4

Safety Product description

Safety instructions

Make sure that any person installing, taking into operation

and operating the self-dehydrating breather:

• is technically qualified and competent

• fully complies with these assembling instructions

Improper operations or misuse could cause danger to:

• life and limb

• the equipment and other assets of the operator

• the equipment proper function

Safety instructions in this manual are shown in three

different forms to emphasize important information.

Safety notes on the equipment operation

Electrical installation is subject to the relevant national

safety rules.

It is mandatory to connect the grounding cable.

This information indicates particular danger to life and health.

Disregarding such a warning can lead to serious or fatal injury.

It is important to observe the limit values indicated on

the nameplate and in the operating instruction before

commissioning the device.

All relevant fire protection regulation must be strictly observed.

This information indicates particular danger to equipment or

other property of the user. Serious or fatal injury cannot be

excluded.

Installation, electrical connection and fitting the device may only

be performed by qualified personnel and only in accordance

with this instruction manual. It is the responsibility of the user

to ensure that the device is used for specified application only.

For safety reasons, please avoid any unauthorized and improper

usage.

During the regeneration phase, the surface temperature

increases. Touching the surface is dangerous.

This notes give important or specific information concerning the

equipment or as to work with the equipment.

WARNING

WARNING

WARNING

CAUTION

CAUTION

CAUTION

NOTE

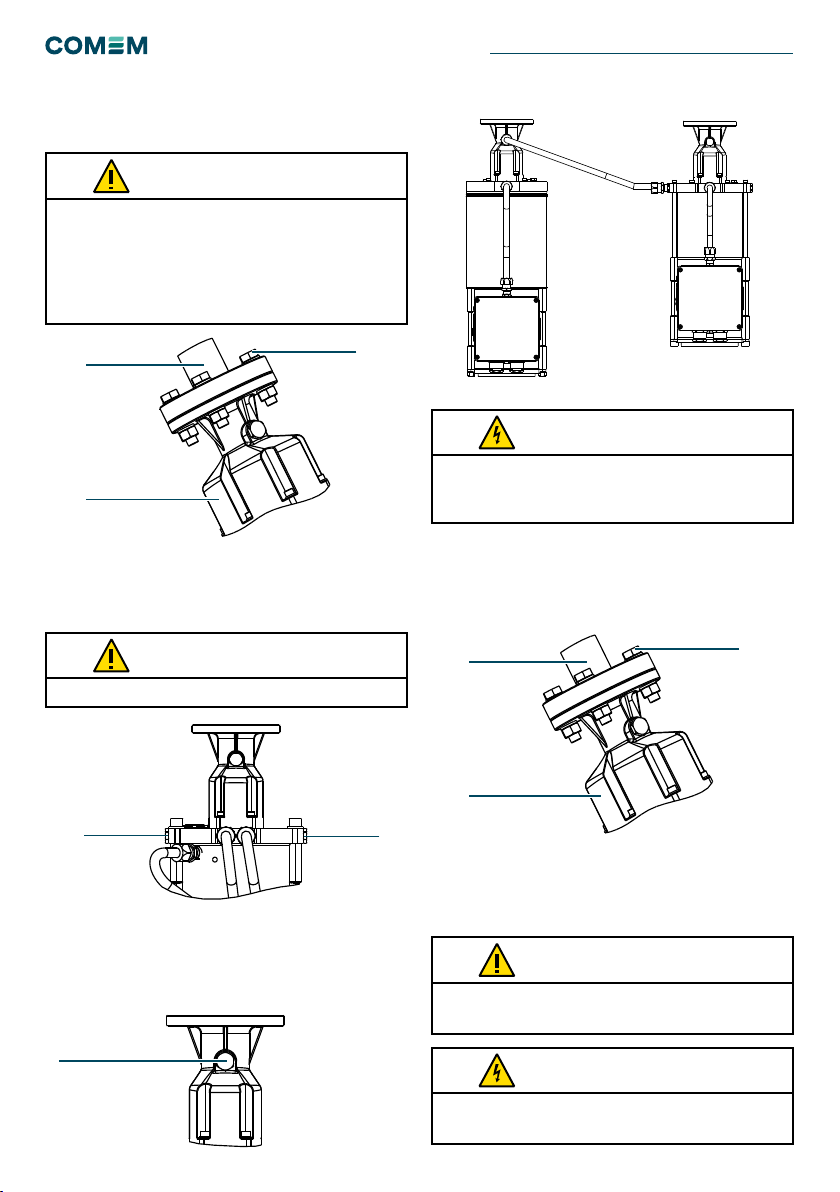

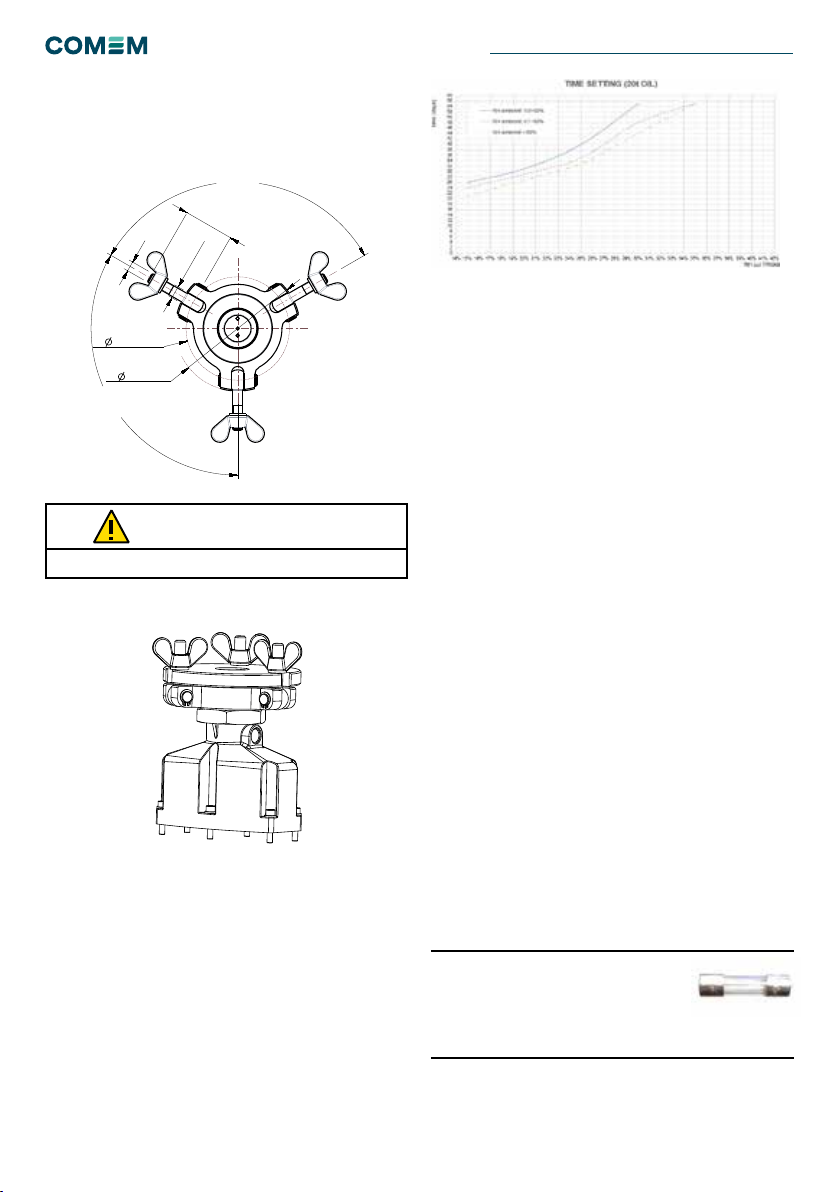

The dehydrating breather is used for oil-insulated tran-

sformer and on-load tap-changer to dry the air which is

suctioned in by the oil conservator during the thermal

contraction of the oil mass.

During the normal operation the oil conservator intakes air

that passes through the metallic filter.

The metallic filter stops dust, sand and other particles

from the contaminating air.

The air then passes through the salt tank 1 (Fig.14-15/1).

The tank is filled with silica gel that absorbs the moisture.

The dehydrated air goes through piping to the oil

conservator.

After a pre-determinate time (settable) a solenoid

valve blocks the passage of air through tank 1 and

deviates through the “plenum chamber” 2 (Fig.14-15/2)

(for eSDB10C it deviates the air through the main

self-dehydrating breather eSDB15, eSDB30, eSDB40 or

eSDB14C). At the same time, a heating system inside tank

1 is activated. The water vapor leaving the silica gel is

expelled outward by a fan that also dissipates the heat.

After the salt regeneration in tank 1, the solenoid valve is

de-energized and the air flow through tank 2 is inhibited.

The salt in this tank (2) is also dehydrated, regeneration of

the salt in tank 2 follows automatically (not for eSDB10C).

