1Function

1.1 Input Voltage Range

¡If output voltage value doesn’t fall within specications, a unit may

not operate in accordance with specications and/or fail.

1.2 Overcurrent Protection

¡Overcurrent Operation

An overcurrent protection circuit is built-in and activated over

105% of the rated current or above. It prevents the unit from short

circuit and overcurrent. The output voltage of the power supply

will recover automatically if the fault causing over current is cor-

rected.

When the output voltage drops after OCP works, the power supply

enters a “hiccup mode” where it repeatedly turns on and off at a

certain frequency.

1.3 Overvoltage Protection (Excluding MG15)

¡Over Voltage Protection (OVP) is built in. When OVP works, out-

put voltage can be recovered by shutting down DC input for at

least one second or by turning off the remote control switch for

one second without shutting down the DC input. The recovery

time varies according to input voltage and input capacitance.

Remarks :

Note that devices inside the power supply may fail when a voltage

greater than the rated output voltage is applied from an external

power supply to the output terminal of the power supply. This

could happen in in-coming inspections that include OVP function

test or when voltage is applied from the load circuit.

1.4 Isolation

¡When you run a Hi-Pot test as receiving inspection, gradually

increase the voltage to start. When you shut down, decrease the

voltage gradually by using a dial. Please avoid a Hi-Pot tester with

a timer because, when the timer is turned ON or OFF, it may gen-

erate a voltage a few times higher than the applied voltage.

¡

Please note that if foreign matter such as flux during soldering

adheres to the vicinity of the case, the withstand voltage and iso-

latiion resistance may decrease.

1.5

Output Voltage Adjustment Range(MGS/MGFS Only)

