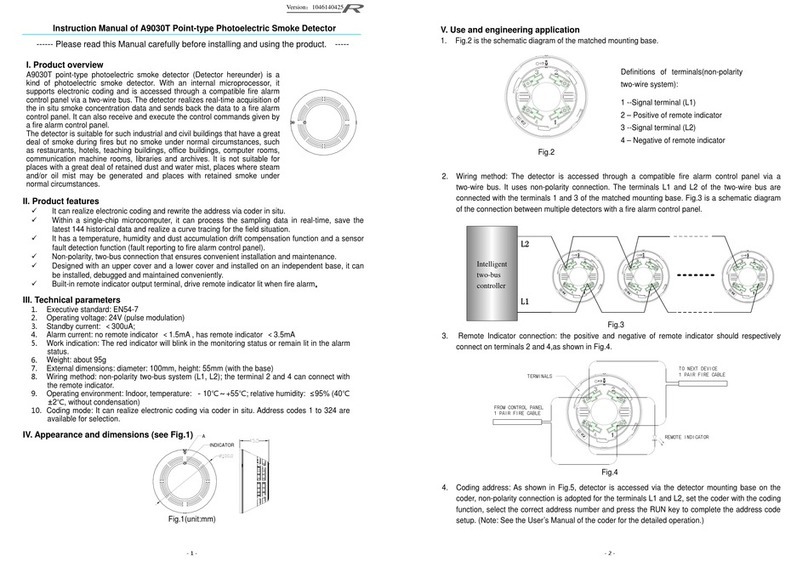

To remove the keeper pin (for models so equipped), use the supplied hex wrench to remove the set screw,

then pull the pin completely from the carabiner frame. To reinstall, insert the keeper pin through the hole in

the gate side of the frame, then ensure the pin is fully seated in the blind hole in the spine side of the frame.

Reinstall the set screw, taking care not to overtighten and stripping the threads or head. Use a thread locker to

ensure the set screw does not back out during use.

CARRYING, MAINTENANCE & STORAGE

Clean and dry this equipment after each use to remove any dust, debris and moisture. During use, carrying

and storage keep the equipment away from acids, alkalis, rust and strong chemicals. Do not expose the

equipment to ame or high temperatures. Store in a cool, dark, dry location. Do not store where the equipment

may be exposed to direct sunlight or moist air, particularly where dissimilar metals are stored together.

REPAIR

All repair work shall be performed by the manufacturer. All other work or modications void the warranty and

releases CMC from all liability and responsibility as the manufacturer.