No maintenance is required for replacement and

regeneration of the desiccant.

SELF-DEHYDRATING BREATHERS eSDB-10C/12C/14C

D

C

B

A

654

3

21 7 8

E

F

A

B

C

D

E

F

1 2 3 4 5 6 7 8

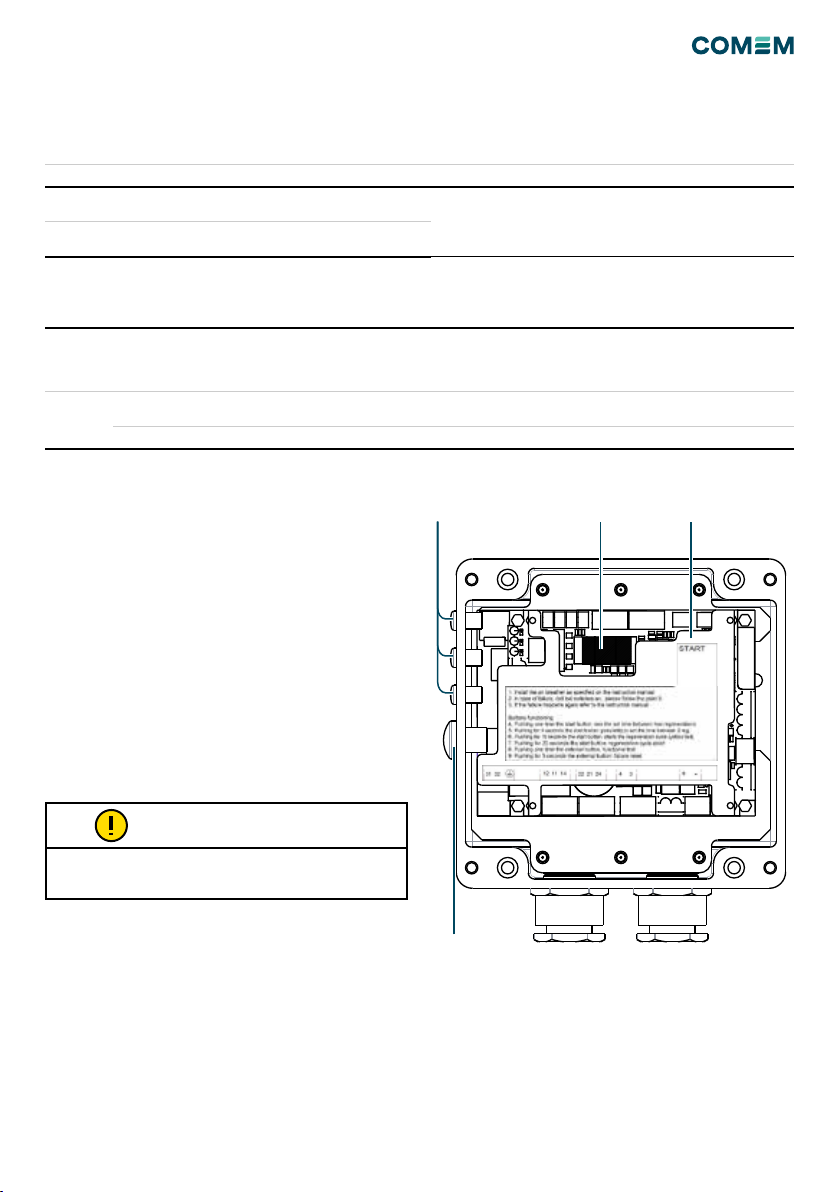

This document is issued by means of a computerized system.

The digitally stored original is electronically approved. The

approved document has a date entered in the `Approved'-field.

A manual signature is not required.

DRAWING SHEET ISO 5457: 1999-A3T

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

parties without express authority is strictly fobidden.

1/13

A

Development

NE-359

SHEETITERREVSTATUSDOCUMENT ID

ITABB-9AAE306693 -

RESPONSIBLE DEPARTMENT

CONNECTION ESDB10C

COMEM

TITLE / SUPPLEMENTARY TITLECOMPANY

Component Drawing-

PROJECT IDWORK ORDER IDBASED ON DOC IDDOCUMENT KINDAPPROVED ON

--Diego Boro

APPROVED BYREVIEWED BYCREATED BY

© COPYRIGHT ALL RIGHTS RESERVED

ESDB14C

ESDB10C

C

M

Y

CM

MY

CY

CMY

K

ai16208273657_ne-359.pdf 1 12/05/2021 15:49:25

Figure 1