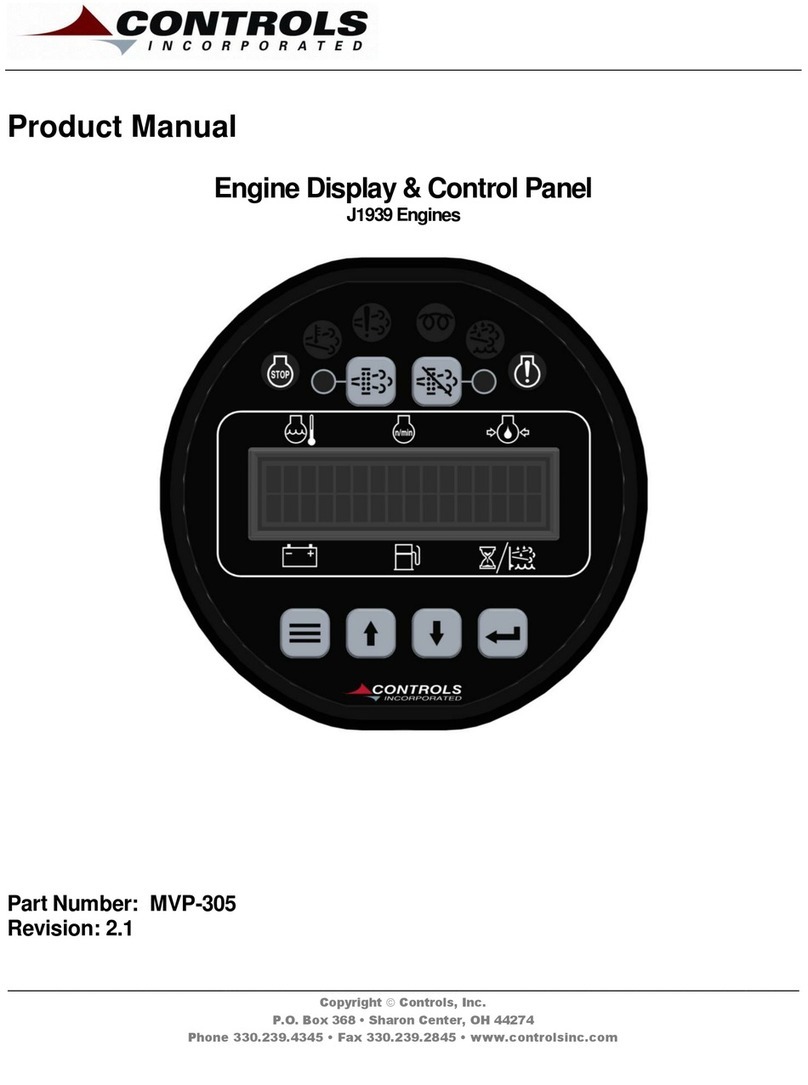

CONTROLS, INCORPORATED

C O N T R O L S Y S T E M S & S O L U T I O N S

- 1 -

TABLE OF CONTENTS

QUICK SET UP……………..………………………………………….…………………..……………………………….……………….…………...2

PRIOR TO STARTING ENGINE………………..……………………………………………………………….……………….…………...3

ENGINE TYPE: MECHANICAL VS. J1939 ENGINE

MANUAL OPERATION THROTTLE SETTINGS

STARTING THE ENGINE………………………………..………………………….………………………………………….………..…….....5

MANUAL START/STOP

PANEL CONNECTORS…………………………………...……………………………………………………………….………………………6

ENGINE HARNESS CONNECTOR

TRANSITION HARNESS FOR MECHANICAL ENGINES…….....……………...……………………………………….…7

MODULE CONNECTORS……………………………………………………………………………………………….…….……………….…8

ENGINE ALARMS, CODES AND MESSAGES…………………………………………………………………………….........10

ENGINE ECU ALARMS/DE-RATE/SHUT DOWNS

PANEL ALARM ANNUNCIATION AND CODE READER

PANEL INDICATION LAMPS

ACTIVE AND STORED ENGINE ECU CODES

CONTROL PANEL SPECIFIC ALARMS AND SHUT DOWNS………………………………………….……………12

CONTROL PANEL SPECIFIC SAFETY ALARMS

CONTROL PANEL ANALOG AND DIGITAL INPUTS………………………………………………………………………13

ANALOG INPUTS

DIGITAL INPUTS

CONTROL PANEL RELAY OUTPUTS…………………………………………………………………..……………………….....…15

MENU SYSTEM……………………………………………………………………………………………..…………………………………….……16

MENU ACCESS, EXIT AND NAVIGATION

MENUS SYSTEM STRUCTURE (VIEWING & CONFIGURATION MENUS)

VIEW MENUS

CONFIGURATION MENUS

COMMUNICATIONS……………………………………………………………………………………..…………………………………….……23

CAN BUS

BATTERY BACKUP……………………………………………………………………………………..…………………………………….……24

EMISSIONS MONITORING…………………………………………………………………………………………………….……………....25

EMISSIONS INFORMATION

REGENERATION

STANDARD REGENERATION

SERVICE LEVEL REGENERATION

REGEN INHIBIT