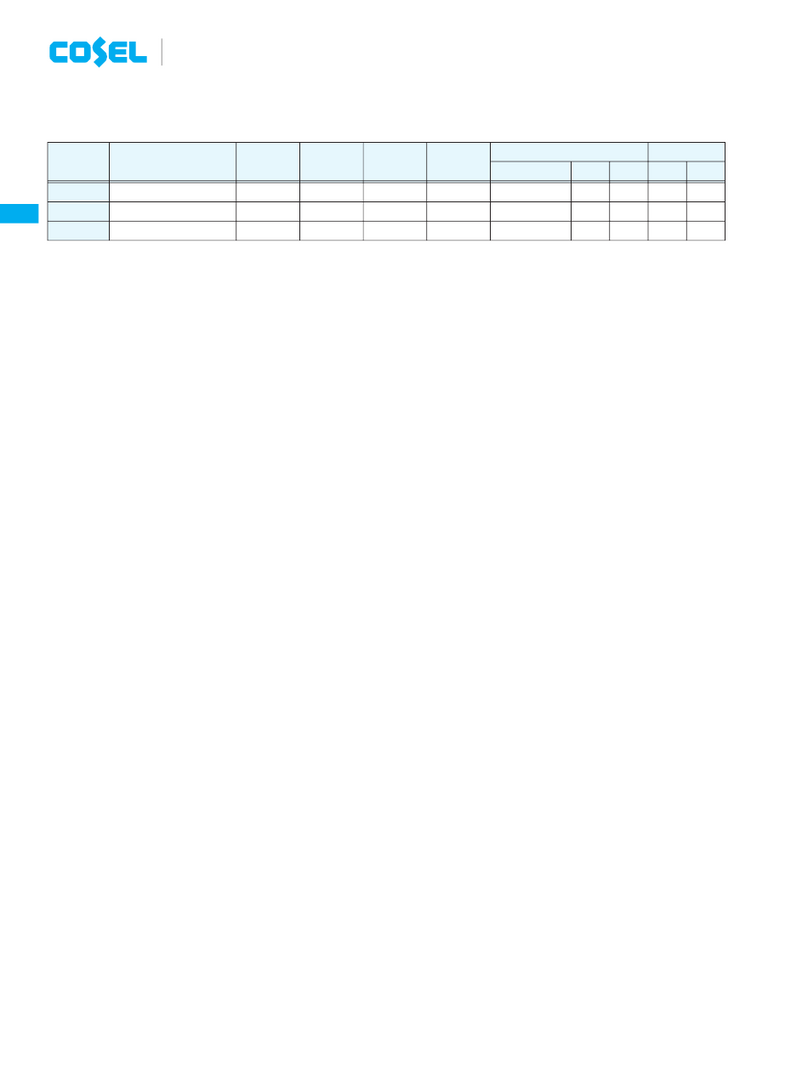

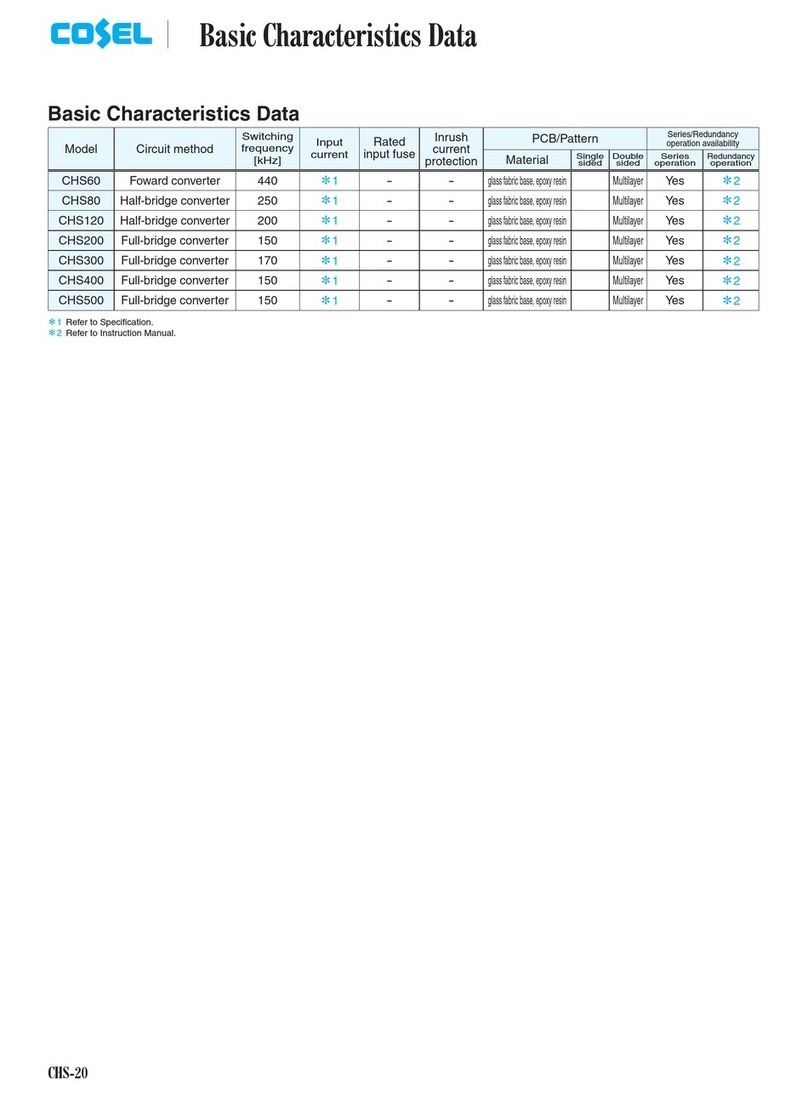

Table 3.1 Specication of TMP, IOG

No. Item TMP IOG

1 Function

Normal operation ”H”

Normal operation ”L”

Overheat detection ”L”

Malfunction of inverter ”H”

2 Base pin -S

3 Level voltage ”L” 0.5Vmax at 5mA

4 Level voltage ”H” 5V typ

5 Maximum sink current 10mA max

6

Maximum applicable voltage

35V max

3.5 Remote ON/OFF

¡Remote ON/OFF circuit is built-in on both side of input(RC1) and

output(RC2

-

RC3).

Output can be controlled by either circuit.

(1) Input side remote ON/OFF(RC1)

¡The ground pin of input side remote ON/OFF circuit is ”-VIN” pin.

Between RC1 and -VIN: Output voltage is ON at ”Low” level or

short circuit(0 - 1.0V).

Between RC1 and -VIN: Output voltage is OFF at ”High” level or

open circuit(3.5 - 7.0V).

When RC1 is ”Low” level, fan out current is 0.3mA typ. When Vcc

