EM 9250 Operator’s manual 71

UK

CONTENTS

INTRODUCTION............................................................................................... 73

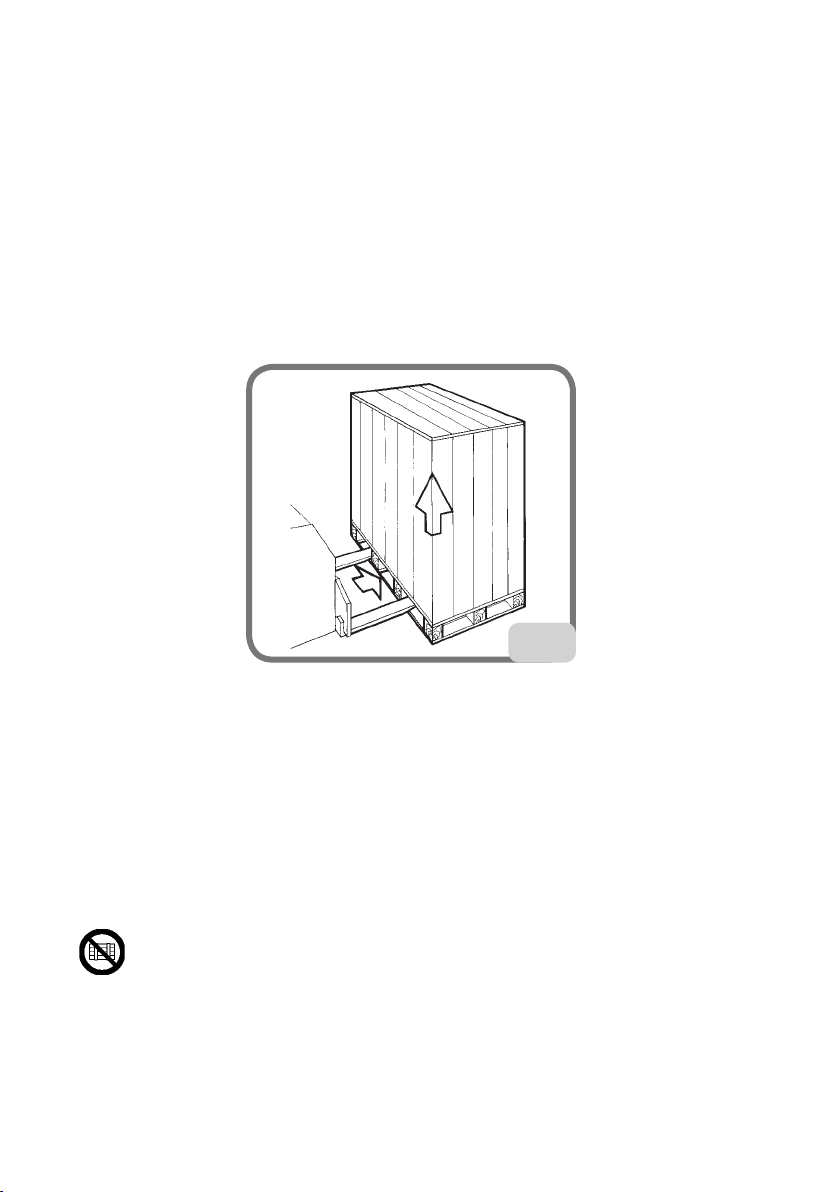

TRANSPORT, STORAGE AND HANDLING.................................................... 74

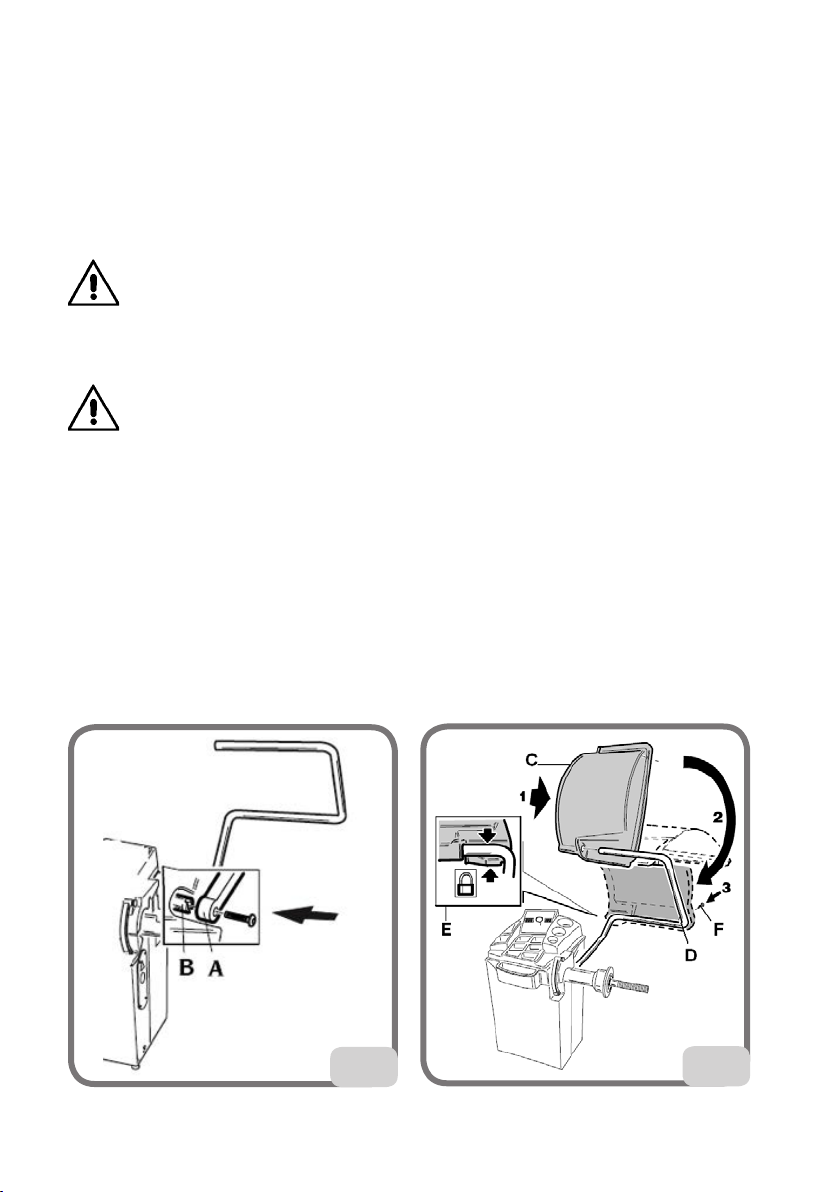

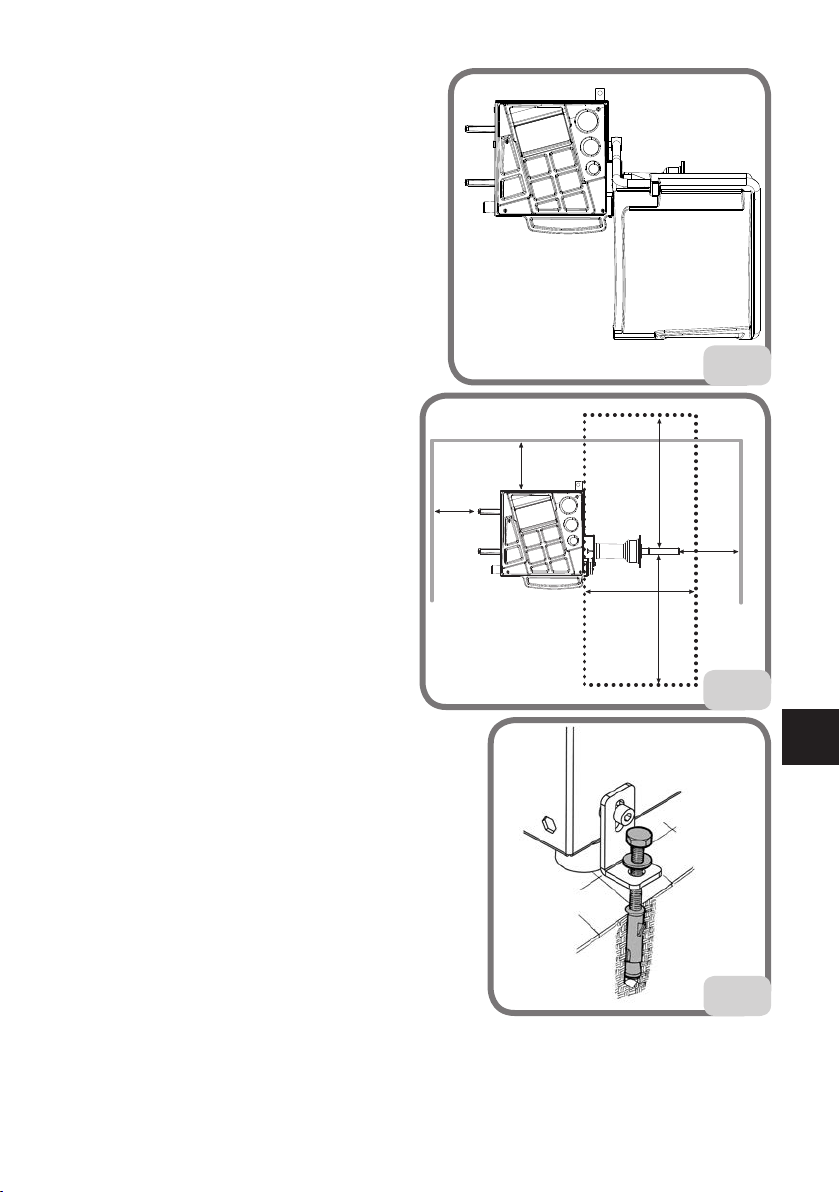

INSTALLATION................................................................................................. 75

ELECTRICAL HOOK-UP................................................................................... 79

COMPRESSED AIR HOOK-UP ........................................................................ 80

SAFETY REGULATIONS................................................................................... 81

MAIN FEATURES.............................................................................................. 82

TECHNICAL DATA............................................................................................ 83

STANDARD EQUIPMENT................................................................................ 86

