Index

1. INTRODUCTION 1

1.1 Icons appearing in the manual .............................................................................................2

1.2 Manual revision history .......................................................................................................3

1.3 Symbols used.......................................................................................................................4

1.4 Intended use and improper use ............................................................................................5

1.5 Safety information ...............................................................................................................6

1.6 Environmental risks and disposal ......................................................................................12

1.7 CE declaration ...................................................................................................................13

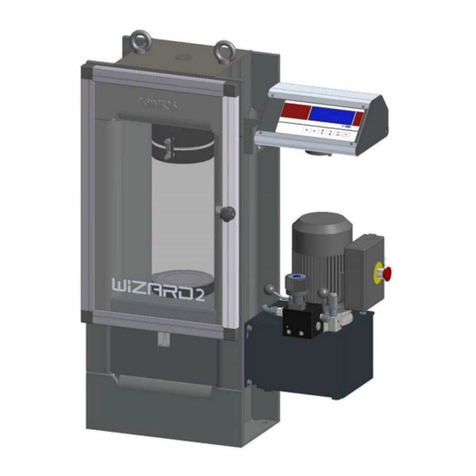

2. DESCRIPTION 14

2.1 Identification plate .............................................................................................................15

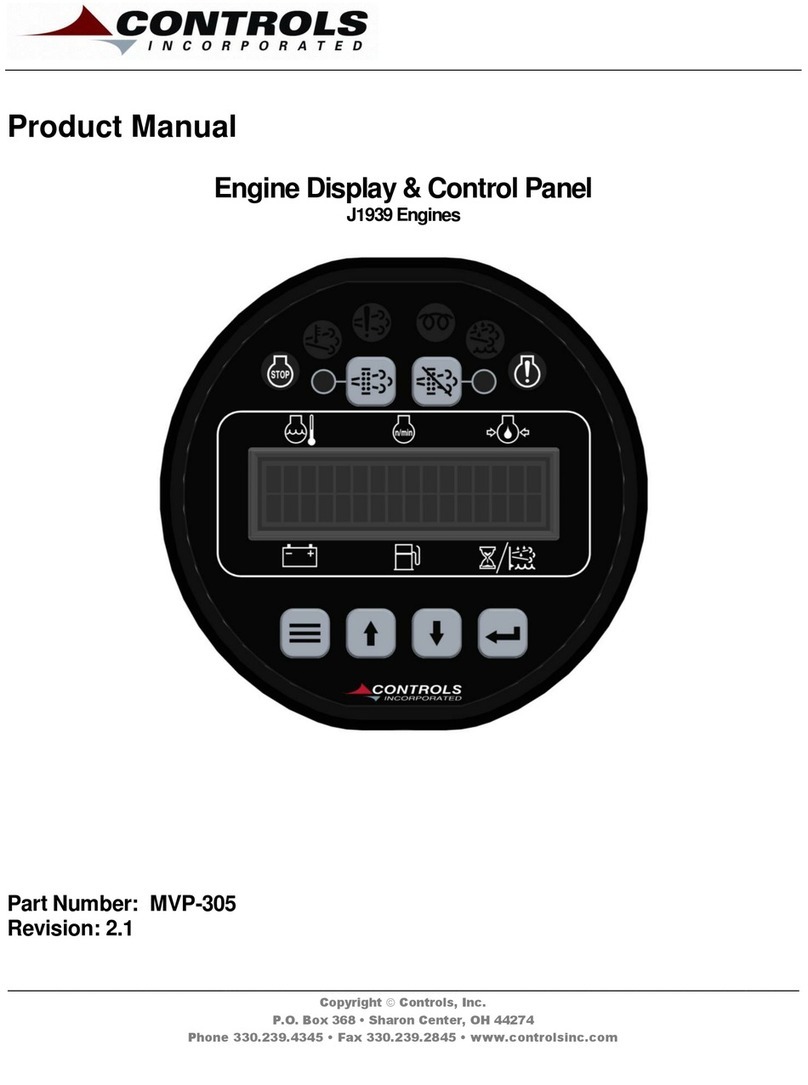

2.2 Commands and controls ....................................................................................................16

2.3 Technical specifications.....................................................................................................17

3. INSTALLATION 18

3.1 Shipment............................................................................................................................19

3.2 Unpacking and inspection..................................................................................................20

3.2.1 How to remove the equipment from the shipping crate ................................................. 21

3.3 Positioning of the unit and space requirements .................................................................23

3.4 Assembling the headframe ................................................................................................25

3.5 Electrical requirements ......................................................................................................30

3.6 Electrical connections........................................................................................................31

4. USE OF THE EQUIPMENT 32

4.1 Mounting the sieves...........................................................................................................33

4.2 Switching on the equipment and use .................................................................................38

4.3 Stopping the cycle via the Emergency button ...................................................................40

4.4 Switching off the unit ........................................................................................................41

5. MAINTENANCE 42

5.1 Operator’s preventive maintenance ...................................................................................44

5.1.1 Grease the ball of the base plate..................................................................................... 45

5.1.2 Lubricate the block of the spherical seat........................................................................ 46

5.2 Authorized service engineer maintenance actions.............................................................47

5.2.1 Checking the vertical movement of the sieve plate........................................................ 48

5.2.2 Checking the play of the upper seating .......................................................................... 52