4

Contents

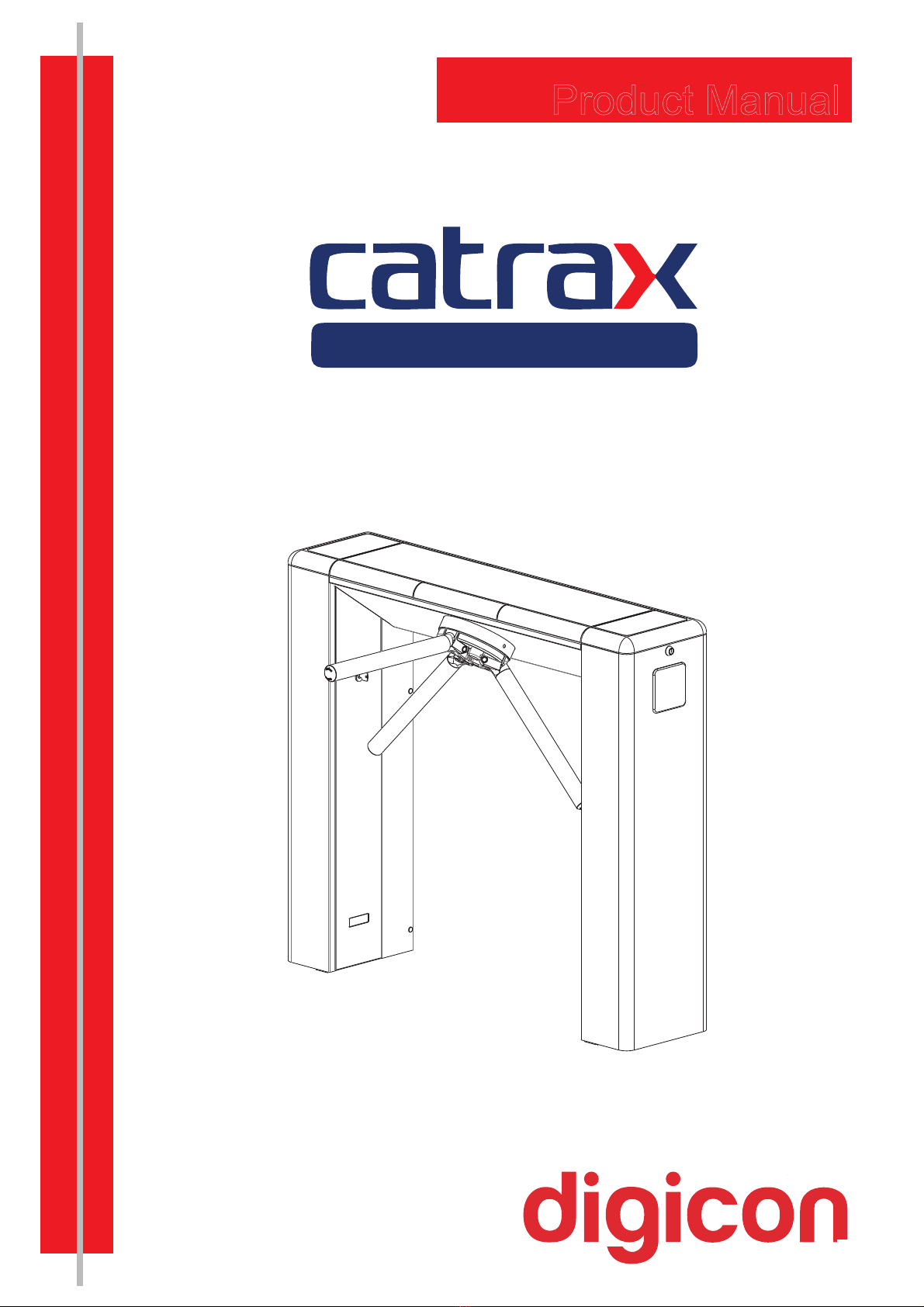

master

1. Important instructions ............................................................................

2. Orientations ...........................................................................................

3. Introduction ..........................................................................................

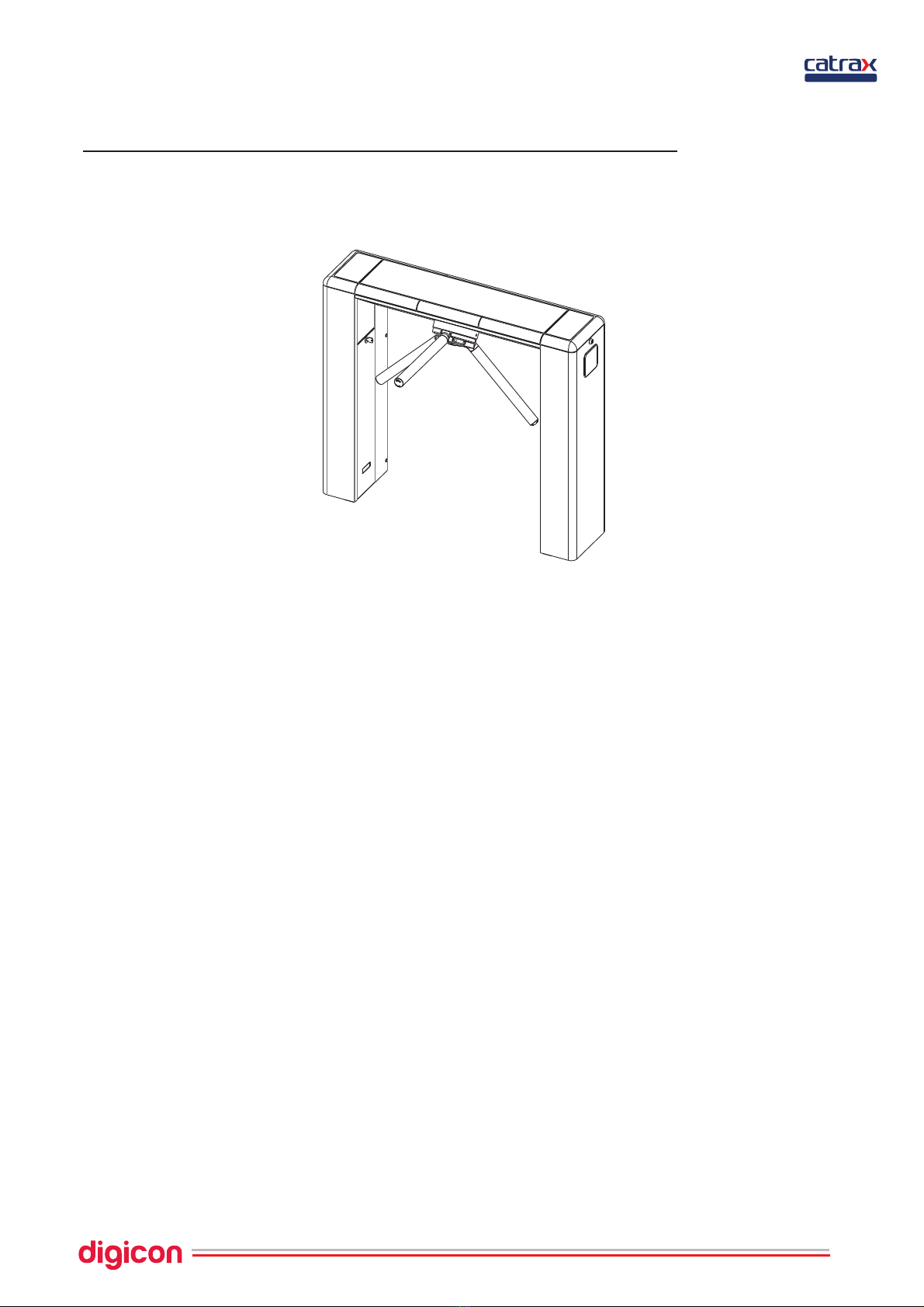

4. Features of .....................................................................Catrax Master

4.1 Operation ......................................................................Catrax Master

5. Installing/Assembling ..............................................................................

5.1 Unboxing .............................................................................................

5.2 Floor drilling and column fixation ............................................................

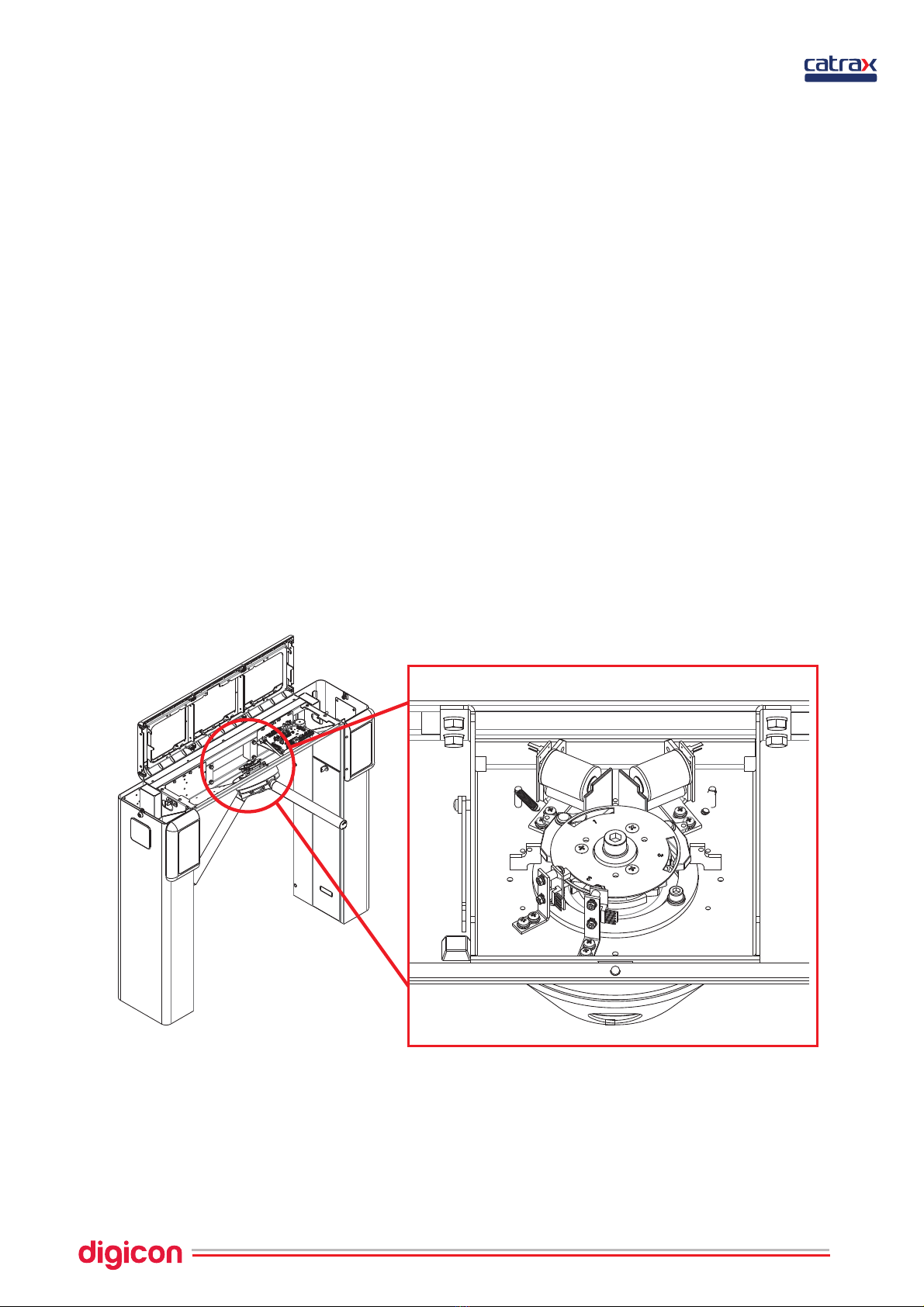

5.3 Assembling the arms ............................................................................

5.4 Accessing after assembly ................................................Catrax Master