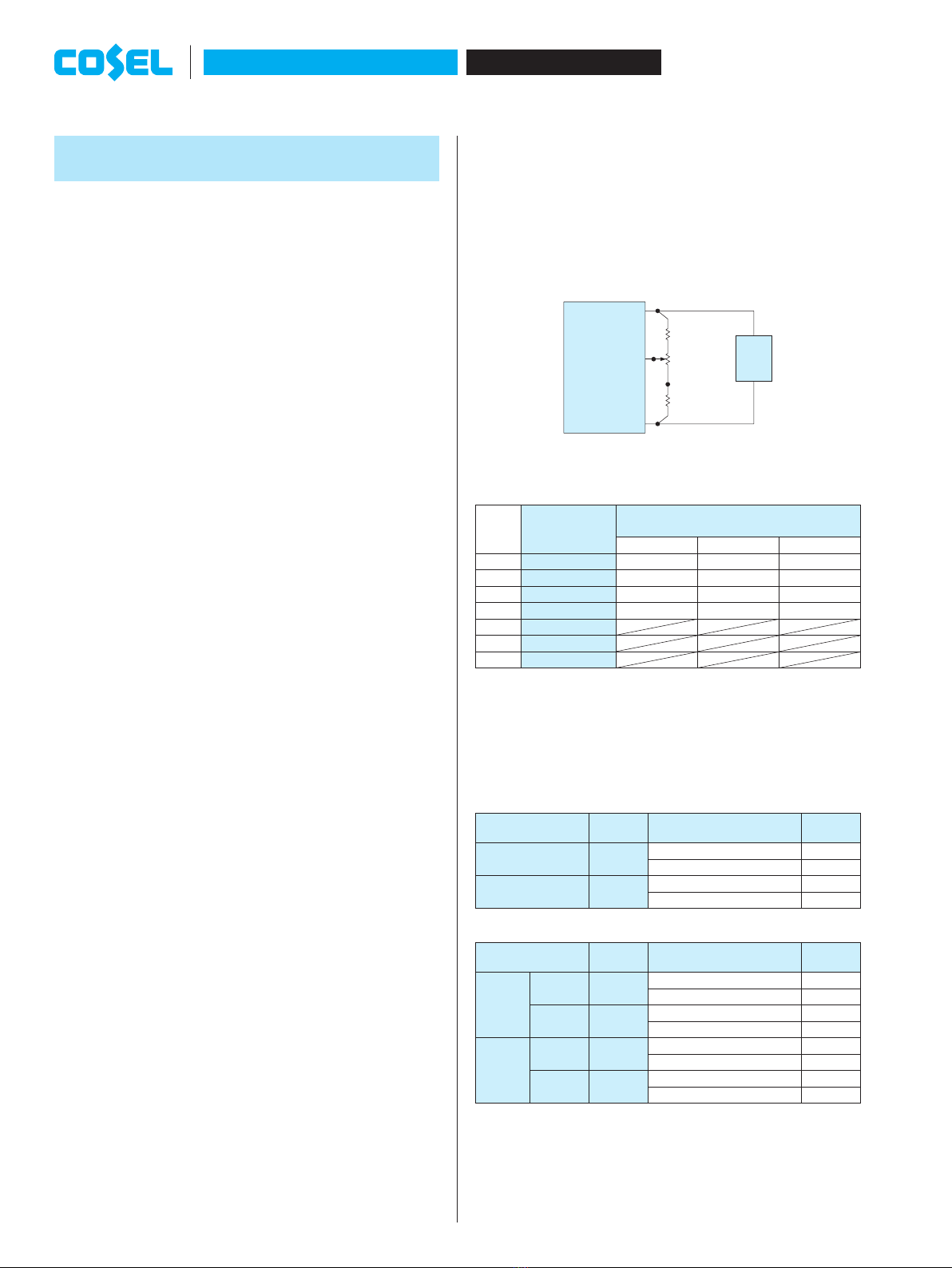

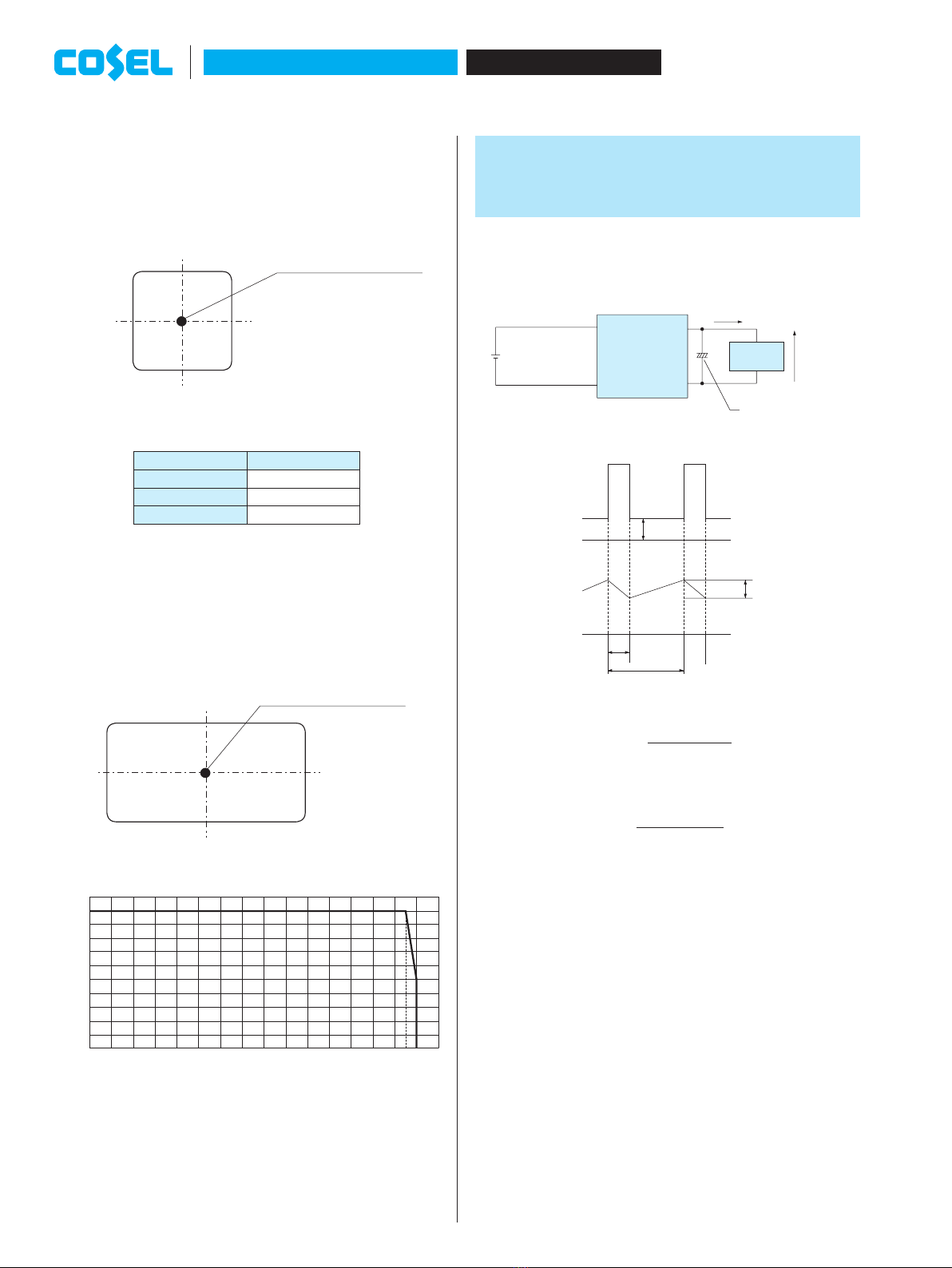

¡The output voltage is adjustable through an external potentiom-

eter. Adjust only within the range of ±10% of the rated voltage.

