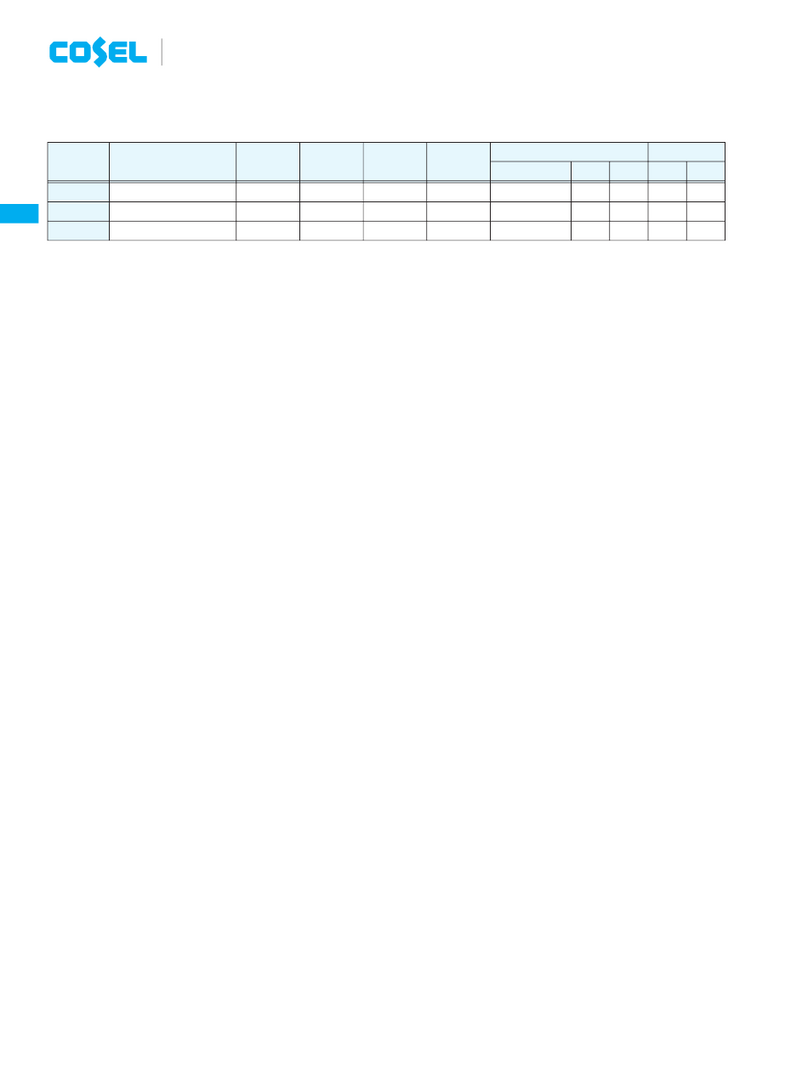

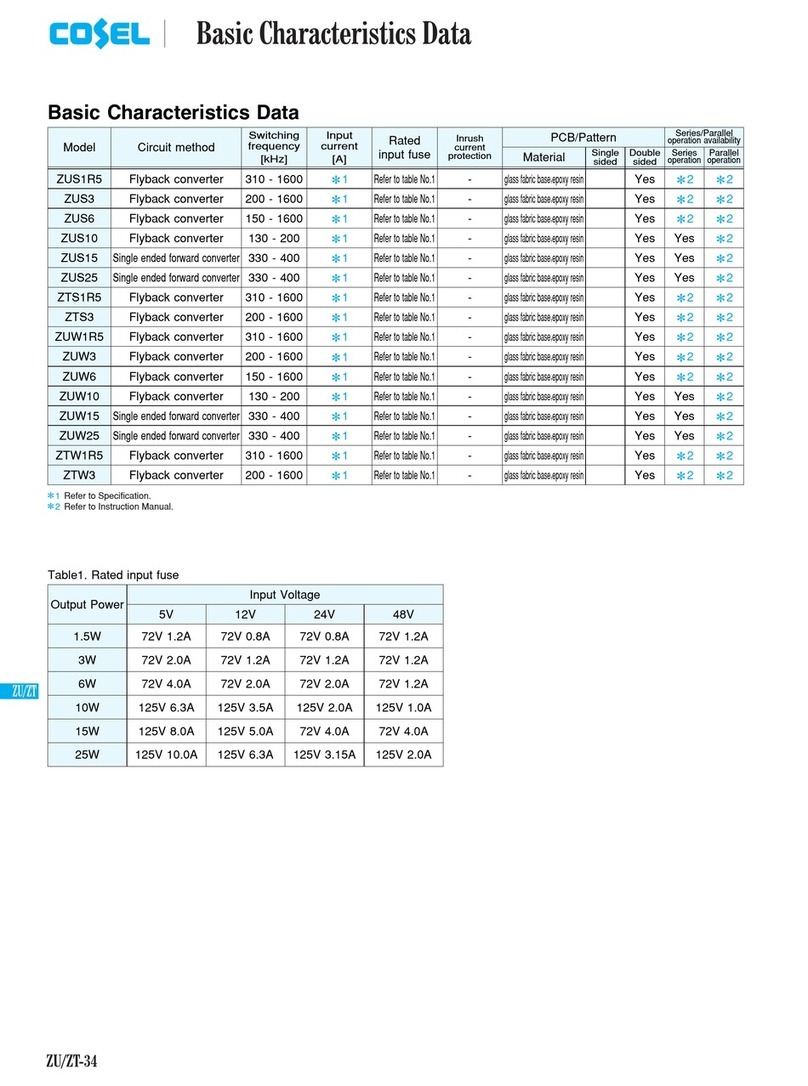

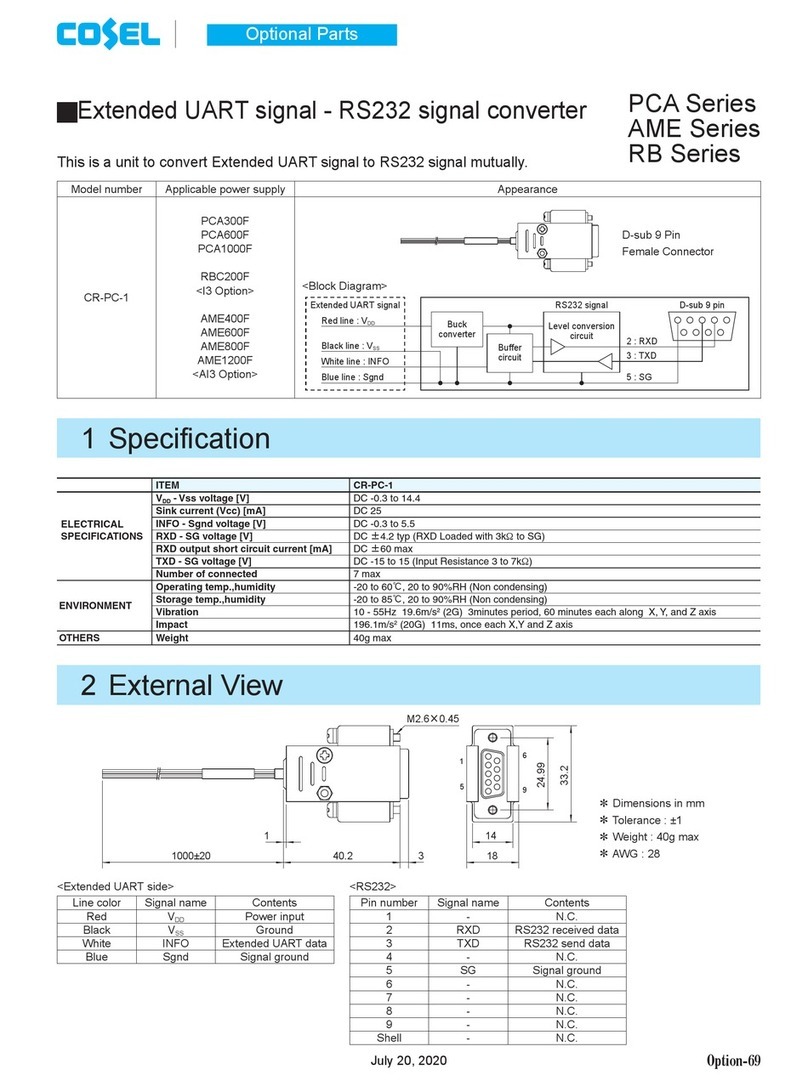

4 Function

4.1 Overcurrent protection

¡Over Current Protection (OCP) is built in and works at 105% of

the rated current or higher. However, use in an over current situa-

tion must be avoided whenever possible. The output voltage of the

power module will recover automatically if the fault causing over

current is corrected.

