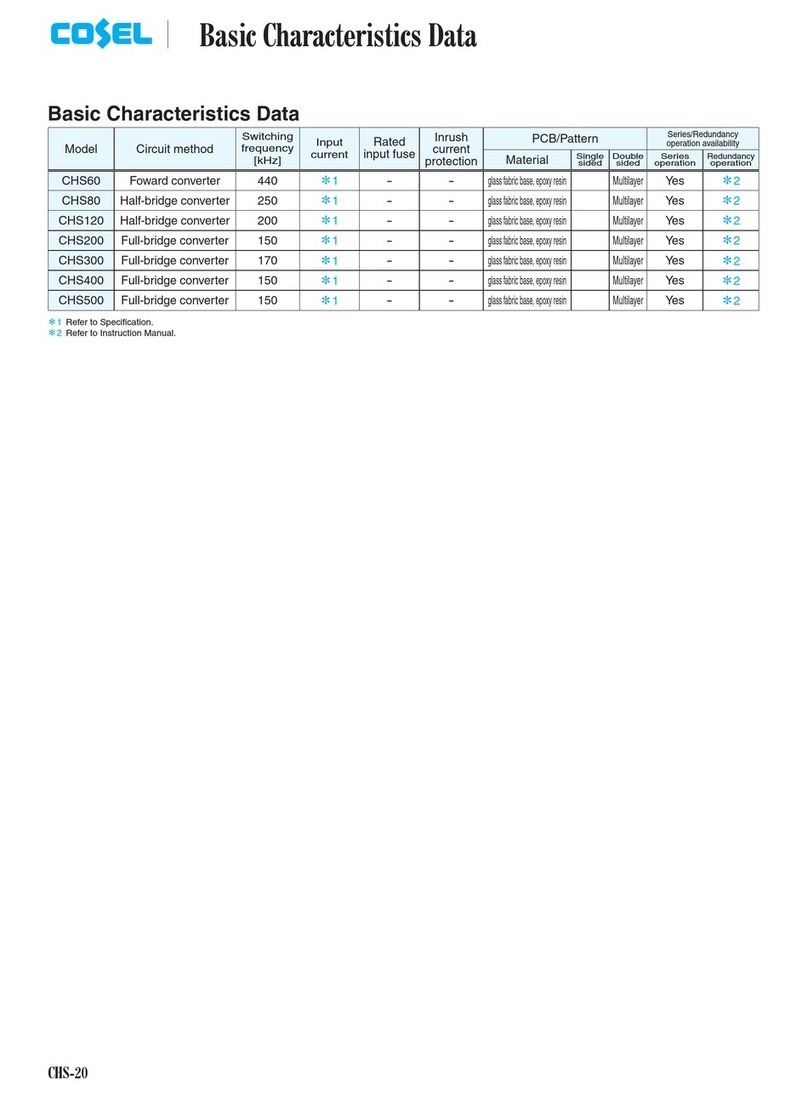

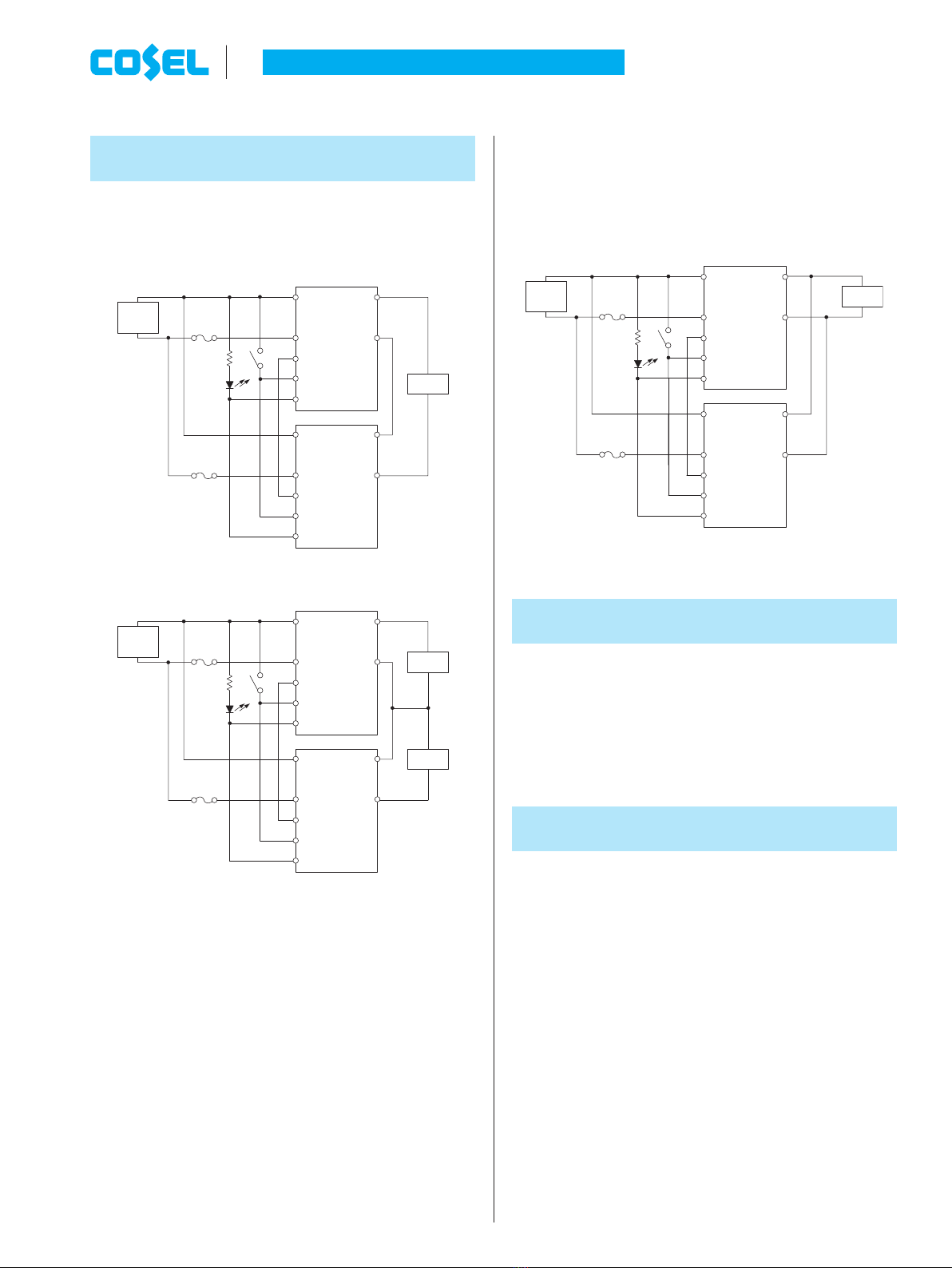

¡In order to use the power supply, it is necessary to wire as shown

in Fig.1.1.

¡When remote ON / OFF function is not used, please open RC pin

or short between RC and -Vin pin.

¡When alarm function is not used, please open ALM pin.

¡In parallel and series operation, connect each PO pin mutually.

When PO function is not used, please open PO pin.

¡The SFS / SFCS series handles only the DC input.

Avoid applying AC input directly.

!! It will damage the power supply. !!

¡Operate with the convection or forced air cooling.

[ Reference : “Derating” ]

