Orion reserves the right to make changes in this document without prior notice.

WARNING!

Safety instructions

READ CAREFULLY!

BEFORE INSTALLING AND STARTING UP THE DEVICE, PLEASE OBSERVE THE

SAFETY INSTRUCTIONS LISTED IN THE FOLLOWING SECTIONS. THIS WILL

HELP YOU TO AVOID MAKING SERIOUS ERRORS THAT COULD IMPAIR YOUR

HEALTH, DAMAGE THE DEVICE AND ENDANGER OTHERS. WE THEREFO-RE

RECOMMEND THAT YOU KEEP THIS MANUAL IN CLOSE PROXIMITY TO THE

INSTALLATION.

THE SAFETY OF THIS DEVICE AND ITS PROPER FITTING DEPENDS,

THEREFORE, ON RESPECTING ITS TECHNICAL CHARACTERISTICS AND

PROPER FITTING, TO BE DONE PROPERLY, AND UNDER SAFE CONDITIONS AS

EXPLAINED IN THE TECHNICAL DOCUMENT THAT COMES WITH THE DEVICE.

THIS DEVICE SHOULD ONLY BE USED FOR THE PURPOSE FOR WHICH IT WAS

EXPLICITLY DESIGNED. ANY OTHER USE IS DANGEROUS. TANSA IS NOT

LIABLE FOR ANY DAMAGE CAUSED BY IMPROPER, WRONGFUL AND

UNREASONABLE USE

STORAGE RECOMMENDATIONS

•THE RECOMMENDED MAXIMUM STORAGE TIME IS 6 MONTHS. IT SHOULD

BE NOTED THAT EQUIPMENT STORED FOR A LONGER PERIOD THAN THE

MAXIMUM STORAGE TIME INDICATED MUST BE INSPECTED BEFORE USED.

•THE UNITS MUST NOT BE STACKED AND SHOULD BE STORED OFF THE

GROUND, UNDER COVER PROTECTED FROM WEATHER, CONSTRUCTION

ACTIVITIES AND EXTREME TEMPERATURES

•BE CAREFUL WHEN HANDLING DEVICES THAT WEIGH OVER 25 KG. IF

NEEDED, USE PROPER SAFETY HOISTING EQUIPMENT.

•MINIMUM TWO PEOPLE MUST ALWAYS BE USED TO MOVE EACH

PEDESTAL, DUE TO ITS WEIGHT AND SIZE. ALWAYS PLAN THE PATH AND

ALLOCATE WHERE THE PEDESTAL WILL BE MOVED TO. THIS IS THE ONLY

WAY TO AVOID ACCI DENTS AND DAMAGE TO THE EQUIPMENT.

BEFORE INSATALLING

•(CHECK, IF SOMETHING IS MISSING, DO NOT CONTINUE UNTIL YOU HAVE

COMPLIED WITH ALL SAFETY PROVISIONS)

•IT IS ESSENTIAL THAT THE INFORMATION ON INSTALLATION AND THE

TECHNICAL DATA FOR THE DEVICE BE OBSERVED DURING UNPACKING AND

INSTALLATION AND BEFORE OPERATING THE DEVICE. THIS INCLUDES

DIMENSIONS, ELECTRI CAL VALUES, NECESSARY AMBIENT AND CLIMATIC

CONDITIONS, ETC.

•FITTING AND TESTING MUST BE BE ONLY PERFORMED BY QUALIFIED

TECHNICIANS.

•LAYING THE CABLES, INSTALLATION AND TESTING MUST FOLLOW PROPER

PROCEDURES AS DICTATED BY LOCAL REGULATIONS.

•MAKE SURE THE DEVICE IS IN GOOD MECHANICAL STATE, BALANCED

AND ALIGNED, AND THAT IT OPENS AND CLOSES PROPERLY. ALSO, IF

NEEDED, FIT SUITABLE PROTECTIONS OR USE PROPER SAFETY SENSORS.

•MAKE SURE THAT THE OPENING TURNSTILE CAN NOT RESULT IN ANY

HAZARDS.