is applied, use 3.5 [Vcc [7V.

When remote ON/OFF function is not used, please short between

RC1 and -VIN.

¡When the DPF-DPG series(Power factor & harmonic correc-

tor module) is used as a front end unit, connect between RC1

pin and ENA pin on DPF-DPG for the start-up time of the

DBS200B/400B/700B control. Please contact us for details.

VIN

or

or

Rc

Fig.3.2 RC1 connection example

(2) Output side remote ON/OFF(RC2-RC3)

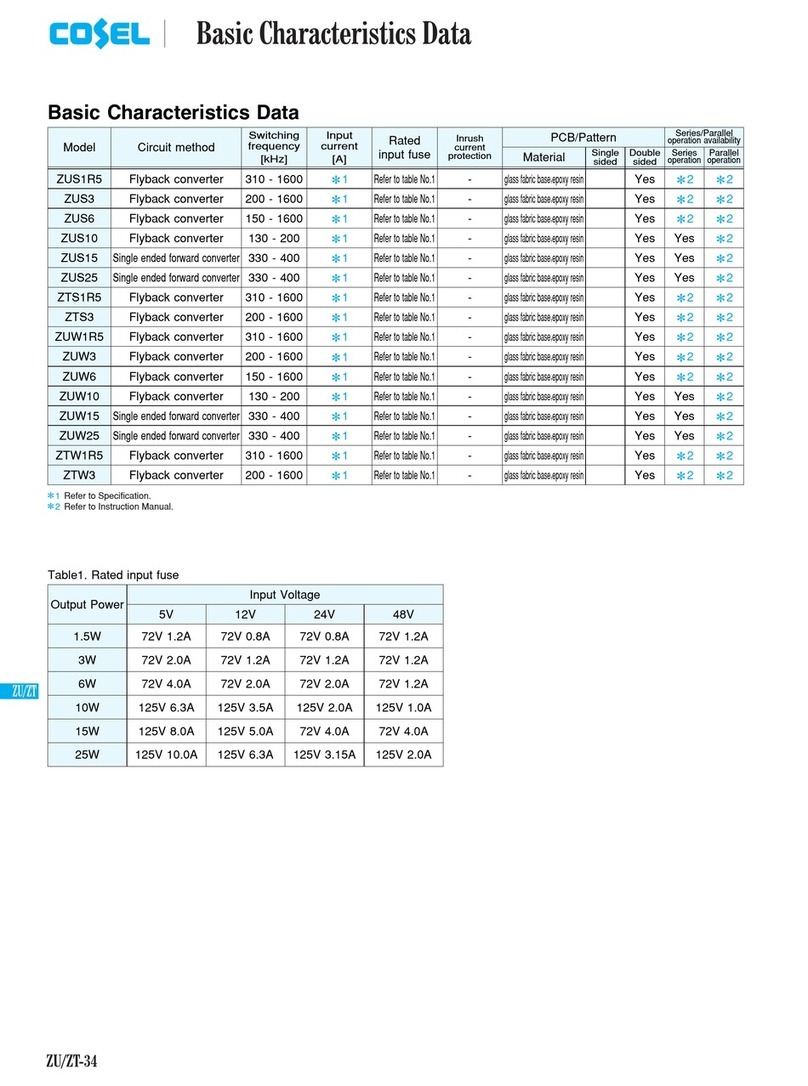

Table 3.2 Specication of output side remote ON/OFF(RC2-RC3)

No. Item RC2-RC3

1 Wiring method Fig.3.3 (a) Fig.3.3 (b) Fig.3.3 (c)

2 Function

Power ON ”H” Power ON ”H” Power ON ”L”

3 Base pin RC2 -S -S and RC2

4 Power ON Open

(0.1mA max)

Short

(0.5V max)

5 Power OFF Short

(3mA min)

Open

(0.1mA max)

¡When the output voltage drops at overcurrent, the average output

current is reduced by hiccup operation of power supply.

