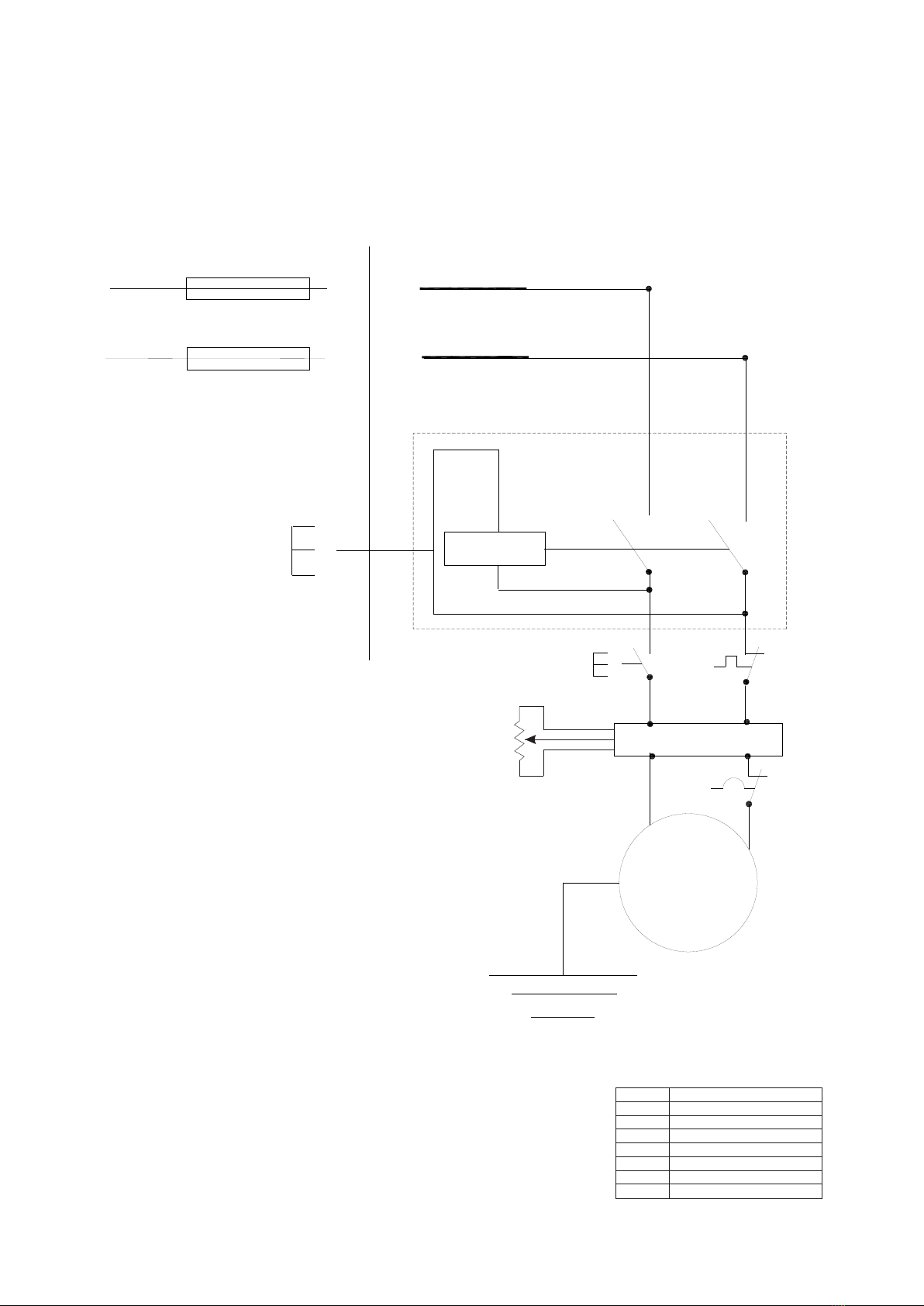

2.5 ELECTRICAL CONNECTION

Check out the plant network on which the machine is connected to

the ground as required by current safety regulations and check out

if the power plug is in good condition.

We reminded to the user that upstream of the network you have to

be protection necessary to safeguard all conductors from short

circuits and overloads.

Rated voltage................................................................. 230 Volt ~

Rated frequency .............................................................. 50/60 Hz

Value max absorption prog .....................................................2.5A

Rated motor speed ......................................... 2000-4200 rev / min

Such protection must be chosen according to the electrical

features of the machine specified below:

Insulation........................................................................... Class B

Nominal power............................................................... 1010 Watt

Intermittent service type ................................................... S4-60%

Power factor............................................................................ 0.96

Sawing machine's motor is also equipped with thermal circuit

breaker protection, which cuts the power supply when the

temperature of the winding becomes too high.