¡To increase the output voltage, turn the potentiometer so that the

resistance value between 2 and 3 becomes small.

¡Please use a wire as short as possible to connect to the potenti-

ometer and connect it from the pin on the power supply side. Tem-

perature coefcient deteriorates when some types of resistors and

potentiometers are used. Please use the following types.

Resistor............

Potentiometer...

¡If output voltage adjustment is not required, open the TRM pin.

¡Output voltage adjustment may increase to overvoltage protection

activation range based on determined external resister values.

Resistor

R2

External

External VR

Resistor

R1

External

Output

TRM

-Vout

+Vout

3

1

2Load

Fig.1.1 Connecting External Devices

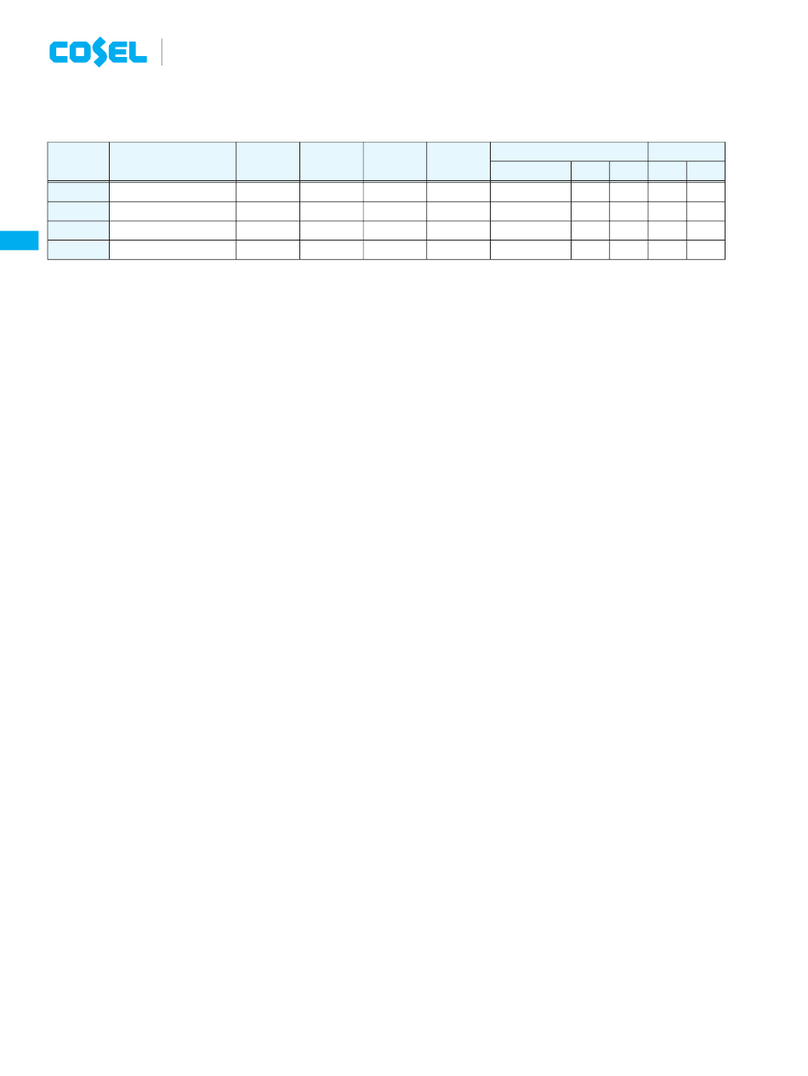

Table 1.1 List of External Devices

Item # Output Voltage

Constant of External Device [W]

(Adjustable within ±10%)