1

Connection for Standard Use

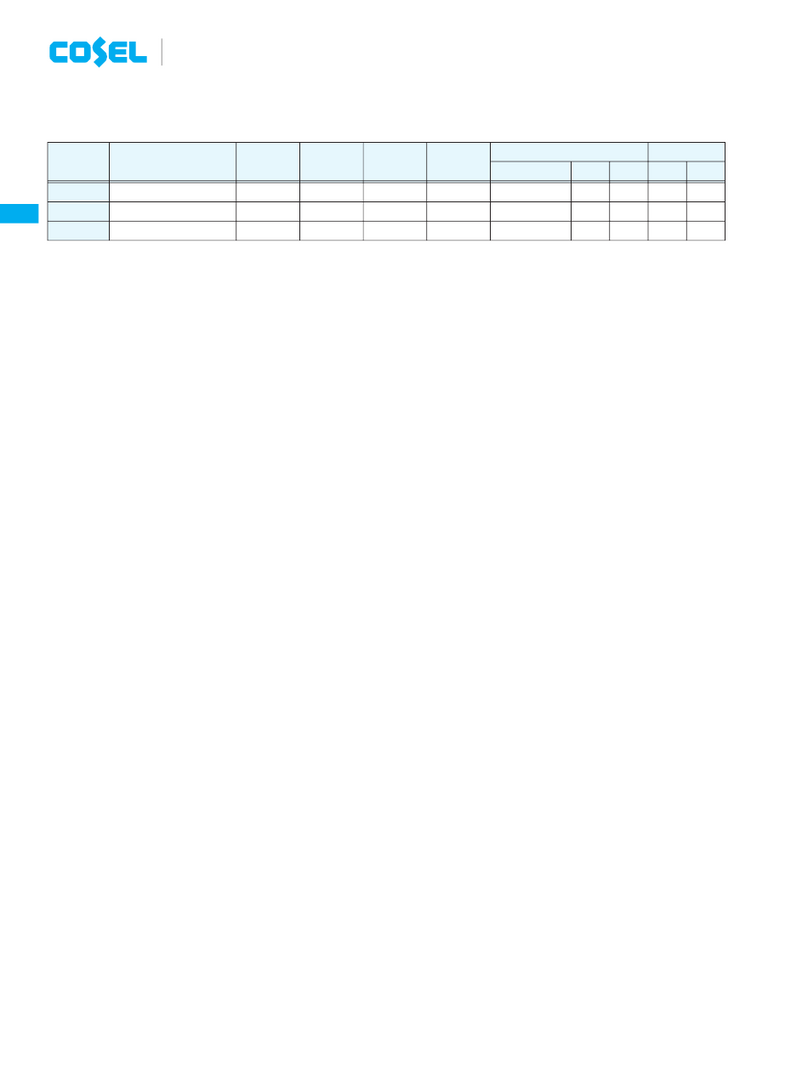

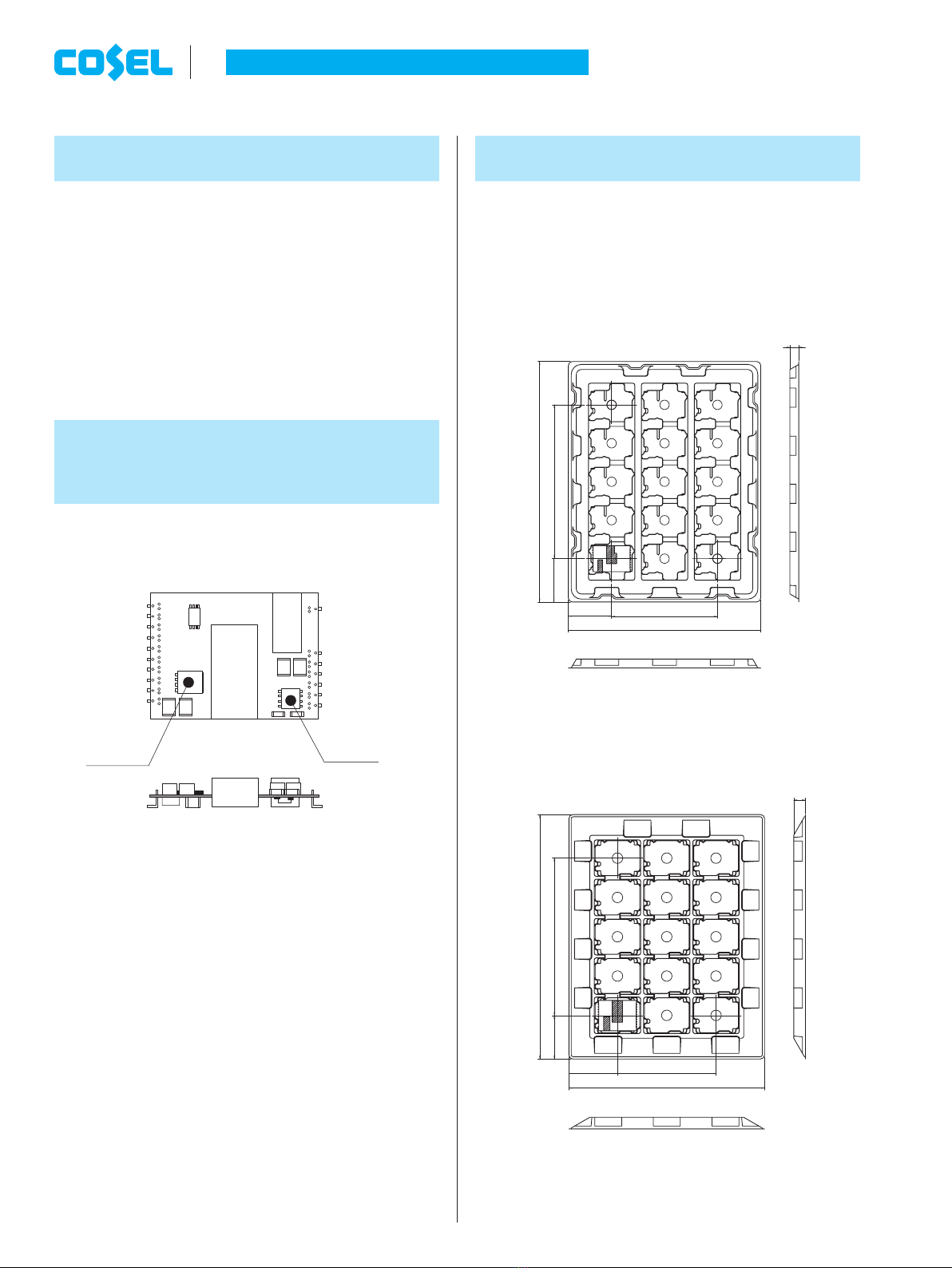

(2) External capacitor on the input side

¡When the distance from the DC line to the unit is greatly extended,

it makes the input feedback noise much higher and the input volt-

age several times higher than the normal level when turned ON. If

this happens, the output power also becomes unstable. In order to

prevent the unit form failing in this way; please connect Ci to the

input pin. In addition, when the lter with “L” is used, please Ci to

the input pin.

(a)

(b)

Ta=-20 to +85CElectrolytic or Ceramic capacitor

Ta=-40 to +85CCeramic capacitor

Note:

When input line inductance becomes excessively high due to inser-

tion of choke coil, operation of the unit could become unstable. In

this case, increase Ci value more than the value indicated above.