In the case of interruption - because of excess temperature-

waiting for the normal recovery (ca.10 min).

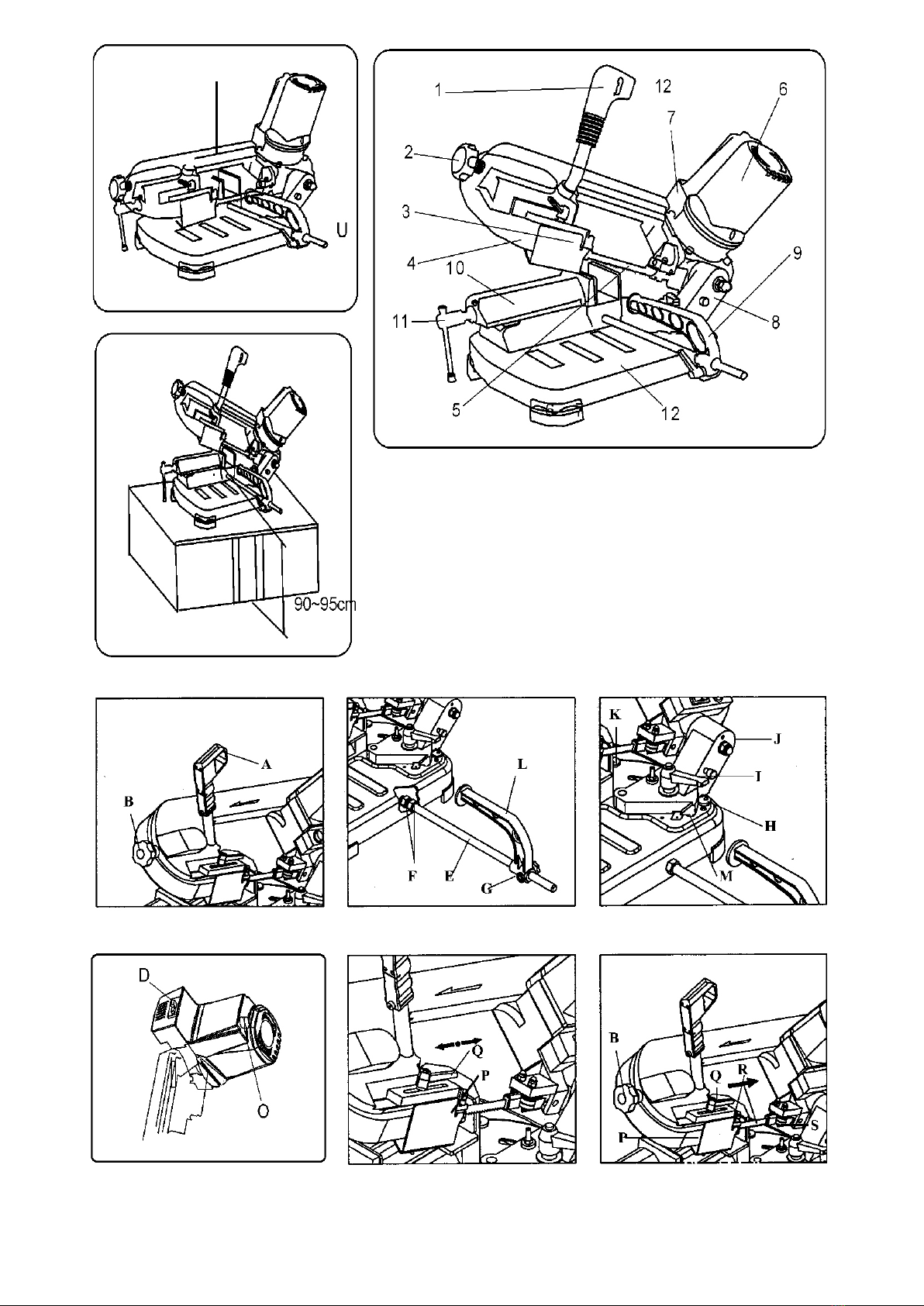

Turn clockwise the knob B to the stop (until the complete packing of

the cup springs) avoiding overtightening.

If it should there be a lack of voltage in the network, wait for it

to re-establish the connection. The electronic regulator and

the main switch include a reset function, which prevents the

automatic restart of the machine. Turn off the main switch

(fig.7D) and reset it, even in case of motor overload.