When the output voltage drops after OCP works, the power mod-

ule enters a ”hiccup mode” where it repeatedly turns on and off at

a certain frequency.

4.2 Overvoltage protection

¡Over Voltage Protection (OVP) is built in. When OVP works, out-

put voltage can be recovered by shutting down DC input for at

least one second or by turning off the remote control switch for

one second without shutting down the DC input. The recovery

time varies according to input voltage and input capacitance.

Remarks:

Note that devices inside the power module may fail when a volt-

age greater than the rated output voltage is applied from an exter-

nal power supply to the output terminal of the power module. This

could happen in in-coming inspections that include OVP function

test or when voltage is applied from the load circuit. OVP can be

tested by using the TRM terminal. Consult us for details.

4.3 Thermal protection

¡Over Temperature Protection (OTP) is built in. If the base plate

temperature exceeds 100C, OTP will work, causing the output

voltage to drop. Output voltage can be recovered by shutting

down DC input for at least one second or by turning RC off for one

second without shutting down the DC input.

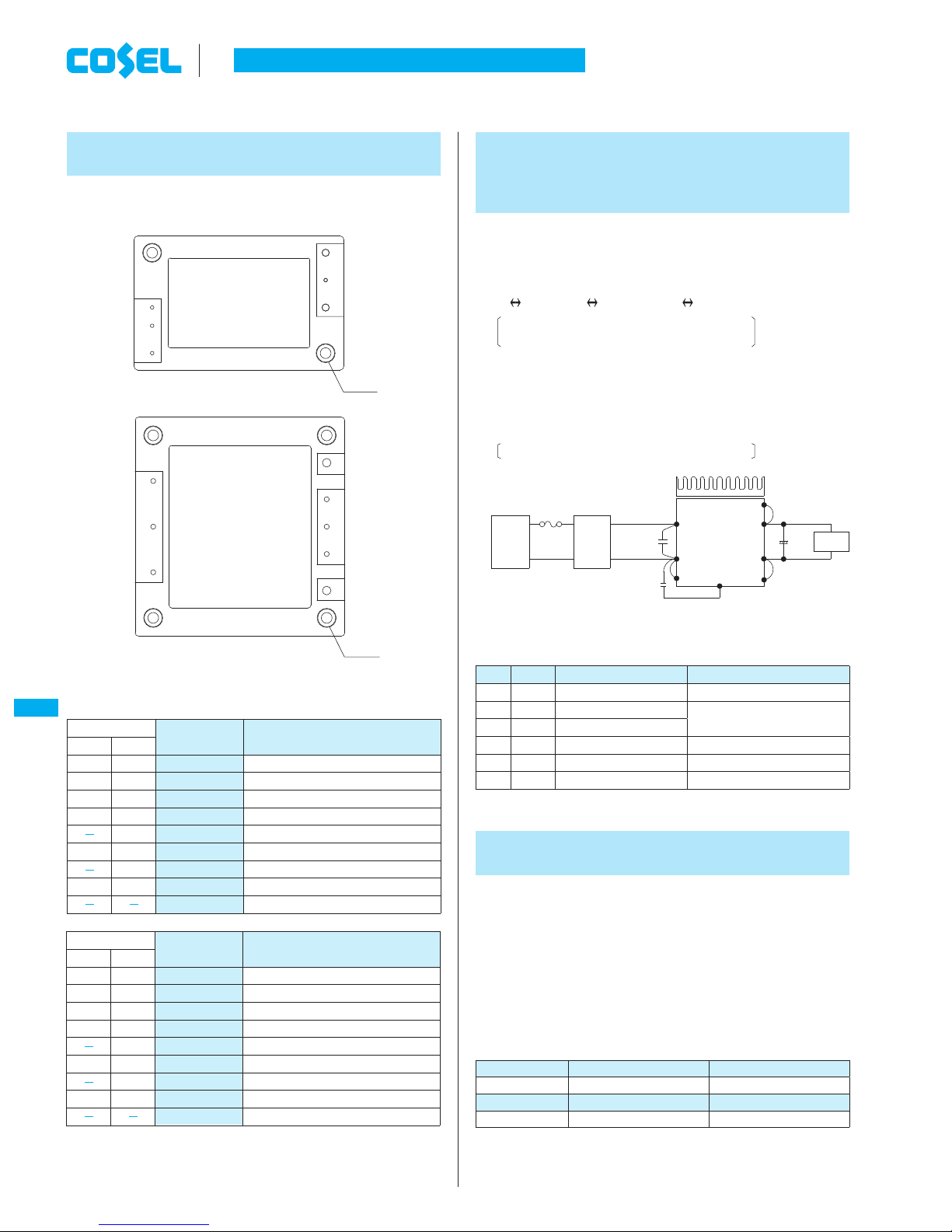

¿DHS200, DHS250

4.5 Remote sensing

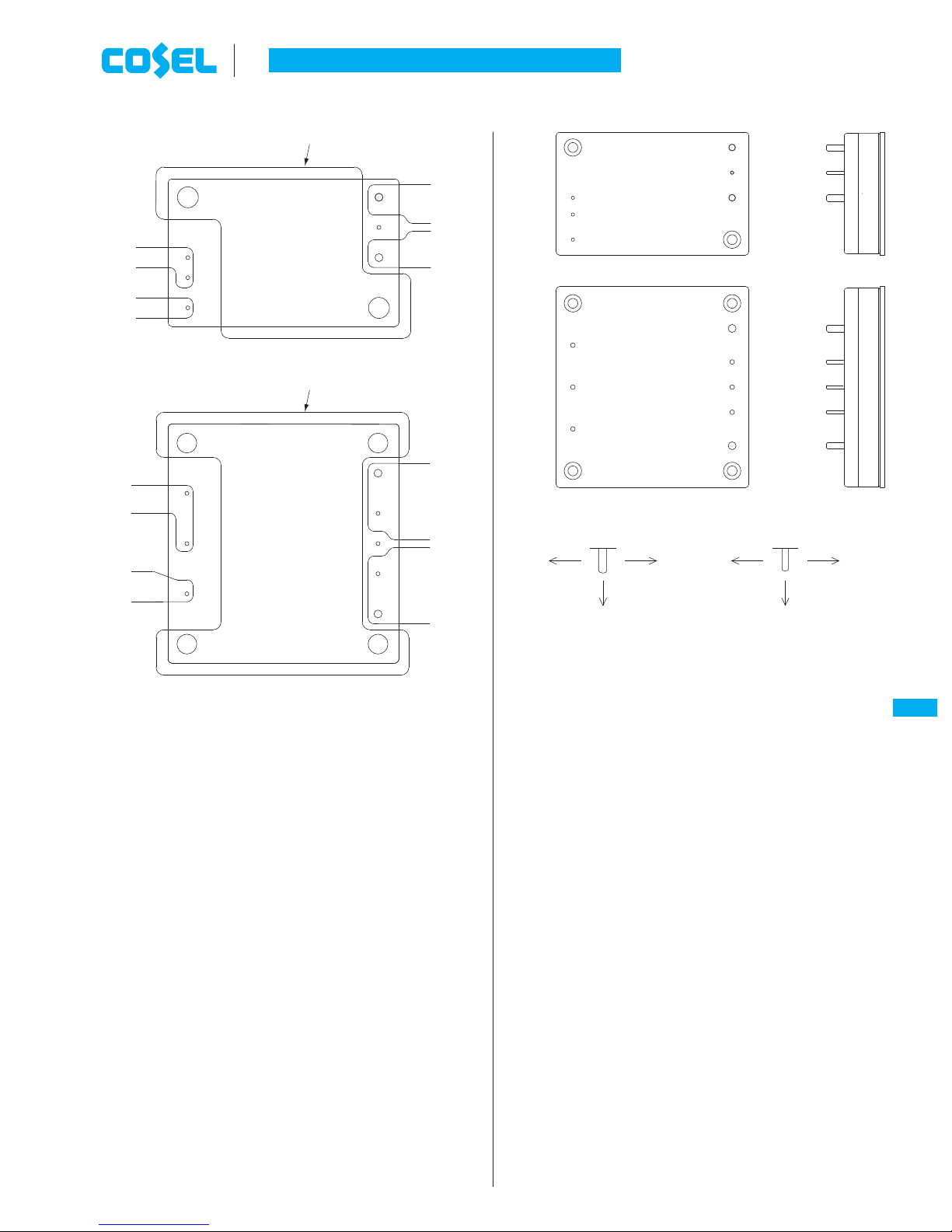

(1) When Remote Sensing is Not Used

¡When remote sensing is not used, make sure +VOUT and +S are

shorted, and that -VOUT and -S are shorted as well.