3.2 Overvoltage protection

¡The overvoltage protection circuit is built-in. The DC input should

be shut down if overvoltage protection is in operation. The mini-

mum interval of DC recycling for recovery is for 2 to 3 minutes().

The recovery time varies depending on input voltage and input

capacity.

Remarks:

Please note that devices inside the power supply might fail when

voltage more than rated output voltage is applied to output termi-

nal of the power supply. This could happen when the customer

tests the overvoltage performance of the unit.

3.3 Thermal detection/Thermal protection

¡Thermal detection(TMP) and protection circuit are built-in.

¡When overheat is detected, thermal detection signal(TMP) turns

”L” from ”H”.

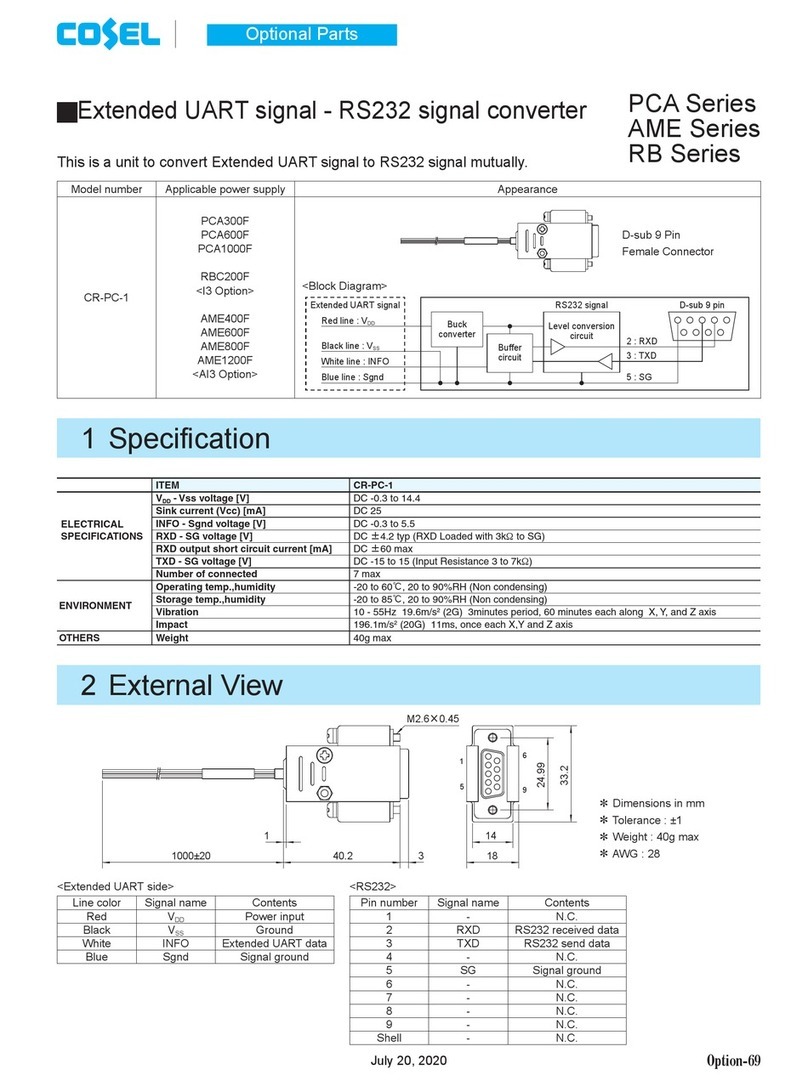

TMP circuit is designed as shown in Fig.3.1, and specication is

shown as in Table 3.1.

¡When overheating continues after detecting the TMP signal, the

output will be shut down by the thermal protection circuit.

When this function comes into effect, input voltage should be shut

off, and eliminate all possible causes of overheat condition and

lower the temperature of the unit to the normal level.

3.4 Inverter operation monitor

¡By using the inverter operation monitor(IOG), malfunction of the

inverter can be monitored.

When inverter operation is in following mode 1or 2, IOG signal

turns ”H” from ”L” within 1 second.

IOG circuit is designed as shown in Fig.3.1 and specification is

shown in Table 3.1.

1Malfunction of inverter.

2The output voltage drops by 60% or less of the rated voltage.

3When output wattage is decreased radically to less than 10% of

rated wattage.

6V typ

22kW

or

IOG

-S

Fig.3.1 TMP, IOG circuit

DC-DC Converters Bus Converter

-

Power Module Type

Instruction Manual

DBS-15 June 26, 2020