Catalogue

1.Important Precautions······················································································3

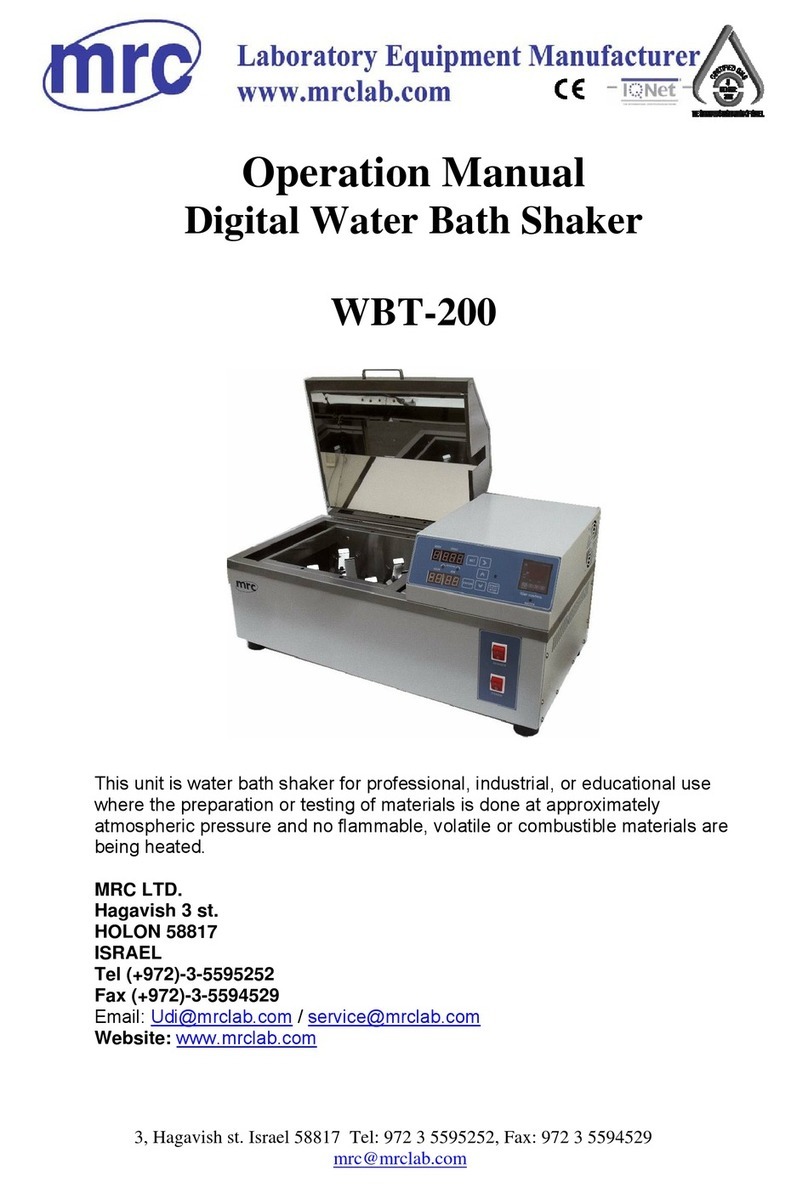

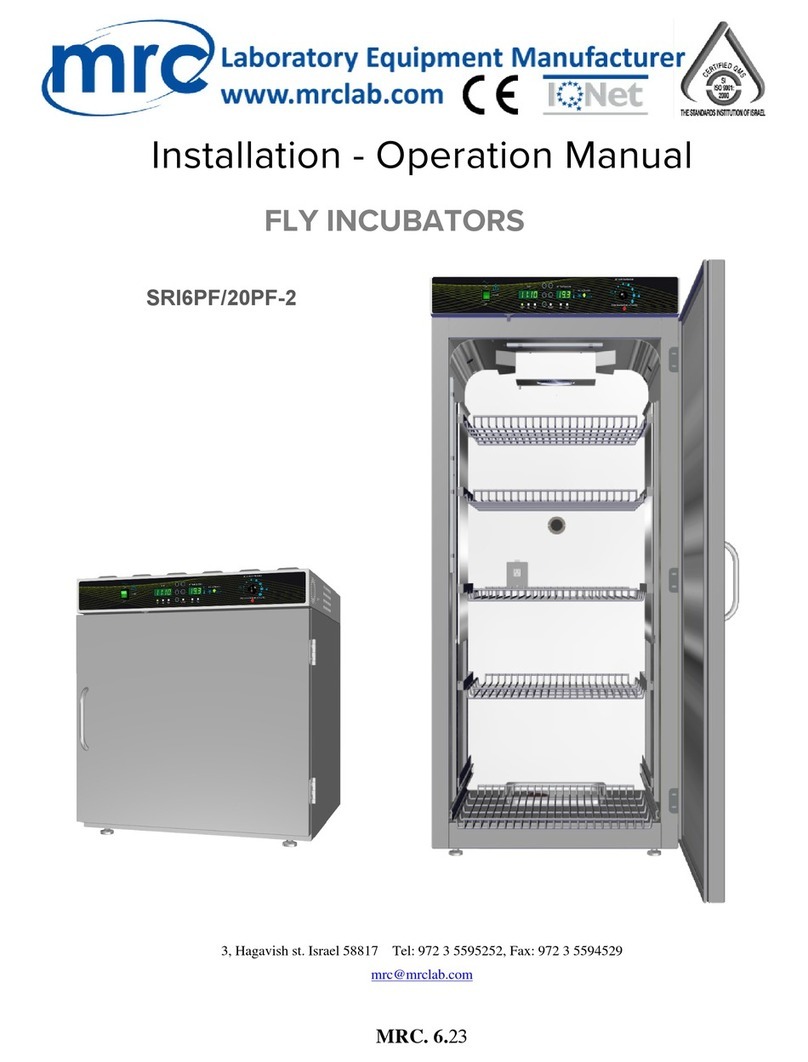

2. Working principle, structure, scope of application·····································································3

2.1 Working principle·····················································································3

2.2 Whole machine structure·····················································································4

2.3 Technical Parameters·····················································································4

2.4 Scope of application····················································································4

3. Precautions when receiving and keeping········································································5

3.1 Received machine··························································································5

3.2 Keep machine··························································································5

4. Installation procedures··························································································5

5. Safe operation···························································································5

6. Debugging·································································································5

6.1 No-load test run··················································································5

6.2 Load test run··················································································5

6.3 Commissioning Precaution···············································································6

7. MIXP-series mixer operating procedures········································································6

7.1 Check machine·····················································································6

7.2 Get the materials ready···························································································6

7.3 Loading···························································································7

7.4 Install Barrel lid·························································································7

7.5 Prepare before starting the machine····················································································7

7.6 Run···························································································8

7.7 Discharge material···························································································8

7.8 Replace variety·····················································································8

8. Equipment maintenance·····················································································8

8.1 Fastening piece························································································8

8.2 Seal···························································································8

8.3 Reducer························································································9