¡Keep the patterns between +S and +VOUT and between -S and

-VOUT as short as possible. Avoid a looping pattern. If noise en-

ters the loop, the operation of the power module will become un-

stable.

(2) When Remote Sensing is Used

¡Using remote sensing with long wires may cause output voltage to

become unstable. Consult us if long sensing wiring is necessary.

¡Sensing patterns or wires should be as short as possible. If wires

are used, use either twisted-pair or shielded wires.

+S

+VOUT

-S

-VOUT

+Co

Short at pin root

Load

+S

Co

-S

+VOUT

-VOUT

+

Wire as close as possible

Load

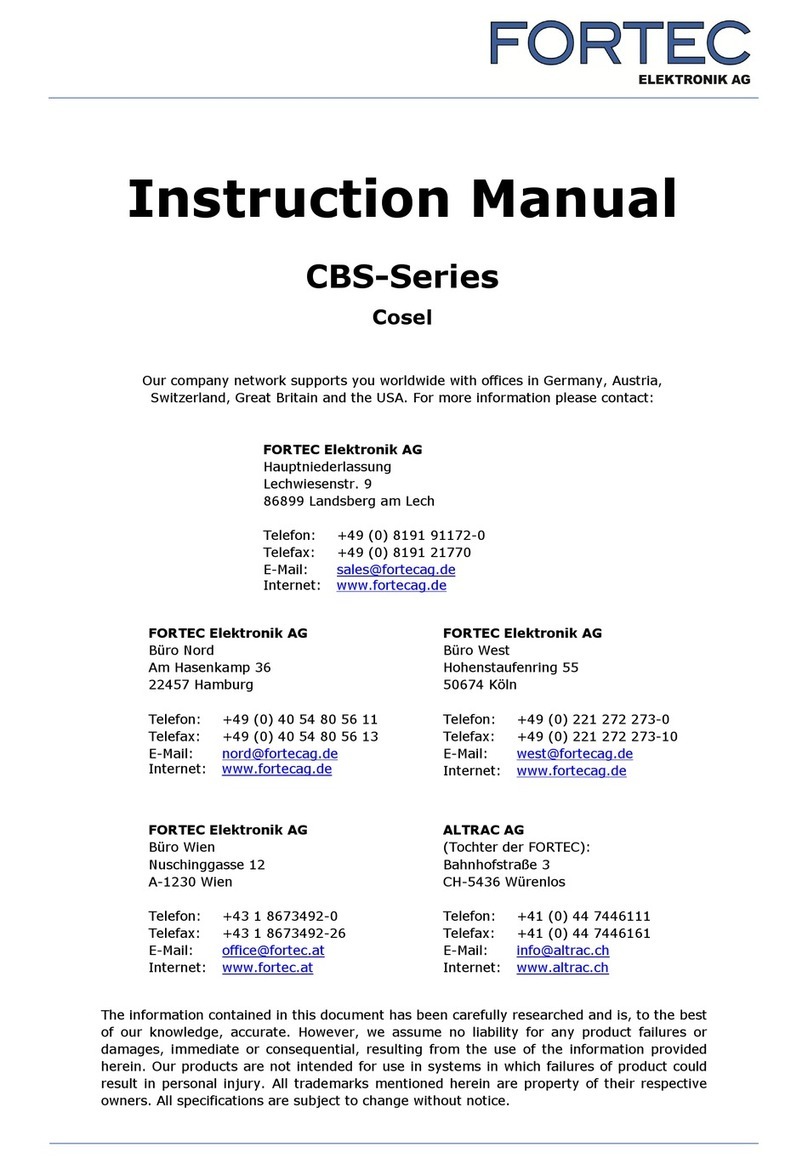

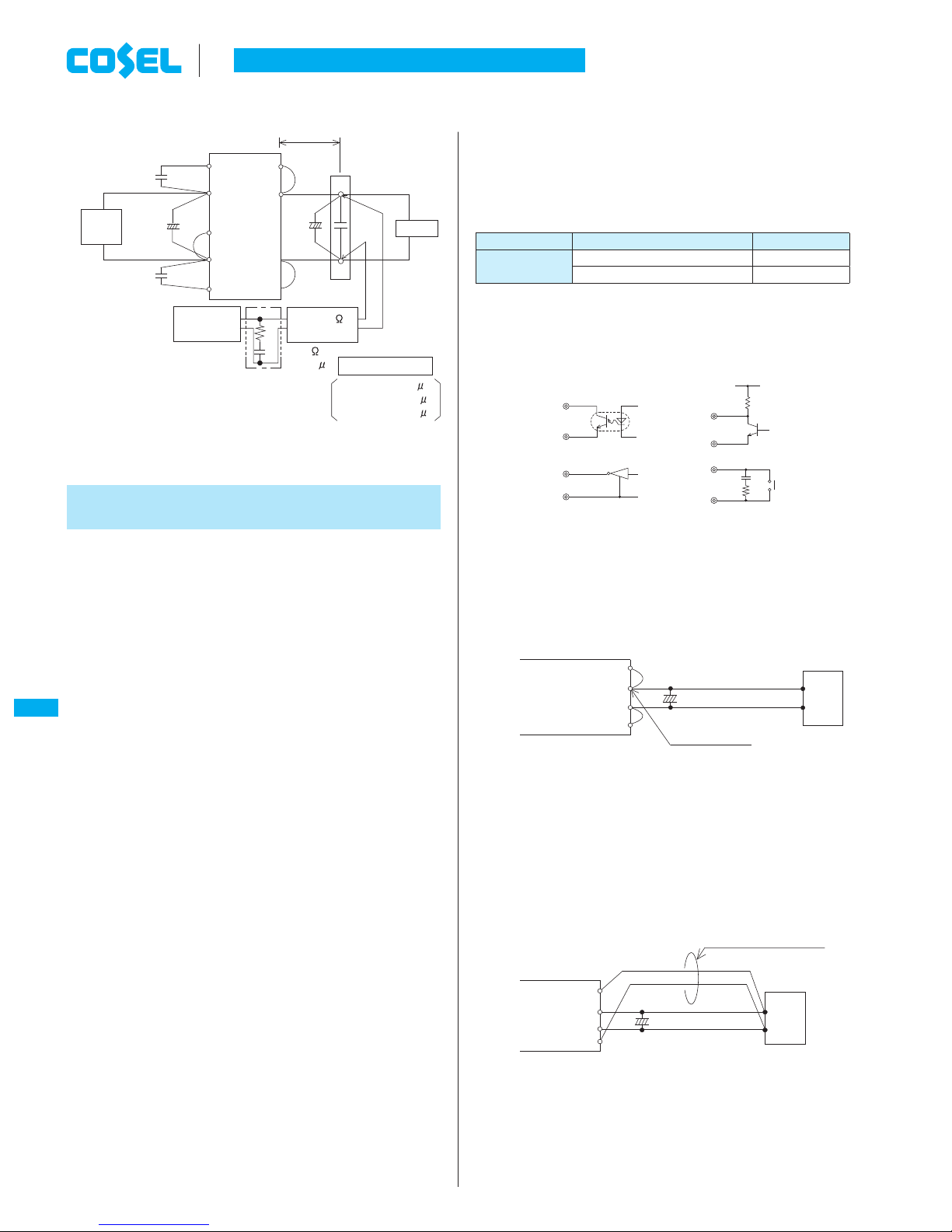

4.4 Remote ON/OFF

¡The remote ON/OFF function is incorporated in the input circuit

and operated with RC and -VIN.

ON/OFF logic Between RC and -VIN Output voltage

Negative L level(0 - 1.2V) or short ON

H level(3.5 - 7.0V) or open OFF

¡When RC is at low level, a current of 0.5mA typ will flow out.

When Vcc is used, keep it within the following rage:

3.5 [VCC [7V.

When remote ON/OFF is not used, short RC and -VIN.