3.0 ADJUSTMENTS (fig.4-5-6-7-8)

3.2 BAR STOP (Fig.5)

If you need to make more cuts pieces of the same length used the

bar stop supplied in order to avoiding repeat all the times the same

measure.

Screw rod E into the hole of the base and lock it with the nut F;

loosen the handwheel G and place the stop L at the required

distance from the blade; locked again the flyer G.

3.3 CUTTING ANGLE (Fig.6)

The sawing machine is enables to make cuts with an angle varying

between 0 ° and 45 ° (0 ° and 60 ° MT-150); simply loosen the knob

I and rotate the turntable to the respective latches.

For all other intermediate angles, rotate the turntable until the

indicator coincides M placed on it with the corresponding position

on the plate.

Then locked again the rotatable support.

3.4 CUTTING SPEED (figure 7)

Your sawing machine is equipped with, an electronic control

system which allows gradual and continuous variation of cutting

speed, adapting it to the type and size of material to be cut (see

CUTTING TABLE).

Then, in order to select the proper speed act on the drive or

increasing it or decreasing it according to your needs.

Example:

Stainless steel: 30 m / min position 1

Steels: 40-60 m / min position 2-3-4

Light alloys: 80 m / min position 6

Tubes and profiles: 70-80 m / min position 5-6

3.5 SLIDING BLADE GUIDE (Figure 8)

The sliding blade guide P with integrated protection that is attached

3.1 BLADE TENSION (figure 4)

If the tighten is too high, the blade tends to come

out from the guides; in this case, slightly loosen

the tension by turning of a turn the handwheel B

anticlockwise.

For best performance, the bi-metal blades that accompany your

sawing machine must undergo to a short break-in procedure.

If after several consecutive cutting machine should suddenly stop,

do not be alarmed: is the thermal protector of the motor, that cuts

the power when the winding temperature reaches the threshold

limit defined the insulation class, avoiding damage to the engine.

4.0 USE

Do not make a proper break-in procedure could

make irreparably compromise the precision

cutting blade.

When all the procedures and operations described so far, you can

start working.

Start now to apply a progressive strain on the piece and finish the

cut.

To make the cut, put yourself in front of the car, and challenged his

right hand grip.

Press with the forefinger of his right hand at the start button (figure

4) and gradually lower the body of the car to get in touch gently the

blade with the workpiece.

Before starting each cutting operation, ensure by

means of a visual check that all guards are intact

and in the proper position.

(see 2.5 )

If during processing were intervene the limiter, lightened slightly

the cutting pressure: this allows among others to safeguard the life

and performance of the blade and to get a cut that is always clean

4.1 RUNNING IN THE BLADE

4.2 OPERATION (figure 7)

The cruise control of your sawing machine is equipped with the

function includes motor protection, obtained by an amperometric

limiter that does not allow him to absorb a higher current than the

set, expressed by the maximum value of absorption programmed

It is therefore necessary to make the first three / four cuts possibly

on a piece full D.40-50mm, exerting pressure on the piece very

slight, increasing it gradually in subsequent cuts.

In this case, release the button and wait for the automatic recovery,

which usually returns after a few minutes.

To realize of what the correct pressure in normal operating

conditions defined by this manual (see CUTTING TABLE),

consider for example that the first cut of steel (es.C40) D.50mm full

must be made in about 4 minutes; after testing, the same

workpiece can be cut easily in about 2 minutes. A running-well

executed, results in a better cut quality, both as a finish that as

precision, and a longer life of the blade.

Switch the main switch D on the position - in this way the machine is

ready to operate.

Between cut and another, during the positioning of the workpiece,

release the button A always, do not try to block it or alter in any way

the functional characteristics.

Keep the left hand still far away from the cutting area and do not

seek in any way to reach during the cutting operations.

to your cutting machine, you can make the cut while maintaining

the guided part of the blade and necessary to fully protect the

unused processing.

Loosen the handle Q and slide the blade guide P so closer or

farther away from the workpiece, as shown in the figure.

To facilitate the replacement of the blade and keep it guided to

better blade guides outside of the sawing machine are eccentric

and adjustable.

3.6 BEARING blade guide (figure 9)

If this is not done, it is uncovered a portion of the

blade not required for processing, which can create a

residual risk of contact with it, as well as affecting the

quality of the cut.

They must always be placed in light contact of the same, but not

completely blocked.

To zoom in or out blade guides you have to simply rotate slightly

with 10mm spanner head screws S.

Pag.5