vii

able of Contents

Section4–OperatingInstruction4‐1

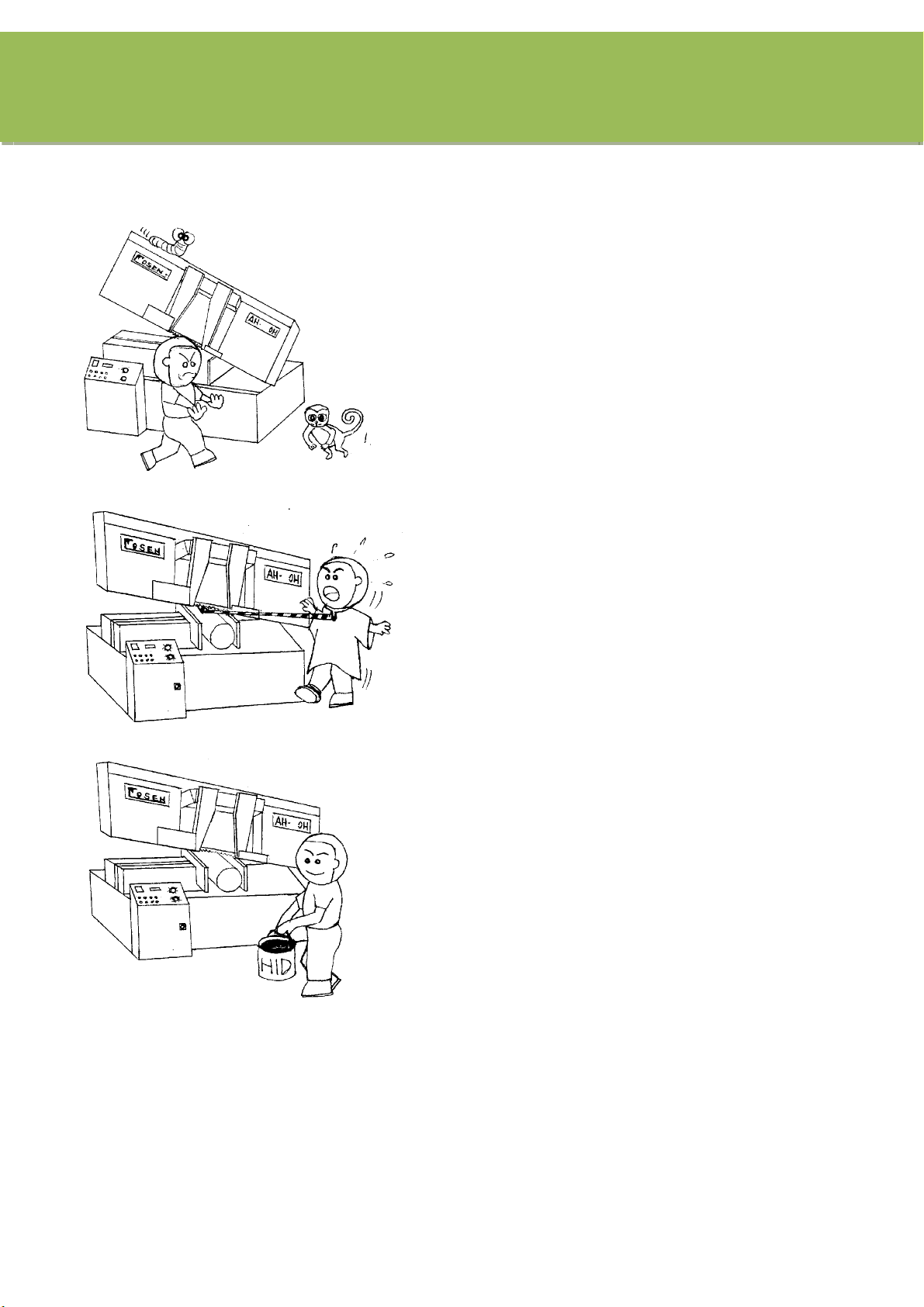

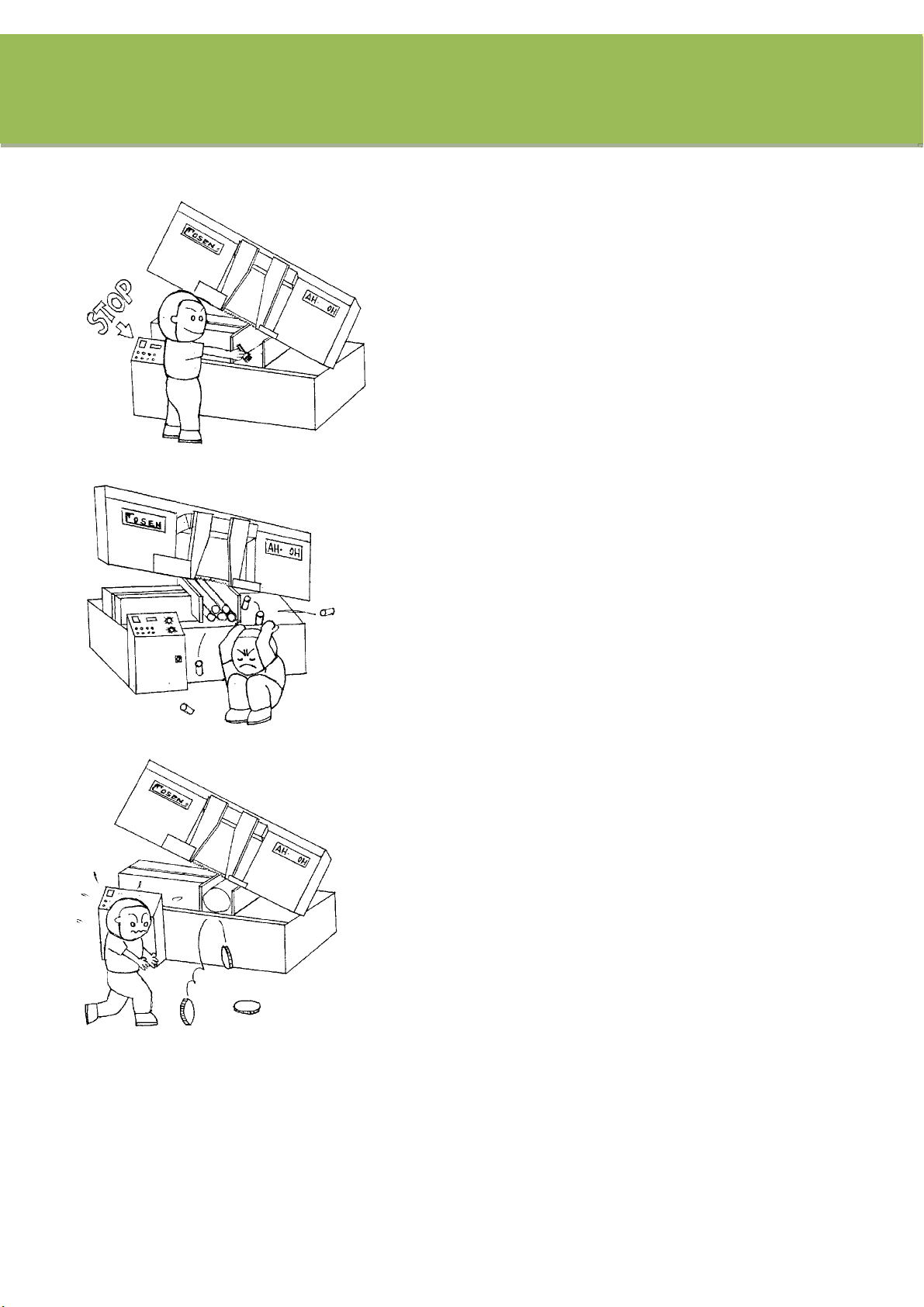

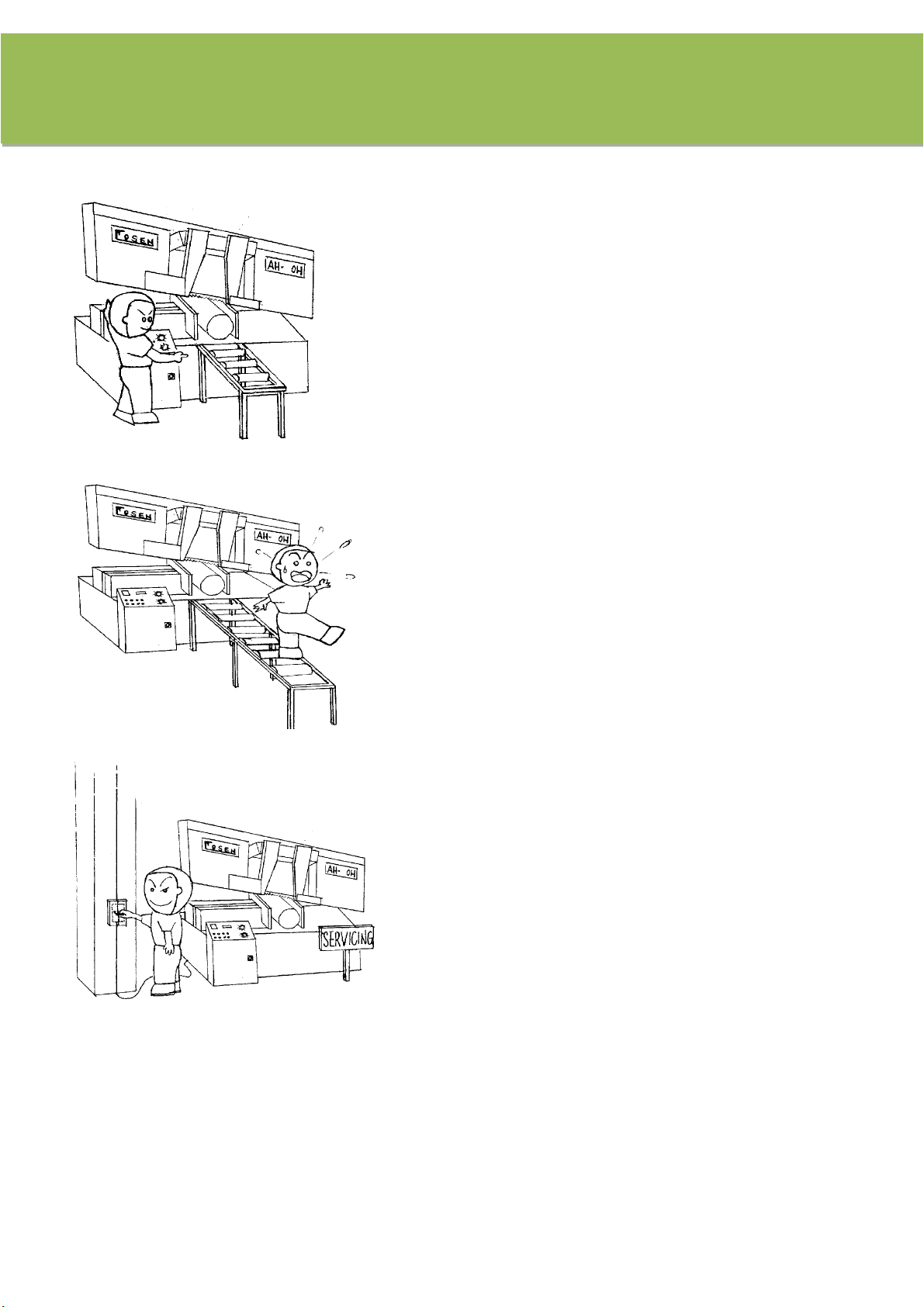

SafetyPrecautions…………………..…………………..……………………………………….……………………. 4‐2

BeforeOperating…………………………..……………………………………………………………………………. 4‐3

ControlPanel……..……………………………………..………………………………………….……………………. 4‐4

ControlPanel………………….………………………………………………………………………..……. 4‐4

ControlButtons……………………………………………………………………………………….…….. 4‐5

HMITouchScreen&Functions…………………………………………………………….………… 4‐7

HMIErrorCodes………………………..……………………………………………………….…………. 4‐16

StandardAccessories………….………………………..……………………………………………….…………… 4‐17

OptionalAccessories…….…….………………………..…………………………………………….……………… 4‐19