C

1:3.3 - 15V 10

F

24 - 28V 4.7

F

48V 2.2

F

FG

Cin

2200pF

100mm

+VIN

-VIN

FG

+VOUT

-VOUT

-S

+S

C

1

Co

+

+

RC

2200pF

Measuring board

Load

DC

input

Oscilloscope

BW:100MHz

1.5m 50

Coaxial Cable

R=50

C=0.01 F

R

C

+S, -S : DHS200/250

DC-DC Converters Bus Converter.Power Module Type

Instruction Manual

DHS-18

DHS

Fig. 4.1 RC Connection Example

Table 4.1 Remote ON/OFF Specifications

Transistor

IC Relay

Vcc

Opto coupler

RC

-VIN

RC

-VIN

RC

-VIN

RC

-VIN

Fig. 4.2 When Remote Sensing is Not Used (DHS200/250)

Fig. 4.3 When Remote Sensing is Used (DHS200/250)

DHS200

DHS250

DHS200

DHS250

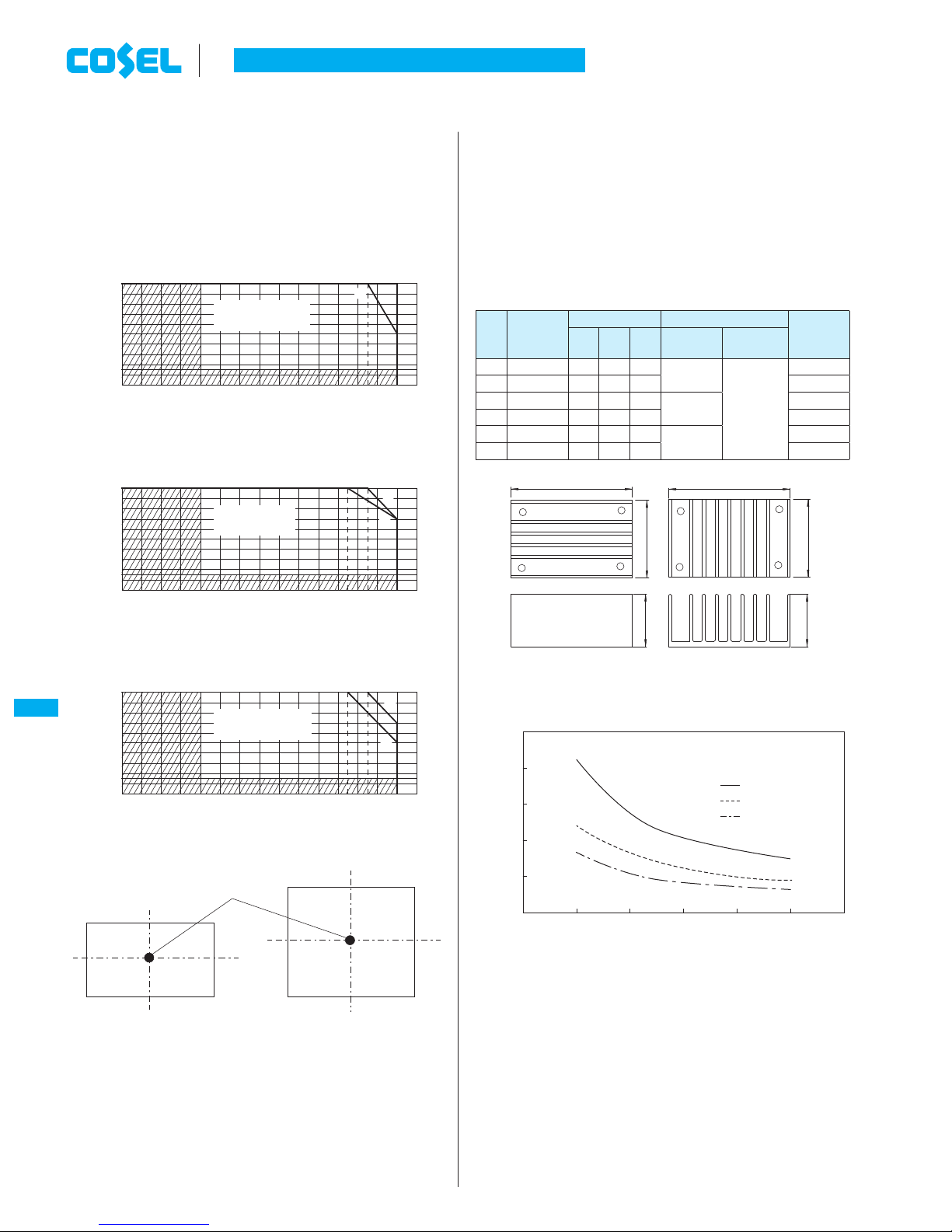

Fig.3.5 Method of Measuring Output Ripple and Ripple Noise

medhs1.inddDHS-18medhs1inddDHS-182015/06/1911:08:052015/06/1911:08:05