OPTIONAL ACCESSORIES .............................................................................. 86

GENERAL CONDITIONS OF USE................................................................... 86

DISPLAY PANEL ............................................................................................... 87

DISPLAY PANEL - STATUS ICON.................................................................... 88

DISPLAY PANEL - CONTROL KEYPAD .......................................................... 89

1. SWITCHING ON THE MACHINE............................................................... 90

2. BALANCING PROGRAMME SELECTION................................................. 90

3. ENTERING WHEEL DIMENSIONS

(ALU1P AND ALU2P PROGRAMMES EXCLUDED)................................. 92

4. ENTERING WHEEL DIMENSIONS IN BALANCING PROGRAMMES

ALU1P OR ALU2P........................................................................................ 98

5. ENTERING DIMENSIONS IN THE MOTORCYCLE PROGRAMMES.... 101

6. WHEEL SPIN ............................................................................................. 101

7. UNBALANCE DISPLAY WITHOUT ROUNDING-OFF ............................ 102

8. APPLYING BALANCING WEIGHTS ......................................................... 102

9. APPLYING BALANCING WEIGHTS IN THE ALU1P

OR ALU2P PROGRAMMES ...................................................................... 104

10.PROGRAM FOR POSITIONING THE WEIGHTS BEHIND

THE SPOKES “HIDDEN WEIGHT”

(ONLY WITH ALU 1P AND ALU 2P PROGRAMMES)............................. 106

11. PROGRAM FOR DIVIDING THE WEIGHT ON EITHER SIDE OF THE

SPOKE “SPLIT WEIGHT” (ONLY WITH MOTORCYCLE PROGRAMMES) 108

12.UNBALANCE OPTIMISATION PROGRAMME “OPT”............................. 109

13.ENABLING THE OTHER OPERATOR ..................................................... 111

14.SPIN COUNTER......................................................................................... 112

15.GENERAL CONFIGURATIONS - SET UP................................................ 112

15.1. SET UP - SELECTING VEHICLE TYPE (CAR-MOTORCYCLE)........... 113

ORIGINAL INSTRUCTIONS

COMIM - Code 4-119438 dated 09/2015.