Unrolling&InstallingtheBlade…………………………………………………………………….……………. 4‐21

AdjustingWireBrush………..……………………………………………………………………….………………. 4‐23

AdjustingCoolantFlow………..………..…………………………………………………………………..………. 4‐23

AdjustingSawArm………..……………………………………………………………………….…………………… 4‐24

AdjustingBladeSpeed………..………..……………………………………………………………………………. 4‐24

Test‐RunningtheMachine………..………………..…..…………………………………………………………. 4‐24

Breaking‐IntheBlade………..………..…………………………………………………………………..…………. 4‐25

UsingTopClampforBundleCutting………..……….………………………………………………………… 4‐25

CuttingOperation………..………..……………………………………………..……………………………………. 4‐26

TerminatingaCuttingOperation………..………..…………………………………….………………………. 4‐26

Section5–ElectricalSystem5‐1

ElectricalCircuitDiagrams……….…………………..…………………………………………………………….. 5‐1

Section6–HydraulicSystem6‐1

HydraulicDiagrams……….…………………..……………………………………………………………….………. 6‐1

Section7–BandsawCutting:APracticalGuide7‐1

Introduction……………………….…….…………………..……………………………………………………………. 7‐1

SawBladeSelection………………….…………………..…………………………………………………………… 7‐1

SomeSawingPractices…………….…………………..………………………………………….………………… 7‐4

SawPitchSelection……………………………………………………………………….……………….. 7‐4

MaterialSizeandSawPitch………………………………………………….….……………………. 7‐4

Section8–Maintenance&Service8‐1

Introduction……………………….…….…………………..……………………………………………………………. 8‐1

BasicMaintenance………………….…………………..…………………………………………….………………. 8‐1

MaintenanceSchedule…………….…………………..……………………………………………………………. 8‐1

BeforeBeginningaDay’sWork………………………………………………………………………. 8‐2