AC-DC Converters Value-added type Instruction Manual

SNDPF-8

SNDPF

4.5 Inverter operation monitor (IOG)

¡Use IOG to monitor operation of the inverter.

When unit operation stopped due to overvoltage protection, ther-

mal protection or the event of a failure in the power supply, IOG-

signal state changes to ”H” from ”L” within 1 second.

And output voltage becomes an equal value to the full-wave recti-

fied AC input voltage.

If IOG signal status keeps ”H”, there is a possibility that unit and/or

external circuit is damaged. In case like this, please check the unit

and/or external circuit conditions in your system.

IOG can be used for monitoring failures such as redundant opera-

tion.

¡IOG may become unstable in case of start-up or sudden change

of load current. Set the timer with delay of more than 5 seconds.

¡During parallel operation, unstable condition may occur when load

current becomes lower than 10% of rated value.

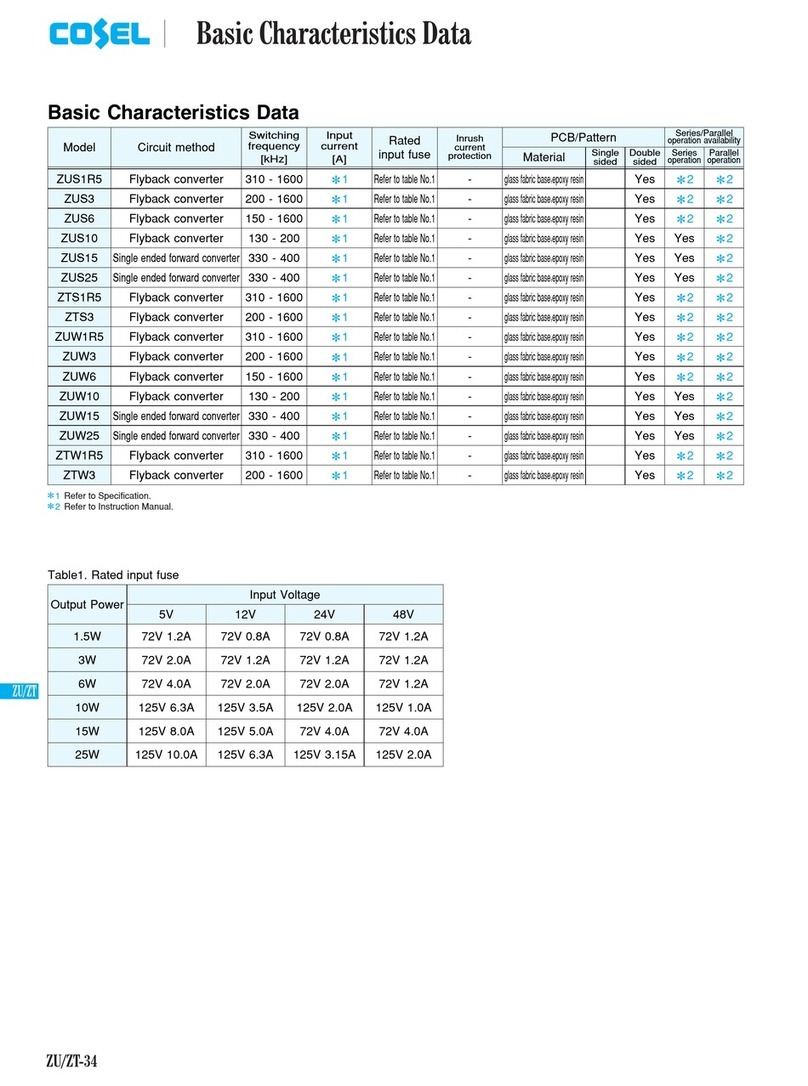

Table 4.2 Specification of IOG

No. Item IOG

1 Function L Normal operation

H Malfunction of inverter

2 Output level L 0.6Vmax at 10mA 10mA max

H Open collector 35V max

3 Base pin -VOUT

4.6 Auxiliary power supply circuit for external

signal (AUX)

¡The AUX pin can be used as the power source with the open col-

lector output for lOG .

¡Shortprotection resistance (4.7kW) is built in.

Output voltage decreases as the output current increases.

4.7 Isolation

¡For a receiving inspection, such as Hi-Pot test, gradually increase

(decrease) the voltage for a start(shut down). Avoid using Hi-Pot

tester with the timer because it may generate voltage a few times

higher than the applied voltage, at ON/OFF of a timer.

5 Series and Parallel

Operation

5.1 Series operation

¡As input and output are not insulated, series operation is impos-

sible.

5.2 Parallel operation

¡Parallel operation is available by connecting the units as shown in

Fig.5.1.

Synchronization output current balance, ENA signal is performed.

¡As variance of output current drew from each power supply is

maximum 10%, the total output current must not exceed the value

determined by the following equation.

Output current in

parallel operation = the rated current

per unit X(number of unit)X0.9

In parallel operation, the maximum operative number of units is 5.

¡When the output-line impedance is high, the power supply is be-

come unstable. Use same length and thickness (width) wire (pattern)

for the current balance improvement.

¡Connect each input pin for the lowest possible impedance.

When the number of the units in parallel operation increases, input

current increases.

Adequate wiring design for input circuitry such as circuit pattern,

wiring and current for equipment is required.

If temperatures of aluminum base plates are different in the power

supply for parallel operation, values of output current will change

greatly.

Design radiation to equalize plate temperatures by attaching the

same heatsinks.

¡Fuse, each diode to the output terminal of each power supply in

order to ensure safety Please connect.

The output side diode if the following three parallel units are omit-

ted Can be.

¡Input voltage of the power supply to operate in parallel, please

supply the same strain.

¡Keep drawing current per pin below 7A for CN1/CN2.

Noise

Filter

AC IN

Load

*Common signs among CN4 and CN5 represent the same potential.

*Please connect each CB, C-AUX and C-ENA.

+V

Di

Di

Di

ENA

-

V

+V

ENA

-

V

+V

ENA

-

V

SNDPF1000

CB

SG

C-AUX

C-ENA

SNDPF1000

CB

SG

C-AUX

C-ENA

SNDPF1000

CB

SG

C-AUX

C-ENA

CN4

CN5

CN4

CN5

CN4

CN5

Fig.5.1 Parallel operation

OG UPFRHKPFF