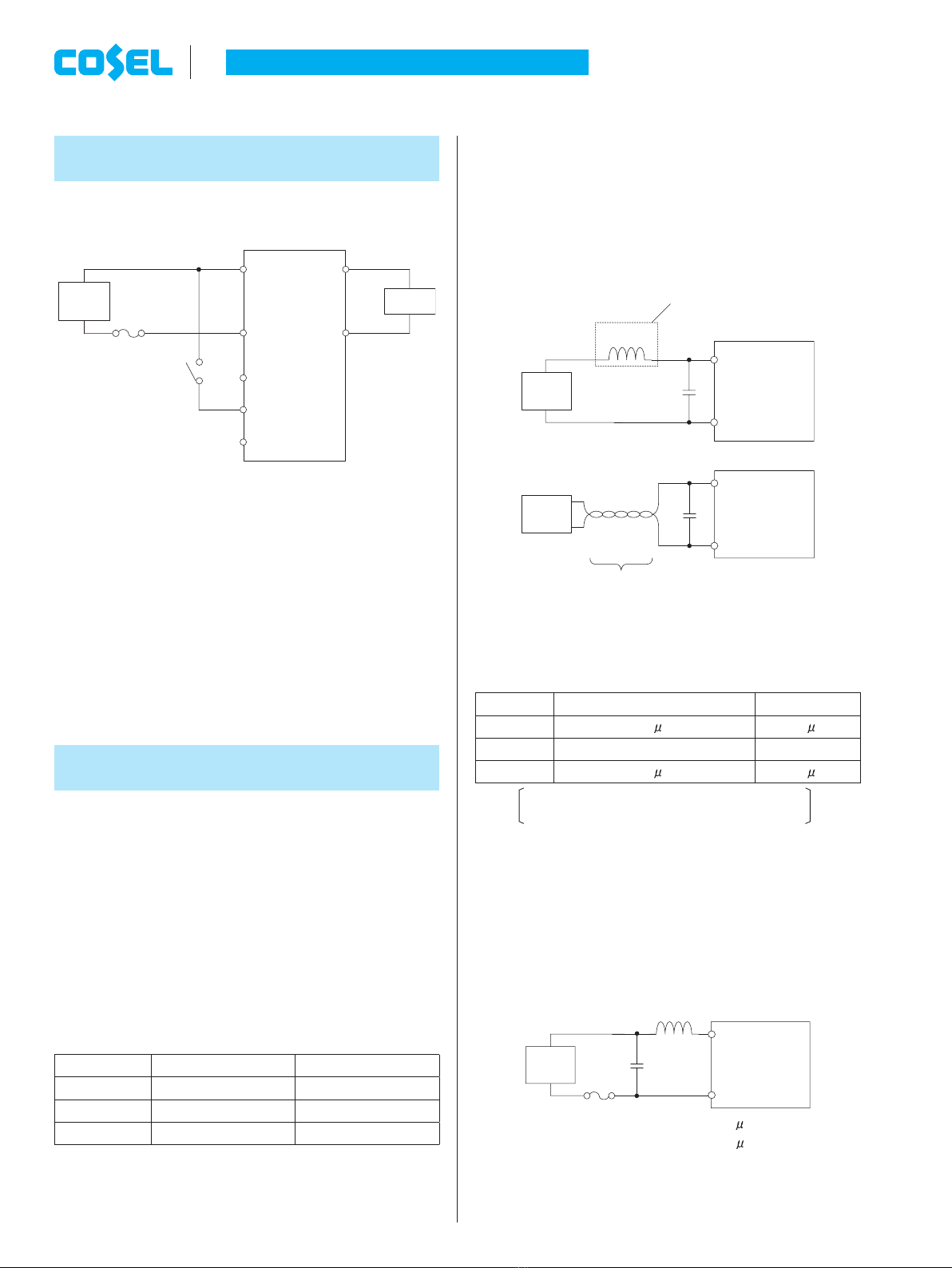

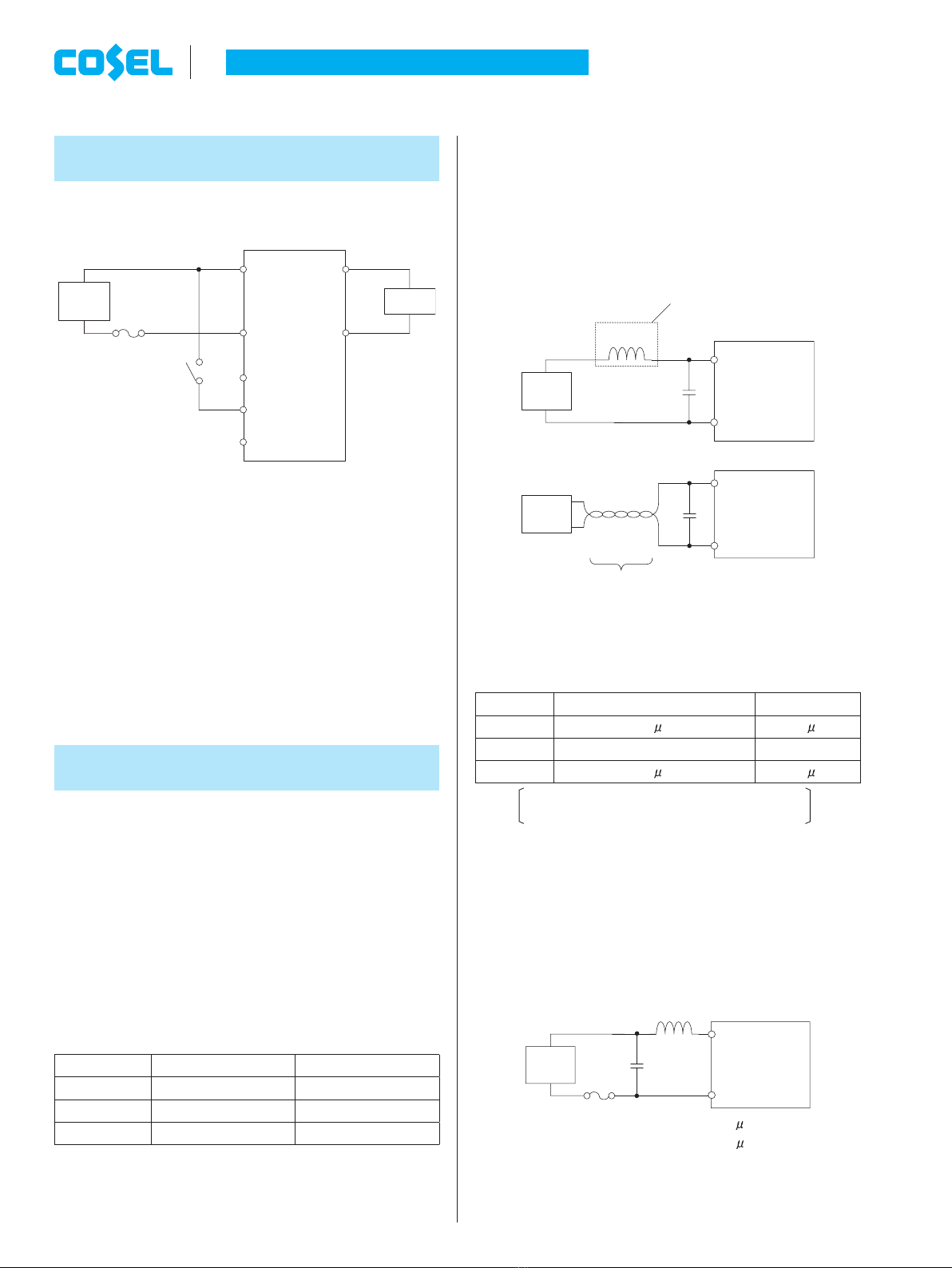

(3) Conducted noise

¡Install an external input lter as shown in Fig.2.2 in order to re-

duce conducted noise.

The result for this solution is shown in Fig.2.3.

C1 : 1 F(ceramic capacitor)

