3318832013

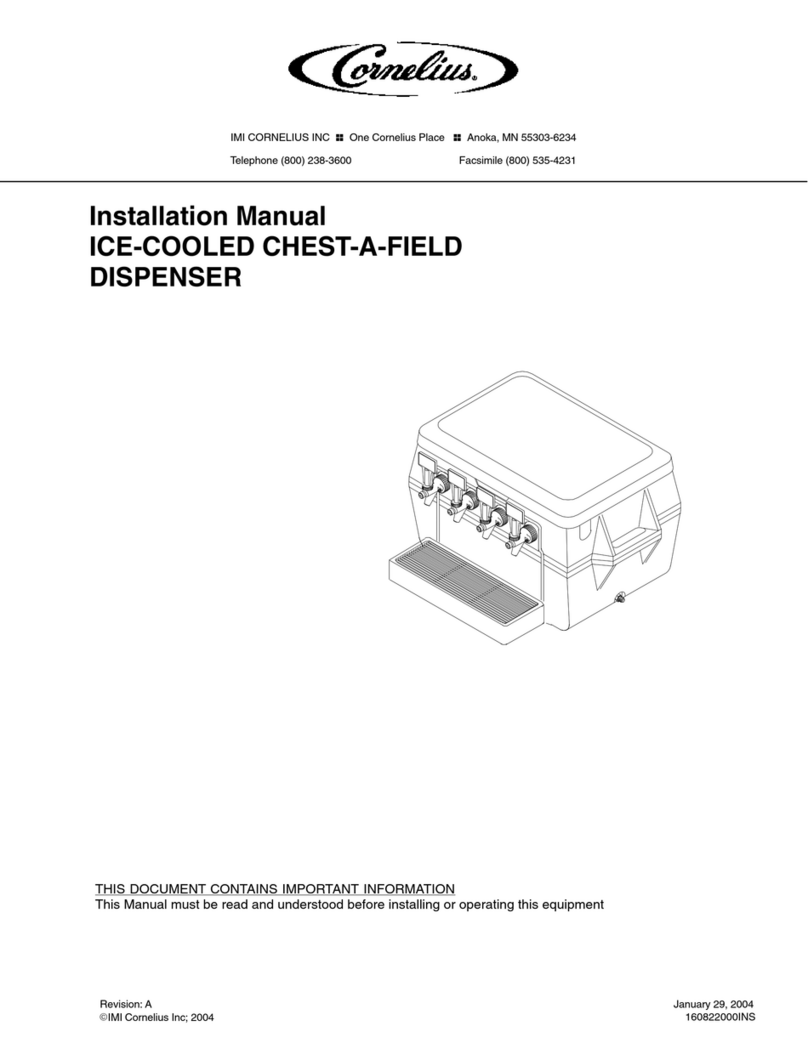

1. Install drain hoseonUnitand securewith provided clamp.

2.Route driptraydraintube downto and connect to permanentdrain.