VR R1 R2

1 3.3V 1k 100 100

2 5V 1k 100 270

3 12V 5k 10k 1.5k

4 15V 5k 10k 1k

5 ±5V

6 ±12V

7 ±15V

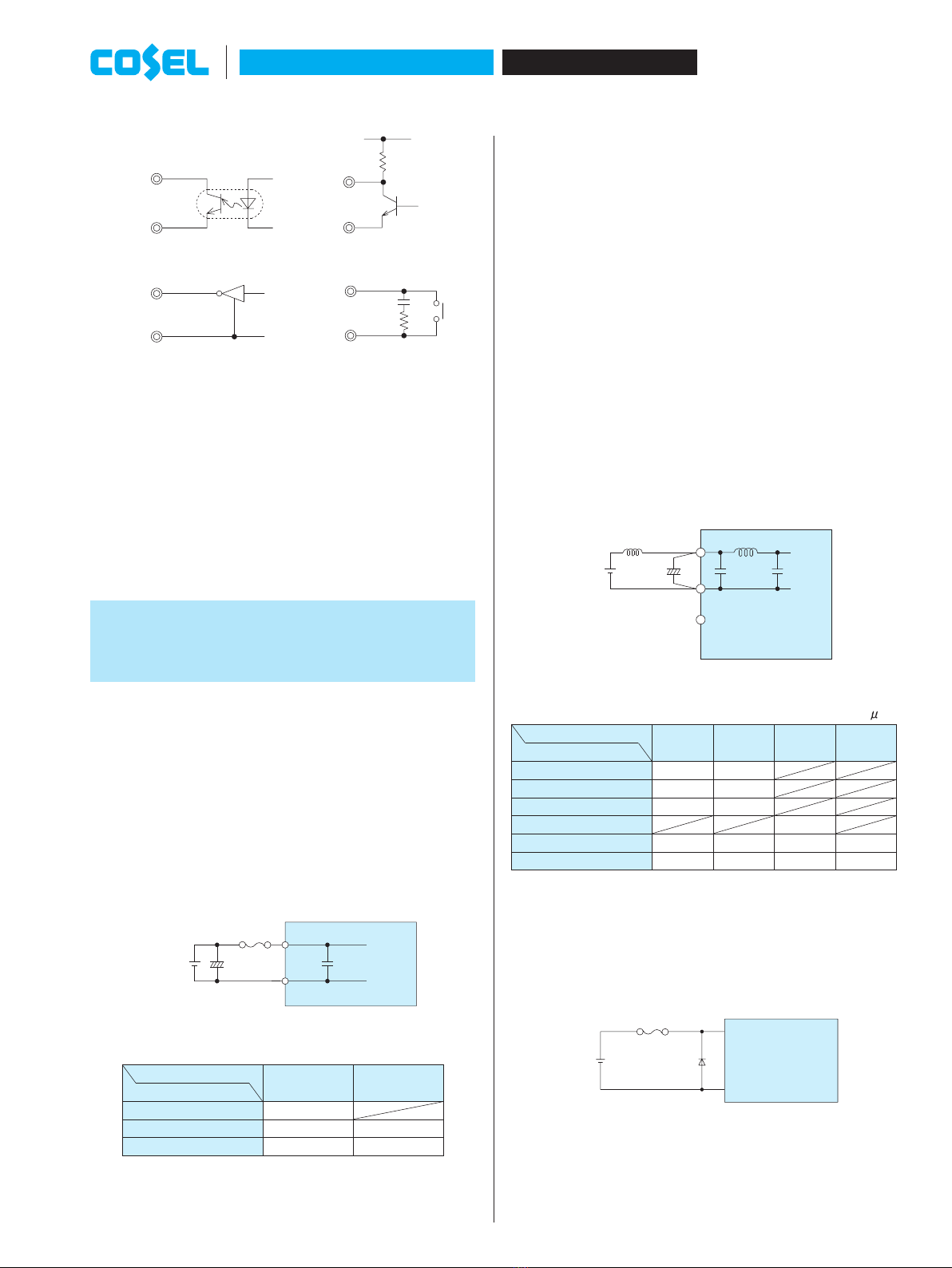

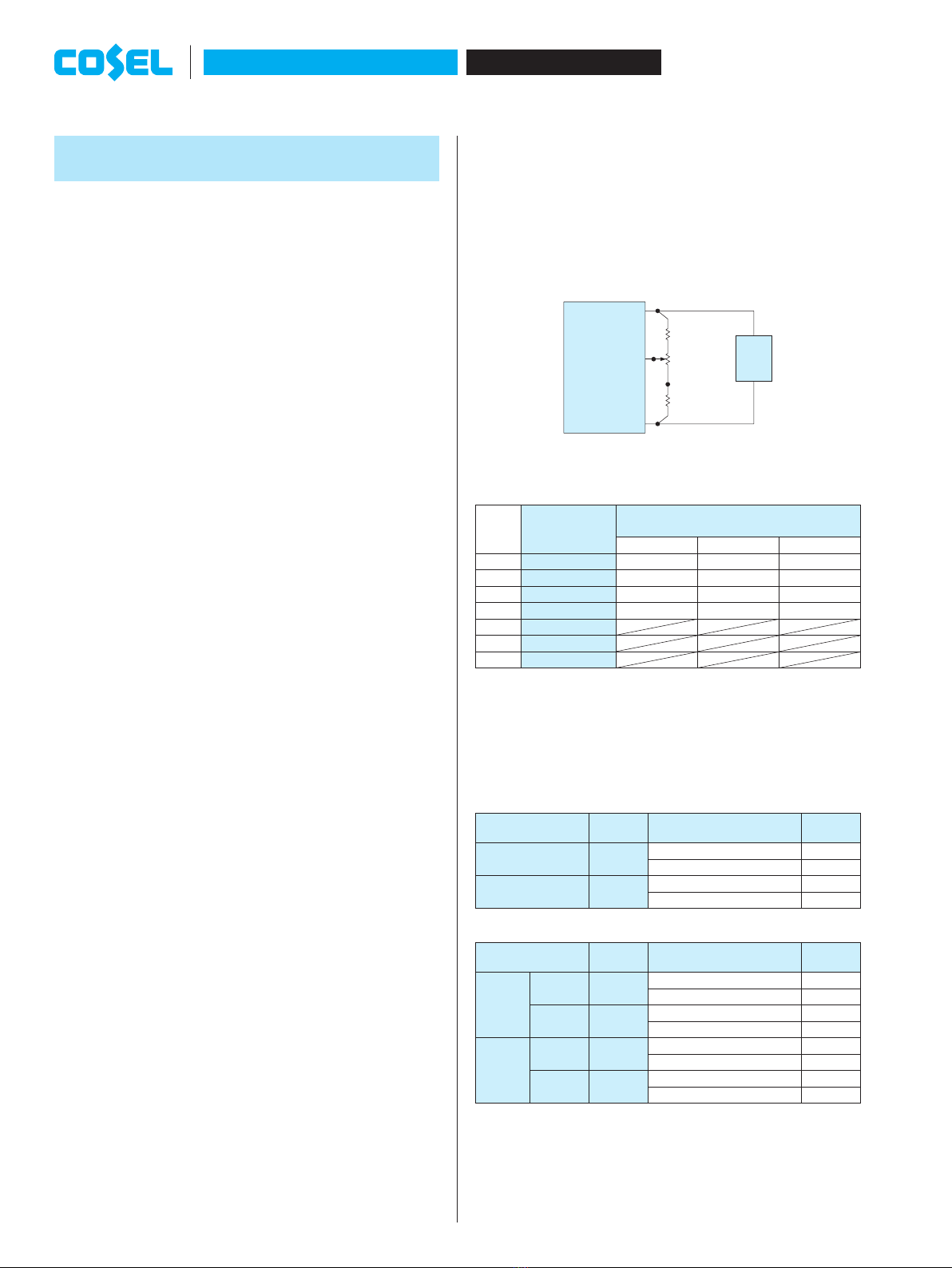

1.6 Remote ON/ OFF

¡The remote ON/OFF function is incorporated in the input circuit

and operated with RC and -Vin. If positive logic control is re-

quired, order the power supply with “-R” option.

Table 1.2 Remote ON/OFF Specications (MG15/MG30)

Model ON/OFF

logic Between RC and -Vin Output

Voltage

Standard

Negative

Llebel (0 - 1.2V) or short ON

Hlebel (3 - 12V) or open OFF

Option-R

Positive

Llebel (0 - 1.2V) or short OFF

Hlebel (3 - 12V) or open ON

Table 1.3 Remote ON/OFF Specications (MG40/MG80)

Model ON/OFF

logic Between RC and -Vin Output

Voltage

MGFO

O05O

Standard Negative

L lebel (0 - 0.4V) or short ON

Hlebel (3 - 12V) or open OFF

Option-R Positive

Llebel (0 - 0.4V) or short OFF

Hlebel (3 - 12V) or open ON

MGFO

O24O/

MGFO

O48O

Standard Negative

Llebel (0 - 0.8V) or short ON

Hlebel (3 - 12V) or open OFF

Option-R Positive

Llebel (0 - 0.8V) or short OFF

Hlebel (3 - 12V) or open ON

¡When RC is at low level, a current of 0.5mA typ will follow out.

(MG15/MG30)

¡When RC is at low level, a current of 0.05mA typ will follow out.

(MG40/MG80)

¡When remote ON/OFF is not used, short RC and -Vin.

Metal Film Type, Temperature Coefficient of

±100ppm/Cor below

Cermet Type, Temperature Coefficient of

±300ppm/Cor below

DC-DC Converters PCB Mount Type

MG15, MG30, MG40, MG80 Instruction Manual

MG-81 October 21, 2020