L1 : 1 H

2

Wiring Input/Output Pin

2.1 Wiring input pin

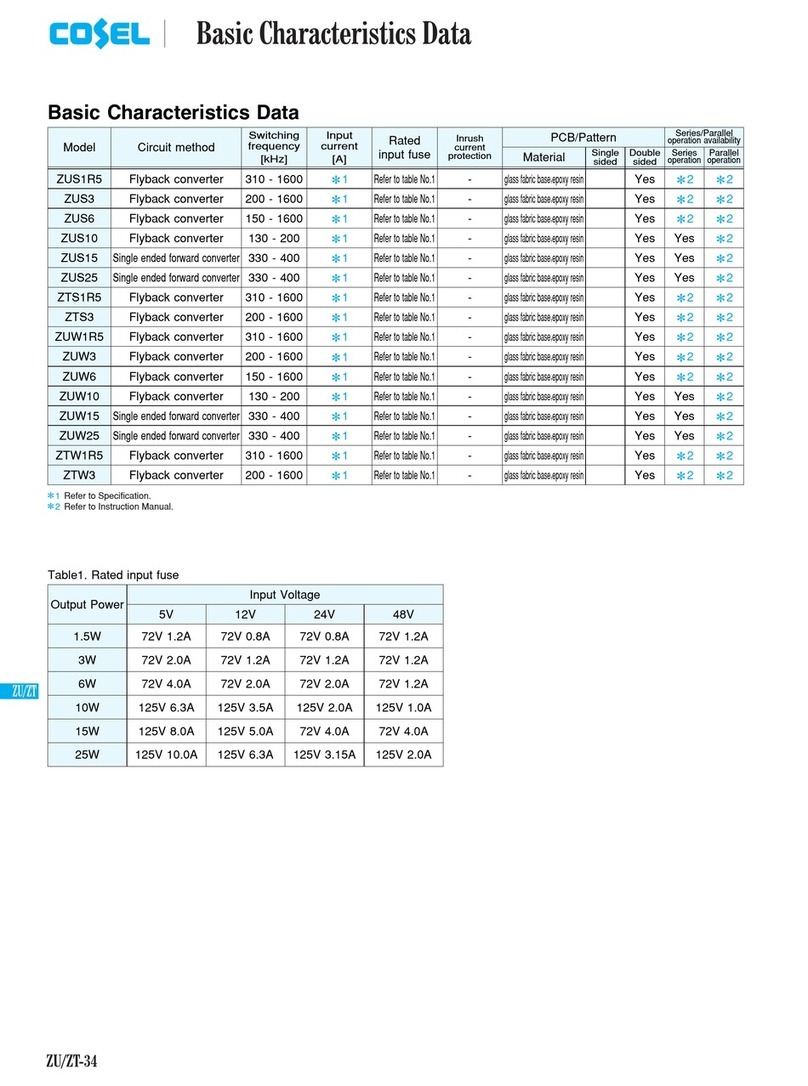

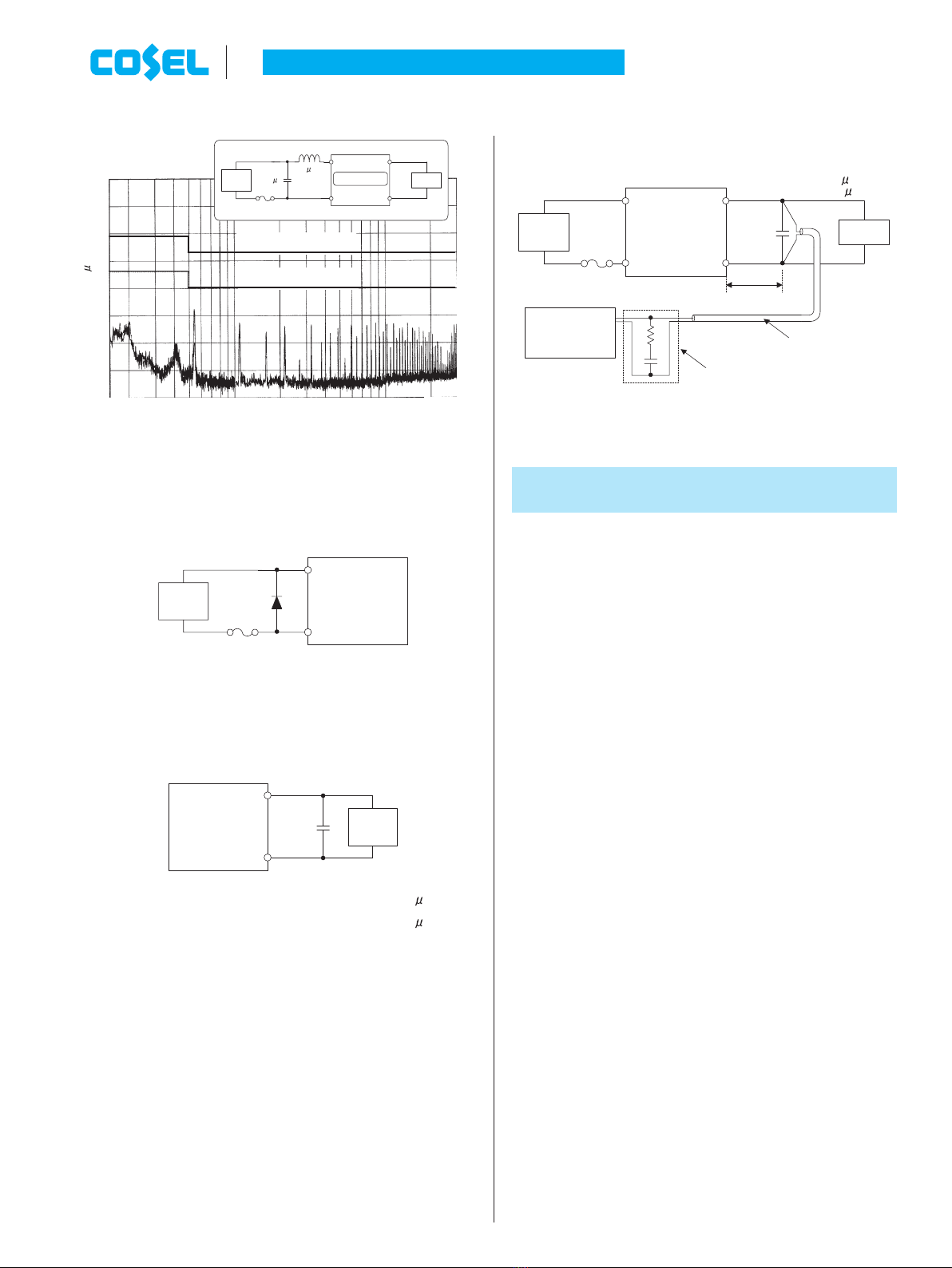

(1) External fuse

¡The SFS / SFCS series is not internally fused. To ensure safe op-

eration and to receive each Safety Standards approvals, please

install an external fuse (fast-blow type).