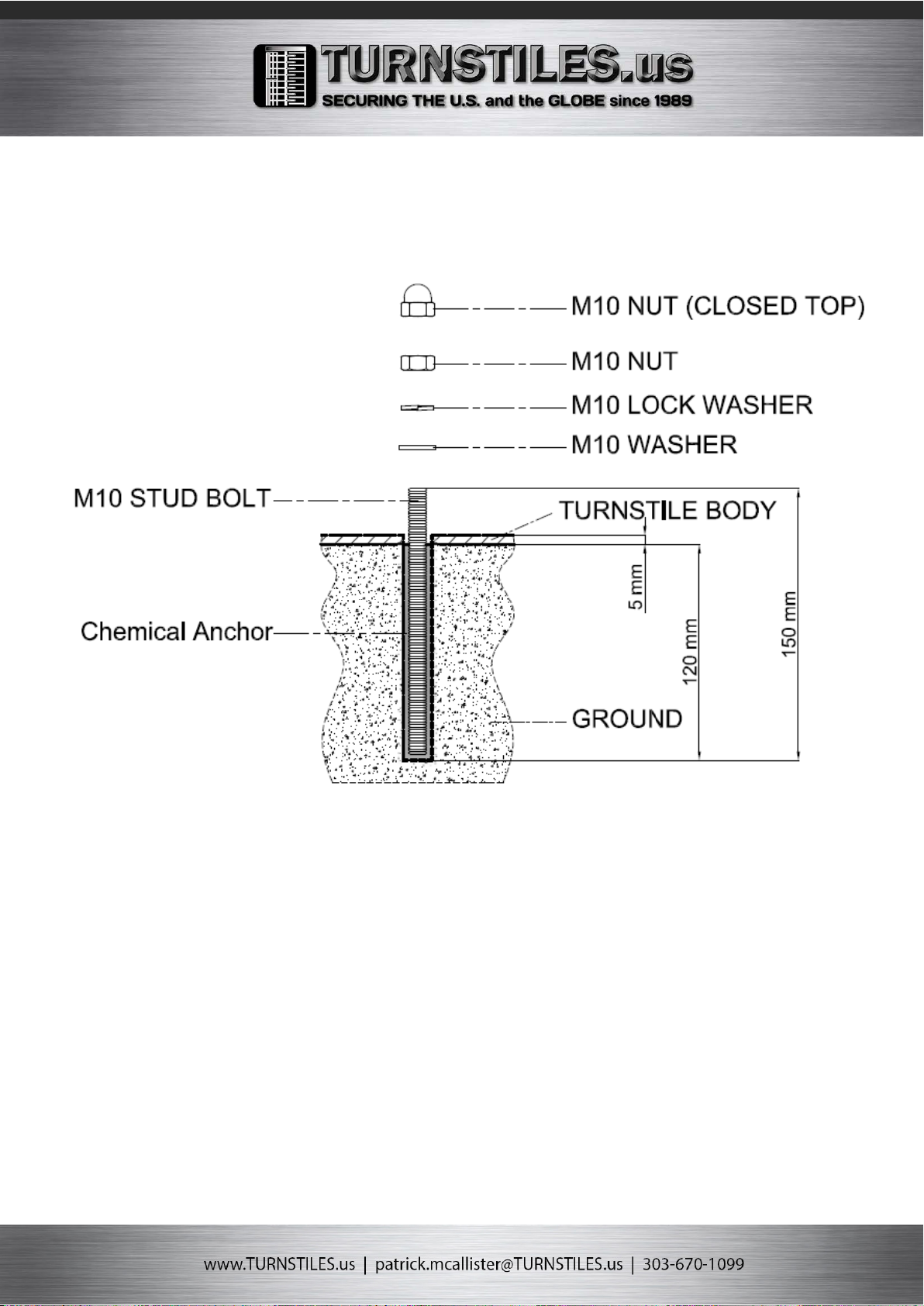

•DO NOT INSTALL THE DEVICE ON TO SURFACES THAT COULD YIELD AND

BEND. IF NECESSARY, ADD SUITABLE REINFOR CEMENTS TO THE

ANCHORING POINTS.

