CONTROLS, INCORPORATED

CON T R O L S Y S T E M S & S O L U T I O N S

- 1 -

1) Introduction

1.1 The C3M-115 is a sealed microprocessor-based engine control system for industrial engines. It is based on

the Controls, Inc.iMech series controller platform with aFreescale 8 bit processor.

1.2 The product is packaged into water tight, polycarbonate enclosureformaximum durability. The controller is

plug & play with a sealed bulkhead engine connector incorporated into thecase.

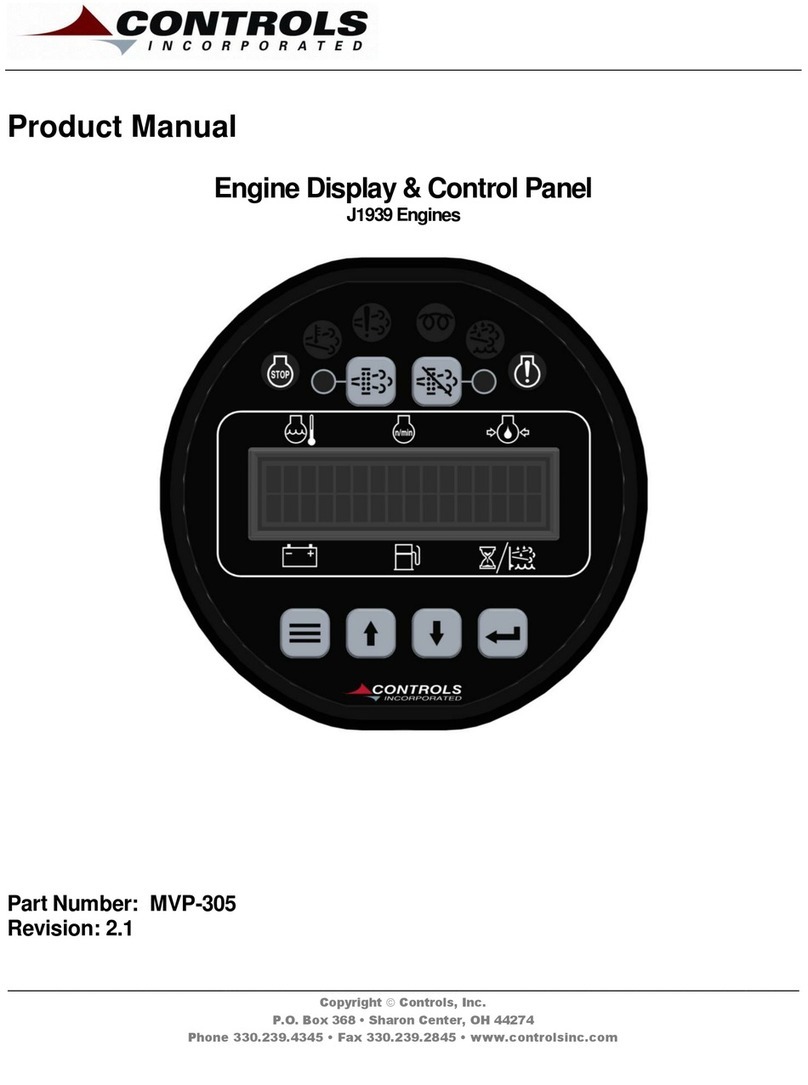

1.3 The digital OLEDdisplay is 1”H x 4”W with two rows of 16 characters. Character height is approximately ½”.

The display has an operating and storage temp rating of -40C to+80C and isviewable in direct sunlight

1.4 The unit monitorsall critical enginefunctions and hasfull time display of Oil Pressure, Engine Temperature,

Engine Speed, BatteryVoltage, Fuel Level and Engine Hours.

1.5 Analog Input is available forfuel level monitoring.

1.6 Digital Flex Inputis availableforexternal shutdown switches.

1.7 Engine speed control optionsinclude:(requirea thirdparty device to drive)

1.7.1 Off –Nofunctionalityfrom the control panel.

1.7.2 Momentary–Two contactclosures for Upand Down when arrow buttons are pressed.

1.8 The controller with corresponding amber or red LEDilluminations above the digital display monitors engine

safety alarms. Text messages are displayed automatically.

iMech™ C3M-115