¡When the input voltage from a front end unit is supplied to multiple

units, install a fast-blow type fuse in each unit.

¡Fuse must be connected to the +Vin side if to -Vin side is used as

ground, or fuse must be connected to -Vin side if +Vin side is used

as a ground.

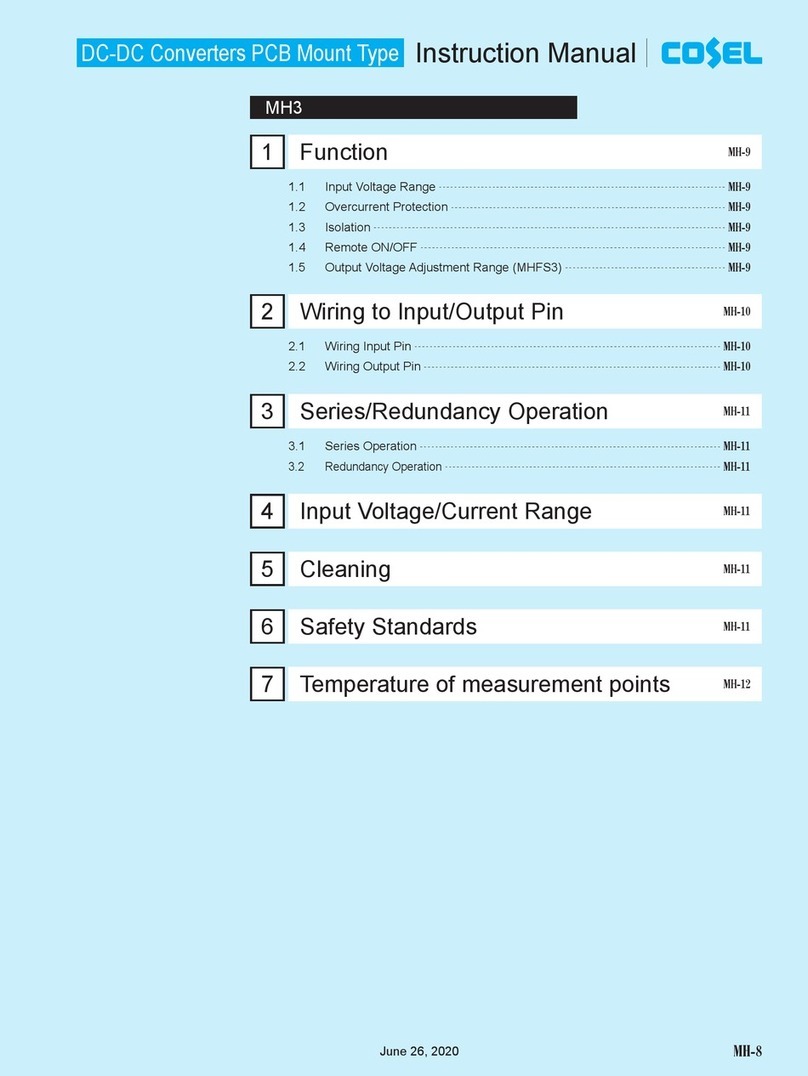

DC-DC Converters PCB Mount Type Instruction Manual

Fig.1.1 Connection for standard use

Model SFS1524 / SFCS1524 SFS3024 / SFCS3024

Rated current 2A 4A

Model

SFS1048/SFS1548/SFCS1548 SFS2048/SFS3048/SFCS3048

Rated current 1A 2A

Table 2.1 Recommended fuse (fast-blow type)

Fig.2.1 Connection method of capacitor at input pin

Model SFS1524 / SFCS1524

SFS3024/SFCS3024

Ci 33 F 68 F

Model

SFS1048/SFS1548/SFS2048/SFCS1548 SFS3048/SFCS3048

Ci 10 F 22 F

Fig.2.2 Recommended external input lter

Table 2.2 Recommended capacitance Ci

+Vin

RC

PO

ALM

-Vin

DC

Input

+Vout

-Vout

Load

SW

Fuse

+Vin

-Vin

DC

Input

L

high impedance source

Ci

+Vin

-Vin

Ci

DC

Input

C1

+Vin

-Vin

DC

Input

SFS/SFCS-20 June 26, 2020