•ONLY INSTALL ON A LEVEL SURFACE.

•MAKE SURE ANY SPRINKLER SYSTEMS CAN NOT WET THE DEVICE FROM

THE GROUND UP.

INSTALLATION SAFETY

•SUITABLY SECTION OFF AND DEMARCATE THE ENTIRE

INSTALLATION SITE TO PREVENT UNAUTHORIZED PERSONS FROM

ENTERING THE AREA, ESPECIALLY MINORS AND CHILDREN.

•THE DEVICE MUST BE CONNECTED TO AN EFFICIENT, PROPER

GROUNDING SYSTEM.

•TANSA DECLINES ANY LIABILITY FOR USING NON-ORIGINAL

PRODUCTS; WHICH WOULD RESULT IN WARRANTY LOSS.

•APPLY WARNING SIGNS WHERE NECESSARY AND IN A VISIBLE

PLACE.

•ESD (ELECTROSTATIC DISCHARGE) REFERS TO THE MEASURES

TAKEN TO PROTECT COMPONENTS VULNERABLE TO ELECTROSTATIC

DISCHARGES AGAINST SUCH DISCHARGES AND HENCE FROM

POTENTIAL DAMAGE OR DESTRUCTION.

CABLE CONNECTIONS

•NO CABLES MAY BE CONNECTED OR DISCONNECTED DURING A

STORM (DANGER OF BEING STRUCK BY LIGHTNING).

•WHEN CONNECTING OR DISCONNECTING ANY OF THE LEADS,

ALWAYS HOLD THEM BY THE PLUG.

•NEVER PULL ON THE CABLES THEMSELVES. DOING SO COULD

CAUSE A CABLE TO BECOME DETACHED FROM THE PLUG.

•LAY THE CABLES SO THAT THEY DO NOT PRESENT A DANGER

(TRIPPING) AND CANNOT BE DAMAGED, BY BEING BENT, FOR

INSTANCE.

•PLEASE CHECK DEVICES WITH ADJUSTABLE RATED VOLTAGE TO

DETERMINE WHETHER THE PRESET RATED VOLTAGE OF THE DEVICE

CONFORMS TO THE LOCAL MAINS VOLTAGE. AN INCORRECT

SETTING MAY LEAD TO DAMAGE TO OR DESTRUCTION OF THE

DEVICE.

•BEFORE OPERATING, CHECK WHETHER ALL THE CABLES AND

WIRES ARE IN A PERFECT, UNDAMAGED CONDITION.

•ENSURE IN PARTICULAR THAT THE CABLES HAVE NOT BEEN BENT,

HAVE NOT BEEN LAID TOO TIGHTLY ROUND CORNERS, AND THAT

THERE ARE NO OBJECTS LOCATED ON TOP OF THEM. ALSO MAKE

SURE THAT ALL CONNECTORS HAVE A TIGHT FIT. DEFECTIVE

SCREENING OR WIRING MAY DAMAGE YOUR HEALTH (ELECTRIC

SHOCK) AND CAN DAMAGE OTHER DEVICES.

•THE SYSTEM EARTHING (EARTH WIRE) IS CONNECTED TO THE

PEDESTAL ENCLOSURE. THE EARTHING OF THE ENCLOSURE IS NOT

REQUIRED FOR ELECTRICAL SAFETY, ALTHOUGH THIS MAY BE

REQUIRED TO CONFORM TO CERTAIN STANDARDS.

•MAKE SURE THAT NO OBJECTS (E.G. JEWELLERY, PAPER CLIPS,

ETC.) OR LIQUIDS GET INSIDE THE DEVICE. THIS CAN LEAD TO

ELECTRIC SHOCKS OR SHORT-CIRCUITS.

•PROPER OPERATION AND COMPLIANCE WITH THE EMC

(ELECTROMAGNETIC COMPATIBI-LITY) LIMIT VALUES IS ONLY

GUARANTEED WHEN THE ENCLOSURE IS MOUNTED CORRECTLY AND

THE SIDE PANELS ARE IN PLACE.