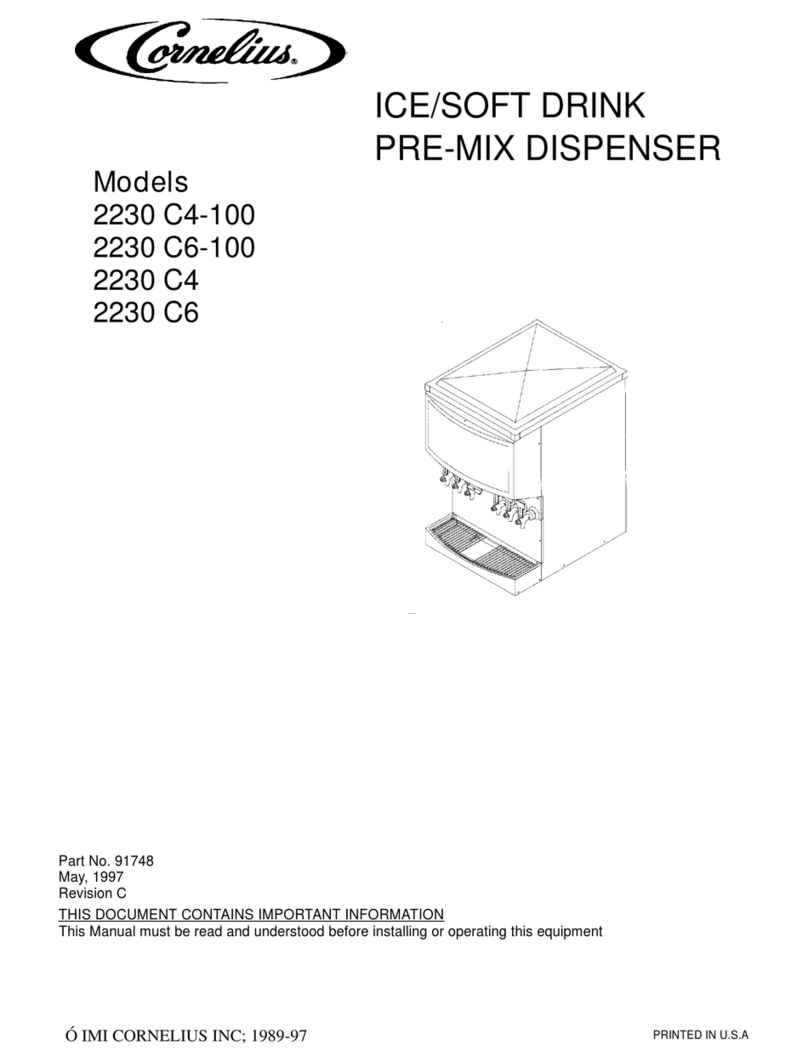

Note:TheUnitsyrup,waterand CO2source tubes may eitherberoutedinthrough opening inlower

back sideof theUnit tolocation behind thefrontpanelortubes may beroutedupthrough hole cutin

the countertop toinsideof theUnit.Cutnecessaryholeincountertop ifapplicable.

3.RemoveUnit frontaccess panel(see Figure 1)foraccess tothe Unitsyrup connecting tubesand for rout-

ing waterinlet tube tothe waterpump.

4.Routesyrup sourcetubes(numbered foridentification)up to and toinside of the Unit. Connectnumbered

syrup sourcetubestomatching numberlabeled Unitsyrup inlet tubes.

5.Route plainwatersourcetube up tothe Unit. Connectplainwatersourcetube towaterpumpinleton water

pump and motorassembly.

6.RouteCO2sourcetube up tothe Unit. ConnectCO2sourcetube tolabeled UnitCO2inlet tube.

7.PlaceUnitin operating position on the countertop.TomeetNSFInternational(NSF) requirements,seal

Unit tocountertop withsilastic sealant, such asDow Corning RTV731 orequivalent.

8.Remove hood fromUnit. Fill watertankwithclean wateruntil water runsoutofoverflowintothe driptray

pan.Uselow-mineral-contentwaterwherealocalwaterproblemexists.

WARNING:TheUnitmustbe electricallygroundedtoavoid possiblefatalelectricalshock

orseriousinjurytotheoperator.TheUnitpowercordis equippedwithathree-prong plug.

Ifathree-hole(grounded)electricaloutletisnotavailable,use anapprovedmethod to

ground theUnit.

9.Plug Unitpowercordinto electricaloutlet.

10.PlaceUnitpowerswitchin“ON”position.Refrigeration systemwill startand begin building an ice bank.

WARNING:CO2displaces oxygen.Strictattention mustbeobservedintheprevention of

CO2(carbon dioxide)gas leaks inthe entireCO2and soft drink system. IfaCO2gas leak is

suspected,particularlyina small area,immediatelyventilatethe contaminatedarea before

attempting torepairtheleak.Personnelexposedto high concentration ofCO2gas will experience

tremorswhicharefollowedrapidlybyloss ofconsciousness and suffocation.

11.Makesure primaryand secondaryCO2regulatorsadjusting screwsareturned tothe left (counterclock-

wise)until all tension isrelieved fromadjusting screws springs, then open the CO2cylindershutoff valve.

12.Adjusting CO2regulators.

A.AdjustsecondaryCO2regulatorforthe dispenserintegralcarbonatorto nominal80-psig.INLETCO2

PRESSURETOCARBONATORMUSTNOTEXCEED125-PSIG.

B.Sugarsyrup tanks SecondaryCO2regulator-- Adjustsugarsyrup tanks secondaryCO2regulatorto a

minimumof45-psig.

C.Low-calorie(diet)syrup tank secondaryCO2regulator-- Adjustlow-calorie(diet)syrup tank secondary

CO2regulatorto 10-psigforsyrup linesup to 30-feetinlength.Syrup lineslongerthan 30-feetinlength

mayrequireaslightlyhighersetting of12-psigmaximum.ExcessiveCO2pressuremay causelow-calorie

syrup carbonation resulting inafoamydrinkbeing dispensed.

D.Bag-in-BoxSystemsyrup pumps--Adjust the Bag-in-Box systemsyrup pumps secondaryCO2regulator

to 70-psig.DONOTEXCEEDMAXIMUMPRESSURE SPECIFIEDONTHE SYRUP PUMPS.

13.Turnonwatersupplytothe Unit. Check forwaterleaks and repairifevident.