6. Optional items .......................................................................................

6.1 Rear closure kit ....................................................................................

6.2 Collecting box kit .................................................................................

6.2.1 Connection of collecting kit to control board .........................................

6.3 Operational pictogram kit ......................................................................

6.4 Orientation pictogram kit .......................................................................

6.5 Electronic counter kit ............................................................................

6.6 Power supply .......................................................................................

6.7 Control board .......................................................................................

6.7.1 Inputs...............................................................................................

6.7.2 Outputs ............................................................................................

6.7.2.1 Return signals .................................................................................

6.5.2.2 Electromagnets ...............................................................................

6.7.2.3 Sound alarm ...................................................................................

6.7.2.4 Connection scheme .........................................................................

6.7.2.5 Pictogram ......................................................................................

6.7.2.6 Pictrogram connections ....................................................................

6.7.3 Configuration od control board - Switch ds1 ...........................................

6.7.4 Examples of some configurations .........................................................

6.7.5 Serial configuration ............................................................................

6.8 Anti-panic system .................................................................................

6.8.1 Power connection ...............................................................................

6.8.2 Assembling the arms ..........................................................................

6.8.3 Maintenance tests ..............................................................................

7. Maintenance ..........................................................................................

7.1 Preventive and corrective routine maintenance .........................................

7.2 Solving problems ..................................................................................

8. Technical characteristics ..........................................................................

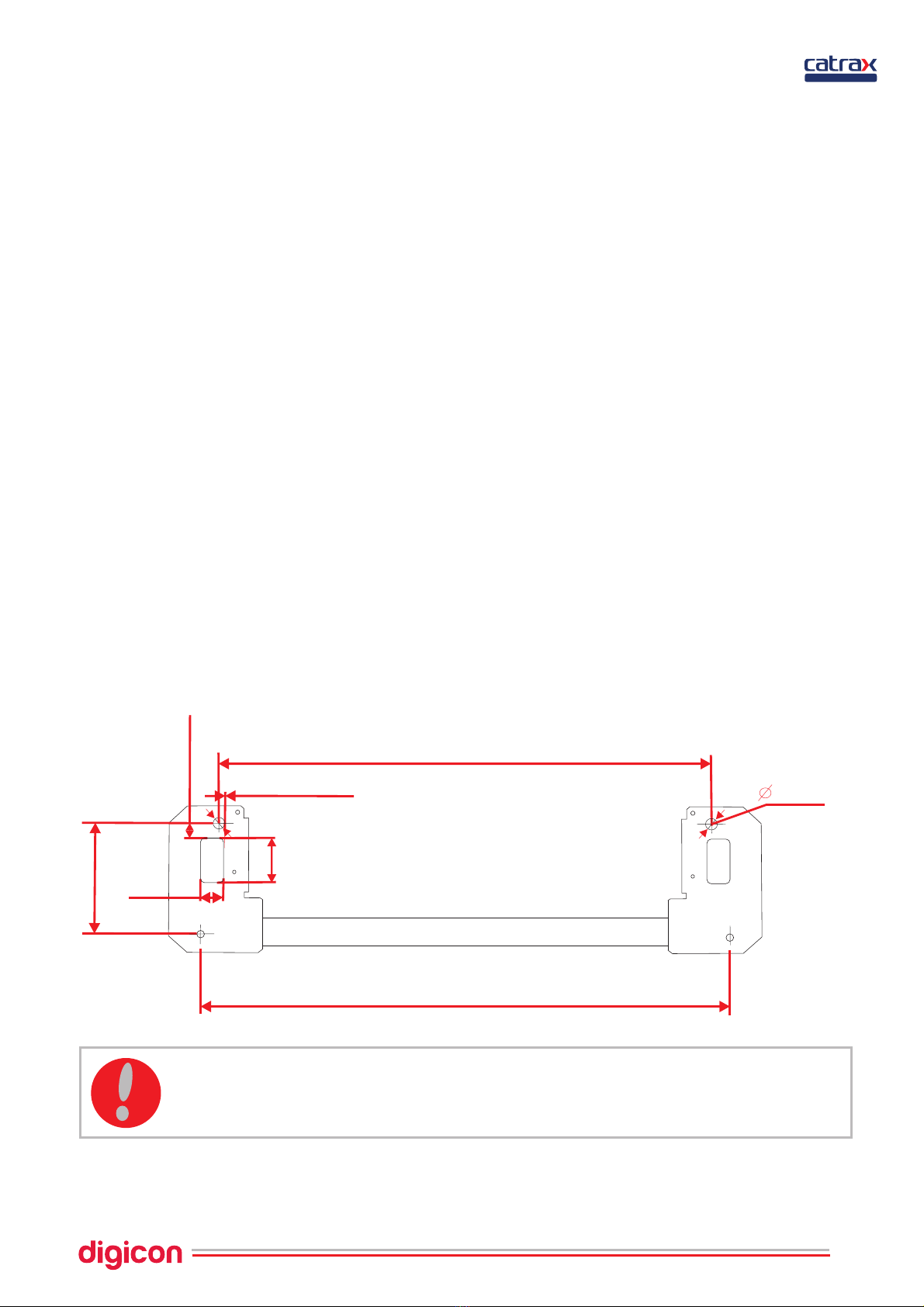

8.1 Dimensions ..........................................................................................

9. Cleaning ...............................................................................................

9.1 Maintenance and conservation of stainless steel ........................................

10.Warranty and technical assistance ............................................................

05

06

06

07

08

09

09

10

11

12

14

14

14

15

15

16

16

18

18

20

21

21

21

21

22

22

22

23

23

24

25

26

27

28

29

29

31

32

32

34

34

35